At some point you realized that the gearbox does not change gears, we will try to figure out the reason. The complex device does not allow you to immediately understand why the automatic transmission does not change gears. The reasons can determine the signs that reflect the behavior of the machine. The most correct and common cause of gearbox failure was the driver. Unprofessional use of the car leads to the fact that sooner or later something breaks. The car has become in demand and useful, not everyone will climb under the hood to check the degree of wear of a particular part in order to prevent breakdown before it occurs.

What is automatic parking?

Like a manual transmission, an automatic does the same job, only on its own. At the foot of the gearshift knob on the automatic transmission there are the following symbols:

- P - This is parking and starting the engine. It's called parking. It is used to immobilize a car after the car has been parked and the hand brake has been applied. We have already studied how to park in reverse using diagrams: parallel and perpendicular options.

- D - This is forward movement.

- R - This is reverse. Reverse, that is, movement in the opposite direction. It can only be turned on when the brake pedal has been pressed all the way and the car has stopped. If you install the rear view camera correctly, it will turn on when you engage reverse gear.

- N - This is the neutral position. In neutral, the engine does not transmit rotation to the automatic transmission. Used during long stops or to warm up the car.

- L - This is a low gear. Used for slow traffic, for example, you have left the road, and it is impossible to drive there quickly. In fact, this is an analogue of the 1st speed of a manual transmission.

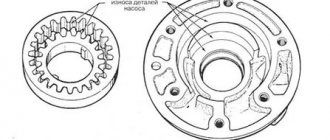

Friction disc wear

When changing gear into an automatic transmission from reverse gear, the car begins to slip. The reasons for the machine's behavior are hidden in:

- displacement or deformation of friction discs;

- rupture of rings or couplings;

- valve sticking.

Worn clutches

Disc wear can also affect the performance of the transmission. For example, it is impossible to switch to reverse gear, while at the same time moving forward is only possible in second. The reason for this behavior of the car lies in the wear of components; rubber parts are easily worn out when driving.

You won't be able to drive a car when it's cold. If, when warming up, the car slips at forward and reverse speeds, then you should pay attention to the properties of the oil used, and if possible, it should be replaced. In addition, there may be another reason for this behavior of the car - a clogged filter.

When starting to move, the car slips in place, the movement itself continues, the speed switches perfectly. This may also indicate wear on the friction discs. In this situation, attention should be paid, among other things, to the condition of the torque converter (hub wear is possible) and to the piston cuffs.

Automatic transmission: device

This device is a type of transmission that automatically selects the desired gear ratio appropriate for the speed of movement.

- Hydraulic transformer housing.

- Driven wheel (turbine).

- Reactor wheel.

- Drive wheel (pump).

- Oil pump.

- Excitation windings of an electric motor.

- Torque converter lock-up clutch (clutch).

- Damper.

- Torque converter housing.

- Gearbox housing.

- Friction discs of lock-up clutch.

- Lock-up clutch housing.

- Planetary reductor.

- Gearbox driven shaft flange.

- Oil pan

- Hydraulic valves of the gear shift control system.

- Valve box.

Automatic transmission does not shift gears - troubleshooting

A fairly serious breakdown in cars occurs when the automatic transmission cannot shift to a higher gear. There can be a lot of reasons for this, because the automatic transmission is connected to the entire engine and electronics of the car. Most often, the reason that the automatic transmission does not shift gears is its freezing.

If suddenly in winter a car with an automatic transmission does not shift gears, then perhaps the oil in it has simply frozen from the cold. This problem is dealt with in different ways; the greatest results are achieved by insulating the automatic transmission and engine. You also need to change the oil in the automatic transmission, filling it with one that is suitable for the climatic conditions.

Automatic transmissions are also completely different in design, but are most often used with a torque converter. In such a system, the connection between the engine and the wheels is ensured by oil pressure. The quality of operation of such an automatic transmission directly depends on the quality of the oil in it.

Gear shifting problems

The design of automatic transmissions is quite complex; they are all hung with sensors, just like the injection engine itself. If at least one of these sensors fails, then it is quite possible that the automatic transmission will stop shifting gears. It often happens that due to shaking and an aggressive environment, wires from sensors fall off or poor contact is formed.

Another reason that the automatic transmission does not want to change gears may be clogged oil filters or low oil level. In this case, the filters are changed and new oil is added. Also, automatic transmission malfunctions can be diagnosed based on error codes.

Automatic transmission care

In order for the automatic transmission to work faithfully for many years, it must be properly cared for. This is a rather delicate device in a car; the automatic transmission is very afraid of overheating and poor quality oil. In any automatic transmission you need to change the oil from time to time, generally this should be done no later than after 50,000 km, it all depends on the type of fluid.

In addition, the fluid needs to be renewed every 15,000, draining some of the old and adding new.

When a complete oil change occurs in an automatic transmission, the filters must also be changed. It would be a good idea to replace the sensors, because the failure of any of them leads to problems with the automatic transmission.

After filling in fresh oil, do not forget to check it before the next run. The condition of the oil should be monitored regularly by examining its color. In addition, if the oil level is too low, the automatic transmission will quickly fail.

The automatic transmission is also afraid of wheel slipping, so you should not skid for a long time on a slippery surface; it is best to push the car from the outside.

