Watch the installation of the Acoustic shelf on the VAZ 2114 until the end.

It’s better to watch until the end, if you have any questions, ask me, I will answer as quickly as I can.

If the necessary markings remain on the cardboard sheet made by our client, it should be attached to the plywood and the future shelf should be cut out strictly according to the size of the template. This step of the work requires special concentration, since only if it is carefully cut will the shelf be able to fit into the trunk slots.

Holds on with latches

Next, the lifting part of the structure is cut out of plywood, after which it must be connected to the fixed part of the shelf using hinges. The horizontal lifting part will be held back by latches installed on the edges of the shelf.

Monitoring the quality of the fuel mixture using a lambda probe

What does error 4 mean on the Lada Priora and how to fix it?

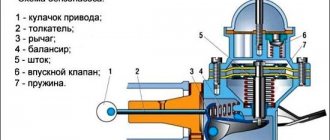

The optimal composition of the fuel mixture was calculated (14.7 parts of air per one part of fuel), the combustion of which produces the least amount of harmful gaseous waste, which is successfully neutralized by the catalyst. The range of maximum effective action of the catalyst is very narrow - a hundredth part (1= 1±0.01). Such precision of the supplied air portion can only be ensured by electronic control. It is carried out by the on-board computer ECU. And the peripheral link in this chain is the residual oxygen sensor - the lambda probe.

Oddly enough, the amount of air supplied is not measured where the air is sucked into the fuel system, but by calculations based on excess oxygen in the exhaust gases. It is the lambda probe, which is placed in front of the catalyst in the exhaust manifold, that transmits data about this parameter to the ECU. So, the controller reads signals from the oxygen sensor. He reports the presence of free oxygen molecules in the exhaust that have not entered into a combustion reaction. This means that the fuel share was small and should be increased. Analyzes and makes its calculations, the ECU sends tasks to increase (or decrease) the portion of fuel required for a given volume of air.

How is the error diagnosed?

Assuming no other trouble codes exist, you can diagnose code P0171 by checking the engine for vacuum leaks with a vacuum gauge and checking the fuel system pressure with a pressure gauge.

Most likely the cause of the error will be found during these two tests. If the cause is not in the fuel system or excess air, then the next step is to check the MAF sensor (mass air flow sensor) and oxygen sensors (lambda probe).

If all these tests have been performed and no problems are found, then most likely the fault is in the engine control unit.

If the control unit has recorded two DTC codes - P0171 and P0174, then it is very likely that the problem is excess air, air leaks in the intake tract. If there is no suction, then the next step is to replace the air filter and clean the flow meter. If the problem persists, the first (front) oxygen sensor may need to be replaced.

Restoring the correct operation of the probe

VAZ 2115 error 8

Error codes will need to be reset from the ECU after troubleshooting. Moreover, if the cause is low-quality gasoline, you will have to drain it and fill it with high-quality fuel. And only after that reset the codes.

Clean dirt and carbon deposits with active reagents.

The lambda probe is a consumable item. If you have diagnosed its final breakdown, then it needs to be replaced. It cannot be repaired, since damaged precious metal threads cannot be replaced, even at dealer service centers.

You can replace the old probe with an original or universal device from Bosch. Mounting with an adapter makes it suitable for any make of car. When installing a new sensor, do not forget to lubricate its threaded part with sealant.

Timely replacement of the lambda probe, even if it has simply exhausted its service life, will increase engine power and ensure its uninterrupted operation.

Fuel system

Checking the fuel system will not be superfluous. It is important to check the performance of the injectors here, but this can only be done with special equipment. Often, most injector problems are associated with low-quality gasoline - then you can get away with simply washing these parts. Then check the fuel pressure level and the performance of the fuel pump, if there is one in the system. Check the voltage at the pump. Among other things, check the fuel pressure regulator and fuel filter.

Causes of a lean mixture in VAZ-2114 error 0171

Check Engine. What does it mean and why does it light up?

Any car enthusiast has at least once experienced such a situation when the car began to move jerkily while driving. And this situation manifested itself especially openly in the first gears and at moments of sharp release of the gas pedal.

Injector problems

You don't have to be an expert to understand that the problem here lies in the operation of the injector. And first of all, before we start studying lean mixture, let’s try to find out what it is

This is important only because such a reason can lead to expensive repairs for the car.

Why do jerks happen?

The presence of jerks while the car is moving is a problem that directly or indirectly indicates the presence of problems with the engine, or more precisely, a loss of power. In total, there are two features that affect the development of power in the engine - fuel supply and the ignition system.

If with the ignition, everything is more or less clear, due to the inspection of the generator, spark plugs, ignition wires for faults, and the battery for charge, then in the case of the ignition system everything looks much more complicated.

High voltage wires are marked with arrows

Inspecting the condition of the spark plugs

To ensure a successful engine start, it is necessary to mix the fuel and air mixture in ideal proportions; this is what the injector is responsible for.

It happens that when mixing these proportions, a malfunction occurs, and the mixture turns out to be rich or lean.

A clear example of the air-fuel mixture ratio.

