The gearbox is a rather complex unit that requires proper attention and diagnostics. Today, the problem of poor gear engagement is relevant for many vehicles, so it is important to understand how the unit is diagnosed and repaired. From this material you will learn why first gear is difficult to engage, what is the reason for this, and how you can engage first gear if necessary.

For what reasons do interruptions occur?

The gearbox is not only one of the most complex, but also one of the most basic components in any vehicle. The reasons for malfunctions that make it difficult to engage first gear can be associated with both incorrect use of the unit and driving on a bad road surface. In any case, if you don’t know why the speed turns on poorly, then this indicates a certain breakdown of the unit itself.

Gear lever

It should be noted that a similar problem often occurs in older cars that are bought second-hand and not at car dealerships. Therefore, if you purchased a used car, then you shouldn’t even be surprised by such a problem, especially since similar faults will appear in any car sooner or later. In addition, if you try to turn on the speed and this happens, but very poorly and with great difficulty, then over time the unit selector may completely stop responding to any commands from the motorist. Naturally, not every driver will be able to constantly start driving in second gear, so it is important to understand the reasons why first gear is difficult to engage.

Below is a list of breakdowns that can cause the gear lever to shift gears poorly:

- The problem is in the clutch operation - the mechanism engages poorly, disengagement is incomplete. This problem often occurs in domestically produced cars and in most cases it is due to the fact that the mechanical clutch cable comes off from the mounting point. In fact, it is not particularly difficult to identify this - if the cable breaks, the pedal will be recessed into the floor and will not move. This, as you understand, is directly related to the operation of the clutch, and not the gearbox.

- There was a breakdown in the operation of the drive rod for controlling the gear shift mechanism. Then not only the first, but also the reverse and other speeds will turn on poorly.

- Failure of the unit's jet thrust.

- For unknown reasons, the fastening bolts located on the side or selector rod for selecting the gearbox mode have become loose. The problem is solved by tightening the bolts.

- The transmission gear shift drive was incorrectly adjusted.

- The plastic elements in the gearbox control drive have failed or have expired.

- The link was poorly adjusted. As you know, the purpose of the rocker is very important in connecting the gearbox and the gear selector, so incorrect adjustment may well be the cause of the problem. In addition, the plastic bushings on this link could wear out or fail.

- Failure of synchronizers can also be called one of the most common failures in a gearbox. Unit synchronizers are brass bushings necessary for easier switching of unit modes. Since brass itself is a soft material, it can wear out and wear out during the operation of the vehicle. To correctly diagnose the condition of the synchronizers, you should pay attention to the operation of the gearbox - if a grinding or unpleasant sound appears when shifting gears, then the problem is in them. Moreover, this sound will appear constantly when you try to engage first gear. If only sound appears, but the gearbox selector switches to one mode or another without problems, then a malfunction will occur soon.

- Failure of gearbox bearings. Such a malfunction does not occur so often, one might even say that it is rare, but any motorist can still encounter it. If you own a car with a manual transmission, then the bearings could get stuck in it, as a result of which the shaft stops rotating along the path. In such cases, it is difficult to engage first gear; at other speeds the problem usually does not appear.

- The box shaft has failed. The unit shaft is usually not subject to operational wear or very heavy loads, but the malfunction may be caused by a factory defect. In the event that even minor mistakes were made in production, the shaft may well break. If so, then the problem of engaging the first gear may be just the beginning of a major breakdown that you will face. As practice shows, often in such cases the unit itself breaks down completely.

- The problem of clutch failure is relevant for owners of cars with automatic transmission. There are cases when, if the clutches are not functioning correctly, a push occurs when the first speed is turned on, but then everything works fine. The problem can only be solved by replacing the clutches.

Failed bearing

You, as a motorist, need to understand that failure of the unit shaft or bearings cannot be diagnosed at home. Only experience and equipment will help you understand this reason. Accordingly, if problems arise with turning on the first speed, it is advisable to immediately contact a professional.

Causes of gearbox failure

The complex mechanism constantly works under load and under extreme conditions. Constant vibration, rising temperatures, dust and dirt. If one or more speeds fail to turn on, you should check:

- cable tension and integrity;

- fastening the scenes;

- wear on the clutch disc;

- petals on a basket;

- bearing integrity;

- plug condition.

Clutch

When the clutch discs wear out, the pedal moves up and its position becomes higher than the others. In this case, when turned on, a crunching sound may be heard and the lever does not move, as if it is resting against an obstacle. You should not force the assembly, as this can lead to more serious damage - the gears will fly.