If it turns out that the automatic transmission malfunctions or does not change gears at all, then the car should be sent to a service center for repairs. As for self-repair, you can only try changing sensors, filters and oil. If you have no experience in automatic transmission repair, it is better to entrust this matter to specialists.

How to use an automatic transmission correctly?

Like any automatic system, automatic transmission requires careful handling. Correct operation of the automatic transmission consists of the following steps:

- Start the engine and warm it up, especially if it is cold outside, as the oil in the engine and automatic transmission thickens, which leads to strong friction of the mating parts. Find out how to change the oil in an automatic transmission.

- Depress the brake pedal all the way and set the gearbox lever to position D (drive).

- Remove the car from the handbrake and smoothly release the brake lever. After which the car will slowly begin to move.

- We press on the gas pedal and as we gain the speed set for each gear, the automatic machine will begin to change gears. Switching the machine is accompanied by slight jolts. It is possible that if there are problems with the operation of the automatic transmission, this is due to the mechatronics of the DSG, which often has to be repaired in some brands and models of cars.

- When the speed decreases, such a gearbox begins to downshift itself.

Some automatic transmissions have W modes or Snow flake designations. This means that in W mode, that is, the box is set to winter mode. In winter mode, the automatic transmission does not use first gear; the car starts from 2nd or 3rd gear. Because of this, the car slips less and reduces gears only to avoid skidding at low speeds.

Important! To prevent the automatic transmission from breaking, you need to follow one very important rule: do not move the selector (lever) when the car is moving from position D to R or P. This rule should not be forgotten if the car is raised with a jack or lift and mode D is turned on to check the brakes on the stand .

You can shift the automatic transmission selector only after the car has come to a complete stop and the brake pedal is fully depressed.

It is forbidden to switch to the N-neutral position when the car is driving, so as not to create an emergency situation on the road, especially if there is ice. It is necessary to put it in “neutral” during long stops so that the automatic transmission cools down.

Video “Automatic transmission device”

You can learn everything about the structure of the unit from the video.

› Possible automatic transmission malfunctions in front-wheel drive vehicles

To everyone who is faced with the problem of front-wheel drive automatic transmissions - read!

First, the problem is numbered - below is the solution, numbered!

There is no forward movement, the car is slipping in place.

Reverse movement is normal: Causes of the malfunction: 1. Wear of the friction discs of the forward clutch C1.

3. Wear or breakage of the oil sealing rings of this coupling. 4. The valve for switching from 1st to 2nd speed is stuck. Remedy:

2. Replace the cuffs.

4. Disassemble the valve mechanism and clean the valve.

There is no going back. There are 1st and 2nd speeds forward, but no 3rd speed.

Causes of the malfunction: 1. Wear of the friction discs of the forward clutch C2. 2. Wear or breakage of the piston cuffs of this clutch. 3. Wear or breakage of the oil sealing rings of this coupling. 4. The spline in the sun gear drum housing is cut off. Remedy: 1. Replace the friction discs with new ones. 2. Replace the cuffs. 3. Replace the oil sealing rings with new ones. 4. Replace the faulty part with a new one.

There is no movement back, forward there are all shifts.

Causes of the malfunction: 1. Wear of the friction layer on the brake band. 2. Wear or breakage of the brake band piston cuffs. 3. The brake band piston rod is broken. Remedy: 1. Replace the brake band. .2. Replace the cuffs on the piston. 3. Replace the part with a new one

There is no movement back or forward. When shifting from “P” or “N” to any speed, there is no noticeable push to engage any gear. Causes of malfunction:

2. The drive gear of the oil pump does not work, it has come off and there is no clutch between it and the torque converter. 3. Insufficient amount of oil in the automatic transmission. 4. The filter mesh is very dirty. 5. Severe wear of clutch friction discs and brake band. 6. Wear or breakage of the piston cuffs of these couplings. 7. Wear or breakage of the oil sealing rings of these couplings. 8. The 1st speed activation valve is stuck. Remedy:

2. After making sure that the diagnosis is correct, unscrew the bolts holding the torque converter to the flywheel and place 2 mm washers between the torque converter and the flywheel. Tighten the bolts. 3. Add oil to the upper level with the car running. 4. Flare the filter, wash and blow out the mesh or replace with a new filter. 5. Replace the brake band and discs of these clutches. 6. Replace the cuffs of these couplings. 7. Replace oil sealing rings. 8. Disassemble the valve mechanism and clean the valve.

There is no movement back or forward. When shifting from the “P” or “N” position to any speed, there is a noticeable push to engage the gear, but the car slips and does not move. Causes of the malfunction: 1. The torque converter is faulty. 2. Small amount of oil in the automatic transmission. 3. Oil filter mesh is dirty. Remedy: 1. Replace the torque converter. 2. Add the missing oil. 3. Flare the filter, rinse and blow out.

There is a movement back. Only 1st gear is engaged forward.

Causes of the malfunction: 1. The control valve in the centrifugal speed switch is stuck. 2. The helical gear on the gear selector shaft has broken. 3. The cotter pin securing the helical gear on the switch shaft was cut off. 4. The valve for shifting from 1st to 2nd gear is stuck. Remedy: 1. Disassemble, wash and clean the valve. 2. Replace the gear or gear selector. 3. Install a new cotter pin.