In order for the car to obtain maximum power when burning fuel in the cylinders, it is necessary to bring its indicator to the level of 0.85 - 0.9, when excess oxygen = > 1 (at this indicator, gasoline burns completely without residue - approx.), and when there is a lack of oxygen and the readings are equal to carfrance.ru

Rich working mixture

Rich working mixture (a

A rich working mixture has a reduced combustion rate and causes the engine to overheat, and its operation is accompanied by sharp popping noises in the muffler. It burns out in the muffler and is accompanied by the appearance of black smoke from it.

A rich working mixture (a1) contains less air than theoretically required. Rich mixtures are used to increase engine power, but this reduces engine efficiency due to high fuel consumption.

A rich working mixture (a1) is a mixture containing less air than theoretically necessary. The operation of automobile engines on lean mixtures is accompanied by a decrease in power by 5 - 6% and an increase in efficiency by 8 - 10% compared to operation on a mixture corresponding to maximum power.

Detonation resistance with rich working mixtures (grade) also increases, but to a lesser extent.

The cause may be an abnormal, too rich working mixture, ignition with too much advance, or inconsistency of ignition with engine operation due to a malfunction of the magneto clutch.

| Fuel volatility etc. |

The evaporation of some of the gasoline under these conditions can result in an overly rich mixture, resulting in rough idling and, in extreme cases, engine shutdown due to carburetor flooding due to gasoline periolation.

The evaporation of some of the gasoline under these conditions can result in an overly rich mixture—leading to rough idling and, in extreme cases, engine stalling due to carburetor flooding due to gasoline percolation.

Outbreaks in the exhaust system of installations can occur for the following reasons: the exhaust valve is not tightly closed; the ignition timing is incorrectly adjusted (late ignition or small ignition timing); a very rich working mixture that continues to burn out upon release; the valve timing is incorrectly adjusted (only after a major engine overhaul); The ignition is turned on after fuel is supplied to the cylinder of the rotating engine.

Signs and consequences of running the engine on a rich working mixture are: black smoke and shots from the muffler, loss of engine power, excessive fuel consumption and dilution of the oil in the engine crankcase.

Signs and consequences of the engine running on a rich working mixture are: black smoke and shots from the muffler; loss of engine power; excessive fuel consumption and oil dilution in the engine crankcase.

The evaporation of gasoline is also associated with the unsatisfactory operation of a hot engine at idle, when, with low gasoline consumption and a low speed of its pumping through the fuel system, the temperature of the gasoline increases. The evaporation of some of the gasoline under these conditions can result in an overly rich mixture, resulting in rough idling and, in extreme cases, engine shutdown due to carburetor flooding due to gasoline percolation.

Since 2 3-dimethylbutane has high anti-knock properties and good performance on a rich working mixture, the ethylation of isobutane has become the subject of numerous studies, especially after it was shown that the reaction in the presence of aluminum chloride and hydrogen chloride at 25 - 35 or in the presence of fluoride boron and hydrogen fluoride at 0 - 5 gives products containing 45% hexanes, consisting of 70 - 90% 2 3-dimethylbutane, 10 - 25% 2-methylpentane and less than 3% 2 2-dimethylpentane.

For internal combustion engines to operate, it is necessary that the air sucked into the cylinders contain hydrocarbons in such an amount that would ensure the most favorable ratio between oxygen and combustible substances. Therefore, the saturated steam pressure should not be too high, otherwise a very rich working mixture may form, but at the same time it should not be too low.

Lean mixture on the injector, causes and symptoms

Motorists often complain about such a nuisance as a lean mixture on the injector. We will consider the reasons why this phenomenon occurs in the article.

To begin with, let us identify the signs by which such a “diagnosis” can be made, such as a lean mixture on the injector; we will analyze the reasons that cause it below. So, what should the driver be wary of in this regard?

- Of course, the engine stalls for no apparent reason.

- The engine stalls at idle.

- The movement of the machine is jerky.

- You can hear “automatic bursts” in the intake manifold.

A single symptom is not guaranteed to indicate a lean mixture in the injector. But it makes you wary and assume exactly that. Next, you should carry out an external inspection of the necessary components and check them. The following actions should be considered mandatory. You need to check the spark plugs, coil, all cables, slider, distributor cover. If everything is in order, there is a very high probability that the cause of the problem is the lean mixture on the injector.

To finally make sure of this, you need to turn out the spark plugs. They should be a normal light brown color. A darker color indicates a lack of air, a lighter color indicates an excess of it.

The main causes of a lean mixture on the injector

- The main reason is filters and injectors clogged with dirt. It is clear that in this case, fuel does not enter a particular engine in the proportion required for a normal mixture.

- Excessive air leakage from the side. The reason for this may be depressurization of the collector, a crack in the line (some pipe or hose is damaged).

- Worn or damaged fuel pump.

- If the car has a mechanical injection system, it is possible that the pressure control regulator may not operate correctly due to clogging.

- Clogged surface of the throttle valve due to the constant deposition of fuel vapors on it.

A lean mixture can form not only as a result of the lack of supply of the required portion of fuel, but also as a result of the supply of excess air. What reasons cause this trouble?