It is typical for such wear that the clutch pedal falls to the floor and you can hear from drivers that the VAZ 2109 does not engage the gears. Usually this applies to all gears, but only first and reverse can fail.

You can check by removing the rubber plug. The destroyed disc leaves fibers that look like tangled strands of hair. If such a phenomenon occurs, then a new clutch disc should be installed.

Due to constant loads, the cable stretches and must be periodically adjusted and tightened. In this case, the VAZ 21093 does not engage the first and second gears, and the rear may also fail. To fix the breakdown, you need to drive into the pit and tighten the cable. If it is worn out, replace it immediately. You can do this yourself.

A similar breakdown can also manifest itself in the failure of the gears to engage while the engine is running. Sliding along the splines is limited and fixation does not occur.

Basket

The reason for difficult shifting of individual gears, especially if there is a crackling sound that gradually fades while moving, may be the destruction of the spacer ring in the basket. Notice that there are drops of oil on the outside. Then remove the basket and check the O-ring and disc blades. Pay attention when purchasing new parts, because on some models the disk is missing and then you have to install pins and secure it yourself.

Backstage

A loose link must be tightened with an assistant. No special knowledge or skills are required, just the ability to hold the lever in the desired position while you crawl under the car and tighten the bolts. When the scenes on the VAZ 2109 are loosened, the speeds do not engage, and especially the rear ones.

Place the car on a hole or hill to have access to the bottom. Set the lever to neutral if several speeds do not engage. When only the reverse gear does not work, make adjustments using it. An assistant must hold the shift knob in the specified position without moving it anywhere.

It is necessary to loosen the bolt from below by 13, check the engagement of the gears, and having installed everything in place, tighten the bolt. If there is a problem with several gears, everything is done the same way, but it is set to neutral, or rather the shift knob is in the middle position. You can watch the video on how to do this.

Fork

Most often it fails on the road. If you slow down at a traffic light, the speed will not turn on to continue driving. A crack that forms on the fork body can lead to its destruction at any time, even under minor loads.

How to engage first gear without harming the gearbox?

Often, inexperienced motorists, turning the gearbox selector from second to first speed, may notice how some difficulties arise, in particular, how difficult it is to engage first gear. In such cases, a novice driver often tries to turn on the speed using force, simply by driving the selector into the desired position. This should not be done under any circumstances, since such actions can be fraught.

Actually, having noticed such a drawback in the manual transmission, motorists developed a rule - the first speed should be engaged only in order to move away. In all other cases, second, third and fourth gears are engaged. Experienced motorists especially often use this rule, but we would like to say on our own that this is fundamentally wrong.

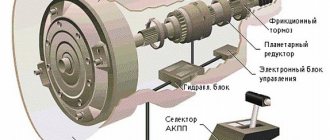

Operating principle of gearbox synchronizers

Any driving instructor will tell you that the choice of speed should be based on driving speed and engine crankshaft speed. In principle, even parking normally is only possible in first speed. If you try to park in second gear, you will have to maneuver very quickly, and in such cases there will be a strong load on the clutch. Actually, just like the gearbox unit itself. Accordingly, you must learn one simple rule for yourself - you can engage first gear when driving only if the speed is low and the crankshaft speed is low.

Theory of gearbox operation

Every motorist who understands the structure of a gearbox knows that all modern cars with a manual transmission are equipped with synchronizers. This element is one of the important components of the unit. The purpose of synchronizers is to equalize the speed of all gearbox shafts. In addition, these elements are responsible for painless and shock-free gear shifting for the box.

It should be noted that directly when the driver pushes the gearbox selector when switching from second to first gear, you can feel an obstacle. This obstacle prevents the activation of the first speed and it is this obstacle that is called the synchronizer. If the gearbox is relatively new or a synchronizer has recently been installed on it, then you will not experience problems with the transition from high speed to low speed. The first gear will be engaged without any obstacles.

Worn out synchronizer

But if your vehicle has already traveled more than a hundred thousand kilometers, then this will directly affect the functioning of some elements of the unit. In particular, first of all, synchronizers will stop working normally - they simply will not be able to perform the tasks assigned to them initially. Then the motorist is forced to perform various “tricks” that our grandfathers told us about - these are all kinds of gas shifts with double disengagement of the clutch and so on.

Troubleshooting

Many transmission malfunctions that cause the reverse gear to disappear or fall out can be eliminated without removing the unit from the car.

