Internal combustion engine. From the name it is clear that its work is associated with high temperatures. And in any heating-related process, control over the temperature level is necessary. It is unacceptable for it to change below or above the required norm in order to ensure uninterrupted operation of the system, as well as to avoid breakdowns that could be caused by temperature failure.

In Lada cars, as in any other, the engine temperature is helped to regulate the coolant, which not only cools or heats the engine, but also protects the system from corrosion and blockages.

The condition of the coolant is monitored by a small but very important device - the coolant temperature sensor.

On the VAZ 2110, the coolant detector is installed on the thermostat housing, which allows the sensitive element to be in direct contact with the measurement medium. This device has a negative temperature coefficient, which means that as the heating of the liquid increases, the resistance of the detector decreases.

It is worth noting that the VAZ 2110 temperature sensors are installed in one place, which does not change depending on the type of engine or its features. Whether it is a model 2112 16 valves or 8 valves, a VAZ 2110 injector or a carburetor, the temperature detector will be in the cylinder head, checking the temperature level of the coolant passing through it and sending data, thanks to which the ECU turns the fan on or off.

The temperature sensor sends the collected information to the electronic control unit (in other words, to the dashboard), which, after analyzing the data received, adjusts the level of fuel enrichment, as well as the operation of the cooling system.

A malfunction of the DTOZ can lead to engine overheating due to the fact that the temperature indicator data may not coincide with the actual engine heating data. If the transmitted indicators are higher than the actual ones, the system will constantly run the fan, which is not very good for the operation of the car. And if it’s lower, then it’s even worse - the engine will overheat and boil, which can lead to its breakdown.

Some signs of a broken coolant temperature sensor:

- difficulty starting the engine in any weather (which can just as easily be considered a sign of leaking fuel injectors);

- uncharacteristic color of exhaust gases;

- malfunctions at idle speed;

- a sharp increase in fuel consumption.

Engine operating temperature on the VAZ-2110 - is there a difference?

Despite the fact that 8 and 16-valve VAZ engines have a slight difference in the design of the cooling system, the operating temperature for both engines is the same. Engine operating temperature on the instrument panel.

The factory provides a normal engine operating temperature ranging from 87 to 103 degrees . Maintaining the temperature within these limits can be greatly influenced by certain issues related to the performance and quality of the cooling system elements.

Let's look at each of them briefly.

Engine tuning VAZ 2112 1.5 16V

Chip tuning of VAZ 2112 engine

The first thing that comes to the mind of a novice tuner is engine firmware; all companies promise that your engine will at least fly... all this is heresy. Firmwares give the most minimal effect, which is very difficult to feel; you have to think about chip tuning when the engine is with a turbine; aspirated engines are a waste of money. Since it is correct to boost the VAZ 2112 engine, with minimal loss of life and with a maximum increase in horses. The simplest and fairly standard way to increase the power of a VAZ 2112 engine is to replace the camshafts with STI-1 (for a standard receiver), STI-3.1, STI-2 or Stolnikov 8.9 (more expensive than others), to make life easier for the engine, we install a light ShPG from 126 engine, throttle body 54-56 mm, mounted receiver and exhaust 4-2-1. At the output we have about 120 hp. Refinement of the cylinder head and evil wide-phase shafts can increase power to 130-140 or more hp. To this it is worth adding a crankshaft with a stroke of 75.6 to increase the engine capacity of the VAZ 2112 to 1.6 liters, lightweight T-shaped valves, modification of the cylinder head and intake manifold, at the output we get about 140-150 hp. For the city, these indicators are enough for almost any car enthusiast.

Installing a compressor on a VAZ 2112

An alternative method of modifying the 2112 engine and obtaining similar power is to install a compressor. The well-known video clearly explains everything that is required for the successful implementation of the project using an eight-valve engine as an example; this compressor can also be installed on a 16-valve engine, the engine output will be more than 130 hp. You can use other compressors, but blowing more than 0.5 bar into a standard engine without reducing the compression ratio is risky.