- Dirt gets into the air flow sensor.

- Failure of the EGR pressure sensor.

- Air entering the intake manifold as a result of incomplete closing of the EGR valve.

- Just a vacuum leak.

These are the main reasons for the formation of a lean mixture on the injector.

October 9, 2020 Teor21 ← Welding aluminum semi-automatically in argon at home How can you check a ball joint without a lift →

Mass air flow sensor

Sometimes you need to check everything you can. It’s worth starting with diagnosing the sensors. As you know, one of the most popular problems is a clogged or clogged air flow sensor. If a large amount of dirt has accumulated on it, this often leads to a slow response of the ECU to air flow and air change. Additionally, the sensor may become contaminated by fuel vapors that pass through the intake manifold. Additionally, deposits can accumulate through the throttle body when the engine is not running. A layer of paraffin is deposited on the sensor, due to which incorrect data about the proportions of the fuel mixture enters the ECU.

Then a situation arises when the engine control unit cannot add the required amount of fuel to the mixture (and the amount of air is already quite large). And then an error appears on the sensor display - lean fuel mixture.

How does a lambda probe work?

The principle of operation of the oxygen sensor is to monitor the amount of air (oxygen) in the exhaust gases. Why oxygen? Because it has been scientifically proven that complete combustion of the fuel mixture occurs at a rigid fuel to air ratio of 1:14.7. To assess this ratio, the composition of the mixture, the concept of “excess air coefficient” was introduced, which is defined as the ratio of air entering the cylinders to the amount of air contained in the optimal air-fuel mixture, which is usually denoted by the Greek letter “λ” (lambda). The formula is as follows: if “λ” is equal to “1” - the mixture is lean.

Due to the constant deterioration of the environment throughout the world, the requirements for harmful CO emissions are constantly becoming more stringent, so almost all modern engines are equipped with oxygen sensors, catalysts and other systems aimed at making the exhaust less toxic. The control unit regulates the fuel supply through the injectors and also monitors the correct operation of the lambda probe. In the event of a malfunction, a report in the form of an error will be recorded in the appropriate log, and the driver will see the hated “Check Engine” inscription on the instrument panel.

How to check the serviceability of the lambda probe will be discussed in my article today. You will learn about the signs of malfunction, the causes, and how to check the oxygen sensor at home.

Oxygen sensors come in various types, among which there are one-, two-, three-, and also four-wire ones, it all depends on the configuration (presence of a heater and power supply circuit). Almost all modern lambdas are heated.

First, let's talk about why the lambda probe fails. The reasons may be the following:

- Excessive lead content in fuel;

- Antifreeze gets inside the sensor;

- Violation of the tightness of the sensor housing during cleaning or as a result of exposure to chemicals. substances;

- Severe overheating of the sensor housing due to the use of unsuitable (low-quality) fuel.

Signs of a malfunctioning oxygen sensor:

- Jerking while moving;

- Increased fuel consumption;

- Problems with the catalyst;

- Unstable engine speed;

- High exhaust toxicity.

Tuning the air/fuel mixture (AFR) is about making the mixture optimal for combustion in the engine.

The ideal ratio of gasoline and air , in which the entire mixture burns completely, is considered stoichiometric (ideal). The engine runs well if the gasoline + air mixture burns well. The mixture burns well if it is optimal. The mixture is optimal if 1 g of gasoline is supplied to 14.7 g of air. The optimal fuel-air mixture burns as quickly as possible and delivers the right amount of energy without unnecessary heating. The main thing in the optimal formation of the fuel-air mixture is the mass air flow sensor.

AFR is the air to fuel ratio in the engine combustion chamber.

Ideal fuel/air ratio for gasoline engines (stoichiometric mixture) = 14.7/1 (AFR) for gasoline/diesel.

14.7 g of air per 1 g of gasoline.

Each fuel requires its own fuel/air ratio.

Lean or rich mixture. The air-fuel mixture can be lean or rich.

I want to go for a ride with you! On one paid Pilot there seemed to be no problems; the automatic transmission generally shifts smoothly. And I recently installed the Vagovsky one, I think the original one is better, and why does the box get stuck sometimes from first to second. I'm going to change the TPS Pilot to this device. It works better smoothly . From the intersection it's a nice thing to pedal 1 2 3 perfectly switch themselves in time. TPS Pilot non-contact I thank the smart, honest, temperamental people for their reviews and dissemination of information.

Car diagnostics

The appearance of a lit “Check Engine” lamp on the instrument cluster signals the driver that a problem has arisen in the vehicle’s electrical system. You need to understand that checking the vehicle yourself and at a service station can give different results. Special equipment available to professionals will allow more accurate detection of faults.

Self-diagnosis

On a VAZ 2115, the owner can do independent diagnostics and find out what errors are stored in the memory of the engine control unit. The procedure is carried out by calling up fault codes on the dashboard or using a diagnostic adapter.

To carry out diagnostics on the electronic instrument panel, you must perform a certain sequence of actions:

- Sit in the driver's seat of the car, insert the key into the ignition and press the daily mileage reset button located on the instrument cluster.