There is reverse movement, but only 1st and 2nd gears are engaged forward, there is no 3rd gear.

Causes of the malfunction: 1. The 3rd speed activation valve in the valve mechanism is stuck. Remedy: 1. Disassemble the valve mechanism and clean the valve.

The car drives normally, but on a long climb at the last speed it begins to slip and switches to a lower speed prematurely. Causes of the malfunction: 1. The oil level in the automatic transmission is low. 2. General wear of the cuffs, o-rings and discs of this coupling. Remedy: 1. Add oil to the upper level. 2. Replace the discs, cuffs, and sealing rings of this coupling.

When starting from a stop, the car slips a little, but then after picking up a small speed it drives normally, switching to other speeds. Causes of the malfunction: 1. The torque converter has a lot of wear on the turbine wheel hub splines, which causes the gearbox shaft to slip at high engine speeds. 2. Wear of the friction discs of the forward clutch. 3. The piston cuffs of this clutch are worn or torn. Remedy: 1. Replace the torque converter. 2. Replace the friction discs of this clutch. 3. Replace the cuffs on the piston.

The car moves when the gear shift lever is in the “N” position.

Causes of the malfunction: 1. The adjustment of the cable or gearbox control drive lever is incorrect. 2. Clutch piston C1 eating. 3. Due to prolonged slipping, the discs were welded to the plates in clutch C1. Remedy: 1. Adjust the drive cable. 2. Disassemble the clutch block and eliminate the malfunction. 3. Disassemble the clutch, replace the cuffs, friction discs and plates on the piston.

Gear changes occur at speeds higher than normal.

Causes of the malfunction: 1. The adjustment of the throttle valve control cable is incorrect. 2. Sticking of the centrifugal regulator valve. 3. Partially clogged filter mesh. 4. The throttle valve in the valve mechanism has stuck. Remedy: 1. Adjust the cable. 2. Remove, wash and clean the valve. 3. Flare, wash and blow, or replace with a new filter. 4. Disassemble the valve mechanism and clean the valve.

When you press the gas pedal sharply, there is no downshift (kick-down effect).

Causes of the malfunction: 1. The pressure sensor or the kick-down foot switch is faulty. 2. The control valve for switching from 3rd to 2nd gear is jammed. 3. Break in the electrical circuit of the sensor or foot switch. 4. The throttle control cable is incorrectly adjusted. Remedy: 1. Replace the pressure sensor or kick-down switch. 2. Disassemble the valve mechanism and clean the switch valve. 3. Find the fault in the circuit and fix it. 4. Adjust the throttle control cable.

Engine braking does not occur in 1st and 2nd gears.

Causes of the malfunction: 1. The brake band of the 2nd gear brake has failed during engine braking. 2. Wear or rupture of the tape piston seals. 3. The modulating valve is stuck during engine braking. Remedy: 1. Replace the brake band. 2. Replace the sealing collars on the piston. 3. Disassemble the valve mechanism and clean the valve.

Clutch slipping when changing gears.

Causes of the malfunction: 1. Average clogging of the filter mesh. 2. Low oil level. 3. Clutch C1 is faulty. Remedy: 1. Disassemble, wash and blow out the filter mesh or replace the filter. 2. Add oil. 3. Replace or repair the coupling malfunction.

No movement on "D". There are only 1,2 and reverse speeds.

Causes of the malfunction: 1. Wear of the friction discs of the forward clutch C1. Remedy: 1. Replace the disks with new ones. Also replace worn cuffs on the piston.

No shift to 3rd gear. It goes back fine.

Causes of the malfunction: 1. The oil sealing rings in the centrifugal regulator were worn out. 2. Valve jamming in the centrifugal regulator. Remedy: 1. Replace the rings with new ones. 2. Disassemble the centrifugal regulator and clean the valve.

No shift to 3rd gear. During high acceleration, the gear sometimes engages.

Causes of the malfunction: 1. Excessive wear of the oil sealing rings of the 3rd gear clutch. Remedy: 1. Replace the oil sealing rings with new ones.

The car jerks and slips when driving.

Causes of the malfunction: 1. Freewheel F1 has failed. Remedy: 1. Replace the faulty clutch with a new one.

Gear changes in the automatic transmission occur with noticeable impacts, and not jolts as before.

Causes of the malfunction: 1. General wear of the friction discs of all clutches and brakes. Due to this, large gaps formed in the sets of disks and plates. Remedies: 1. Major repairs with replacement of all clutch and brake discs.

There is no movement back or forward. There is main pressure in the machine.

Causes of the malfunction: 1. The splines in the turbine wheel hub were cut off. Remedy: 1. Replace the torque converter.

There is no movement back or forward. There is no main pressure.

Causes of the malfunction: 1. The oil pump shaft splines in the torque converter front cover housing were cut off. 2. The splines on the oil pump reactor shaft were cut off. Remedy: 1. Replace the torque converter. 2. Replace the reactor shaft

2 years Tags: possible automatic transmission malfunctions in front-wheel drive vehicles

The most common malfunction of modern cars - the automatic transmission does not change gears - has become a real headache for car owners who have managed to enjoy this accessory.

