Parts and spare parts, maintenance, service and repair

GAZ cars

ZIL cars

KAMAZ vehicles

MAZ cars

KRAZ cars

URAL cars

- URAL-4320, 5557

- Engine YaMZ-236

- __________________

- MAP OF SITE

Maintenance and adjustment of the GAZ-66 steering

The steering mechanism of the GAZ-66 car consists of a globoid worm and a roller meshed with the worm.

The upper part of the GAZ-66 steering shaft is pivotally connected to the lower part. The column is also hinged to the cabin. This design of the steering shaft and its fastening makes it possible, if necessary, to tilt the vehicle's cabin.

Fig.1. Steering shaft GAZ-66

1 — steering wheel; 2—bearing; 3—adjusting washers; 4—upper steering shaft

The upper part of the steering shaft, placed in the steering column of the GAZ-66, rotates on two ball bearings 2 (Fig. 1).

To prevent axial movement of the shaft in the steering column, when the steering wheel is on, adjusting washers 3 are used, which are installed between the end of the hinge fork and the spacer sleeve of the lower ball bearing. After adjustment, the shaft should rotate easily.

Steering rods GAZ-66

The steering drive consists of steering rods equipped with ball joints. The transverse steering rod has threads at the ends for screwing on ends, with which you can change the length of the rod and thereby adjust the toe-in of the front wheels,

A power steering valve is attached to the front end of the GAZ-66 steering rod.

If for some reason the valve has been removed, the tension of the ball pin springs should be checked and, if necessary, adjusted.

When tightening the two bolts securing the valve and the rod, you need to center the body along the spool, checking the freedom of movement of the latter.

After assembling the power steering valve with the rod, the rod end cup with the spool must move freely in the longitudinal direction by the amount of the working stroke (3.4 mm).

When assembling the steering rod joints, you need to lubricate them generously.

Power steering GAZ-66

The GAZ-66 hydraulic power steering reduces the force that must be applied to the steering wheel to turn the front wheels, reduces shock loads in the steering mechanism resulting from road unevenness, and increases traffic safety, allowing you to maintain control over the direction of movement in the event of front tire rupture.

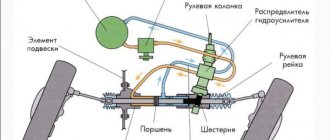

The hydraulic booster consists of a pump, control valve, power cylinder and oil lines.

The GAZ-66 power steering pump with a reservoir is installed on the engine. It is driven by belts. The pump, with the exception of the pulley and calibrated hole in the cover, is completely unified with the power steering pump of the ZIL-130 car.

Fig.2. Power steering pump (power steering) of the GAZ-66 steering drive

1 - blade; 2 - cover; 3—mesh filter; 4 - tank; 5 — filter bypass valve; 6 - collector; 7 — safety valve; 8 - bypass valve; 9 — pump cover; 10 - distribution disk; 11 — starter; 12 — rotor, 13 — pump shaft; 14 - pulley

The GAZ-66 power steering pump is of a vane type, double-acting, and has two valves located in cover 9 (Fig. 2).

Safety valve 7, placed inside the bypass valve, limits the oil pressure in the system, opening at a pressure of 6500-7500 kPa (65-75 kgf/cm2).

Bypass valve 8 limits the amount of oil supplied by the pump to the control valve as the engine speed increases.

A tank 4 for oil is installed on the pump. A breather is screwed into the reservoir cap to limit the oil vapor pressure inside the reservoir.

All oil returning to the power steering pump passes through a strainer.

In case of filter clogging, a bypass valve 5 is provided. In addition, a filler strainer 3 is installed in the tank.

Adjusting the steering of a GAZ-66 car

Set the front wheels to the straight-ahead position.

Check the steering wheel play and if the steering wheel play, after eliminating the looseness in the tie rod and steering linkage fastenings, exceeds 25° with the engine running (10° for a vehicle within the warranty period), it is necessary to adjust the longitudinal tie rod and steering joints mechanism.

Adjusting the steering rod joints of the GAZ-66

Unscrew the rear hinge plug and tighten it until it stops, then unscrew and tighten it.

