A fairly common problem during the operation of an internal combustion engine is the oil pressure light on the dashboard coming on. This lamp indicates that the engine oil pressure in the engine lubrication system drops below the permissible level. Low engine oil pressure can occur for various reasons. Among the main malfunctions, experts identify:

- malfunction of the oil pressure sensor;

- low quality motor oil;

- mismatch of engine oil for a specific engine type;

- decrease in oil level as a result of a leak or increased oil consumption (waste, problems with rings or valve stem seals);

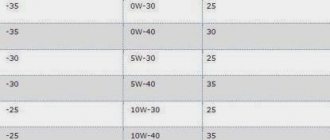

- using oil whose characteristics are not suitable for current operating conditions (viscosity index too high or low);

- oil pump malfunctions, decreased performance;

- blockage of the oil filter or oil channels of the engine lubrication system;

Next, we will focus on the problem when the emergency oil pressure reduction light comes on cold and/or hot. In other words, the oil pressure warning light does not go out or blinks/blinks after starting a cold engine, and the oil pressure warning light also lights up on a warm engine that is idling.

Read in this article

Why can the oil pressure light come on on a warm and cold engine?

Let's start with the fact that the oil pressure indicator lamp is not an indicator of the level of the oil itself and its quality. The purpose of this device is to record oil pressure or its absence in the central line of the engine lubrication system. It turns out that the oil pressure light comes on if the pressure in the system has dropped below the permissible level.

Please note that it is normal for the oil pressure light to light up briefly (1-3 seconds) or blink after starting the engine. The fact is that the oil pump does not maintain constant pressure in the system after the engine is stopped. Oil pressure begins to build up from the moment the crankshaft is cranked by the starter. If the oil pressure light does not go out or continues to blink for a longer time after starting, then this may indicate a malfunction, low level or quality problems with the engine oil.

It should also be added that during cold periods, the engine oil in the crankcase thickens (especially mineral oil) and the oil pump takes more time to raise the pressure in the lubrication system to the required level. If the oil pressure light stays on longer than usual, then the first step is to turn off the engine and check the oil level using the dipstick or by analyzing the oil level readings on the dashboard.

You should also remember about this phenomenon when the oil pressure light comes on briefly while driving in a fully functional car. This can occur as a result of severe body roll during active driving of a vehicle with a so-called “wet” sump. To put it simply, the oil in the oil pan overflows heavily to one side of the tilt, gets agitated, and foams. All this makes it impossible for the oil pump to effectively extract and supply lubricant into the system under the required pressure. To eliminate this phenomenon and prevent negative consequences on sports rally cars that require long-term operation in such conditions (overcoming difficult obstacles, jumping, constant rolls), a dry sump system is installed. In all other cases (if the warning light is on for a longer time), the situation can be considered an emergency.

Engine oil under the required pressure must be stably supplied to loaded pairs and friction units: crankshaft and camshaft bearings, to the turbocharger rotor, to hydraulic timing valve compensators, hydraulic belt tensioners, phase shifters of the variable valve timing system, etc. The operation of such components at low pressure in the oil system leads to the formation of scuffing on the liners and journals of the crankshaft and camshaft, rapid abrasion of antifriction coatings at the interfaces of parts, overheating of loaded elements, etc. With insufficient pressure in the lubrication system, an engine is subject to severe wear and overheating; liners may rotate, shafts may jam, turbocharger failure, etc.

Reasons for oil consumption

Among the many reasons that lead to the engine eating oil are:

- Piston ring wear

Most often the piston has 3 rings. On top there are compression rings (2 pcs.), and under them there is an oil scraper ring, which ensures the removal of excess engine oil, which lubricates the walls of the engine cylinders. The wear of the edge of this ring leads to an increase in its consumption.

In addition, when the engine overheats, the compression rings lose their elasticity. This contributes to the appearance of such a phenomenon as “flutter” (the rings begin to oscillate at high frequency both along the radius of the piston and between the edges of the piston groove). In this case, the engine oil is pumped out like a pump. A “blue” exhaust indicates wear of the piston rings. The defect is eliminated by replacing worn rings, which requires disassembling the engine.