This invention has proven its usefulness and relevance, relieving the driver of many problems when driving, parking, overcoming obstacles, but there are some shortcomings, and to a greater extent - unprofessional use

– often lead to automatic transmission failure.

The automatic transmission does not change gears - such a “diagnosis” can be caused by many reasons

. However, before subjecting the automatic transmission to detailed testing, you need to make sure that this is the cause of the problems with the car: often similar symptoms are caused by malfunctions of other components and assemblies of the car - the fuel system, ignition, gas distribution system, as well as the engine.

Only after making sure that the cause of the problem is the gearbox should you start repairing it (after preliminary diagnostics).

Below we will list the most typical breakdowns characteristic of automatic transmissions of domestic and foreign production. Let us warn you right away: it is impossible to take into account absolutely all options within the framework of the article; we will focus only on the most popular ones.

Symptoms and possible causes of breakdowns

1.

The car refuses to move forward and slips in place. Reverse gear works flawlessly. Possible causes of the problem:

- severe wear of the discs on the direct clutch;

- the cuff on the coupling is torn;

- failure of oil rings;

- gear shift valve clogged.

2.

Reverse gear does not work; only the first two of the forward gears work. The first three reasons are similar to the previous ones, the malfunction can also be caused by the failure of the spline joint in the sun gear drum.

3.

Reverse gear does not work, forward gears work fine. Causes:

- the friction layer of the brake band is worn out;

- the cuff on its piston is worn out or torn;

- Broken brake band piston rod.

4.

The car does not move, reverse gear also does not work. Gear changes do not cause a characteristic click. Causes:

- failure of the oil pump drive gear;

- low oil level in the box;

- severe contamination of the filter mesh;

- wear of discs in the clutch and/or brake band;

- failure of the sealing rings.

5.

When overcoming a long climb, the car switches to a lower gear prematurely. Causes:

- Discs and/or cuffs are heavily worn, possibly O-rings.

6.

Slipping is observed at start, then the operation of the automatic transmission returns to normal. Causes:

- the hubs on the turbine wheel are worn out, which causes the gearbox shaft to slip;

- friction discs are worn out;

- The piston cuffs have failed.

7.

The machine moves forward or backward even though the lever is in neutral. Causes:

- the drive cable or lever is incorrectly adjusted;

- contact of discs and coupling plates.

As already mentioned, here are only the most typical faults that are most often encountered in the practice of using automatic transmissions. Even a quick acquaintance with them convinces: in case of any malfunctions expressed by the formula “the automatic transmission does not change gears,” you need to contact a reputable car service center. Why must it be “respectable”?

To correctly make a “diagnosis”, high-quality computer diagnostics is required

Moreover, it may well turn out that the automatic transmission is not the only cause of failures. Troubleshooting on your own is not recommended, because... Diagnosing a malfunction in a personal garage and correctly eliminating it is quite difficult.

The box has a rather complex structure, and it is impossible to answer this question right away. But based on some indirect signs, you can determine the essence of the problem and try to fix it yourself.

Overdrive mode

OVERDRIVE mode is a high gear, when engaged, the engine and automatic transmission are rigidly coupled by blocking the hydraulic transformer.

Set to OVERDRIVE when you need to drive at one speed in fourth gear for a long time. When this mode is turned on, the driver feels a slight jolt, as if it had shifted to 5th gear, but, in fact, it was the hydraulic transformer that was blocked.

OverDrive is activated by a button on the shift lever. And it also turns off with a second press of the button. You can also disable this mode by pressing the gas pedal all the way.

Problems associated with a lack of transmission fluid

1. When you move the shift lever to any of the positions, a push is felt, but the car does not move either forward or backward. A low oil level can occur due to leaks, or due to a dirty oil filter. Treatment methods are obvious: replace, fix, clean. And be sure to add fluid to the level.

2. On an automatic transmission, changing gears

in the highest mode, during a long climb, slipping and premature transition to a lower gear are observed. This occurs because insufficient fluid level reduces hydraulic forces. The cause may also be wear of the clutch discs, wear of the cuffs or o-rings. Replacement and topping up help solve the problem.

3. When changing speeds, the clutch slips. This may be a problem with the main pressure being insufficient. Or the filter is clogged.

4. The car slips, and the oil foams and turns light brown. There is low pressure in the line. This phenomenon occurs when water enters the box, which forms a foamy emulsion. The reasons, in addition to the low level of the “transmission”, may be contamination of the valve body, or a stuck pressure relief valve in the oil pump.

Kickdown mode

If you sharply press the gas pedal to the floor on a car with automatic transmission, the KICKDOWN mode is activated. On an automatic, this mode serves for sharp acceleration, which is very convenient when overtaking or ahead of other vehicles.

In KICK DOWN mode, the transmission will only shift when the engine speed reaches maximum.

If you need to turn off automatic acceleration, simply take your foot off the gas pedal or ease the pressure on it.

It broke out in the apartment and won’t turn on, what should I do?

If the light in the house goes out or the sockets stop working, you need to go to the distribution panel and check the circuit breakers. Usually it is enough to simply turn on the machine by lifting the handle up.

If the electrical network is overloaded with powerful devices, they should be correctly distributed among other outlet groups. If there are many additional lamps installed in the house, it is recommended to install a separate machine for them.