- Turn the lock key to the ignition switch position.

- Release the key, starting the self-diagnosis process. Visually, this will look like turning on the backlight, all signal lamps, possible symbols on the LCD screens and testing the instruments (the arrows will move across the entire scale in both directions).

- Press the key again and release. The second press displays the software version of the instrument cluster on the screen located under the speedometer (inscription like Uer x. x).

- Press the key again, after which the errors in the memory will be displayed on the screen.

Instrument cluster VAZ 2115, the button is located on the right side of the speedometer

The driver can perform self-diagnosis on the electromechanical panel and the “January-4” control unit according to the following sequence:

- Turn off the ignition.

- Open the diagnostic connector cover located on the center console.

- Connect contact B to the negative terminal of the battery (to the body). Contact A, connected to the engine crankcase, is suitable for this.

- Turn on the ignition. The “Check Engine” lamp will flash code 12, which means the diagnosis has begun. The light signals are given as follows - a long flash, then a pause (about 2 seconds), two short flashes, a long pause (about 3 seconds). Signal 12 is sent three times. If there is no signal, the diagnostic system is inactive or faulty. After this, the Check Engine light will flash and list the errors in memory. Each code is repeated three times. If there are no errors in the memory, code 12 will continue to be transmitted.

To read controller errors, a special K-Line adapter is used, which is connected to the diagnostic connector using a connector. This connector is located on the center console behind a plastic plug (below the cigarette lighter and ashtray). The adapter has a cord with a USB connector at the end that connects to any laptop. A special program for reading and resetting errors must be installed on the device (OpenDiagFree version 1.4 or 1.6).

The procedure for reading errors is quite simple, you need to:

- Check the level of process fluids.

- Open the connector cover and turn on the ignition.

- Connect the adapter or scanner to the diagnostic socket.

- Launch the software on the laptop.

- View available errors in the program dialog box.

- Decrypt the codes using the program interface or decryption table.

- Eliminate the causes of malfunctions and re-diagnostics.

Uncertain reasons

In other situations, it happens that a lean mixture is formed on the injector of a VAZ 2107 car, the reasons for this are completely unknown. The diagnostics carried out indicate the presence of a malfunction with a lean mixture, but do not allow us to determine the cause that led to its formation. In this case, you will have to search at random - look through all the systems.

There are only two reasons for an engine running on a lean fuel mixture - too much air and not enough gasoline.

Lots of air. Almost always, extraneous air leaks lead to uneven engine operation. The revolutions do not change (no matter what they write in the Toyota section about Markovniks), they drop slightly or change smoothly with a period of a couple of seconds. As a rule, air leaks occur through damaged intake manifold seals, through torn diaphragms of the brake booster or servos of auxiliary engine systems. For many engines, the crankcase ventilation system is designed in such a way that there is always a vacuum in the crankcase (so that the seals do not leak). Accordingly, if excess air enters the crankcase, for example through a loosely inserted oil dipstick, a leaky oil filler neck, or a ventilation hose simply routed under the hood, then this air from the crankcase enters the cylinders. This air turns out to be superfluous there, since it is not taken into account by the air flow sensor and the engine control unit simply knows nothing about this air.

Low on gasoline. The reasons for this are the following: low fuel pressure in the rail (dying fuel pump, dirty fuel filters), low throughput of the injectors (due to contamination), or short opening time.

How to determine the cause. The first thing we do is unscrew the spark plugs after the engine has been running under load for at least half an hour. — If the carbon deposits on them are light (whitish), then this is a sign of operation on a lean mixture (the type of spark plugs must naturally correspond to the engine model). — If the carbon deposits on the spark plugs are light or normal (not black), but noticeably different in color in different cylinders, then either there is an air leak or contamination of the injectors. If you wish, you can take a syringe of 10 cubes, fill it with gasoline and pour this gasoline in through one of the holes near the receiver while the engine is idling. If the mixture is lean due to air leaks, the engine will run noticeably smoother and increase speed. I myself prefer checking the injector opening times. The fact is that this time is approximately the same for all modern engines (we do not consider specially charged engines). When a warm engine is running at idle, this time is within 2-2.5-2.7 ms (those who wish can check this time for their engine independently). If the injectors are heavily contaminated, or the pressure in the fuel system is reduced, then this time will be about 3 ms or even longer. In this case, it is worth washing the injectors with Vince, without removing them from the engine. — If after washing the opening time of the injectors has changed little (by changing this time you can very accurately judge the degree of contamination of the fuel system), you need to measure the pressure in the system at the inlet (!) of the fuel rail. We do this using the simplest device consisting of a conventional dial tire pressure gauge, a tee and connecting hoses. The opening time of the injectors can be measured with any oscilloscope. — If the carbon deposits on the spark plugs are very light and approximately the same, you can immediately measure the fuel pressure. — Short injector opening times are very rare. I had a chance to encounter this on a Subaru (there was some kind of left coolant temperature sensor) and on a Padzherik (the electrolytic condensers in the engine control unit dried out).