- Engine cylinder wear

During natural wear, the cylinder walls become deformed. This is largely due to failure to schedule engine oil changes and the use of low-quality engine oil.

At the same time, due to the increased gaps between the piston and the cylinder wall, chips, scuffs and scratches may form on them, in which thickened engine oil accumulates, inaccessible to the oil scraper ring. During the next operating cycle, it simply burns out, increasing waste losses.

If the cylinder has taken on an oval shape as a result of wear, then oil begins to enter the combustion chamber, which leads to smoke in the exhaust. If the cylinders are severely worn, a major overhaul of the engine is necessary.

- Leaks in the lubrication system

Drivers often notice traces of oily leaks under the car or on the outer surfaces of the cylinder block. They appear due to failure:

- crankshaft oil seal;

- cylinder block or oil filter gaskets;

- oil seals.

Such defects are eliminated by replacing unusable parts. If auto lubricant leaks from under the oil filter gasket, replace the entire filter.

IMPORTANT! One of the most common and easy to fix causes of leakage is a loose oil filter.

- Engine oil leaking into the cooling system line

If the consumption of auto lubricant has increased, but there are no visible signs of leaks, and there is no smoke in the vehicle exhaust, then most likely it “goes” into the cooling system line. In this case, a change in color and foaming of the coolant is observed. The reasons for the appearance of such a defect may be a failure of the head gasket of one of the cylinders and a crack in the cylinder head. Such malfunctions are eliminated by replacing the gasket or cylinder head.

The oil pressure light comes on at idle: ways to check

Now let's talk about the case when the low oil pressure warning light comes on while the engine is idling. Below we present available methods for identifying malfunctions, which will generally be useful in diagnosing the condition of the engine lubrication system and engine oil pressure.

- If the oil pressure light comes on, then you should check the engine oil level in the engine and its condition. If the level drops, add oil. A suspicious condition of the oil (black color, excessive thickness) will require thorough flushing of the oil system and subsequent oil change. The smell of gasoline/diesel, an emulsion on the oil filler cap, or severe dilution of the engine oil will indicate problems with the CPG or cracks in the cylinder head/cylinder head. On a working engine, the combustion chambers should be sealed, fuel and antifreeze from the cooling system should not enter the lubrication system.

- The oil pressure lamp may come on at idle immediately after changing the oil during the first start. In this case, the warning light may remain on for 10, 15 or even 20 seconds. If after the specified period of time the low oil pressure lamp does not go out, then you should check the oil filter. The product may be of poor quality, poorly screwed (oil leaks are noticeable in the area where the filter is attached) or defective.

- Check the oil pressure sensor. The oil pressure level at idle speed at around 800 - 900 rpm should not be less than 0.5 kgf/cm2. It is also worth noting that emergency oil pressure sensors on different engines may have different response ranges, which on average range from 0.4 to 0.8 kgf/cm2. This means that if there is a sensor designed to operate at 0.7 kgf/cm2, already during a pressure drop to 0.6 kgf/cm2 the sensor will turn on the emergency oil pressure lamp. This is done for conditional notification of a decrease in pressure in the line of the internal combustion engine lubrication system.

How does the oil pressure light work?

Once behind the wheel of the car, the driver turns on the ignition. He will see a red oil pressure light on the dashboard. This means that the sensors are working properly, the wiring from the sensors to the instrument panel is intact, and the light bulbs have not burned out. If this lamp does not light, you should invite a specialist to check the wiring leading from the sensors. Another reason for a non-working light bulb is a burnt-out LED on the dashboard or damage to the panel itself. In this case, you need to put all the components in order, since obviously non-working oil pressure monitoring devices can mislead the motorist.

After starting the engine, the driver will see that the oil pressure light has gone out. This is fine. The oil pump pumps oil from the sump, it flows through the filter through channels to the rubbing parts, and fills the hydraulic compensators. There are special sensors installed in the filter block or on the cylinder head that are activated if the oil pressure is normal. As soon as the oil pressure drops, the sensors turn off and a light comes on on the dashboard. This is a signal to the driver that there is a problem with the oil pressure.

Modern engines have a more complex system - there are several sensors that allow you to monitor oil pressure at any temperature range and engine speed.

