Unstable engine operation makes you want to identify the reasons why the engine does not gain speed or does not develop sufficient traction, and what is causing the breakdown. Imagine, you press the gas pedal, but the engine simply “refuses” to obey the command, and the speed does not increase.

Or the engine picks up speed up to a certain point, and then it’s as if something is holding it back, but the power does not develop. The task of diagnosing this phenomenon is quite complex, which can be caused by many factors.

One of the common reasons that the engine cannot gain speed and develop sufficient power is a malfunction of the fuel system. For all types of engines, regardless of the type of fuel, the fuel system must be checked for operability first, and especially the technical condition of the fuel pump.

It is a faulty fuel pump that causes the engine to “starve”, hence its very sluggish operation. As for diesel engines, here first of all you need to check the injectors and plunger pairs of the fuel pump, the failure of which leads to the engine losing its power and often refusing to start.

Electrical problems

The reasons why the engine does not pick up speed may also lie in various defects in the fuel system, which lead to air being sucked in through depressurized areas (broken hoses, leaky washers), which has an extremely detrimental effect on the operation of the fuel system. It is also worth checking the fuel system filters, since dirty and clogged filter elements lead to the engine not developing power.

Why doesn't the engine rev up? List of reasons and sequence of actions

On injection engines, it is necessary to determine how the timing marks are set, since the timing of ignition and injection of the fuel mixture depends on this. You also need to check the tension of the timing belt, as well as the correctness of its installation, since its incorrect fit and installation of teeth can also affect the development of power of the car engine itself.

After checking the fuel system, the engine ignition system follows. The first step is to check the condition of the spark plugs, especially their tips. Pay attention to the spark plug insulators: if they have longitudinal brown deposits on them, they must be replaced immediately. If the tips are carbon deposited, it must be removed and cleaned.

For this purpose, you can use coarse sandpaper. Now you need to carefully examine the condition of the distributor and high-voltage wires. Then it will be necessary to measure the wires so that one of them does not have too much resistance, or that there is no break in it.

A block with ballasts may fail and may also be the cause of the problem in question. To find it, lift the hood and you can easily see a ribbed block under the windshield. This is ballast resistance.

Why doesn't the engine rev up? List of reasons and sequence of actions

Other reasons

Another reason why the engine does not develop power is the intake of air into the cylinders; on the way after the mass air flow sensor there is an air flow sensor. The fact is that the mass air flow sensor supplies information to the machine’s computer about how much air has entered the cylinders, and it, in turn, calculates the composition of the fuel mixture. And since the information is unreliable due to excess air, the mixture becomes lean, which leads to reduced engine thrust.

Replacing a clogged air filter, which needs to be changed every six months, will also help solve this problem. The fact is that due to dirt in the filter, the supply of air masses becomes difficult, as a result of which the engine barely picks up speed and develops very little power.

It would be a good idea to look at the color of the exhaust gases: if they are black, the operation of the check valve may be impaired.

One of the possible reasons for engine failure and the inability of it to develop the required power could be a simple breakdown of the car’s computer. If this is the case, then try unscrewing the injectors; you will see a large amount of gasoline pouring out of the injector. Moreover, such a breakdown can only be eliminated by replacing the on-board computer.

Why doesn't the engine rev up? List of reasons and sequence of actions

Considering the reasons why the engine does not pick up speed, let's pay attention to another important aspect - the operation of the catalyst, which often gets clogged. To check it, unscrew the spark plug, then start the engine and make several sharp presses on the gas pedal.

If there is a sharp increase in power and the engine picks up speed very quickly, then the problem lies there. In this case, it will need to be replaced.

When operating a gasoline or diesel engine, the driver may encounter the fact that when pressing the gas, the engine does not gain speed. Note that after installing LPG on a car, a problem often arises when the engine does not pick up speed on gas, although the car drives normally on gasoline. Malfunctions of various kinds can be hidden either in fairly simple things or indicate the need for serious repair of the internal combustion engine. Next, we will look at why a diesel engine does not pick up speed or a gasoline engine refuses to spin up.

Read in this article

Frequent malfunction: the engine does not gain speed and what should the driver do?

If the engine has stopped gaining momentum, then the first thing you need to do is analyze when and how this manifested itself. In other words, the unit stopped spinning unexpectedly, or the problem with gaining speed gradually progressed. You should also pay attention to the presence or absence of other symptoms.