If the cause is a loosening of the bolt securing the clamp on the rod, then to correct the defect it is necessary:

- Place the car on a lift.

- Completely loosen the clamp nut.

- Place the gearshift lever in the fully engaged reverse gear position.

- Fully engage reverse gear at the gearbox using the shift rod on the crankcase.

- Tighten the clamp mounting bolt.

Backstage adjustment

If tightening the clamp does not help get rid of the problem, then you need to check the condition of the shift drive parts. One of the reasons why the reverse gear does not engage may be a poorly adjusted rocker.

To make adjustments to the mechanism, you may need the following tools:

- two wrenches with a size of 13 mm, preferably a socket design;

- any wrench or 10 mm socket;

- small hammer;

- slotted screwdriver.

Methods for engaging first gear

So, if the modes in your vehicle are difficult to engage and you have already understood the reasons and theory, then let’s move on to the most important thing - methods for engaging first gear. The simplest method in this case would be to activate first gear while driving the car. You need to push the unit selector forward without any effort and do this until the corresponding synchronizer comes into operation. However, it should be noted that this method is relevant for most passenger vehicles and some trucks.

It should be taken into account that this cannot be done in most old trucks, since the design of the unit itself does not allow this, since they simply do not have synchronizers. In addition, you need to take into account that this method of activating the first speed is hardly relevant if the synchronizer on your vehicle has already exhausted its service life. This will simply be impossible.

Double car re-gas

Then the driver will only have to wait a while until the car practically stops in order to turn on the desired speed. Or use force to engage the gearshift lever. In principle, neither the first nor the second method can be called the optimal solution to such a problem. As practice shows, it is best to use the same old-fashioned method with re-gasping.

You can find out how to do this below:

- So, while driving in second gear, start depressing the clutch pedal.

- When you press the pedal, move the gearbox selector to the neutral position. Having done this, you can disable the clutch pedal.

- Then, when the pedal is completely lowered, you need to lightly press the gas with your right foot, pressing the pedal. In this case, pay attention to the tachometer, which shows the number of revolutions. You need to increase the revolutions to two and a half thousand per minute, that is, the needle should be at the number 2,500. Here, pay attention to one important nuance - the greater the difference in angular speeds of the mating gears of the box, the higher the number of revolutions needs to be raised. That is, 2,500 is the minimum, add gas if necessary.

- Then depress the clutch pedal again.

- Next, the box selector should be moved to the initial mode activation position, that is, first speed. Here, also pay attention to the fact that if the selector does not enter the required position correctly, then most likely you simply did not give enough gas. If this is the case, then repeat the steps, only add more gas.

- As a result, you need to release the clutch pedal smoothly, not abruptly. If you did everything correctly, the gearbox lever will move to the required position without any problems, shocks or extraneous sounds.

If you were unable to do this, then do not be discouraged - rarely does anyone manage to perform a double gas change the first time. By repeating the procedure several times, you will be able to remember everything that needs to be done to correctly engage the first speed. Actually, the same methods allow you to activate first gear when driving in third, for example, if in an emergency you need to brake the engine. In this case, the higher the driving speed, the longer you will need to wait for the synchronizers to help you. Or you need to press on the gas more.

But do not regard double throttling as a way out of the situation. This method can be called a temporary solution, but the unit will still have to be repaired. Since replacing synchronizers is a rather complex process, we recommend that you seek help from specialists. If you still decide to perform this procedure yourself, then the instructions provided below will be useful to you.

Changing synchronizers

Replacing gearbox elements is carried out in several stages. We will not describe them in detail, since all actions are individual for each individual car.

Moreover, if you have never encountered such a procedure, you are unlikely to be able to perform it yourself:

- First you need to remove the gearbox from its installation location. To do this, use the recommendations in the service manual or search our resource - here you can find several instructions. The dismantled gearbox is thoroughly cleaned of dirt and dust.

- After this, you should remove the clutch cable retainer.

- Next, unscrew the four nuts that secure the rear cover of the unit; move it to the side.

- After this, unscrew the screw securing the fifth speed fork. Then turn it on, to do this you need to move the synchronizer clutch down with the fork. This must be done in such a way that the coupling splines are together with the gear. Having done this, you should activate either the third or fourth speed.

- Then you need to unscrew the nut that secures the input shaft. To be able to move it out of place, pull the key firmly, since it is most likely tightened with force. Carry out similar actions with the nut that secures the secondary shaft.