If the light does not go out after starting the engine, you need to turn it off. Working without oil can damage the bearings on the crankshaft and damage other rubbing parts.

We recommend: Why does the engine speed not drop and what to do?

The main reasons for the oil pressure warning light to come on

So, the warning light usually lights up after starting the engine or when it is idling. There may be several reasons for this phenomenon, but the main thing is to understand and accept for yourself that this should be a signal that there is some kind of malfunction. Therefore, you need to take appropriate measures so as not to worsen the situation. In any case, if the lamp blinks, it means that you need to identify the malfunction and do everything to eliminate it as soon as possible.

Among the main reasons for the indicator to light up are the following:

- Reduced lubricant pressure in the system. This is one of the most common reasons, but even today there are owners who stubbornly do not notice signs of oil leakage or do not look into the engine compartment. Why does pressure drop, you ask? Because the oil gradually leaves the system. Therefore, you should pay attention to any stains on the engine or under the car where it is parked. Do not forget that by simply adding lubricant to the system, you do not solve the problem, but only forget about it for a while.

- Another reason for the warning light to blink is due to the use of low-quality oil filters. Some of the lubricant remains in them even when you stop the engine. If the filter is of dubious quality, then it does not retain oil, but it directly flows into the crankcase. Thus, a periodic drop in pressure occurs.

Lack of lubrication may be associated with failure of the pressure relief valve. It should be in the closed position if the pressure level in the system is insufficient. However, when the valve fails or gets stuck, the pressure generated is not enough, which causes the warning light to light up.

- Another reason is a faulty pressure sensor. It is directly related to the operation of the control indicator, since it is connected to it by the same wire. As soon as the pressure returns to normal, the contacts should open, as a result of which the indicator should go out. This will not happen if the sensor itself has become faulty.

- The indicator also starts blinking if the oil pump screen is clogged. It acts as an obstacle to particles of dirt, metal, dust and any other unwanted elements that lead to wear on the pump. If the oil is not dirty, but of normal quality, then it freely penetrates through the mesh. When it is contaminated, the required pressure is not created in the system, which leads to the warning lamp coming on. Most often, this reason manifests itself on a cold engine, because as it warms up, the lubricant becomes more liquid and passes through the mesh much more easily.

The oil pump itself may also fail. It is this that creates an acceptable level of pressure in the entire system. If this does not happen, the sensor contacts close, which leads to the appearance of a signal indicator on the panel. Therefore, in this case, you will have to dismantle the oil pan and pump to eliminate the problem.

Does oil burn in a fire and the reasons for its combustion?

It turns out that often the oil begins to burn in the engine not only because of the quality of the oil used, but also for other reasons. Machine oils have different compositions. Worn piston oil rings also lead to loss of oil. It is necessary to replace the rings if the engine does not have to be completely repaired.

If the car has been idle for a long time, you can “decarbonize” the rings. This is done in the usual way. The driver drives along the highway. You have to drive a long way to get the revs up to the red zone of the tachometer. It is possible to use special chemicals used for spark plug holes. Just first you need to make sure that it is safe.

You need to use high-tech samples, and not cheap copies from a well-known brand. If there are no defects in the car and good original oil from a reputable manufacturer is used, then the oil cannot burn. Good oil will extinguish any fire. To avoid falling into the trap of a supplier of cheap oils, you need to contact specialized stores to buy oil for your car.

How does the oil sensor work and why can it fail?

Now let's consider the situation if you are on the road and the low pressure indicator has triggered.

The very first thing you need to do is stop the vehicle and turn off the engine. As soon as it cools down, you will have to check the lubricant level in the system. There is a special dipstick under the hood for this purpose. It is wiped dry and immersed in its original place. It is quite possible that the level will be below the minimum level. This means that somewhere there is a leak or depressurization of connections. You can set off again only after adding oil to the engine. If the lamp continues to light after starting and does not go out subsequently, it makes sense to think about towing the car to the nearest service station or to a trusted auto mechanic. The matter may turn out to be quite serious, so it is advisable to conduct the examination in a calm environment. Since we have already said that the causes of low pressure may be associated with a faulty sensor, it would be useful to understand the principle of operation of this device. There are certain contacts inside it. Until the ignition is turned on, there is no pressure in the system, so the contacts are closed. When you turn the key and turn on the ignition, but before the starter starts, the warning lamp should be on. If this does not happen, then there may be some kind of malfunction. Maybe the light bulb itself simply burned out, or maybe the contacts were broken or the sensor itself failed. As soon as we start the engine, the contacts open, leading to the light bulb going out.

