While operating a vehicle, many motorists notice oil leaking from under the oil filter. This problem may be relevant both for owners of fairly old cars with high mileage, and for relatively new internal combustion engines.

In the first case, oil flows in the area of the oil filter due to the fact that the oil pump of the lubrication system may not have a pressure reducing valve that prevents excess pressure in the system. Most often, the problem appears after a cold start in winter, when the oil thickens in the crankcase of the power unit. The thick lubricant simply does not have time to pass through the filter, resulting in oil being squeezed out.

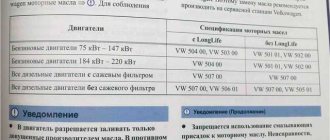

Recommended

We should also read the article about why oil is squeezed out through the breather. From this article you will learn about the causes and ways to eliminate such a breakdown.

As for modern engines, leaks for this reason are not normally allowed, since the presence of an excess pressure relief valve in the design of modern systems eliminates this possibility. For this reason, an oil leak from under the oil filter housing is a malfunction and becomes a reason for diagnosing the power unit.

In this article we will talk about the reasons why oil leaks from the oil filter, what to do if an oil leak is detected from under the oil filter cap or housing, and also how to fix it.

Main signs of a malfunctioning oil pump

The vehicle's lubrication system ensures stable and durable operation of the main engine components. The engine contains many parts that experience strong friction during operation and quickly wear out without constant lubrication.

Many motorists are interested in the question - how to recognize a faulty oil pump? If the oil supply is insufficient, a so-called “oil starvation” occurs. It can lead to engine failure, resulting in a complex and expensive overhaul of the power unit.

One of the first signs that the oil pump is damaged will be a light on the instrument panel. If this happens, you should check the pressure in the oil supply system, and also pay attention to the oil consumption.

- Reduced oil pressure in the system.

- Noticeable increase in oil consumption.

If the pressure in the device decreases, the car cannot be used until the cause of the problem is determined and the car is repaired.

There are several main reasons for system malfunctions. Here are some of them.

Replacing the pressure relief valve

If the quality of the consumable material is normal and the filter device is working, the reason must be sought in the performance of the pressure reducing valve.

You can carry out the work of replacing the part yourself.

What will you need?

For repairs, prepare a set of wrenches and rags.

Stages

The replacement is done like this:

- Remove the timing cover.

- Find the bypass valve; you need to unscrew the plug from it. Use a wrench to unscrew.

- Remove the spring from the technological hole. It is used to control the operation of the device. If the spring is intact, then excess pressure in the system is released. Examine the integrity of the device. If it is working, then it should be free of burrs and other types of defects.

- Pay attention to the coils. In a working spring they are tight. If you can stretch it with your fingers, then the metal is already weak.

- Measure the height of the device. It is 44.72 mm. If the height is less, then part of the device is broken off. Remove the spring piece from the mounting hole and replace the spring.

An engine fluid leak can occur on absolutely any engine. The gist of this is that there are many different seals in an engine that can become damaged due to use. As a result, the unit will leak over time and the car owner will be faced with the problem of why the oil is leaking and what to do about it.

[Hide]

Causes of oil pump failure

- drop in oil level in the engine crankcase;

- damage to pressure monitoring devices;

- use of low-quality oil;

- using the wrong oil for the vehicle;

- failure of lubrication or safety valves;

- oil filter contamination;

- clogged oil receiver and blockage in the pump housing.

The blockage may be due to a dirty engine crankcase. To eliminate this problem, it is enough to remove the crankcase (after draining the oil) and clean the pan of dirt.

Malfunctions in the oil pump can manifest themselves in the form of various problems. They can be determined during diagnostics. The main possible problems with the mechanism are listed below.

Why is oil leaking from under the oil filter?

Let's start with the fact that the list of reasons why oil is squeezed out in the oil filter area is quite wide. Most often, the culprit is the owner himself, who has not changed the oil filter for a long time.

- Under certain conditions, contamination of the oil filter can lead to the fact that the throughput is greatly reduced; lubricant practically does not pass through the filter media. At the same time, to protect the engine from oil starvation, the filter design usually has a special bypass valve (allows the oil to bypass the filter element), but the possibility of failures during its operation cannot be ruled out.

Oil pump malfunctions:

- gasket damage;

- oil filter clogged;

- the filter is not secured securely;

- increased wear of main parts;

- failure of the pressure reducing valve.