Attention MAT (18+)

Throttle for VAZ 2112

To increase the stability of the engine and the response of the gas pedal, install 4 throttles. The bottom line is that each cylinder receives its own throttle valve and, thanks to this, resonant air vibrations between the cylinders disappear. We have more stable engine operation from bottom to top, plus this intake is shorter and air gets into the cylinders as quickly as possible. The most popular method is to install a 4-throttle intake from Toyota Levin on a VAZ. You need to purchase: the unit itself, make an adapter manifold and pipes, in addition to this you need a nulevik filter, injectors, MAP (absolute pressure sensor), fuel pressure regulator and firmware. There are also ready-made 4-throttle intake kits on sale that are quite suitable for use. It is recommended to install a light piston engine (from Priora, for example), because turning a heavy piston is an additional waste of energy, wide-phase shafts, for example STI-6 or STI-7 Touring Light, a modified cylinder head with light valves and solid pushers, Opel C20XE springs, spider exhaust 4-1 or 4-2-1 at 51, and better than a 63 pipe. With the correct configuration, the 2112 engine produces about 180-200 hp. To completely launch the car into space, at a volume of 1.5 liters, we install STI Sport-8 shafts. There is no point in writing a motor configuration for such shafts; very few people decide to assemble such a thing. The disadvantages include a reduction in engine life and this is not surprising, because the engines on the pipes spin at 8000-9000 or more rpm. So you cannot avoid constant breakdowns and frequent repairs of the 2112 engine.

Cooling radiator

Boiling of the coolant can be caused by a clogged cooling radiator, and it can become clogged both inside and outside. Clogged honeycombs of the engine cooling radiator.

Cleaning the radiator regularly will ensure normal engine operation and will help prevent antifreeze from boiling. When checking the condition of the radiator, we pay special attention to the presence of leaks and the integrity of the honeycombs, the absence of cracks in the tanks and the condition of the pipes.

water pump

The water pump is responsible for the complete circulation of coolant through the cooling and heating system. Antifreeze leaking from under the pump.

Maintaining the normal operating temperature of the antifreeze also depends on the efficiency of the pump. The main pump malfunctions include bearing failure, leakage and destruction of the pump impeller. This can occur as a result of both physical damage to the impeller and destruction as a result of cavitation processes. Cavitation is most often caused by the use of low-quality antifreeze or untimely replacement.

Causes of overheating

All possible causes of overheating of the power unit of a VAZ 2109 car, as well as other cars, can be divided into two categories:

- External reasons;

- Internal reasons.

As you know, domestic nines are equipped with injectors and carburetors. Therefore, we will get acquainted with all the likely situations that can lead to overheating of one or another type of engine.

External

Let's start with the external reasons for the increase in engine temperature.

Causes

Features of the situation

Low coolant level

Quite often the engine overheats due to a low level of coolant in the expansion tank. It is not always possible to immediately detect a leak in the system. Antifreeze requires a very small hole in order for it to completely drain out of the tank over several tens of kilometers. The most dangerous leak is coolant entering the combustion chamber or oil, which leads to water hammer

If your engine begins to overheat, pay attention to the condition of the thermostat. This unit controls the movement of coolant along a large or small circuit. If the thermostat breaks down, the coolant stops moving in a large or small circle. In the first case, the engine will have difficulty warming up to operating temperature in winter, and in the second, the engine will constantly overheat

Radiator clogged, ineffective cooling

If almost the main component of the cooling system, that is, the radiator, becomes dirty, overheating will not be avoided. If there is dirt on the radiator fins or its “honeycombs,” heat transfer is significantly reduced. Plus, pay attention to the performance of the fan. It may not work due to belt tension, a broken temperature sensor, or a failed fan motor.

Long-term operation in unacceptable conditions

Often the cause of increased engine temperature is the driver himself, who overestimates the capabilities of his car and operates it in conditions that are contraindicated for it. These include prolonged idling, improper slipping, increased speed - all these situations negatively affect the condition of the engine, since the cooling system does not have time to perform its functions.