Bendix replacement

Regardless of whether you are going to replace the bendix or rebuild it, you will first have to remove it from the starter. There are two types of starters:

- With a “beak”, where the front support of the starter shaft is made in its housing.

- And without the “beak” where the front starter support bushing sits in the crankcase.

The most common mechanisms are of the first type, the “beakless” ones are familiar from the VAZ of the “eighth” family.

Since you can change the Bendix on the starter only by removing the starter itself, first the battery ground is disconnected, and the power cable and the solenoid relay control wire are removed from the starter. Having unscrewed the fastenings of the starter to the crankcase, we pull it out.

Regardless of the design of the starter, the solenoid relay is first removed, since its plug later interferes. We unscrew the nut on the power terminal of the starter winding, remove the terminal, then unscrew the screws connecting the retractor to the housing. We take out the relay winding, after which the core can be easily disengaged from the Bendix fork.

Then we disassemble the starter. Having unscrewed the longitudinal coupling bolts of the covers, remove the “beak” or front cover of the starter. After this, you can easily remove the fork from the Bendix and pull the rotor towards you.

A thrust bushing is installed on the rotor, limiting the stroke of the bendix. Before removing the bendix from the starter, you need to compress this bushing. In garage conditions, an open-end wrench is used, the mouth of which fits onto the rotor shaft, but rests against the bushing with its jaws. Having firmly fixed the key in a vice, we rest the thrust sleeve against its jaws and apply a sharp blow to the end of the shaft through a drift made of durable wood, copper or aluminum, so as not to damage the shaft itself. After this, the retaining ring installed inside the bushing jumps off the groove and releases it. After removing the bushing, pull the retaining ring off the shaft by prying it off with a thin screwdriver.

After this, we take out the Bendix assembly. Installing the Bendix is done in the reverse order, and the main difficulties are caused by pressing the thrust bushing back. It should be taken into account that it is asymmetrical - on one side there is a wide chamfer, which makes it easier to enter the locking ring. When removing the bushing, the retaining ring is deformed; it must be straightened before assembly. The thrust bushing must be seated on the retaining ring without distortion, otherwise the edge may be squeezed out of the groove on the rotor, the ring will bend and will not allow the thrust bushing to be pressed into place.

Something else useful for you:

Causes of a lean mixture

There are several main reasons why the mixture is supplied to the car lean. But, they are all divided into two main groups: a large amount of air and a small amount of fuel.

A lean mixture error can occur in the case of excessive air supply, then the problem lies in the incorrect operation of the fuel flow sensor. This can happen when the channels become dirty. The second reason can be called the problem of vacuum leakage. And reason number three talks about the problem of air intake through the EGR valve when it is broken or does not close tightly enough.

Check the EGR valve

Checking the EGR valve (video)

In order to eliminate the EGR valve, it is necessary to remove it from the car and check its operation. The test is carried out with compressed air. Compressed air can be taken from a compressor, a tire pump, or, in extreme cases, from the tire itself. Learn more about video verification.

How is the check carried out?

Check sensors. One of the most common causes of the P0171 code is a clogged air flow sensor (MAF). The sensor's response to changes in air flow may be slow due to dirt accumulated on its wire. It can also be contaminated by fuel vapors that escape through the intake manifold and throttle body when the engine is not running. These vapors deposit a waxy layer on the sensor wire, which causes a signal to be sent indicating that there is not enough air in the mixture. And the engine control unit, in turn, does not add fuel when the amount of air increases and the overall balance of the mixture is disrupted. All this leads to a lean fuel mixture and the appearance of error P0171. Often, along with this error, errors p0100 or p0102 may appear, which clearly mean a malfunction of the mass air flow sensor. To solve the problem, the sensor itself must either be cleaned using a special cleaner for electrical appliances or carb cleaner (spraying onto the sensitive element), or a new one must be installed.

For cleaning, use only carb cleaner or electrical cleaner. Other substances may damage the sensor.

Check for vacuum leaks. If the cause is not the mass air flow sensor, then you should check for a vacuum leak. Depressurization can occur at any point in the inlet pipe, as well as at the outlet of the throttle body - at the connection point between the vacuum hoses and the intake manifold, in the throttle body gasket, in the inlet manifold gaskets. It is also worth inspecting the hoses of the crankcase ventilation system, fuel vapor recovery system and plugs on the intake manifold for physical damage. The entire exhaust system near the oxygen sensor, half a meter before and after it, must be sealed. In another case, the sensor readings may be incorrect (for example, an error may occur when a corrugation burns out). The easiest way to check for leaks is using an auto scanner (by checking the fuel balancing value).

If your vehicle is equipped with a differential pressure sensor in the exhaust gas recirculation system (DPFE), then the code P0171 may appear if it is faulty.

Such sensors fail quite often when the car has high mileage. You should check it if the car's mileage is already more than 90 thousand kilometers.

This sensor is mounted on the engine and is connected by two hoses to a pipe through which exhaust gases are discharged to the recirculation valve (EGR). Corrosion in the sensor leads to its sensitivity decreasing, as a result of which it transmits information about the lack of gases and the EGR valve remains open longer, which leads to an increase in the air level in the mixture and its leanness.