- Next, lift the fifth speed gear and remove it with the synchronizer and the secondary shaft fork. Please note: the clutch should not move from the hub at this point. Installation of new elements is carried out in the reverse order. You need to be as careful as possible. As you can see, in general the process is quite complex and responsible, so do not bother replacing synchronizers without experience.

Video “What to do if gears are difficult to engage”

Recommendations on what to do if it is impossible to engage first gear were given by a Ukrainian driving instructor.

Any gearbox has a complex structure with many interconnected parts, and the failure of even one part immediately affects the performance of the gearbox as a whole.

So often the cause of a gearbox malfunction is such a breakdown as one of the speeds being knocked out.

In this article, we will look at the main reasons for the question of why transmissions fail.

In order to make it easier to understand the reason for knocking out a certain speed, you need to briefly consider the principle of operation of the gearbox.

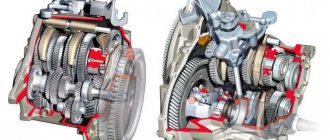

How does a manual transmission work?

A conventional manual gearbox consists of 3 shafts. These are the primary, intermediate and secondary shafts. The secondary shaft is located coaxially with the primary shaft, inside which there is a bearing into which the end of the secondary shaft fits, allowing it to rotate independently of the primary.

The intermediate shaft is a single unit with gears cast on it. It has a rigid connection through a gear to the input shaft, which causes it to rotate along with the gears of the gears.

When the gearshift knob is in neutral and the clutch pedal is not depressed, the input and intermediate shafts rotate.

On the secondary shaft of the gearbox there are gear blocks, 1st and 2nd, as well as 3rd and 4th, 5th gear and reverse gear are usually located in the rear compartment of the gearbox housing.

The blocks, in turn, consist of a hub, a gearshift clutch and 2 synchronizers. The hub has splines inside, the same as on the secondary shaft, thanks to which it can move forward or backward, depending on the gear engaged.

Reverse gear of VAZ 2109 does not engage: causes and repairs

The situation when reverse gear does not engage on a VAZ 2109 is one of the most common problems with this car model. In addition, the VAZ 2108/09/099 “Samara” and VAZ 2113/14/15 “Samara-2” cars were equipped with the same type of gearbox (gearbox), so this transmission malfunction is typical not only for “Nines”.

Often, an attempt to engage a gear is accompanied by a strong crunch of gears, and if the gear is able to be engaged, the gearbox makes noise when moving in reverse. Other owners are faced with a situation where the gear shift lever moves forward all the way, but reverse gear does not work. At the same time, there are no complaints about shifting forward gears.

Changing the gearbox oil

Replacing the gear selection mechanism

Comments and Reviews

The reasons why reverse gear engagement is poor or difficult may be as follows:

- loosening of the fastening clamp of the rocker, due to which the length of the rod is not enough to fully engage the gear;

- jamming of the reverse speed lock;

- spring breakage and debris getting into the guide grooves of the gear selection mechanism;

- spontaneous loosening of the selection mechanism mounting bolts;

- the clamp bolt is cut off;

- wear of the clutch disc and release bearing;

- incorrect adjustment of the clutch and clutch pedal;

- low oil level in the box or the need to replace it.

Transmission malfunctions and causes

Our instructions will help you determine the causes of malfunctions and know what to do about them. What does a “flying” (spontaneously switching off) transmission tell us:

- If a gear in the box begins to “fly out”, this means that the gear block of this particular gear has worn out.

- The locks on the clutch and gear are also worn out, this requires their replacement

- Such a nuisance arises in the event of violation of the rules for operating the machine, prescribed in the manufacturer's manual.

- Due to an incorrectly selected speed mode when changing gears (recommended 3000-3500 rpm)

- Switching too quickly without waiting for a pause (2 seconds), and also with a faulty or incorrectly (poorly) adjusted clutch

- All these listed factors create an increased load on the gear synchronizers, and the load on the synchronizer goes to the gear block and leads to failure

- It is also worth adding that some owners (when doing DIY repairs) or unqualified repairmen, based on various considerations, do not replace the gear clutch or expect that the problem will be solved by replacing only one synchronizer of the problematic transmission

- I’ll say right away that such an unforgivable oversight will require a re-repair of the gearbox in the near future to eliminate this problem entirely

- It is worth immediately noting that this problem is preceded by such a clear sign as a “crunch” heard when switching this gear

- Timely replacement of the synchronizer will help you avoid later more expensive and time-consuming repairs.