It is necessary to check the quality of the contact all the way from the input to the machine to the lamps and sockets. Weak contacts need to be tightened.

Why is it not removed from parking in automatic transmission?

The first thing you need to check is whether the brake lights (brake lights) are on at the rear. If they do not light, then you need to check the STOP fuse. The fuse is the most common cause of equipment failure, so you need to check from it, and this is the easiest repair. The STOP fuse is located in the fuse box in the passenger compartment or under the hood.

If the fuse is serviceable and there are no burnouts, then you should next check the brake light switch. The contacts often oxidize and cause a circuit break, which is why the brake lights do not light up.

If the brake light switch is fully operational, then next you need to check the automatic transmission control cable. It happens that the labels get lost and need to be adjusted again.

If the cable is in good condition, then check the selector switch sensor (lever). If there are problems, it must be replaced.

If the sensor is normal, then we check the automatic transmission itself. Automatic transmission diagnostics are checked with a special scanner, when connected, an error code will appear on the screen of the connected laptop or phone, which must be deciphered.

The test of an automatic transmission before 1998 with an OBD-1 or OBD-2 scanner is carried out in the following order:

- Warm up the engine and drive at a speed above 20 km/h.

- Stay. Turn off the engine. Leave the ignition key in the lock.

- Turn on the ignition, but do not engage the starter.

- Turn off the ignition.

- Place the selector in position D using the emergency button. Also enable hold. In this case, Power does not need to be touched.

- Turn on the ignition.

- Set the selector to position 3 and turn off hold.

- We put the selector in position 2 and turn on hold.

- We set the selector to position 1 and turn off hold.

- Press the gas pedal 2/3, that is, more than half. Wait 4 seconds.

- We watch the Power indicator. If you blink slowly, you need to read the errors. If Power blinks frequently, then there are no errors.

Automatic transmission text with a year of manufacture after 1998:

- Turn on the ignition.

- Turn off the ignition.

- Turn on the ignition.

- Place the gearshift knob in position 1.

- Turn off the ignition.

- Turn on the ignition.

- Handle to position 2.

- Handle to position 1.

- Handle to position 2.

- Handle to position 3.

- Handle to position D.

Let's look at the indicators.

Here are examples of errors:

11 open, short circuit or stuck solenoid valve a 12 open, short circuit or stuck solenoid valve b 13 open, short circuit or stuck solenoid valve 3 14 open, short circuit or stuck solenoid valve 2 15 open, short circuit in the circuit or jamming of the switching solenoid valve 1 21 open, short circuit in the atf temperature sensor circuit 22 open, short circuit in the air mass meter circuit 23 open, short circuit in the engine speed sensor circuit 24 open, short circuit in the circuit or jamming of the solenoid valve c 25 open, short circuit in the torque control signal circuit 31 open, short circuit in the throttle position sensor circuit 32 open, short circuit in the vehicle speed sensor 1 circuit 33 open, short circuit in the vehicle speed sensor 2 circuit

….

75 Automatic transmission Incorrect shift sequence. Automatic transmission diagnostics required. 79 Automatic transmission Overheating of the automatic transmission, automatic transmission diagnostics are required. 81 Automatic transmission Incorrect voltage in the 2-3 shift solenoid circuit; Automatic transmission diagnostics are required. 82 Automatic transmission Incorrect voltage in the 1-2 shift solenoid circuit; Automatic transmission diagnostics are required. 83 Automatic transmission TCC solenoid circuit - high voltage on the solenoid when activated; Automatic transmission diagnostics are required. 84 Automatic transmission Incorrect voltage in the 3-2 shift solenoid circuit; Automatic transmission diagnostics are required. 85 Automatic transmission TCC solenoid jammed - automatic transmission diagnostics required. 90 Automatic transmission Incorrect voltage in the TCC solenoid circuit; Automatic transmission diagnostics are required.

Gears are difficult to engage with the engine running: possible reasons

At the very beginning, it should be noted that the inability to engage a gear with the engine not running may indicate a serious gearbox malfunction, which consists of failure of the synchronizers. The second reason may be wear or breakage of the gears. It is also possible that the components and mechanisms responsible for transmitting force from the lever in the cabin to the gearbox when selecting a gear may become jammed.

To accurately determine the causes, in the first case it will be necessary to remove the box for disassembly and subsequent troubleshooting; in the second case, it is necessary to identify and replace broken components. In some cases, it is enough to carry out their prevention: removal, lubrication and careful adjustment.

As for problematic switching when the internal combustion engine is running, then the list of the most common faults includes:

- lack of gear oil in the gearbox;

- problems with the clutch mechanism;

What not to do with automatic transmission

The design and operating principle of the automatic transmission assumes the following types of prohibited actions:

- The car should always be warmed up before driving. When operating a cold automatic transmission, the service life decreases, especially in severe frost, when the transmission oil thickens. To choose the right transmission oil, an oil rating of 75w90 was compiled. You can move the selector to different positions with the brake pedal pressed. If you need to drive urgently, then the gentle operating mode of the automatic transmission in this case will be a smooth start and movement without jerking.

- An automatic transmission is a “soft” technical device that does not like the crazy loads and jerks that drift enthusiasts make. When off-road, switch to low mode L.