The oil pump in a car has a fairly long service life and breaks down infrequently. Most often, breakdowns are caused by improper operation of the car engine, poor-quality repairs or the use of low-quality oil. A decrease in oil pressure and an increase in its consumption are the main signs of a malfunction of the oil pump, after detection of which the system should be immediately diagnosed and the cause of the failure eliminated.

A puddle of oil under the car will make any driver worry. Every time I go out and have a free minute, I try to warm up the engine at the garage and only then move. An oil leak in the area of the oil filter is a serious thing, even if you have complete confidence in the serviceability of the oil pump and filter, it is worth delving deeper into the problem. It's not even about what squeezed the oil through the oil filter. It squeezed out - that's understandable. The problem is why, for what reasons, high pressure occurs, which squeezes the oil out from under the oil filter.

In most cases, the problem is solved by tightening the filter housing more firmly, sometimes even using improvised tools. Most knowledgeable motorists consider the following to be the culprits of the incident:

- incorrectly selected lubricant viscosity;

- malfunction of the pressure reducing or bypass valve;

- low-quality product with a weak and soft body;

- loosely twisted oil filter housing on the fitting;

- Poor quality o-ring rubber seal.

Oil is leaking from under the filter: why and what to do?

The main reason why oil is squeezed out from under the filter, as a rule, is starting a cold engine. At this moment, the consistency of the lubricant is so thick that it simply does not have time to pass through the oil filter.

This usually occurs on older vehicles that have an oil pump that does not have a bypass valve. This certainly cannot happen with new cars, except perhaps if it is not tightened well enough, and then it presses oil from under the filter.

In pursuit of engine life

Before making a diagnosis as to why the lubricant was squeezed out, it is worth correctly assessing the conditions under which the problem occurred. Let's take into account the temperature and quality of materials. We will not consider the fourth position; in this case, the oil leak from under the oil filter was the result of inexperience rather than dishonesty. You only need to tighten it by hand, making sure to lubricate the sealing gasket with oil. If you tighten the filter using a tool - a wrench or a special puller, the rubber may be deformed too much, and the edge of the filter cover will come into contact with the mounting flange. In this case, the tightness of the connection will remain in question and the lubricant can be squeezed out at any time.

The first typical mistake that causes oil to squeeze out through the oil filter is high speed in cold weather. Ordinary mineral oil thickens at low temperatures to the state of jelly or grease. A gear pump can raise oil pressure up to 10 bar and squeeze it out through any gap, but it’s difficult through a microsponge or filter paper, and the cold oil flow is very reluctant to pass through the bypass valve.

Often such experiments lead not only to the lubricant being squeezed out from under the oil filter, but also to damage to the hardened seals on the crankshaft. In the latter case, repairs will cost several times more than a conventional device replacement.

Advice! If you often drive in severe frosts, switch to 0W20 viscosity oil and an oil filter with a spring bypass mechanism. The rubber flapper valve works much worse in severe frost. Also, be sure to check the operation of the spring valve before installation. Often the reason that grease is squeezed onto the road is a jammed valve.

If the filter element is designed for light, low-viscosity synthetic oil, then its design will have a reduced number of inlet holes, and they will be of smaller diameter. Due to the high viscosity of cold mineral water, the main flow of oil is not able to be squeezed out through small holes. As a result, the housing was swollen or the oil filter gasket was pressed out.

The second, most common mistake is the inappropriate use of various types of revilitants that offer quick restoration of rubbing surfaces. In most cases, all the debris added to the oil ends up in the filter element and bypass valve, blocking the flow and, as a result, forcing the lubricant through the seal.

Do not use traditional recipes for flushing the lubrication system - mixtures of kerosene and oil, gasoline and oil, kerosene with acetone and benzene. At best, such an explosive mixture will dissolve sediment in the drain channels and in the engine sump. Attempts to start the engine and idle result in light and low-viscosity fluid leaking and squeezing out through the oil seals and the housing seal. Residues from such flushing can lead to swelling and deformation of all gaskets in the lubrication system.

A similar effect is possible from high-viscosity motor oil. Advertising for such products promises normal oil pressure for worn engines. In hot weather, this oil actually works better, but with the arrival of cold weather it can easily squeeze out any rubber bands from under the filter. Moreover, oil filters are not designed for such innovations, and as a result, oil leaks from the oil filter.

