Cars admin26.02.2020

Since all UAZ drivers have plastic inserts in the kingpins, which need to be changed every 10 thousand kilometers, there was no question of replacing them with a more reliable design. The only question was when to change. We continue, together with Magazin4x4, to improve the UAZ-2206 car.

There are several alternative designs on the market: a king pin with bearings and a king pin with bronze liners. King pins on bearings are more capricious; they cannot withstand shock loads. Although there are many opinions and many copies have been broken. We decided to supply a proven option: a kingpin with bronze liners from our long-time partner STO Vaksoil-Service

Since the 2020 Loaves have hybrid axles, a kit for Spicer-type axles is needed. We chose a complete set: with gaskets, cuffs and the correct kingpin wrench.

At the same time, if we were to climb into this node, it was decided to replace the SHOPK with new, reinforced ones, with castor +5°

SHOPK - Ball Joint Steering Knuckle

The right and left SHOPK differ from each other, and so as not to confuse them, they are signed.

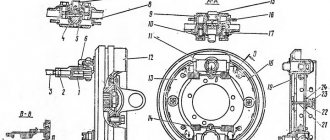

The technology for installing a bronze liner and modernized kingpins is practically no different from that set out in the “Repair and Operation Manual”. There is also a wonderful instruction, with pictures, from the technical director of the Vaksoil-Service service station, Pyotr Mazurov, on the operation and repair of the pivot assembly of UAZ vehicles

Let's start with disassembling the pivot assembly of UAZ cars/ For our case, let's add that the 2020 UAZ Bukhanka already has front brakes with ABS installed, so we also need to remove the ABS sensor/

And after dismantling the steering rods, all steering ends were replaced with RedBTR products

The chassis of any car is subject to serious loads. UAZ is no exception. Moreover, some of the models are used for off-road use, where the load on the suspension increases tens of times. Any UAZ uses a classic suspension scheme - a pivot one. Over time, these elements fail. How to determine their wear and replace the king pins on a UAZ? You will find out the answer in our article today.

Symptoms of a problem

Symptoms of a breakdown do not appear immediately. So, the motorist will notice uneven tire wear.

- Raise the front axle.

- Check the wheel play without removing it in the radial and axial direction.

- When worn out, the UAZ kingpin is replaced with a new one.

They also check the distance between the beam and the fist. The gap should not exceed 0.2 millimeters.

Characteristic

What is a kingpin? UAZ "Patriot" is equipped with this mechanism from the factory.

View gallery The kingpin is a rod with a hinged connection between the steering knuckle and the ball joint. The element is located in the front of the car. The kingpin provides the ability to control the wheels without interrupting the torque supply.

How to replace kingpins with your own hands?

First, drain the oil from the bridge. If it is black, it cannot be reused. Next, we remove the wheel bolts and jack up the car. Having hung the bridge, we begin to dismantle the caliper and brake shield - they will interfere with us when replacing the kingpins on the UAZ.

Next, screw an M10 bolt into the kingpin. Then we pull out the cap and remove the element in this way. If dismantling with a bolt does not work, a steel plate will be required. We fix it above the kingpin and make an M10 hole. We screw our bolt of the appropriate diameter through it. Place several nuts under the plate and tighten them.

When replacing the UAZ kingpin, it is important to completely clean the old bushing of grease. A new one is being laid in its place. Litol-24 is used as such. Next, a new king pin is installed. It is hammered through a wooden die. The king pin is not pressed in completely - it is important to eliminate the slightest distortion. Otherwise, it will go tight and with a characteristic sound. If this happens, the kingpin is pulled out and pressed in again. All other elements are assembled in reverse order.

Kingpins on modern cars

Current kingpins are equipped with spherical hinges, which gives them reliability and the ability to operate for a long time under heavy loads, even without additional lubrication. It is these king pins that are used on almost all vehicles intended for transporting goods and driving on bad roads and beyond: trucks, some SUVs and pickups. The transverse and longitudinal angles of inclination of the kingpin significantly affect the driving performance of the car.

Owners of UAZ Patriot often encounter a malfunction of the pivot group. Let's look at how to replace the kingpin on this car yourself.

What kind of king pins are there on the UAZ Patriot?

A kingpin is a mechanism that limits the angles of rotation of a wheel. There are several types of such devices for Russian SUVs:

- Pins on bushings. A classic option that is suitable for a quiet ride. On a flat asphalt road, you can drive with it for quite a long time, but if you catch a hole or a stone, run over a speed bump at full speed, or simply load the axle, the bushings may simply fall apart. There are several types of such pivots:

- Factory king pin. It is a simple spherical support with plastic inserts. Such a kingpin is simple and cheap to produce and is quite reliable with moderate use. Considering that the UAZ Patriot is not bought for a quiet ride on smooth roads, owners have to periodically adjust the gaps and change the liners (which is inexpensive, but time-consuming).