- If a car with an automatic transmission does not start, then you should not try to start it by towing. You can tow, but at a speed of no more than 40 km/h and at a distance of no more than 30 km. This is because the oil pump only works when the engine is running. And when towing, rotation is transmitted from the wheels and then through the gearbox, so without oil supply, wear will be faster. It is better to use a tow truck if possible.

- If the car has all-wheel drive and an automatic transmission, then in the event of a breakdown such a vehicle can only be transported by a tow truck or, if towed, then with the driveshaft removed.

Why does the machine keep knocking out?

Main reasons for triggering:

- network congestion;

- failure of a device included in the circuit;

- breakdown of the lighting fixture;

- switch malfunction;

- short circuit.

Overload is a condition when the power of the connected devices exceeds the rated power for which the switch is designed.

To avoid such a case, you need to carefully select the socket group to which powerful household units will be connected.

Connecting a broken electrical appliance can also cause a blackout. When the machine breaks down due to the lamp being turned on, the problem should be looked for in the lamp base, the quality of the contact or the transformer of the LED chandelier. In most cases, the shutdown is due to a short circuit.

The machine on the meter is triggered and turns off without unnecessary load

Short circuit (SC) is one of the main causes of knockout. If there is a sudden power outage, there is no need to immediately try to connect the circuit breaker. First you need to check the conductors, the stability of the socket contacts, and the absence of a short circuit in the socket (for lamps). Then you should check the wiring with a tester, and the faulty section should be replaced by an electrician. After checking these factors, you can turn on the machine.

When replacement is needed

If the connected total load is within normal limits, and the short circuit was not detected by the tester, the cause of the breakdown may be a malfunction of the machine or poor contact.

If the switch periodically trips, it is recommended to replace it with a device of similar rating.

Tightening contacts can also help.

Using a handbrake with an automatic transmission

Both cars with manual transmission and cars with automatic transmission must be equipped with a hand brake. Mechanical ones often break down and drivers don’t bother to repair the handbrake by adjusting or replacing the cable. But, if it is an automatic transmission and not a manual transmission, then in case of a breakdown the handbrake must be repaired.

In the operating instructions for a car with an automatic transmission, it is recommended that after stopping the car, set the selector to position P (parking) immediately before or after applying the handbrake. But many drivers do not use the handbrake, they only leave it in parking. But, it is better to install a handbrake, especially on a slope. Extra security doesn't hurt.

When the engine is running and the selector lever is in neutral, it will not be possible to shift the lever into parking, since the handbrake is not applied. This is good security for a forgetful or careless driver.

Reasons for knocking out a machine gun

There are 5 main reasons why the machine in the apartment breaks down and does not turn on:

- There is a short circuit in the electrical wiring.

- Overload of the electrical line.

- Malfunction of lighting fixtures or one of them.

- Circuit breaker failure.

- Incorrect operation of one of the electrical appliances.

Machine defect

The likelihood that a defective device was purchased and installed is negligible, especially if preference was given to branded models. The only effective way to check the functionality of the machine is to install a new one in its place. If the new device also crashes, the reason lies in something completely different.

Like other electrical devices, a circuit breaker has its own service life. Wear of components leads to decreased performance and deterioration of technical characteristics.

Faulty household appliances

The reason for knocking out the machine can also be household appliances. You can verify this in the following ways:

- Remove all connected household appliances from sockets.

- If the machine is not knocked out, you need to gradually connect one electrical device at a time.

- As soon as the machine turns off, it will be clear which device is faulty.

If some household appliances are directly connected, for example, dishwashers or air conditioners, they can only be de-energized at the distribution panel.

Incorrect operation of lighting fixtures

There are situations when the machine is knocked out when the lighting device is turned on. This indicates a malfunction of the chandelier.

- Short circuit in the lamp base. Unscrew all the bulbs and connect them one by one.

- Poor contact between the wiring inside the chandelier and the supply conductor.

Troubleshooting methods

Once the source of the problem has been found, you can begin to eliminate the causes of the malfunction.

If the problem is in the engine

The simplest cause of problems when shifting gears can be a leak of brake fluid, which is the working fluid for the clutch. If there is insufficient lubrication in the clutch hydraulic system, it will not engage fully. Therefore, first check the fluid level in the car's tank. If the level is low, check for leaks, repair defects and bleed the clutch. When the fluid level is at the normal level, the clutch elements should be inspected.

Clutch problems

The clutch consists of three main components:

- disk;

- release bearing;

- baskets (pressure disk).

Will manual mode kill automatic transmission?

Now many new car enthusiasts are deciding for themselves which car to choose. Perhaps the most important criterion is the choice of transmission - automatic or manual, and as sales statistics tell us, automatic transmissions are growing exponentially.

It is understandable that it is very convenient in the city. However, on many automatic transmissions, there is a so-called “manual mode” when you physically change gears, usually this is a plus and minus on the lever (made with a button like mine) or shifting the gearbox lever.

Long drive on the highway

Let's imagine a situation where you are planning to travel very far and for a very long time, for example, to a resort. It is clear that this trip will not be complete without a car. What could be important for an avid motorist who loves a measured way of driving?

Of course, savings. There are other types of motorists for whom the most important thing is speed and time, but here we will talk about the former. It is in such a situation that the manual mode of an automatic transmission can become useful.