Engine operation under detonation conditions

If the driver ignores the appearance of detonation in the cylinders, the engine cooling system will not be able to cope with the load. Add to this the hot weather, and then you won’t envy the engine

Exhaust valve burnout

If the exhaust valve fails, the gases heated to an impressive temperature will overheat the engine. The situation can only be corrected by repairing the power unit

Water pump problems

If the water pump fails or stops working properly, coolant will not be able to circulate through the system. Pump failure may be due to tension in the drive belt, defective pump blades, or breakdown of the pump itself.

Thermostat

Internal reasons

There are several reasons that contribute to internal engine overheating.

Causes

Peculiarities

Accumulation of deposits inside the combustion chamber

This is a typical problem for old VAZ 2109 carburetor and injection engines, which have driven more than 200-300 thousand kilometers. Excess oil forms in the combustion chamber. Oil burns poorly, causing plaque to accumulate on the walls. This leads to overheating, which the temperature sensor cannot report. The malfunction can be determined by the bluish smoke protruding from the exhaust pipe. Or the impaired performance of the motor will indicate this

Thermostat

Most of the complaints are made specifically to the thermostat, the bypass valve, which directs the coolant in a full or small circle, depending on the degree of heating. Thermostat location under the hood.

For example, the engine may not warm up to the legal 87–90 degrees due to a stuck valve. However, most often thermostat malfunctions occur due to the quality of the thermoelement . Despite the fact that each thermostat is marked on the body, which indicates the valve response temperature, the indicated temperature does not always correspond to reality.

So, at the specified operating temperature of 85 degrees, the thermostat can pass liquid in a large circle already when warming up to 75–80 degrees . As a result, the temperature will not correspond to the norm, the engine will not be able to warm up to the optimal value. The only solution is to test the thermostat before installation. To do this, the thermostat body is placed in a vessel with water and heated to the specified temperature, periodically checking the condition of the valve. A discrepancy between the thermostat response temperature, even by 3–5 degrees, will not allow you to obtain the optimal operating temperature while driving.

Characteristics of motors 2114

Since the release of the Lada Samara VAZ-2114, the technical characteristics of the gasoline drive have been constantly improved. Owners of domestic cars, in principle, do not have questions about what kind of oil to pour into the engine, since standard requirements apply for Zhiguli, Lada and Samara - 5W30 or 10W30.

Oil change 2114 with engine flush

In addition, you should know what kind of oil to use in transmission gears - the instructions from the AvtoVAZ manufacturer recommend using the GL-4 group of lubricants with a viscosity of 80W85 (mineral), 75W90T (synthetic) or 85W90 (semi-synthetic).

After filling with synthetics, the box becomes noisy, the oil is more expensive, but the lubricant is mostly imported, which provides additional guarantees. Domestic manufacturers most often produce semi-synthetics of average quality for engines and transmission gearboxes.

The technical characteristics of the engine are as follows:

| Characteristics | Engine modification | ||||||||

| 2111 | 21114 | 11183 | 21124 | 21126 | |||||

| Years of installation | 2003 – 2007 | 2003 – 2007 | 2007 – 2009 | 2009 – 2013 | 2009 – 2013 | ||||

| Volume | 1500 cm3(1.5 l) | 1596 cm3 (1.6 l) | 1596 cm3 (1.6 l) | 1599 cm3 (1.6 l) | 1597 cm3 (1.6 l) | ||||

| Power | 56.4 kW (77 hp) | 59.5 kW (81.6 hp) | 59.5 kW (82 hp) | 65.5 kW (89.1 hp) | 72 kW (97.9 hp) | ||||

| Torque moment | 115.7 Nm (3200 rpm) | 125 Nm (3000 rpm) | 120 Nm (3200 rpm) | 131 Nm (3700 rpm) | 145 Nm (4000 rpm) | ||||