The fact is that the failure of a previously serviceable engine to gain speed after any repairs or other manipulations may simply be the result of assembly errors, a not connected sensor, etc. In such cases, the malfunction can be quickly and accurately determined after an independent inspection or immediate return of the vehicle to the service center where the car was previously repaired.

IAC diagnostics, idle speed sensor

Use a pxx tester to verify the presence of floating rpm

To check whether the speed on the Lada Granta is floating, look at the IAC sensor. It is located on the throttle body, therefore, in the same place as the sensor responsible for the throttle position. It is secured with two mounting screws. In order to verify its functionality, one multimeter will be enough.

To begin diagnostics, you need to turn off the ignition and disconnect the block to which the wire from the sensor leads, and, using a multimeter, measure the resistance level between the contacts of the regulator.

If the vehicle readings are normal, it should be within approximately 80 ohms. In the same case, if the indicators turned out to be significantly higher than the IAC norm, it will be necessary to replace it.

The idle speed sensor, abbreviated as IAC, is the same idle speed control, or IAC. Its immediate purpose is to stabilize and automatically adjust the idle speed of the Lada Grant, which is used in the daily functioning of the car. In appearance, it is an electric motor equipped with a cone-shaped needle.

At the moment when the ignition is turned on directly, the rod located on the regulator fully extends and rests against a specially made calibration hole. It is located directly in the throttle pipe. After this, the sensor begins to count steps until the required time and returns the valve to its original state upon completion of operation.

It is necessary to take into account that when you start warming up the Lada Granta engine, the sensor readings should not exceed 50 steps. If their volume is much smaller or larger, it means that air volumes are constantly changing, which in the future can lead to significant damage.

The best prices and conditions for the purchase of new cars

Why the engine does not gain momentum: from simple to complex

At the very beginning, let's look at simpler and more obvious faults. The set of revolutions while driving is greatly influenced by the efficiency of delivery, the timing of ignition and the completeness of combustion, as well as the composition of the fuel-air mixture.

A common reason why an engine does not pick up speed (injector, carburetor, diesel, gas car) is problems in the ignition system, as well as in the air and fuel supply systems. Experts highlight the following:

- Severe contamination of the air filter reduces the ability of air to penetrate through the filter element, as a result of which the engine becomes uneven, the unit loses power and does not gain speed. Another common cause of air supply problems may be that a foreign object (rag, plastic bag, etc.) may accidentally end up in the air filter housing.

- You should also pay attention to the leakage of excess air at the intake as a result of various defects in the intake system. The problem can appear unexpectedly or gradually progress. Note that the engine usually does not gain speed in case of strong air leaks. The fact is that in the composition of the fuel-air mixture, the normal ratio of air and fuel in such a situation noticeably deviates from the norm. The mixture turns out to be very “lean” (lots of air and minimal fuel). With such a charge, the engine starts, but does not gain speed while driving, and also runs intermittently.

- A similar picture can be observed when the required amount of fuel is not supplied to the unit. The culprit may be the fuel filter, which can also become severely clogged. Note that there may be no problems with starting the engine, since there is enough fuel for the XX mode. At the same time, while driving, the car may twitch, react to pressing the gas pedal with a long delay, dips may occur when the speed increases, or the unit may not spin above a certain mark on the tachometer.

- A dirty fuel pump mesh filter can also lead to similar symptoms. Deposits from the fuel tank tend to accumulate on this filter over time. As a result, the fuel pressure in the system becomes insufficient, the pump performance drops, and the engine itself is not able to operate normally in different modes. It often happens when the engine picks up speed and stalls precisely because the grid is clogged.

Now let's talk about problems that may require certain knowledge, skills and equipment for diagnosis, and also be a reason for a visit to a car service center. Let's start with the fact that this list of faults usually includes those when the engine does not gain speed due to the failure of any element of the ECM, ignition system, power supply, etc. In other words, we are no longer talking about “consumables” (spark plugs, wires, filters, pipes), but about details. In parallel with this, one should also take into account whether the breakdown occurred unexpectedly or whether the fault progressed gradually.

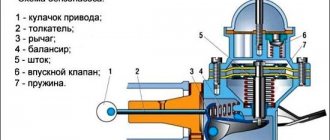

- One of the reasons may be misaligned timing. Violations of the synchronous operation of the gas distribution mechanism regarding the intake and exhaust strokes lead to the fact that the intake and exhaust valves open untimely. The malfunction occurs as a result of errors during timing belt replacement if said timing belt has jumped one tooth or more teeth. Also, the cause may be incorrectly adjusted valves (the problem does not manifest itself sharply), various problems in variable valve timing systems, breakdown of the timing chain drive, etc.