A situation where the lubricant is squeezed out from under the oil filter results in:

- savings on flushing the oil system with special liquids;

- the bad habit of not changing the oil, but adding it as it decreases;

- use purified surrogates instead of normal high-quality oil.

If flushing was not used when changing the oil, as an option, you can pre-install and use a cheap simple filter. After a hundred kilometers, most of the dirt will be deposited on such a filter, and it will need to be replaced with a new high-quality version. But such a recipe is only allowed when using high-quality oil with good detergent additives.

The habit of adding oil instead of replacing it is typical for owners of old, worn-out engines. The amount of sludge deposits and varnish films compensates for metal wear in rubbing surfaces. In such cases, the filter may leak after a large amount of gasoline and water gets into the engine sump, even in relatively mild frost.

The high cost of good motor oil has led to the emergence of special cleaning technologies that make it possible to clarify used oil, increase its viscosity and remove foreign odors. But even after the cleaning procedure, such a lubricant contains a significant amount of hydrocarbons, which easily turn into varnish films and sludge, tightly clogging the filter cartridge.

What are the differences and types of oil filters?

Currently, several types of oil filters are produced. They are:

The difference between the types of oil filters is as follows:

- The main oil flow from the pump in a full-flow filter is passed through the filter elements. This means that completely purified oil is supplied to the engine components and assemblies. The fundamental role in this design belongs to the bypass valve, which regulates the pressure level in the motor.

- Cleaning the oil from impurities when using a partial flow filter requires more time. The part has two circuits: in the first, oil circulates freely, passing from the pump to the rubbing parts, in the second, it is passed through the cavity of the filter element. The cleaning quality is higher than when using a full-flow filter.

- The combined version combines both filtration methods. This cleans the oil even more thoroughly.

For carburetor internal combustion engines, you can use a filter that allows abrasive particles smaller than 20–40 microns to pass through. To ensure uninterrupted operation of the injection motor, you will have to purchase a part whose throughput does not exceed 10–15 microns.

How does oil purification occur in a diesel engine?

A diesel engine has even higher requirements for oil purity, and therefore it is unacceptable to use filters used on gasoline engines. Before the oil enters the diesel engine, it goes through three stages of purification:

- preliminary, which is carried out in the fuel tank;

- rough;

- thin.

At each stage, different types of filters are used.

Using fake low quality oil filters

The problem of counterfeit products is especially relevant during the winter period of operation or the engine break-in period. First of all, counterfeits use low-quality materials for the filter layer, rubber seal and bypass valve elements.

One of the noticed defects that catches the eye after the oil filter has been squeezed out is a violation of the geometry of the box:

- swollen sides of the body;

- extruding the cover with a threaded bushing “into the dome”;

- deformation and extrusion of the valve rubber.

You can easily determine the quality of the oil filter by blowing into the inlet hole. In a fake, the weak valve petal will easily open; in the original product, it will not be possible to overcome the valve resistance by simply exhaling. In addition, it is worth paying attention to the condition of the filter “accordion” and the rubber ring of the seal.

If the edges of the paper are folded unevenly or are unevenly colored, or metal burrs are visible inside the center core, this is a fake. It is worth paying special attention to the elastic band. The height of the ring above the surface of the lid should not be more than 0.8 mm; the material is quite elastic and rigid, but not hard. Soft rubber will not withstand high pressure - it will instantly deform and be squeezed out of the groove.

A characteristic feature of VAZ cars is the tendency for the pressure relief valve on the engine oil pump to jam. This often happens due to dirt getting into the lubricant or engine overheating. Therefore, if there are repeated episodes of lubricant leakage, do not puzzle over why the oil filter is being squeezed out, but clean and adjust the operation of the pump.

Attention! One of the reasons why oil flows from under the oil filter may be a violation of the perpendicularity of the position of the central fitting onto which the filter is screwed. After installation, the filter housing and cover do not adhere to the flange surface evenly and evenly, but at a barely noticeable angle. In this case, the rubber seal will not provide the necessary tightness, and lubricant will leak under any conditions on any filter. The cause of such a defect may be impacts on the filter housing or excessive force during removal.