| Weight | 127.3 kg | 112 kg | 112 kg | 121 kg | 115 kg | ||||

| Compression ratio | 9,8 | 9,6 | 9,6 | 10,3 | 11 | ||||

| Nutrition | injector | ||||||||

| Engine diagram | Inline (L) | ||||||||

| Ignition | module | coil | coil | coil for each spark plug | |||||

| Number of cylinders | 4 | ||||||||

| Location of the first cylinder | TVE | ||||||||

| Number of valves on each cylinder | 2 | 2 | 2 | 4 | 4 | ||||

| Cylinder head material | aluminum alloy | ||||||||

| Intake manifold | aluminum | plastic with receiver | |||||||

| An exhaust manifold | with catalyst | ||||||||

| Camshaft | 2110 | 2111 | 2112 | ||||||

| Cylinder diameter | 82 mm | ||||||||

| Piston stroke | 71 mm | 75.6 mm | |||||||

| Pistons | Yes | No | No | Yes | No | ||||

| Valve bend | Yes | No | No | Yes | No | ||||

| Crankshaft | 2112 | 11183 | |||||||

| Fuel | AI-95 | ||||||||

| Environmental standards | Euro 4 | Euro 2 – 4 | Euro 3 – 4 | ||||||

| Fuel consumption highway/combined cycle/city | 5,7/7,3/10 | 6/7,3/10,4 | 6/7,8/11 | 5/7/9,5 | 5,4/7,2/9,8 | ||||

| Oil consumption 1000 km | 0,7 | 0,5 | |||||||

| Engine oil for 2114 | 5W-30 and 10W-30 | ||||||||

| Engine oil volume | 4 l | 3.8 l | 3.5 l | 3.6 l | |||||

| Operating temperature | 95° | ||||||||

| Motor life | declared 150,000 km, real 250,000 km | ||||||||

| Adjustment of valves | washers between camshaft cams and tappets | hydraulic pushers | |||||||

| Cooling system | forced, antifreeze/antifreeze | ||||||||

| Coolant quantity | 7.8 l | ||||||||

| water pump | plastic impeller | ||||||||

| Candles for 2114 | A17DVRM, BPR6ES | AU17DVRM, BCPR6ES | |||||||

| Gap between spark plug electrodes | 1.1 mm | ||||||||

| Timing belt | length 698 – 1125 mm depending on attachments | ||||||||

| Cylinder operating order | 1-3-4-2 | ||||||||

| Air filter | Nitto, Knecht, Fram, WIX, Hengst | ||||||||

| Oil filter | Mann W914/2 | ||||||||

| Flywheel | 2110 | ||||||||

| Flywheel mounting bolts | M10x1.25 mm, length 26 mm | ||||||||

| Valve stem seals | code 90913-02090 inlet light code 90913-02088 exhaust dark | ||||||||

| Compression | from 14 bar | ||||||||

| XX speed | 750 – 800 | 800 – 850 | |||||||

| Tightening force of threaded connections | spark plug – 31 – 39 Nm flywheel – 61 – 87 Nm clutch bolt – 54 – 87 Nm bearing cap – 59 Nm (main) and 43 – 53 Nm (rod) cylinder head – four stages 20 Nm, 71 Nm + 90° + 90° | ||||||||

For high-quality maintenance of internal combustion engines, the engine manufacturer issues a manual containing a description of the drive parameters, the frequency of replacing consumables and step-by-step repair operations. The same operating manual recommends the volume of oil in the gearboxes in the engine.

Broken timing belt

Sensors, ECU firmware and fan

The accuracy of the coolant temperature sensor also greatly affects operating temperature. The temperature sensor is located near the thermostat housing.

The sensor sends an electrical impulse to the electronic control unit, which in turn gives a command to start the cooling fan. The normal temperature at which the fan should start is 105 degrees . If the sensor readings are incorrect, the fan will start earlier (in this case, the antifreeze will not warm up to normal) or later. Then the engine may overheat and the antifreeze may boil, especially antifreeze of poor quality.

Temperature sensor VAZ 2114

This car model has two sensors, both in the cylinder head and in the thermostat. They work with the temperature of the fluid leaving the radiator and the engine. Apart from this difference, other nuances remain identical to those described above.

Also, the features that distinguish the temperature sensor on the VAZ 2114 apply to models 2113 and 2115.

We recommend to buy

Airlock

In addition, an air lock in the cooling system can greatly interfere with the circulation of coolant.

A plug may occur after the liquid boils, as well as due to improper replacement of antifreeze or depressurization of the system. As a rule, air is removed from the cooling system through the throttle body pipe, as the highest point of the closed cooling system. After removing the plug, the engine will warm up to the nominal temperature and will not overheat .