How to check pressure

If it is not possible to contact a car service in the near future, you can try to find the cause yourself, and for this we need to find out how to check the oil pressure. A special device that measures the pressure in the system is designed for these purposes. It is sold ready-made or you can make it yourself based on any pressure gauge, a rubber hose with a fitting, the thread of which should be the same as that of the oil sensor.

First you need to unscrew the thread on the sensor, preparing for the fact that oil will immediately begin to flow. After this, a pressure gauge is inserted into the system and the engine is started. At the time of startup, a second person must watch the instrument readings. If the value is less than 0.5 kg/cm2, it is necessary to stop the engine.

Reasons for lack of oil pressure

Malfunctions can happen at any time, even while the car is moving and the engine is running. Most often, car enthusiasts, especially beginners, simply do not have time to notice the moment of fire or simply do not pay attention to the fact that the pressure has dropped and the pressure sensor lights up. Usually, beginners stop the car only when there is a knocking noise in the engine. If there are knocking noises, the engine will require serious repairs.

The reasons why the oil pressure has dropped will be determined by repairs. Pressure may drop after recent repair work. If the repair was not carried out by the owner of the car, you must find out the reason for the repair. If there was an engine knock, but the oil pump did not undergo checks and maintenance, and possibly replacement, this is often the main reason. Qualified auto mechanics always check the oil pump.

The oil pump is the “heart” of the engine and the rest of the car’s components. The oil pump determines how long the car will run. Depending on the design features, the oil pump drive can be of various types: direct with installation on the crankshaft, using an intermediate shaft, using a chain and other methods.

Direct drive has virtually no disadvantages. It fits directly onto the crankshaft lugs. An oil pump with such a design may fail or stop working only if the crankshaft stops. If a drive with an intermediate shaft is used, there is a spline connection. The spline pitch is quite small, and therefore the splines may be subject to wear.

The oil pump is considered the heart of a car engine

The splines can be subject to wear both directly on the oil pump shaft and on the drive. If the spline wear is insignificant, the oil pressure lamp will simply blink from time to time. If the slots have completely become unusable, you can watch the lamp light up brightly. The malfunction can be eliminated by replacing the oil pump shaft, or, as is usually done in most cases, replacing the drive.

As for the chain drive, here you can adjust the chain tension. If it is weak, then the chain is already worn out. That's why the oil pressure light may come on. If the oil pump has been removed, you must remember to fill it with oil. Otherwise, there is every chance of spending a lot of time diagnosing the car. Beginners often forget about this, and the car does not start.

If a crack appears in the oil intake or on its flange, the pump will pump air. In this case, the air plug will not allow the oil pump to create the necessary pressure in the system. This trouble can be eliminated by replacing parts that have become unusable, or eliminating the crack directly by welding in an argon environment.

The pressure relief valve may be faulty due to a foreign object somehow getting into it, or due to amateur assembly. This problem can be resolved by cleaning, reassembling, and then installing and adjusting.

About additives and properties of oils for increasing pressure in the system

Some car enthusiasts are interested in whether there is motor oil that increases the pressure in the system. Rather, we are talking about special additives that improve its characteristics. The main result from the use of such compounds (for example, SUPROTEC) can be called the restoration of the previous parameters of operating processes in the engine. The surfaces of working parts and mechanisms of the piston group, worn out by constant friction, are partially restored, and their oil-holding capacity increases. As a result, fuel combustion efficiency increases and engine compression improves. Many oils contain special additives that are aimed at reducing engine lubricant consumption.

This is where we will end today’s material. There are many interesting articles ahead of us in the field of engine maintenance and car maintenance in general. Therefore, subscribe to our updates to receive useful newsletters in the future. Bye!