Video about what to do if the oil filter gasket is pressed out:

Motor oil performs several functions: it lubricates rubbing parts, cools and lubricates them. Without engine oil, the engine will immediately stall - the first to fail will be the crankshaft liners, which will turn into foil, and there will also be scuffing on the crankshaft itself. In principle, other parts will not have time to fail, since the liners without oil turn into foil within a minute.

Oil starvation of the engine leads to irreversible consequences - in addition to cheap bearings, the crankshaft is damaged. And it often happens that the scuffs on the crankshaft remain larger than the last repair size, which means purchasing a new expensive part.

Engine oil starvation does not mean that there is no oil at all, just that some parts did not have enough of it due to a low level, low throughput of the lubrication system due to clogging or other reasons. It is not necessary that the entire engine does not receive oil; most often, individual engine components do not have enough oil.

Video “What to do if consumables leak”

You can learn how to solve the problem of leakage of consumables from this video.

While operating a car, car owners often encounter trouble in the form of a leak from the oil filter. A puddle that forms under a car is an unpleasant situation and exciting for the driver. An oil leak in the filter area does not bode well, as it hides a number of unfavorable factors. This problem can occur both in a used car and in almost new internal combustion engines.

Causes of engine oil starvation

There may be several reasons.

- There is not enough oil in the engine - the level is low, someone leaked it and did not top it up

- The oil has not been changed for a long time, it has thickened, collected in pieces on the walls of the engine and does not flow into the sump

- The oil receiver screen is clogged

- The oil filter is clogged and the bypass valve is stuck

- The oil injectors are stuck in the open position and the pressure in the system has dropped

- The pressure reducing valve on the oil pump is broken and oil flows through it into the return line.

- Oil channels clogged

- Come up with a reason yourself (if possible, write down in the comments what other reasons there may be)

1. Any engine consumes oil due to waste - some more, some less. If you don’t look under the hood and check the oil level for a long time, then at one point the oil will become so low that it will no longer reach the oil receiver. First, this will happen when the car leans over while climbing a hill, then when it turns at speed and the oil, under the influence of centrifugal force, rushes away from the oil receiver. It is, of course, small things, but gradually the oil will become less and less, but it will stop flowing to the most remote corners of the engine.

2. When the oil is not changed for a long time, some kind of thick and non-flowing fuel oil is formed in it, which likes to collect on the walls of the block and in the head. The liquid fraction is becoming less and less, and hence we look at point 1. This happens especially often on modern cars, on which the manufacturer recommends extended oil change intervals (Long Life, up to 30,000 km). And if at the service you come across not very responsible technicians who do not drain all the old oil, there will be problems. Change the oil at least once every 10,000, or better yet, more often.

3. The dung that forms in the old oil (see point 2) can clog the oil receiver screen and then the oil will stop flowing into the lubrication system. Although the grid becomes clogged for other reasons.

4. The oil filter consists of a housing and the actual paper filter element. All the smallest particles of dirt clog the pores in the paper and over time the filter's throughput is lost. To prevent oil starvation when the filter is clogged (usually this does not happen if you change the oil on time, although how much dirt gets into the engine also depends on the air filter and operating conditions on dusty roads), the filter has a bypass valve - in In the normal position it is closed, but as soon as the flow capacity is lost, the valve opens under the influence of vacuum created by the oil pump. When the valve jams, naturally the oil will not come from anywhere, and less and less oil will circulate through the lubrication system with less pressure.

5. Some engines, mostly turbocharged ones, have oil injectors that spray oil onto the pistons to cool them. The injectors open under pressure, and when there is no oil pressure in the system, they close. If the injector is faulty and opens, the pressure in the system will decrease, which means the oil will not reach remote corners of the engine. Although if you have a budget foreign car with a low-power engine, such as a Ford Focus or Chevrolet Aveo, then you should not worry - they do not have such a system

6. The oil pump has a pressure relief valve, which is designed to relieve excess pressure. If it jams, the pressure in the system will drop, especially at low speeds, which will lead to oil starvation.

7. The engine lubrication system consists of oil channels. The most vulnerable part is the crankshaft. The crankshaft has oil channels through which oil flows from the main journals to the connecting rods. These channels are very narrow and can very easily become clogged with all sorts of dirt, which will lead to oil starvation of the connecting rod bearings.

8. You can come up with some other reasons, if you missed something, write in the comments

Repairing oil leaks

Oil leaks harm your engine

In automobile engines, motor oil is used to lubricate internal moving parts - the crankshaft, connecting rod bearings, pistons and valve train. This oil is kept from leaking from major engine parts by a set of caps, gaskets and seals.