- Reinforced king pin. This option is suitable for off-road enthusiasts and active lifestyles. Needless to say: hinges with bronze liners inspire much more confidence than plastic, and they last much longer. If you consider yourself to be an experienced “jeeper,” then it is better to replace the factory kingpin immediately after purchase with a reinforced one or even more reliable options, which we will discuss below. They are produced by companies specializing in spare parts for off-road enthusiasts, so finding them will not be difficult.

- Ball pin. It has a long service life and simplicity. If assembled correctly, it requires virtually no adjustment or lubrication: the assembly becomes virtually sealed, the gap between the body and the ball is minimal;

- Bearing king pin for UAZ Patriot. Quite a new offer for Patriot owners. With proper installation and good components, there is no need for constant adjustment and frequent replacement. They are durable, but difficult to install and cannot be repaired in the field.

Causes of kingpin wear

No matter how wear-resistant the kingpin is, there are a number of reasons that significantly reduce its service life. These include:

- intensive driving on broken and simply bad roads;

- lack of lubrication or leakage;

- wheel imbalance;

- factory defects / low quality parts (before purchasing a kingpin, it is better to study reviews of the manufacturer).

When to change the kingpin

Adjusting the UAZ king pins

A mandatory step after replacement is adjusting the steering. Otherwise, problems may arise with tire burning and the car pulling to the side. The adjustment is done using spacers. Start with the top kingpin. For the bronze element, 4 spacers, each 0.5 mm thick, are used. For roller bearings - 5 with the same thickness. Next, we tighten the mechanism and go for a test drive. It is unacceptable for the wheel to heat up. If this is the case, the kingpin will need to be loosened by reducing the number of shims.

Installation.

The bearing pin for the UAZ Patriot will last as long as possible if the parts are installed correctly. Typically, replacement occurs when play appears in the rotating mechanism. This means that the plastic inserts have collapsed and the gaps in the part have greatly increased.

We perform the following procedure:

- The hub is removed along with the steering knuckle.

- The remains of the kingpin are trimmed with a grinder, after which they should be knocked out and the cut area should be cleaned.

- Bushings from bearing supports are welded onto the prepared surface.

- We press the cups into the bearing races.

- The dimensions of the parts are made in such a way that the parts fit as tightly as possible, so they can be installed with tension.

- We install the bearing and crankcase in place, having previously updated the lubrication of the parts.

Which ones to choose?

In addition to the factory carbon fiber ones (which owners do not recommend installing in any way), there are several types of king pins:

- Bearing.

- On a bronze bushing.

The first type has a complex design. Such UAZ kingpins combine the lower half with a tapered bearing and thrust ring, as well as a cage.

Bronze elements are highly resistant to shock loads - such bushings are an order of magnitude stronger than bearing bushings. But the steering will be tighter. The cost is almost identical to the previous ones - 1.5 thousand rubles per set. These are excellent kingpins for UAZ “Loaf”, “Hunter” and 469. True, like the previous ones, they require regular lubrication and inspection. We will describe this procedure in detail below.

Required Tools

Before starting repair work, the car is thoroughly washed to remove dirt, because... the ingress of dust and small debris into moving mechanisms or lubricant will lead to rapid wear of the installed parts.

To tighten the kingpins on a UAZ Patriot you will need the following tools:

- standard set of special linings;

- set of open-end wrenches;

- heads of different diameters;

- hammer;

- jack - 2 pcs;

- torque wrench;

- a wrench with an attachment for adjusting the pivot units.

A special key can be found in repair kits for kingpins and bearings. If it is not there, you will have to buy it separately. A kingpin wrench is similar to a splined pad with lugs that fit into slots on a lug nut. To ensure accurate tightening, use a torque wrench.

About syringing

This is the name for the procedure for lubrication of mechanism bushings. It is produced through grease nipples using a specialized syringe. A waterproof lubricant (for example, Litol-24) is placed inside the latter.

How often should the pins be injected? This procedure is performed every 20 thousand kilometers or once a year. This simple preventative measure will extend the life of the bushings and ensure easier steering rotation. This is noticeable already from the first meters of the road.

Algorithm for replacing the king pin on a UAZ “Bukhanka”

- The front axle of the car should be hung on jacks ; jacks are more often used. Additionally, something strong is substituted so that if the jack breaks, the car does not fall.

- The transmission oil needs to be drained from the axle.