Check the fuel system. As already mentioned, the lean mixture error code P0171 can also appear if there is insufficient fuel volume with which the mixture is saturated. To check the health of the fuel system, the following tests are performed:

- The performance of the injectors is checked (on a stand);

- Checking fuel pressure;

- The performance of the fuel pump is checked;

- The voltage supplied to the fuel pump is checked;

- The fuel pressure regulator is checked;

- The condition of the fuel filter is checked.

These tests can also be performed using an in-vehicle scanner. The fuel pressure parameter and fuel balancing value are checked.

If error P0171 occurs intermittently, but with some frequency, the reasons may be unreliable connection of the sensor and controller harness contacts, mechanical damage to the harness, or poor grounding of the controller.

Mixture too rich

A mixture that is too rich results from an elevated fuel level in the float chamber due to a leaking float, a worn or clogged needle valve, or a bent lever shaft.

| The influence of the boiling point of gasoline on its consumption during vehicle operation.| The influence of the distillation temperature of 90% gasoline on the octane number of gasoline of various origins. |

When liquid gasoline is forced into the engine intake system (this phenomenon is called percolation), a too rich mixture is created and normal carburetor operation becomes impossible.

When liquid gasoline is forced into the engine intake system (this phenomenon is called percolation), a too rich mixture is created and normal carburetor operation becomes impossible. If gasoline evaporates into the mixing chamber or into the atmosphere, the fuel level in the float chamber decreases and the engine can be started only after the required amount of gasoline has been supplied by the gasoline pump.

| Contact cleaning is interrupted - f, g. |

If all parts of the spark plug protruding into the combustion chamber are covered with a velvety soot (Fig. 3.5 6), then this may be caused by a mixture that is too rich, a clogged air cleaner, a weak spark, a long engine idle time, and improper valve adjustment.

The reasons for the over-enrichment of the mixture of a warm engine can be: a) pouring gasoline into the mixing chamber of the carburetor following - - the effect of the needle valve ndi-noyadavkagch 4li - to the neck level of gasoline in the float chamber, caused by wear of the needle valve; b) adjusting the idle jet to make the mixture too rich; and c) injecting gasoline with the accelerator pump into the mixing chamber when the throttle pedal is pressed sharply.

| The formation of fire hazardous conditions in room L, where static electricity discharges can occur, can be prevented.| Limits of ignition of vapors of mixtures (along the vertical axis, vapor pressure according to Reid at GZP K. |

Typically, electrostatic discharges in the open air do not cause fires or explosions, since the constant movement of air makes the mixture too lean. In enclosed spaces, in most cases, ignition does not occur due to the mixture being too rich.

After warming up the engine, you should make sure that there are no leaks of fuel, oil and coolant, and that the readings of the instrumentation are correct. The release of black smoke from the muffler usually indicates poor-quality carburetor adjustment (the mixture is too rich), and on VAZ cars, in addition, there may be increased wear on the valve oil caps.

Using a mixture of the wrong composition has a very noticeable effect on the performance of the engine and the vehicle as a whole. First of all, throttle response deteriorates; This deterioration occurs with both too lean and too rich mixtures. The engine runs unevenly and the car moves jerkily.

As the practice of operating capacitor ignition systems on cars of various brands has shown, in some cases starting a hot engine with these systems is worse than with a conventional battery system. Analysis showed that this occurs when the carburetor is incorrectly adjusted, when a too rich mixture enters the cylinders of a warm engine.

| A drop in air and fuel temperatures as the aircraft ascends. |

The operation of the carburetor is also disrupted by siphoning that occurs when the engine is stopped. Gasoline vapor collects at the bottom of the metering chamber and forces liquid gasoline into the intake system, resulting in a mixture that is too rich.

In this case, a distinction is made between lower and upper limiting gas concentrations at which combustion is still possible. In particular, mixtures that are too lean in fuel do not ignite because the resulting combustion source has too low a temperature due to the dissipation of thermal energy at the moment of formation of the source. But too rich mixtures cannot ignite, since their calorific value is also too low due to lack of oxygen, and combustion cannot spread from the source due to heat losses and a decrease in the temperature level of the reaction.

Rich mixture

A rich combustible mixture contains less than 13 kg of air per 1 kg of gasoline.

This mixture burns slowly, engine power decreases, and large excess consumption of gasoline occurs. If there is less than 5 kg of air per 1 kg of fuel, then the mixture will not ignite at all from an electric spark. A rich combustible mixture per 1 kg of gasoline contains less than 13 kg of air.

The carburetor is preparing a fuel mixture that is too rich. Copious dry carbon deposits are deposited on the insulators and electrodes of the spark plugs, causing misfires. Dry carbon deposits are deposits of unburnt carbon particles and can be easily removed by cleaning.

A rich combustible mixture enters the prechamber; it is ignited by a spark in spark plug 1, penetrates in the form of two flames into the main chamber, where it ignites the lean mixture.