There are two types of leaks, in which the oil may be under pressure or not. Oil leaks without pressure, by gravity, are less aggressive, while leaks under pressure are dangerous. If the leak is difficult to locate, clean the engine with a strong detergent, run it for a short time and check again using a flashlight. Start checking from the top of the engine and work your way down.

What Causes These Failures

Over time, engine gaskets and seals become hard and easily crack when exposed to heat. When this happens, oil is able to leak out and contaminate surrounding surfaces or the exhaust system. There it burns, creating smoke coming out from under the hood.

These types of oil leaks can be identified by the smell coming from the air conditioner or interior heater. If the gasket on the oil filter or pressure sensor mount fails, pressurized oil in the engine may leak out while the engine is running. Such leaks can leave the engine without oil in a short period of time.

In most cases, you will need to jack up the car and place it on stands to gain access to the underside of the car. Use a flashlight, safety glasses and gloves when working.

1. Leakage from under the filler cap

The oil filler neck is used to add oil to the engine and is located on the cylinder head cover. If the cap is loose, the gasket under it has become unusable, or was installed incorrectly after the next addition of oil, then all this can cause a leak. Check the area around the cover for leaks and, once the cause has been determined, replace or secure the cover in its place.

2. Leaking oil filter

The oil filter is designed to remove carbon deposits and other contaminants that arise during fuel combustion. This filter operates under pressure created by the oil pump and may leak if the mounting is loose. Another reason may be that after the next filter replacement, the gasket was not replaced, which no longer fits properly.

Use a flashlight when checking the filter, change the gasket or tighten the filter more, and then check again for leaks. After this, thoroughly wipe everything around and repeat the check after a while.

3. Leakage from under the engine crankcase drain plug

The drain hole is used to remove oil from the engine. This is a threaded plug with a gasket that seals the connection between the plug itself and the hole in the engine crankcase. If the plug is loose or the sealing gasket is worn out, an oil leak may occur.

Make sure that the leak is coming from under the plug and then check how tightly it is tightened. If the plug is loose and the threaded connection is not tightened, it means that the thread on it has been torn off - it is necessary to replace the plug or repair the engine sump. It often happens that the plug is tightened, but oil continues to flow out - this is due to a worn gasket. To replace it, you will need to drain the oil from the pan.

4. Oil pressure sensor leaking

The oil pressure sensor is used to exchange information with the electronic control unit for engine and transmission systems, with a pressure indicator and a warning light on the dashboard. This sensor operates under the same pressure as the oil filter and can leak if it malfunctions. It is located below the oil filter and has one to two cable connections.

5. Leaking from under the valve cover

The valve cover closes it and prevents oil from splashing out. It is installed on the cylinder head, with a gasket between them. Due to exposure to engine heat and over time, this gasket can become brittle and begin to crack, allowing oil to leak. In some cases, the cover may become loose during operation, which will also cause the above-mentioned oil leak.

Sometimes the leak is fixed by tightening the fastener. If this does not help, you need to replace the gasket with a new one. This gasket failure is a common problem because the cylinder head is the topmost part of the engine that experiences the most heat.

6. Leaking front main oil seal of the engine crankshaft

This seal is used at the front of the engine, which seals the outward end of the crankshaft connected to the front vibration damper. It is installed on the polished part of the shaft and keeps the oil from leaking. When the oil seal fails, oil begins to splash onto the front of the engine and its sump. Use a flashlight to make sure that's where the leak is coming from. If so, replace the seal.

7. Timing chain cover leaking

This cover is installed on engines with a chain drive timing mechanism. The cover is sealed against oil leakage from the engine block using a gasket. If the gasket deteriorates due to heat or age, an oil leak may occur.

This type of leak can be difficult to determine due to the close location of the cover to the front crankshaft oil seal. When replacing the gasket on the chain cover, it is recommended to replace the crankshaft oil seal.

8. Crankshaft bearing rear oil seal leaking

The rear oil seal performs the same functions as the front oil seal, but is located at the rear of the engine. When it begins to leak, engine oil leaks into the transmission bell housing and onto the engine sump. Replacing this oil seal is more labor-intensive because it will require preliminary dismantling of the transmission.