On the dashboard of the car there are light indicators that signal problems in the operation of one or another mechanism of the car. One of them is the oil pressure lamp.

Many drivers have encountered a situation where the oil pressure indicator (OP) lights up and does not go out. This often happens at idle, after starting the car. Next, we will look at what reasons could cause the indicator llama to turn on and how to troubleshoot possible problems?

Why is the light on?

Any car enthusiast has encountered or will yet encounter a burning red oil pressure light on the dashboard of his car. Many people ask the same question: what to do if the pressure light comes on? Drivers often encounter this problem either when the engine is idling or immediately after starting. If you have a problem like this, you can be absolutely sure that your car needs repairs.

What can usually cause problems and what does the light on mean? There are a great many reasons. Car enthusiasts are advised to remember one most important rule. If the light suddenly comes on while the car is moving, then continuing to drive carries the risk of serious damage to the car. If a driver encounters a red light on the road, then the best solution to the problem is to call a tow truck and go to your garage or the nearest car service center or service station.

Then, in calmer conditions, you can identify and possibly eliminate faults. Oil, in addition to direct lubrication, is also responsible for cooling. If oil pressure drops, the temperature of the mating parts will increase. The engine runs the risk of operating in critical conditions. Oil that is hot to the limit will lose its properties and will not be able to create and maintain an oil film if engine speed increases.

Why does a car need an oil pressure indicator?

Continuous light or blinking of the indicator indicates that the oil pressure in the engine is below acceptable standards. In old cars, a special analogue display was installed on the dashboards, displaying the d.m. in the motor, where the current level was shown in units of measurement.

Pressure is measured in kgf/cm2; normal at idle speed is considered to be 0.5 - 0.6 kgf/cm2. In modern cars, this control function is performed by an indicator lamp.

When the pressure drops below 0.3 - 04 kgf/cm2, the signal indicator lights up. The illumination of the light bulb can indicate serious problems in the oil and lubrication system of the internal combustion engine, so such a signal cannot be ignored. Ignoring this can lead to failure of individual parts or the entire engine.

What can cause the oil can to light up on the dashboard?

To understand the reasons for the blinking of the d.m. indicator light. First of all, you need to understand the engine lubrication system itself. The parts of the internal combustion engine mechanism constantly come into contact with each other during its operation, which causes friction.

For example, if you take a crankshaft tenon, it rotates relative to the connecting rod and these parts rub against each other. It is known that parts that rub against each other, working without proper lubrication, quickly wear out and fail. To reduce the likelihood of breakdown and facilitate the operation of rubbing mechanisms, lubricants are used in the motor.

Let's look at the structure of the engine's motor lubricant.

The lubrication mechanism of the power unit consists of:

- The oil pan is a container into which lubricant is poured. It is located at the bottom of the engine, where the oil fluid is directly located, from where it is distributed to all parts that experience friction during operation. These include: crankshaft main and connecting rod bearings, piston system, timing mechanism, etc.;

- Oil pump - responsible for the supply and uniform distribution of lubricant to all rubbing parts of the engine;

- Oil intake - located near the pump, its function is to prevent foreign objects from entering the crankcase along with the lubricating fluid;

- Reducing valve - responsible for maintaining d.m. in the system at the required level, also serves as a protective mechanism for the oil pump;

- Oil filter - serves to clean the lubricant before entering the rubbing mechanisms of the engine;

- Pipes and channels for supplying lubricant to the engine system;

- Dm sensor and pressure gauge - are responsible for measuring d.m. in the engine compartment and transmit data to the on-board computer.

Does Lukoil, Mobile oil burn?

How do oils produced by different manufacturers react to fire? The most common oils are Lukoil or Mobile. In order for the motor to function effectively, you need to pay well. After all, these oils have the appropriate quality.

When using Lukoil oil, an elastic film is created on the engine, which is necessary for reliable protection against wear, regardless of the conditions under which the engine operates. Friction is reduced and engine performance is increased, fuel is saved and noise is reduced. The engine can be started easily even at low temperatures, protecting its parts from wear and preventing low-temperature deposits from appearing on the engine. The quality offered by the manufacturer eliminates the possibility of oil burning in the engine.