Since many routes, and especially resort ones, have an abundance of various descents and ascents, and an automatic transmission will drop one or two steps when driving uphill. This leads to the engine spinning up to high speeds, and consequently to uneconomical driving.

However, we must not forget that in this case you need to drive quite quickly. Many automatic transmissions can limit gear shifting at low speeds, for example, when driving at a speed of 80 km/h it will not be possible to engage sixth gear.

But if you increase the speed, say, to 100 km/h, then this switching is already possible. Of course, you won’t save much; it’s not 2-3 liters per hundred kilometers. However, 6-7 liters at a thousand kilometers can be obtained by competently using the manual mode.

Automatic transmission malfunctions: signs, symptoms, causes

Most foreign cars sold in Russia are equipped with automatic transmission. Cars with automatic transmission are much more convenient and comfortable for driving around the city. Automatic transmissions usually have an impressive service life and, with timely maintenance, last a very long time. Troubles often happen due to the fault of owners who do not understand the intricacies of operating and maintaining automatic transmissions.

Automatic transmission repair

Main problems with automatic transmission:

This can happen for three reasons: there is not enough oil to operate the box, the mechanisms of one of the transmissions have failed, or the control unit is broken. To fix it, you need to diagnose it and make the necessary repairs. If the problem is with the fluid level, you need to top it up, the machine will start working normally.

Things could be worse - the torque converter could also fail.

The torque converter is worn out and its shaft is slipping, or the forward clutch clutches are worn out. To eliminate the unpleasant situation, you will need to open and diagnose the box.

These are engine faults, not gearbox faults, but a visit to the service station is also required.

Worn automatic transmission gear

Any incomprehensible behavior of the box should never be ignored! The reason may not be serious, but driving a car with a faulty automatic transmission is dangerous and can cost the owner dearly.

Next, let's take a closer look at the main problems with automatic transmissions in popular cars.

Ford Focus. Automatic transmission 4f27e

Installed on Ford Focus and Mazda 3. Not a very reliable box. The 4f27e has weak points: belt, automatic transmission cover, brake drum, clutch basket, solenoid. Unlike simple and reliable mechanics, the Ford Focus uses a less reliable 4f27e planetary automatic transmission.

Let's consider a specific case. Symptoms On a 2008 Ford Focus, first the 4th gear disappeared, then the 3rd too. After reaching first gear and engaging second, the 4f27e goes into neutral and the Ford Focus stops.

Automatic transmission 4f27e installed on Ford Focus

What is the possible reason for this behavior of the 4f27e box? Often the 4f27e is equipped with a low-quality solenoid, which can fail and jam. Their defect on 4f27e boxes is determined by the diagnostic system. In this case, the solenoid on the Ford Focus box is replaced.

In early versions of the 4f27e, there is a specific defect in the automatic transmission cover, due to which the pressure in the Ford Focus transmission is greatly lost.

In this case, it is necessary to open the box (this is possible without removing it) and change the cover.

If the box worked in emergency mode for some time, this could lead to failure of its individual mechanisms, which will require replacement. Which is what was done in this case.

If any of the gears fails, this indicates a breakdown of the friction disc, and the color of the oil on the 4f27e changes. This happens at 100,000 km for a Ford Focus.

The absence of reverse gear or its activation with a delay, as well as a change in the color of the oil, indicates wear of the reverse gear friction disc. Ford Focus from 4f27e 2008 sometimes has a factory defect, which leads to wear of the damper spring and failure of the clutch and the need to replace it.

Noise at speed, jerks and shocks when shifting gears, as well as vibration when driving indicate the cause of gear wear, malfunction of the torque converter (donut) or lack of oil. After detecting such faults, the Ford Focus should be taken in for diagnostics.

Below is a video that shows in some detail how a Ford Focus automatic transmission is disassembled if it needs to be disassembled to fix a malfunction.

Mitsubishi Pajero Sport

The Pajero Sport and Delica models are equipped with gearboxes manufactured by Toyota.

Peculiarities. On Pajero, the oil level in the automatic transmission is measured only in the neutral position. In position P, the fluid level will appear to be higher.

The oil filter on the Pajero Sport automatic transmission is disposable; they always need to be changed, even with a partial oil change. The weak resource of the lockup (when it is activated, the fluid coupling is blocked) in the Pajero Sport leads to the destruction of the mechanism and its clogging with automatic transmission parts.

It is noteworthy that these automatic transmissions are more demanding in terms of oil selection than the same ones found on Toyotas.

Mitsubishi Pajero Sport with automatic transmission

Automatic transmission malfunctions on Pajero Sport:

- Slipping;

- Automatic transmission emergency mode;

- Vibration;

Jerks and delays when switching.

Volkswagen Passat B5

They are equipped with ZF series transmissions and have their traditional problems. Recently, confidence in German quality has dropped somewhat. Overall, the Volkswagen Passat is a fairly reliable car if you take care of it. Repairing a Passat model will cost less than, for example, an Audi.

Volkswagen Passat B5 with automatic transmission

Audi A6

Audi A6 cars are equipped with automatic transmissions ZF 5HP19, TF-60ZN, ZF HP24. Problems usually arise if the car owner does not control the level and condition of the oil. A deficiency of oil can occur on the sliding sleeve of the torque converter, after which this can lead to overheating of the box and burning of the clutches.