Air is removed through the throttle body pipe after the engine has warmed up to operating temperature.

conclusions

At the first symptoms of engine overheating, it is better to check the functionality of the temperature sensor and thermostat as soon as possible. But the moment the fan turns on can also be influenced by the ECU firmware and the set threshold on the on-board computer.

Monitor the cooling system regularly and ensure that all operating temperatures are stable!

Many motorists, when operating the 16-valve VAZ-2112 engine, encountered the fact that the engine simply boiled. This is due to the engine overheating. What is the operating (normal) engine temperature? In this article, we will consider what temperature should be in the power unit and its systems, as well as the reasons and methods for solving an increase in this indicator.

Briefly about the models

What is better: VAZ 2112 or VAZ 2114? Descriptive characteristics in the form of a comparison of two models. VAZ-2112: The car is completely reminiscent of the sedan version of the well-known 10. The model has a 16-valve power unit with a volume of 1.5 - 1.6 liters and a power of 92 l/s. A serious drawback is the difficulty of replacing the timing belt, since the valves and the upper part of the piston mechanism may come into contact. VAZ-2114: The modernized model 2109 was released back in 2003 and lasted until 2013. The successor was the Lada Granta sedan. The “Achilles heel” is the weak tie rod ends, which do not last more than 10,000 km. mileage

What should the engine operating temperature be?

Engine operating temperature shown on the instrument panel

If we take the information from the international convention of automobile manufacturers dated December 1, 1992, then the uniform standard for engine operating temperature is considered to be 90 degrees Celsius. With such indicators, the engine operates as efficiently as possible and does not create residual negative effects.

When switching to more advanced engine manufacturing technologies in 2004, it was accepted that a specific indicator of this indicator cannot be held in one position, and therefore they made a gradation of acceptable standards, which amounted to 85-105 degrees Celsius.

Engine overheating shown on the instrument panel

According to data from the manufacturer AvtoVAZ, on a 16-valve VAZ-2112 engine, the operating temperature of the engine is considered to be 87-103 degrees Celsius. At this temperature, all systems function normally, and the motor is not subject to negative factors and consequences.

Dismantling the cylinder head

About the design and operation of the car What is better than Lada Priora or 2112. What is better than VAZ2112 or Priora. Calculations and miscalculations

You will also need to remove the timing belt - there are no differences between different engines.

Let's look at how the exhaust manifold can be detached from the cylinder head. On engine 21120:

- Remove the exhaust pipe of the muffler: unscrew two nuts 1 (key “13”), remove the clamping bar, unscrew six nuts 2 (key “14”) and dismantle, not forgetting to turn off the oxygen sensor. The photo shows three of the six nuts.

Elements of the exhaust pipe

Everything important is under the screen

Now we will talk about engine 21124:

- Disable both oxygen sensors. We unscrew the three nuts securing the protective screen (with a 10mm wrench) and disassemble the bracket by unscrewing the four nuts with a 13mm wrench.

How to disassemble the mounting bracket

Operation with additional muffler

Here we believed that the VUT hose was disconnected from the intake module. Finally, the spark plugs are unscrewed on any of the engines (a “16” tubular wrench).

The tightening torques for the mounting screws are given in another text. In general, on VAZ-2112 hatchbacks, cylinder head repairs begin by replacing the “extended” screws with new ones. The length should be 95mm or less.

The order of unscrewing (left) and tightening the mounting screws

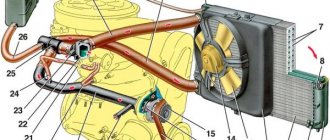

Cooling system design

The engine cooling system has many components that are interconnected, and if one fails, the entire system will not be able to function. So, let's look at the location diagram and decoding of the indicators for the cooling system of a 16-valve engine.