But oil fires occur in the engine for some reason, and it doesn’t matter what brand of oil is used. This can occur if a compound that is not suitable in its properties is poured into the engine. If the oil has a very low viscosity, it will stop and burn. High viscosity will cause a thick film to form on the inner wall of the motor. As a result of both cases, a lot of oil composition will be consumed.

This defect can be eliminated if you use suitable engine oil. The motorist will be surprised by the reduction in consumption of the motor product. But, in any case, you need to choose a composition that has high viscosity.

You can use synthetic oil all the time to switch to a semi-synthetic composition. The engine will not suffer from this in any way, only if the semi-synthetic parameters do not contradict the instructions of the automakers.

What to do if the pressure lamp flashes at idle

If the indicator lamp lights up when the engine is idling, then you need to find the source of the malfunction and neutralize it as quickly as possible.

You can contact your nearest service station for help or try to find and fix problems yourself.

Reduced oil level

To find out how much lubricant is in the internal combustion engine at the moment, you need to do the following: turn off the engine, open the hood and check the oil dipstick in the engine to measure the oil level.

There are special marks on the dipstick that show the degree of immersion in the lubricant. If the level is low, this can be seen by the corresponding mark, in which case it is necessary to add oil.

Sensor check

To check, the engine is started and warmed up, the gas is squeezed out in neutral until the crankshaft speed reaches approximately 1000-1100 rpm.

If the indicator goes out when the gas is released, the sensor may be faulty. To be sure, you can remove it and replace it with a pressure gauge to measure the pressure. If the measurement values are below the norm, then the sensor alerts are correct; if they correspond to the norm, it is faulty and must be replaced.

Checking oil pressure and viscosity

High-quality lubricant in internal combustion engines has good viscosity. It can be checked by carefully inspecting the oil dipstick and also removing the oil pan.

If the oil is very thin, then the time has come for its replacement or it has been missed altogether. The use of diluted lubricant, essentially waste, is harmful to the engine and leads to its rapid wear. It is recommended to change the oil exactly as scheduled.

Oil filter problems

If, after changing the oil in the engine, the indicator lamp continues to blink for more than 10-15 seconds at idle speed, then this may indicate a faulty filter. Breakage/clogging of a part is determined visually.

Oil pump malfunction

To determine the condition of the oil pump, it is necessary to remove the oil pan. It is quite difficult to do this on your own, in particular on foreign car brands. Therefore, if you suspect that the oil pump is faulty, it is better to contact a car service center for qualified diagnostics.

Engine wear

If the engine has a high mileage, the oil lubricant may leak out, as a result of which the pressure will decrease. Long service life and old internal combustion engine parts cause rapid oil consumption, which can be evidenced by atypical noise in the engine and blinking indicator light. The solution to the problem may be replacing worn-out parts with new ones or a complete overhaul of the engine.

To summarize, it is worth noting that driving with a glowing oil pressure indicator is unsafe and can lead to serious car repairs, including a complete engine replacement.

Ignoring malfunctions signaled by the light sensor will inevitably lead to breakdown of the entire internal combustion engine mechanism. Therefore, experts recommend immediately identifying the malfunction and fixing it yourself or at the nearest car service center.

We recommend watching:

- The oil icon on the instrument panel is on

There is a knocking sound when starting the car

Camshaft sensor not working symptoms

- Which oil is best for a diesel engine?

- Car oil rating 5w30

- Why is the oil icon in the car on?

Why does engine oil leak?

So, if the driver regularly monitors the lubrication level, then it will immediately be noticeable that the oil has left the engine. In this case, oil consumption is usually affected by two factors: engine oil leakage and oil burnout.

- Let's start with the most common reasons. For example, it occurs in case of incorrect assembly of the engine and incorrect crimping of the cylinder head. The result is that the head through the gasket is not evenly pressed against the cylinder block, which leads to breakdowns in places where the tightening is loose. The car owner can identify this malfunction with the naked eye by leaks of engine oil from under the cylinder head.

Also, a breakdown of the cylinder head gasket can also result in coolant entering the engine crankcase. In this case, this will be signaled by the appearance of . When removing the oil dipstick from the engine crankcase, you can observe an increase in the oil level and an uncharacteristic whitish tint for oil (emulsion).