- Unexpected breakdowns include failure of the ignition module, as well as malfunctions of the ignition coils. In this case, the cylinders begin to misfire, the engine stalls and loses the ability to gain speed normally.

- In situations with engine speed, the power supply to the injection nozzles should be checked. If problems arise with the wiring, then the control signal is not supplied to the injector or is received intermittently. As a result, the injector does not open in a timely manner, misfires occur in one or more cylinders, the engine does not reach the required speed and loses power.

- The fuel pump or fuel injection pump on diesel engines may fail. This problem usually does not occur immediately (except in cases where the electrical wiring to the pump is damaged). Much more often, the decrease in pump performance occurs gradually. Sooner or later, the pump will begin to pump fuel very weakly; the pressure will only be enough to operate in idle mode. An increase in load and speed will lead to the engine stalling under load, not spinning up, etc.

- In some cases, severe contamination of the injector itself leads to similar results. Driving on low-quality fuel, as well as ignoring the necessary procedure for cleaning injectors every 30-40 thousand kilometers driven, can mean that the performance of one or more fuel injectors has dropped significantly.

- Engine speed can also be affected by the condition of the EGR system, the throughput of the catalyst or particulate filter. As for the second case, due to a clogged catalyst, exhaust gas removal deteriorates, the engine literally “suffocates” and is not able to gain normal speed.

- At the same time, it is necessary to check various sensors of the electronic engine management system. Their incorrect operation can affect the composition of the mixture, that is, the amount of fuel and air supplied to the internal combustion engine. Such sensors include TPS, DMRV and a number of others.

Checking the fuel mixture

Let's say your trimmer won't start. In this case, the first thing you need to do is check whether there is enough fuel in the tank, and also evaluate the quality of the fuel mixture. It is necessary to refuel a motorized unit exclusively with high-quality gasoline. It is recommended to use fuel of a grade not lower than AI-95.

Why won't my petrol trimmer start? This can also be caused by improper preparation of the fuel mixture, which consists of oil and gasoline. The proportions in which these components are combined are indicated by the manufacturers in the trimmer's instruction manual. It is highly not recommended to prepare the fuel mixture in large volumes, that is, for the future.

Another common reason why the trimmer will not start is if there is a clog in the filter area. To confirm your guess, it is enough to dismantle the indicated block and try to start the unit without it. If the trimmer engine starts, most likely you will have to replace the air filter or at least thoroughly blow out the old one.

We suggest that you familiarize yourself with Sea buckthorn oil for adenoids in children

If there is heavy contamination on the surface of the filter element, it is necessary to use a new mesh. When resorting to such actions, you should not leave the suction pipe completely without a filter. After all, haste in this case can lead to the need to repair the entire piston group of the unit’s engine.

What's the result?

Considering that there are many reasons for problems with revving on a modern car, it is optimal to immediately connect the car to diagnostic equipment (scanner) to search for possible errors. This is especially necessary to do in the case when the engine does not pick up speed and the check light on the dashboard lights up.

Such failures are associated with a software malfunction in the operation of the electronic device. The ECU mistakenly takes low speeds (for example 2-3 thousand rpm) for the so-called “cut-off” speed and stops the fuel supply. In other words, the conditional protection against exceeding the permissible maximum engine speed is triggered prematurely.

Finally, I would like to add that timely cleaning of the injector, replacing spark plugs and ignition wires, filters and fuel pump filter elements, cleaning the throttle valve, correct throttle adjustment and a number of other service procedures will allow you to get maximum power from your internal combustion engine. As for cars with gas equipment, not only the engine power and its speed on gas, but also the overall service life of the power unit will depend on the correct installation and configuration, as well as on the timely replacement of filters and maintenance of other elements of gas equipment.

Independent search for the cause

What to pay attention to:

- Check the MAF (mass air flow sensor).

- Examine the IAC.

- Examine the wiring of the DS (speed sensor).

- DPKV (crankshaft position sensor) is the next object of inspection. But the reason, most likely, is not in it specifically, but in its chip or wiring.

- The TPS (throttle position sensor), an element of the throttle assembly, must also undergo a thorough inspection in such a situation. Perhaps a simple cleaning is needed.

- Check high voltage wires and spark plugs.

Once the cause is identified, the problem must be corrected. Your actions in this case depend entirely on what exactly went wrong.