9. Oil cooler adapter leaking

Some engines are equipped with an oil cooler with an adapter with a built-in thermostat. If the seal has become unusable, it will no longer contain leaks between the block and the ring-shaped seal. The cause of the malfunction is heating and vibration during engine operation. Use a flashlight to check the source of the leak and make sure it is not the oil filter but the adapter.

10. Oil level sensor leaking

Some cars have an oil level sensor. It is used to communicate with the vehicle's electronic control unit and to illuminate the oil level warning light on the dashboard. This light indicates to the driver that the engine oil level is low. The oil level sensor has a two-wire connection, is located on the side of the oil sump and is immersed in the engine oil. The mount to the pan is sealed with an O-ring, which can harden over time and begin to leak oil. In this case, it is necessary to drain the oil and replace the gasket.

11. Leak from the engine crankcase

The crankcase is located under the engine and is attached to it with a large number of bolts. The mount is sealed using a gasket. The purpose of the crankcase is to collect oil in one place so that the oil pump can pump it back into the engine's lubrication circulation system. If the crankcase itself or the gasket installed between it and the engine is damaged, oil will leak out. In any case, the pan must be removed and the gasket replaced. Depending on the design of the car, this work can be difficult or quite easy.

12. Leak in inlet manifold

In most V6, V8 and V10 cylinder engines, the intake manifold connects the cylinders together and at the same time protects the cylinder block at the top of the engine from leaks. Over time, oil seals and gaskets age and deteriorate, which causes oil leaks. Unfortunately, this type of malfunction is not easy to fix - this will require dismantling the manifold and replacing the gaskets.

13. Oil leakage from under the cylinder head

Overhead camshaft engines have passages that carry oil under pressure to lubricate the camshaft and valve lifters. The head gasket is responsible for sealing the engine oil that circulates between the cylinder block and its head. This type of leak is difficult to identify due to the engine components making it difficult to locate the fault. These are mainly the exhaust and intake manifolds. Fixing such a problem is also quite difficult - to repair it you need to remove the cylinder head and replace the gasket.

14. Leaking ignition distributor

On engines with an ignition distributor, an annular seal is used, located outside the distributor housing, which is mounted on the engine housing. When the seal becomes hard and cracks, oil begins to leak from the base of the distributor. This problem is easy to identify since its source is located on the top of the engine. To eliminate the malfunction, it is necessary to dismantle the distributor and replace the gasket

Consequences of engine oil starvation

The consequences are terrible. For example, when the crankshaft rotates, it does not come into contact with the liners; there is always oil between them, the so-called oil wedge. But when there is not enough oil, it stops flowing to the crankshaft and liners, then this oil wedge disappears and the shaft begins to rub against the liners and from friction and the resulting increased temperature, the shaft wedges, but since it continues to rotate by inertia, this wedge breaks off, thereby thereby tearing out the surface layer of metal from both surfaces. The result is an insert in foil, deep scuff marks on the crankshaft.

If the oil pressure methodically begins to decrease little by little in the system, that is, less of it passes through the pipeline, the crankshaft connecting rod bearings will be the first to suffer, since they are located the farthest away and the oil approaches them according to the residual principle.

But before this, the hydraulic compensators will most likely start knocking (if they exist, of course), and the turbine also suffers greatly from oil starvation.

If oil suddenly suddenly stops flowing into the lubrication system, then most likely the main bearings will go first, since they are closest to the pump and receive the first batch of oil.

Restoring such an engine is very difficult and expensive; in addition to replacing the liners, you need to grind the crankshaft if it falls within the repair size or buy a new one.

Oil in any engine serves as protection against excessive friction between interacting mechanisms. But during operation, it inevitably becomes clogged with particles of soot and similar debris. To get rid of this waste, an oil filter is used, which, passing oil through itself, traps foreign particles. Over time, the filter becomes very clogged and needs to be replaced.

Oil filter device

Most filters for modern cars are non-separable and consist of:

- The filter housing itself;

- Filter material inside the housing;

- Anti-drain valve;

- An anti-drainage valve that closes when the engine is stopped, preventing oil from leaking out of the filter. While the engine is running, it is constantly open;

- A bypass valve is needed if the oil cannot pass through the filter without delay.

Sometimes problems occur in the oil purification system. The reasons for this are usually:

- The oil filter replacement period has passed, and the dirty filter cannot cope with the job.