The starting device ensures the preparation of a rich combustible mixture when starting a cold engine. At the same time, the expanding groove between the internal profiles A to B of the lever 4 releases the pin of the lever 6 of the air damper, and it will be kept completely closed due to the return spring 7.

Most fires are characterized by the combustion of rich flammable mixtures, accompanied by the diffusion of air oxygen into the flame zone. This circumstance is of great importance when considering extinguishing conditions and the effect of fire extinguishing agents on the fire.

Signs of the engine running on a rich combustible mixture are: black smoke and popping noises from the muffler, decreased engine power, increased fuel consumption, and dilution of the oil in the engine crankcase.

Most fires are characterized by the combustion of rich flammable mixtures, accompanied by the diffusion of air oxygen into the flame zone. This circumstance is of great importance when considering extinguishing conditions and the effect of fire extinguishing agents on the fire.

Analysis of the compositions of combustion products of rich combustible mixtures of different compositions allows us to draw a number of conclusions necessary for further calculations.

To develop full engine power, a rich fuel mixture is required. Therefore, the carburetor is supplemented with a mixture enricher called an economizer. Then the additional amount of fuel, entering through nozzle 7 of the economizer, enriches the mixture to the desired extent. When the throttle is opened sharply, the mixture becomes leaner, which greatly worsens the dynamic qualities of the car and often leads to the engine stopping just at those moments when it is necessary to accelerate the car as quickly as possible. To eliminate this drawback, modern carburetors are usually equipped with special devices called accelerators, which allow some enrichment of the mixture when the throttle is opened sharply.

| Influence of inert gas admixture (N2) on the concentration limits of propane reaction. |

To determine the upper concentration limit (rich flammable mixtures), it is necessary to take into account the energy consumption for the rearrangement of molecules of excess combustible gas.

| Mixing inlet valve. |

To develop full engine power, a richer fuel mixture is required than to obtain normal, economic power. Therefore, carburetors are equipped with mixture enrichers - economizers. In the carburetor under consideration, the enricher is mechanically driven. Then an additional amount of fuel flows through this valve and the economizer nozzle 7, enriching the mixture.

Modern data on the composition of combustion products of rich combustible mixtures show the presence in them, in addition to carbon dioxide CC2, carbon monoxide CO, water vapor H2O and nitrogen N2, as well as an insignificant admixture of molecular hydrogen Ng, the amount of which is small and does not exceed 0.5% of the weight of all combustion products with those compositions of combustible mixtures that are used to power carburetor engines.

Design and purpose of the tachometer

The purpose of the VAZ tachometer is to visualize the readings of the crankshaft. The device shows how fast the crankshaft rotates per minute, these readings are also called engine speed. Structurally, the VAZ 2107 tachometer is a milliammeter connected in one housing to an electronic part; these elements are installed on a printed circuit board.

As for the principle of operation, it consists in measuring the frequency of pulse transmission in the primary circuit of the engine ignition system. With the power unit operating, during one revolution of the distributor shaft, the contacts on the breaker should close and open 4 times. Accordingly, with one revolution, 4 voltage and current pulses are formed in the electrical circuit. As the crankshaft speed increases, the pulse transmission frequency also increases, which, in turn, affects the deflection of the instrument needle.

"Seven" tidy with tachometer

Error Lean mixture

Error on the on-board computer screen

This is a lean mixture error.

Video on lean mixture and fuel economy from “ICE Theory”

A similar problem appears in a situation where the engine takes in a significant portion of air from the atmosphere for one of many reasons. Also, the problem may lie in insufficient fuel injection due to clogging or other problems.

Symptoms and behavior of the car with such an error

This phenomenon can lead to misfires, as well as delays that occur in the car’s response to pressing the gas pedal. The car may start to stall or stall at stops (idling).

In addition, when accelerating, a noticeable twitching is felt, and dips are observed during idle.

Well, the engine itself changes its sound, starting to work extremely unstable. In those engine monitoring and control systems that support Euro 2 and higher standards, there is a lambda probe. It is he who is responsible for controlling the quality of the mixture. It is optimal if there are about 14.7 parts of ordinary atmospheric air per part of fuel.

How does a car behave with a similar problem?

If the engine receives too lean a mixture, this can cause the car to begin to “chop” at idle, and also overheat, since the rate of combustion of the mixture becomes much lower. If you listen closely, you may hear popping noises in the intake manifold. The revs pick up extremely slowly under load.

A lean mixture can be recognized by deposits on the spark plugs.

Burnout of valves and piston system

In the most difficult situations, if the engine overheats very much, this can lead to burnout of the valves and piston system, which entails serious costs for further maintenance and repairs.

A burnt valve will require serious financial investment in car repairs.

High fuel consumption

If a car is used for a long time with such a problem, this can lead to very high fuel consumption, which occurs due to a slow increase in speed. So, drivers have to operate their car in lower gears more often. A lean mixture can occur when the supply balance of its components is upset.