Diagram of the cooling system operation

1 – heater radiator; 2 – steam removal hose of the heater radiator; 3 – outlet hose; 4 – supply hose; 5 – coolant temperature sensor (in the block head); 6 – pump supply pipe hose; 7 – thermostat; 8 – filling hose; 9 – expansion tank plug; 10 – coolant level indicator sensor; 11 – expansion tank; 12 – exhaust pipe; 13 – liquid chamber of the carburetor starting device; 14 – radiator outlet hose; 15 – radiator supply hose; 16 – radiator steam outlet hose; 17 – left radiator tank; 18 – sensor for turning on the electric fan; 19 – fan electric motor; 20 – electric fan impeller; 21 – right radiator tank; 22 – drain plug; 23 – electric fan casing; 24 – timing belt; 25 – coolant pump impeller; 26 – supply pipe of the coolant pump; 27 – coolant supply hose to the throttle pipe; 28 – coolant drain hose from the throttle pipe; 29 – coolant temperature sensor in the outlet pipe; 30 – radiator tubes; 31 – radiator core.

Cooling radiator

Cooling radiator pulled from the engine

As practice shows, this part lasts quite a long time. The main cause of failure is clogged internal channels. So, if the blockage is sufficiently dense, the engine begins to heat up, the high pressure created by the pump can lead to a rupture of the tube and the radiator will leak.

Some car enthusiasts have it soldered and cleaned, but as practice shows, after a short period of time, a leak forms again. Therefore, if this part fails, it must be replaced with a new one.

Exterior tuning

When tuning a VAZ 2112, you should also pay maximum attention to the exterior of the car. Below we will consider the most popular options for tuning the exterior of the VAZ 2112.

New bumpers

In Russia, upgrades using bumpers have been practiced for over 10 years. At the moment, a huge number of service stations and workshops have been created that develop, supply and install plastic body kits. Thanks to the new, modernized aerodynamic bumper, you can not only update the exterior of the VAZ 2112, but also improve air resistance parameters.

However, car enthusiasts who decide to tune the VAZ 2112 bumper should know that the massive, improved bumper significantly limits the vehicle’s cross-country ability.

That is, you can say goodbye to trips to the forest or nature

And in the city there is a risk of hitting the curb while parking, so the dimensions of the new bumper and other body kits should be treated with caution. Remember, the lower the bumper, the lower the ground clearance of your car will be.

New optics

More and more car enthusiasts have recently begun to install special alternative headlights. Tuning the optics of a VAZ 2112 in this way significantly increases the glow distance of the lamps.

Nowadays in stores you can find alternative illumination for both headlights and rear brake lights - signals. The assortment is sometimes simply amazing - car enthusiasts are given the opportunity to choose any optics to suit their taste and pocket. Tuning a VAZ 2112 with the help of alternative headlights will significantly improve the appearance of the car, and will not deprive it of other positive qualities.

An unusual radiator grille will also decorate the exterior. The most impressive look is the aluminum honeycomb grille. Also, for a more intense supply of air to the engine compartment, so-called gills are made in the center of the hood lid. They will make the car’s exterior more aggressive, serious, sporty, and also prevent possible engine overheating.

"Eyelashes on the headlights"

It is also a favorite option for tuning the exterior of the VAZ 2112. “Eyelashes” are easy to install and undemanding to maintain. As practice makes clear, the exterior of the headlights changes significantly when this plastic element is applied to them. Having seen such “eyelashes” in reality, you will immediately understand how effective this detail can be. And its price is 6 times less compared to a set of alternative optics.

Tires and wheels

Installing rims on a VAZ 2112 is already a classic tuning. As practice dictates, the most suitable option for this car are cast or forged wheels on low-profile tires. Fortunately, the range offered today makes it possible to choose the most suitable wheels and tires that will harmoniously complement any body airbrushing.

- Tuning VAZ 2110 with your own hands

- Tuning and restoration of the Chevrolet Chevelle 1970 muscle car

- Photos and test drive of the Mustang Fastback Eleanor Shelby 1967 muscle car

- Tuning car bodies in khaki color

Pipes

KIT kit of cooling system pipes

One of the main components of the cooling system, since it is through the pipes that the fluid circulates through the system. The main malfunction is considered to be wear, namely the appearance of cracks and leaks of coolant. To fix the problem, you need to replace the damaged element.

Of course, it is recommended to change everything in sets, since it is unknown how many kilometers later another one will have to be replaced, and the process itself requires draining the coolant.

conclusions

The operating temperature of the 16-valve VAZ-2112 engine is 87-103 degrees Celsius.