- Oil viscosity does not correspond to outside temperature. Many manufacturers recommend using low viscosity oil for the winter.

Symptoms of a clogged oil filter

To tell for sure whether the oil filter is clogged, you will need to completely disassemble it. Since the filters are mostly not dismountable, this procedure is not cost-effective. But you can determine whether the filter is clogged by a number of indirect signs:

- The engine temperature becomes too high and constantly remains above one hundred degrees (the normal engine temperature should be about 90-100 degrees), which can lead to boiling of the internal combustion engine.

- Fuel consumption becomes unusually high.

- The engine runs intermittently, the speed fluctuates.

- The power drops, and a decrease in dynamic parameters is observed.

Washing a clogged filter, is it worth doing?

Car enthusiasts in the eighties often washed clogged oil filters using kerosene or gasoline. It is worth noting that the filters then were collapsible and quite large. There were also often problems with purchasing consumables, so car enthusiasts had to do the washing. Nowadays, few people do filter washing, filters are inexpensive, and the labor-intensive process does not give a 100% result. If you decide to wash the filter, most likely you have an exclusive car, for which consumables are incredibly expensive or simply do not exist.

The washing process begins with removing the filter, for which a special puller key is used. Kerosene is poured into the filter, but it is better to use kitchen cleaners to remove stubborn dirt. After an hour, the filter should be shaken thoroughly and rinsed with strong water pressure. This soaking and rinsing procedure should be repeated several times.

After all washings, it is recommended to blow out the filter with a strong stream of compressed air. As a result, you will either receive a filter that is 80 percent cleaned, or the filter element will not withstand the aggressive effects of chemicals and will fall apart. It is not a fact that after cleaning the filter will perform its functions well.

Types of oil filters

Oil filters come in the following types:

- Full-threaded. In them, the entire oil flow is passed through a filter, and already purified oil is supplied to the engine. The main role in these filters is played by the bypass valve, which regulates the oil pressure in the engine.

- Partial flow. They have two purification circuits, in one it passes freely, in the other it is filtered. The quality of such cleaning is much higher than that of the first option, but the price is much higher.

- Combined. Combines the advantages of both types of filtration. They clean oil perfectly, but their price is high.

If you are the owner of a car with a carburetor engine, you can use inexpensive coarse filters that allow particles larger than 20 microns to pass through. Injection engines require filters that do not allow particles larger than 10 microns to pass through.

Oil filters produced for gasoline engines are not suitable for diesel cars. Diesel is more demanding on oil quality, so cleaning is carried out more thoroughly. Due to this, the size of diesel filters, as a rule, exceeds the size of gasoline filters.

Oil filter in turbocharger operation

We all know that oil plays a key role in the long-term operation of a turbocharger, and often it is oil (oil contamination, untimely replacement, etc.) that causes turbocharger failure. Dirty oil kills the turbocharger, it affects the turbine much more than any other part of the diesel engine. Under extreme loads, the rotation speed of the turbine shaft can be 250 rpm, and at this time, engine oil is the only thing that cools the turbine, gives it lubrication and prevents metal parts from rubbing against each other. That's why it's vital to keep your oil clean and your oil filter in good working order—the best protection for your turbocharger and engine. The turbocharger has to work under difficult conditions: at high speeds and at high temperatures, and clean filtered oil will protect the turbine from wear.

As mentioned above, a lot of contaminants remain on the filter element that the system cannot remove on its own, so do not forget to check the cleanliness of the filter from time to time and change it if necessary. An oil filter will extend the life of your turbocharger and engine.

Oil filter

, in English it sounds like an oil filter - ensures the purification of engine oil from foreign impurities that enter there during the circulation process. It can undoubtedly be called one of the key elements of the lubrication system of any internal combustion engine. The oil filter is located at the bottom of the engine.

Is it worth paying extra for a branded filter?

The instructions for replacing the oil filter in your car's manual provide for the use of original filters recommended by the manufacturer. The advantages of the original are a guarantee, full compatibility and quality of workmanship. There is only one minus - the price. The non-original has one main advantage - low cost. There are a lot of minuses. These are low-quality materials, rough processing, and sizes that do not match the original. Often, having saved on a filter, you can lose a lot of money on repairing an engine ruined by using a low-quality filter, which may not clean the oil at all. It is better to choose a filter from well-known brands such as Bosch, Filtron, or Goodwill.