- However, in a neglected state, you can no longer count on minimal repairs, especially if the transmission has already started to pop out on its own, or is not fixed at all, that’s the price of negligence

In a VAZ 2109, the noise of the box in neutral indicates the following problem:

- Each gearbox has an acceptable noise limit, which is not the cause of a malfunction, since not a single gearbox operates silently

- There is a GOST for the noise level of standard gearboxes, it regulates external noise - allowed at a value of 96 Decibels (GOST R52231 from 2004), and internal noise at a value of 78 Decibels (GOST R51616 from 2000)

- When the VAZ 2109 gearbox is noisy, the noise can come from the row (it appears during the operation of the gears), as well as from the bearings

- In addition, the level of outgoing noise is affected by incorrectly selected or expired oil in the box, as well as its insufficient level

- Noise may occur when the engine is running if its speed is unstable, or a sports camshaft has been installed and the gearbox resonates with it

- By pressing the clutch pedal, turn off the transmission and the noise disappears

- And having released the pedal, we again hear the operation of the gearbox, assess how critical the noise level is, this or that sound and whether there is a need for mechanical intervention, here only a competent specialist can help you by conducting on-site diagnostics

- The fact is that it is very problematic to give advice or any recommendations regarding noise via the Internet.

- After all, there is a huge amount of extraneous noise that has nothing to do with the box at all, but they are quite often described by car enthusiasts, and they think that the noise belongs specifically to the box (noises of the release or wheel bearing and others)

- It follows from this that it is impossible to do without local diagnostics to accurately determine the causes of noise.

If any gear shifts with a crunch, this means that:

- The 3rd stage in the life of the transmission has arrived, this is when you should clearly decide for yourself whether to kill the box further or change the synchronizer in time

- All transmissions go through these four stages:

- Stage one - this is a new synchronizer, the inclusion is tight and rigid

- Stage two - over time, the synchronizer itself, and the gear block, is gradually developed, and a soft, almost effortless gear shift occurs

- However, with intensive use, the second stage often turns out to be very short or absent altogether (this is rough gear selection, skipping pauses when switching, and complete failure to comply with the speed limit when switching)

- The third stage is the appearance of the first signs that the synchronizer has worn out, either during operation or due to violation of the rules for using the gearbox. Then the gears are engaged with a click (or knock) or “crunch”. If you do not replace the synchronizer at the very beginning of this period, then you will need to replace the entire gear block

- Stage four, the transmission already “flies out”, or is fixed for a very short time or stops being detected completely

- Then you will need to repair the gearbox with replacement of the gear block assembly (gear, clutch and synchronizer)

- In addition, gears may shift with a click or “crunch” when the box is not warmed up, and when the oil viscosity does not meet specifications

- Noises in the box when the car is moving in gears mean problems with the bearing located on the secondary shaft; in addition, it is possible that your oil level has dropped too much. Only timely repairs will help you avoid additional costs in the future.

- Knocks in strictly defined gears, both under and without load, mean a chip or breakage of a gear tooth in a row or main pair

- Knocks at the beginning of movement, or in the process of switching gears from one to another, mean that the satellites or the axis of the satellites have increased wear (or even wear) and urgent repairs are required, otherwise additional financial costs cannot be avoided

Attention: it is even possible that the axle or the satellites themselves may break, and this leads (in 90% of cases) to housing defects (cracks and chips), which will certainly end in its replacement

- If the box on a VAZ 2109 bursts, you decide to buy a new one, or replace the case, both are almost equivalent in cost

Causes of problems with gearboxes

Almost every owner of a domestic car has at least once encountered problems with partial gearbox failure. If reverse gear on your VAZ-2109 has stopped engaging, then the cause may be one of the malfunctions:

- The clutch is not completely disengaged. With this problem, problems occur when all gears are engaged, but sometimes only the reverse one fails.

- The gearbox levers are damaged or broken or their mountings are loose. Problems can only be resolved by diagnosing the box, as well as replacing damaged parts. In this case, moving the lever may be accompanied by a crunching sound.

- If only reverse gear does not work, then with a low degree of probability it is time to claim that the transmission fluid has simply run out. Usually, with this problem, all gears do not engage. If, however, you notice that the gear oil level in the box is extremely low, then simply top it up.

- In practice, there were cases when the rear “speed” could not be engaged due to the poor quality of the fluid in the gearbox. In this case, it must be replaced.

- The most common problem with engaging certain gears is an unadjusted gearbox universal joint. You can notice it by this sign: at first, the backward movement was activated unclearly, and then another mode was activated instead. Later the box stopped working normally altogether.