- Next, remove the brake shield , brake caliper, steering tip and turn out the oil nipple.

- Direct removal of the king pin . You need to screw a bolt with a diameter of M10 into it and try to pull it by prying it by the head. If this does not work, you should firmly fix the steel sheet above the pin and make an M10 hole in it through which the bolt will be screwed. A pair of nuts are attached to the bolt under the plate, through which the kingpin will successfully rise to it.

- Then you can get the washer without any problems, but you need to tinker with the bushing. You can get it out with a sharpened nail, carefully sliding it from the side of the lock under the sleeve. Oscillatory movements must be done in a circle until it becomes possible to grab the bushing with pliers. After removal, the bushing is washed with gasoline, and then a new lubricant, usually lithol, is applied.

- The new kingpin is carefully hammered into place with a hammer, preferably through a wooden board, avoiding the part being distorted.

- The remaining parts are installed in their places.

Sequencing

- The car is installed above the inspection hole, and wheel chocks are placed under the rear wheels.

- A wheel with a faulty kingpin is jacked up and removed using a set of socket wrenches.

- After removing the wheel, you can get to the nuts of the steering rod bipod, there are 4 of them. The nuts are unscrewed using a 24mm open-end wrench.

The wheel is removed, and all 4 nuts on the steering rod bipod are also unscrewed - You should also unscrew the lubrication bolt of the kingpin assembly (it is located in the middle, between the four tie rod bolts).

- Once all the nuts are unscrewed, the steering rod bipod is removed.

It is under it that the pivot assembly is located. The bipod has been removed, the top cover of the pivot assembly is visible - In order to press out the top cover of the kingpin, you should use a puller. The puller bolt is screwed into the lubrication hole vacated by the bolt, after which the puller nut moves down the thread, pulling the top cap of the kingpin up from the steering knuckle body.

The top cover of the kingpin is pressed out using a homemade pullerPressing out the top cover of the pivot assembly is complete, the ball is visible

- Pressing out the bottom cover of the kingpin is also done using a puller, but in order to do this, you will have to go down into the inspection hole.

The lower cover of the pivot assembly is also pressed out with a puller - After pressing out both covers and removing the ball, the steering knuckle body is thoroughly cleaned of dust and dirt, and then the lower cover of the new pivot assembly and the ball are placed in it, the surface of which is pre-lubricated with lithol or grease.

The bottom cover must be thoroughly lubricated with lithol before installing the ball. - Now you need to install the top kingpin cover.

Since the new cover will not fit completely into the body, you will have to lightly tap it with a hammer or other handy tool. To install the top cover of the pivot assembly, you can lightly tap it - Having attached the lid, it should be completely seated.

This is best done using the tie rod bipod bolts: the bipod is installed in place and its bolts are tightened, tightly pressing the top cap of the king pin into the steering knuckle body. The steering rod bipod is installed in place and screwed - The pivot assembly is lubricated through the upper hole (this is done using a grease gun). Then a bolt is screwed into this hole to serve as a plug.

- After the steering rod bipod is screwed on, all that remains is to put the wheel in place and remove the car from the jack.

How to replace it yourself (video)

Steering adjustment

This is mandatory, otherwise problems with driving the car will inevitably occur and premature wear of the tires on the front wheels is possible.

The steering is adjustable with shims. For a standard kingpin, 4 pieces are suitable, and for a roller pin – 5 pieces of 0.5 mm each. After the test ride, you need to touch the wheel and kingpin. When the wheel heats up, a couple of spacers should be removed, but if the kingpin is hot, then add it.

The quality of UAZ control depends on the condition of the pivot. If it malfunctions, you will feel impacts on the steering wheel, so you should replace it in time. It is quite possible to carry out this repair with your own hands, however, if you have the opportunity to contact a specialist, you should not neglect this.

Important points

- You should never press in the top cap of the kingpin using only a hammer, because this can cause it to become distorted. It is better to press it into the knuckle body with the help of four bipod bolts, and these bolts must be tightened crosswise. This will allow the lid to fit as smoothly as possible and no distortions will occur during pressing.

- The new top cap of the kingpin, as a rule, never fits completely into the body: a few millimeters of this cap always protrude above the fist and it is impossible to recess the cap even with the help of strong tightening of the traction arm bolts. That is, a gap appears between the fist body and the rod. To remove it, you should use several gaskets (they can be purchased at a car store, or you can make them yourself). During operation, the pivot assembly will wear in, its top cover will gradually sink into the knuckle body and the need for these gaskets will no longer be necessary. The car owner will only need to tighten the bipod more tightly. But this cannot be done with a new lid, since there is a high risk of breaking it.