The main signs of a lean fuel mixture

The main symptom by which it is determined that a car is running on the wrong mixture is an engine that constantly stalls. With a very small amount of gasoline vapor in the mixture, the spark generated by the spark plug simply cannot ignite such fuel. Another sign is that the car jerks while driving, or even moves jerkily. Sometimes these symptoms can indicate other problems. Therefore, it is worth checking other systems as well. You can tell whether a lean air-fuel mixture is being prepared by looking at the spark plugs. But this is only relevant for injection units. If they are brown, the engine is in perfect order. If the spark plugs are white or light, then there is a lot of air in the fuel composition. If dark carbon deposits are found on the element, this indicates a lack of air. However, carbon deposits are not always a good indicator of an incorrect mixture. If the ignition timing is incorrect, the spark plug color will not match normal. If a lean mixture is supplied to the engine, the car owner will hear characteristic popping noises in the muffler. When it’s just a lean mixture, it will shoot like a machine gun. If, on the contrary, the fuel composition is too rich, then the explosions will be single and short. And finally, the most accurate sign and diagnostic method is to check the exhaust gases using a gas analyzer. If the engine is operating in the wrong mode, the on-board computer or diagnostic system will also report this. In the list of errors of modern ECUs there is an error - a lean mixture. It is designated P0171.

About notOshibka.Ru

Consent to the processing of personal data

I hereby confirm and give my voluntary consent to the website neoshibka.ru (Internet address https://neoshibka.ru/) in accordance with Article 9 of the Federal Law of July 27, 2006 N 152-FZ “On Personal Data” for processing and the use of my personal data specified during the registration process, commenting, or when filling out any other contact form on this site, with or without the use of automation tools, including collection, recording, systematization, accumulation, storage, clarification (updating, changing ), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data in order to collect statistics and improve the services provided by the site. The processing of personal data is also carried out for the purposes of my information notification (distribution of information, if desired, there is an unsubscribe function) and for conducting analytics and statistics.

I am aware that:

- This consent to the processing of my personal data specified during registration on the Site, sent (filled out) using the Site, is valid for 20 (twenty) years from the date of registration on the Site;

- Consent can be withdrawn by me based on a written statement in any form;

- Providing personal data of third parties without their consent entails liability in accordance with the current legislation of the Russian Federation.

I decided to tell everyone about a little-known method of testing the dashboard and identifying errors without an on-board computer. The method is primitive because They developed it at Auto VAZ, but still.

Instructions: Hold down the odometer button, turn the ignition key to the first position, release the button. The arrows start moving, press again, release, and see the firmware version (in the video, ver 1.6). And the third time they pressed, released, saw the error code (if there is one) on the video code: 8. To reset the error code, press and hold the button until the number 0 appears.

https://youtube.com/watch?v=bcKGTcTjpzk

1

Microprocessor error

2

gauge

sensor circuit error

4

High voltage

8

Low voltage

12

Indicator lamp diagnostic circuit faulty

No oxygen sensor/LAMDA probe signal

14

Coolant temperature sensor signal high 15 Coolant temperature sensor signal low

16

On-board network voltage too high

17

Low voltage on-board network

19

Incorrect crankshaft position sensor signal

21

High signal level of the throttle position sensor

22

Low level of the throttle position sensor signal

23

High level of the intake air temperature sensor signal

24

No signal from the vehicle speed sensor

25

Low level of the intake air temperature sensor signal

27

High signal level of the CO potentiometer

28

Low signal level of the CO potentiometer

33

High signal level of the mass air flow sensor For GM NIVA: High signal level of the absolute pressure sensor

34

Low level of signal of the mass air flow sensor For GM NIVA: Low signal level of the absolute pressure sensor

35

Deviation idle speed

41

Incorrect phase sensor signal

42

Malfunction of the electronic ignition control circuit

43

Incorrect knock sensor signal

44

Lean mixture

45

Rich mixture

49

Vacuum loss diagnostics

51

EPROM error

52

RAM error

53

No CO potentiometer sensor signal For GM NIVA: high voltage

54

No signal from the octane corrector sensor

55

Leaning at high engine load For GM NIVA: error in the electronic control unit

61

Degradation of the oxygen sensor/LAMDA probe

Errors are saved until they are reset manually! Errors also add up! Those. If you have errors 8 and 14, the display will show error 22.

Results

- Do not mistake a malfunction of the ECM (electronic engine control system) for a malfunction of the lambda probe.

- The oxygen sensor should be diagnosed by monitoring the voltage with a scanner or motor tester at its signal output.

- A specially lean or enriched mixture makes it possible to monitor the probe’s reaction, from which one can conclude whether it is working or not.

- The performance of the lambda probe can be monitored by the severity of the voltage surges. It can also be used to predict its future service life.

- You should not conclude that the lambda probe is faulty based on the errors generated by it and the ECU.

Lean Burn Codes

Do not think that if a “lean mixture” error appears, only one code indicates the reasons for this. For example, P0171 is standard, but for Ford vehicles this code indicates problems in the first cylinder. Some Honda models may display error P0172, which indicates a lean mixture. On the popular Chevrolet Captiva, the problem with the mixture is indicated differently - P2177. But to eliminate it you need to use universal methods. On a Japanese Mazda-6, code 2178 appears, which also indicates a lean mixture. All this is determined by computer diagnostics.