If this indicator increases, the engine may boil, which in turn can lead to serious negative consequences, such as bending of the cylinder head or major engine overhaul. It is worth carefully monitoring the condition of the components and parts of the cooling system, because they ensure normal cooling and operation of the power unit.

If you find an error, please select a piece of text and press Ctrl+Enter.

Didn't find the information you are looking for? on our forum.

Normal operating t of the internal combustion engine: +90…+95, if above +97 then the internal combustion engine will dull a little, but this t is also considered normal, up to +110 is also normal, but the radiator fan should already turn on. If t is below +90, this is not overheating. We look at the thermoelement for grinding into the thermostat cover (so that when closed it does not etch into a large circle) and the serviceability of the thermoelement itself by boiling it in the thermostat cover. If the lower pipe is cold, this is not a fact that it does not poison a large circle!!! Here, for example, is my excerpt from the topic: SOD according to Kalinovsky: I purchased a 6-hole thermostat assembled, sealed, with an Quality Control Department stamp, for t 85, PRAMO, for 505 rubles. And I also had a thermoelement from a viburnum lying around for a long time, also at t 85. ___________________________________________ Kalinovsky thermoelement: ___________________________________________________ Thermostat with a thermoelement: ___________________________________________________ I boiled both thermoelements in this one body of a new thermostat, result: 1. The thermocouple from the viburnum: opened slightly at +92 (started let water through at atmospheric pressure) at 96 opened slightly by 5 mm +100 opened by 8-9 mm diluted the water to +83 - almost instantaneous slamming. 2. Stock thermocouple Pramo: opened slightly at exactly +85 and went at atm. pressure +86 hole mm 2-3 +88 hole approximately mm 5 diluted the water to +83 - it slows down for about a minute. Now do you understand why your operating temperature in winter is +88 and below? There was a thermoelement left from the new PRAMO thermostat, which turned out to be a little longer (rod) and did not fit tightly into the cover of the Priora thermostat. The cover of the Priorov thermostat was drilled out a little and the thermoelement sat tightly, now it is not blown through. (before these actions I thought about it, I didn’t sit down two mm) Boiling, video 5:52, 24.4 MB, heating and cooling processes: via FTP video 5:52, 24.4 MB ________________________________________________________________ And now sea trials of the “Kalina” thermoelement with the “Pramo” lid : In weather -15, Videoadded t coolant on the move, t air in the driver's compartment, t air flow at the carrier in the legs (16.6 MB) By FTP, 16.6 MB ________________________________________________________________ Warm-up from a cold start, with on. stove, -16 on the street, -15 coolant, -15 in the cabin, at idle, 24 minutes: here is the video, 63.4 MB: Via FTP, 63.4 MB ___________________________________________________________ Warming up from a cold start, with off. stove, -19 on the street, -18 coolant, -17 in the cabin, at XX, 23 minutes: here is the video, 30.4 MB: Via FTP, 30.4 MB ————————————— ——————————————– After a year, RESULT: Summer slave. temperature +92…+94 (tested at temperatures up to +35 C) Winter working. temperature +90…+92 (tested at temperatures down to -41 C)

Sources:

- www.drive2.ru

- carfrance.ru

- www.vazzz.ru

- www.autolada.ru

Technical tuning VAZ 2112

After additional tuning of the VAZ 2112 engine, you can:

install pistons from a two-liter VW power unit, suspending them using enlarged connecting rods (129th) and install a “combat crankshaft” super 1600.

As a result, the working capacity will increase by 100 cubic meters. In the process of tuning the engine, the right solution would be to install a camshaft with a valve lift of 10.7 mm, as well as stiffer, reinforced springs for valves with “split” gears. You can also install a larger throttle and a larger volume receiver.

- To give the car “air”, it is necessary to modify the exhaust and intake channels of the cylinder head (cylinder head).

- You can complete the tuning of the VAZ 2112 engine by installing a new, more powerful fuel pump coupled with higher-performance fuel injectors.

After updating this unit, it will not be amiss to perform chip tuning to fully optimize the operation of the power unit.