Audi develops its own automatic transmissions independently, including for the A6; they are not standard, are not always well designed and can fail after only 50,000 km.

The automatic transmission of the Audi A6 must be equipped with underbody protection, since slight damage to the automatic transmission cover by a stone or a bump on the road, and this can lead to the displacement of the oil filter on the Audi A6, which will lead to an emergency mode on the automatic transmission. In addition, damage to the automatic transmission pan on an Audi A6 can lead to squeezing of the solenoid wire, which may appear intact upon visual inspection. Common automatic transmission faults in the Audi A6 are similar to other cars.

Audi A6 equipped with automatic transmission

ZF HP24 is installed on the Audi A6 with the most powerful engines; they are more reliable and have a long service life. For such Audi A6, the main problem with automatic transmission may be natural wear of the bearing on the turbine shaft, failure of the clutches and torque converter. Signs of this phenomenon are common for incorrect operation of the gearbox in an Audi A6; diagnostics and repairs will be required.

Peugeot 307. Automatic transmission AL4

Produced since 1999, installed on the Peugeot 307. AL4 has a low cost, but due to the unreliability of the mechanisms it is called “long-suffering”. Nevertheless, the AL4 is quite reliable for its price category and, most importantly, repairable. The initial generation of 307 model boxes often failed, people were unhappy.

At first, since the start of production of the AL4, Peugeot was inundated with lawsuits. After some time, specialists developed their own methods to eliminate problems with Peugeot 307 automatic transmissions - they installed more reliable spare parts on them, which led to stable operation of the AL4 gearbox after repair.

Over time, Peugeot modified the box for the 307 model and solved most of the problems.

Automatic transmission AL4 from Peugeot 307

Typical malfunctions of the AL4 automatic transmission on the 307 model:

AL4 on a Peugeot 307 is one of the few gearboxes that would be best sent to a service center for major repairs; their contract versions can also have a lot of faults.

Hyundai Tussan

Hyundai Tussan cars with automatic transmission are prone to problems with the differential.

The drive gear on a Hyundai Tucson may lose several teeth and their impact can break the differential ring, which will lead to shocks for each wheel revolution and jamming of the front wheels while driving.

After this, there will be a lot of metal fragments in the Hyundai Tussan box that can destroy the automatic transmission mechanisms. Methods for repairing such a breakdown can be different: with or without removal, they depend on the qualifications of the service workers.

Removing scratches on a car body without painting.

DON'T WASTE MONEY ON REPAINTING! Now you can remove any scratch from the body of your car in just 5 seconds.

Read more >>

Hyundai Tussan with automatic transmission

Land Rover Discovery

It is equipped with automatic transmission series ZF, TF, JF. The main problem with a Discovery automatic transmission can be natural wear and tear of the housing or damage to it. Automatic transmission repair on Discovery is not cheap; a transmission from a German manufacturer usually lasts 80,000–100,000 km.

The automatic transmission on Discovery is adaptive and adapts to the driving style of the car owner. If the driver drives the Discovery in an aggressive manner, the transmission does not have time to work out and goes into error.

In order to diagnose the automatic transmission in Discovery, you must first reset the errors; perhaps the reason is in the driver, and not in the mechanical part. The oil on Discovery needs to be changed every 48,000 km.

Automatic transmissions on Discovery are installed of a new generation, 6-speed, the electronic unit is located on top of the box, which reduces its dimensions. However, this arrangement can cause the electronic unit to overheat on Discovery and, ultimately, simply burn out. Also, the solenoid valves on Discovery are not the most reliable.

Land Rover Discovery with automatic transmission

Honda SRV

The following automatic transmission models are installed on these cars: M4TA, MDMA, S4XA, SKWA.

The main malfunctions of the Honda SRV are similar to automatic transmissions from other manufacturers. Honda, unlike other car manufacturers, often went its own way, coming up with its own ways of producing cars. Sometimes this led to good results, sometimes not.

From the late 90s to the beginning of 2000, Honda produced its own automatic transmissions, not entrusting this work to companies specializing in this field. Often Honda automatic transmissions were less reliable than competitors, such as Toyota, for example.

Honda recommends pouring special oil into its boxes, which differs in its characteristics. This car has special automatic transmission faults compared to other manufacturers. However, Honda shows decent results in terms of the reliability of its cars.

In the homeland of truly high-quality cars, in America, Honda has been appreciated since the early 90s.

Automatic M4TA from Honda SRV

Toyota

Toyota cars are equipped with very reliable transmissions. In Russia you can easily find a Toyota car from the 1980s and 1990s that still has a factory transmission.

Some modern luxury cars from Toyota and Lexus are equipped with automatic transmissions, which do not require an oil change procedure.

Many owners of Toyota cars drive such cars without changing the oil, significantly exceeding the declared service life.

Toyota Camry with automatic transmission

To eliminate any troubles with automatic transmissions, it is better to contact specialized service stations. Driving with faulty gearboxes very soon leads to their failure, which can result in significant financial losses.

Timely diagnosis and repair will help avoid such troubles.

Below is a video that clearly shows how to repair a Toyota automatic transmission; after watching it, many car owners will find it easier to maintain the performance of their car.