In this situation, under no circumstances should you start the engine, in order to avoid wear on the crankshaft liners, increased wear on the camshaft cams and scuffing on the mirror surface of the cylinder liners.

To solve the problem, it is better to deliver the vehicle by tow truck to the place of repair and replacement of the cylinder head gasket. It is also a mistake to believe that without replacing the gasket, additional tightening of the cylinder head will give results. The fact is that since the head gasket is already deformed, there will be oil leaks at the deformation sites.

A mandatory measure in this situation is to remove lubricating lines from emulsion residues, after which the engine is filled with oil recommended by the engine manufacturer.

For the information of car owners, motor oils of inexpensive brands, but with the appropriate viscosity coefficient, can be used as flushing oil. This will not cause any harm to the internal combustion engine, since the duration of operation of the engine on cheap oil is not significant, the loads are minimal, and the task of such a lubricant is to flush the engine from the emulsion. At the same time, savings on the car owner’s budget are obvious.

- Worn crankshaft oil seal (front or rear) is also a fairly common cause of engine oil leakage. This problem can sometimes be easily diagnosed by an oil puddle under the car or drips. However, in some cases, obvious leaks are not always visible without examining the lower part of the car.

The crankshaft oil seal is made of rubber, but it is not durable and is subject to various influences (elasticity is lost, wear appears, rubber is subject to mechanical wear by abrasive debris contained in engine oil, etc.). In this situation, the solution to the problem is obvious. The crankshaft oil seal needs to be replaced. It is also recommended to fill with fresh engine oil and change the oil filter.

- An oil leak is also on the list of possible causes for a decrease in the oil level in the engine crankcase. The problem arises as a result of incorrect installation of the oil filter (under-tightening or overtightening, as well as abrasive dust getting on the filter gasket). A factory defect in the oil filter is also possible (oil may leak in places where the filter housing is rolled).

The problem is solved by replacing the oil filter. If the filter is not tightened enough, then you need to try tightening it more. By the way, in order to avoid deformation of the rubber gasket of the oil filter, experts recommend lubricating this gasket with oil before installing it.

As a result, the tightness of the gas distribution mechanism valve seals is lost and the engine oil flowing through the leaky valve seals flows down the guides and enters the internal combustion engine cylinders. The lubricant then burns along with the fuel. Engine oil combustion products have a detrimental effect on the performance of piston parts. The problem can be resolved by replacing the valve stem seals.

- The occurrence of oil scraper rings leads to poor removal of the oil film from the inner surface of the cylinder during the piston stroke. As a result, the oil remaining in the combustion chamber actively burns out, forming coke deposits.

Such deposits lead to coking and ring formation. The result of this is a drop in the power of the internal combustion engine and uneven development of the working surface of the cylinders (ellipse), which entails expensive repairs, as well as the need to perform work to replace the piston rings.

Where does the engine oil go: hidden reasons

Let's start with the fact that in addition to the obvious reasons for increased lubricant consumption (oil leakage), there are also indirect ones. For example, .

In simple words, a number of malfunctions in the engine cooling system, insufficiently efficient operation of this system can also lead to the so-called “oil burn”.

The reason is that insufficient heat is removed from the engine, the engine in turn becomes “hotter”, i.e. its operating temperature is forcibly increased by several degrees and the internal combustion engine operates at the upper temperature limit.

Accordingly, being constantly exposed to extreme temperatures, the oil intensively “burns”, and the waste products clog the oil channels, reducing the efficiency of the entire engine lubrication system.

- Oddly enough, problems can also indirectly provoke increased engine oil consumption. The problem lies in the fuel injectors, which, without proper maintenance, over time begin not to spray the fuel mixture, ensuring uniform ignition in the cylinder, but pour fuel in a stream.

As a result, uneven combustion of fuel begins and an increase. In turn, increased detonation leads to the appearance of microcracks in the pistons and piston rings, as well as cylinders (liners). Due to these defects, oil scraper rings do not effectively remove the oil film from the working walls of the cylinders. It turns out that oil breaks into the combustion chamber with all the ensuing consequences.