To adjust the front hinge of the longitudinal steering rod, it is necessary to remove the power steering control valve, for which, having unscrewed two bolts, remove the stamped cover 11 (Fig. 3) with the gasket, undo the cotter pin and unscrew the nut 10 of the central bolt 3 and wrap the two bolts securing the housing 2 of the control valve to rod tip.

Fig.3. The front end of the GAZ-66 steering rod and the power steering control valve

1—gasket; 2—valve body; 3—central bolt; 4—spool valve; 5—cup nut; 6—pin; 7—longitudinal steering rod; 8—steering bipod; 9—ball finger; 10—nut of the central bolt; 11—cover

Turn the bipod 8 so that the cup with nut 5 comes out of the tip forward and you can remove the pin 6.

Tighten nut 5 as far as it will go, and then unscrew it, insert pin 6 into place, push the glass with nut 5 inside the tip and install the control valve.

The tip cup should move freely in the axial direction by 3.4 mm. If the steering wheel play remains greater than normal, the steering mechanism must be adjusted.

Adjusting the worm bearings of the GAZ-66 steering mechanism

Before adjusting the worm of the GAZ-66 steering mechanism, you must make sure that there is axial clearance in the worm bearings. To do this you need:

— tilt the car cabin;

— disconnect the steering shaft hinge fork from the worm shaft;

— disconnect the longitudinal rod from the bipod;

- shake the bipod with your hand. If in this case the worm shaft of the steering mechanism has axial movement relative to the upper cover of the steering housing, then the worm bearings require adjustment.

Adjust the worm of the GAZ-66 steering mechanism in the following sequence:

— Loosen the bolts of the lower crankcase cover and drain the oil. Remove the lower crankcase cover and remove the thin adjusting (paper) shim. Reinstall the crankcase cover and check the worm bearings for longitudinal play. If the play has not yet been eliminated, then you should remove the thick gasket and put the thin one back.

— After eliminating the play, remove the shaft of the GAZ-66 steering bipod, connect the fork of the lower hinge of the steering shaft with the worm shaft and check the force required to rotate it on the steering wheel rim. It should not exceed 0.3-0.5 daN (0.3-0.5 kgf).

— Assemble the steering mechanism, tighten the fastening bolts and fill the crankcase with oil to the level of the lower edge of the filler hole. Insert your finger into the bipod hole, screw on the nut and secure it with a cotter pin.

Adjusting the engagement of the working pair of the GAZ-66 steering mechanism

The clearance in the engagement of the working pair of the steering mechanism is considered acceptable if the play at the lower end of the bipod when the wheels are positioned for straight movement and the worm bearings are correctly adjusted is no more than 0.3 mm.

If the play exceeds this value, then it is necessary to adjust the engagement to bring the play to zero, since operating the vehicle with excessive play leads to failure of the steering mechanism.

Fig.4. Steering mechanism GAZ-66

1—cork; 2—worm; 3—gasket; 4—three-ridge roller; 5—bipod shaft; b—crankcase; 7—lock washer; 8—nut; 9—adjusting screw; 10—roller axis; I—val; 12—locking pin; 13—oil seal; 14—steering bipod

The sequence of the operation for checking and adjusting the engagement of the working pair of the GAZ-66 steering mechanism is as follows:

Design, maintenance and malfunctions of the GAZ-66 power steering

The power steering pump (Fig. 1) is of a double-acting vane type, i.e., for one revolution of the pump rotor, two complete suction and two discharge cycles are performed

The pump rotor contains vases in which the blades are placed. The blades should move freely in the vases without jamming.

In the suction cavities, oil enters the space between the blades and is then forced out into the discharge cavities. Oil is forced out by reducing the volume between the blades as the rotor rotates inside the stator, which has a special profile.

An oil reservoir is installed on the pump. There is a filler filter under the reservoir cap, and a strainer is installed on the drain hose through which the oil returns from the system to the pump.

The pump cover contains two valves. The safety valve (internal) limits the maximum pressure in the system to 65-70 kg/cm2.

The bypass valve limits the amount of oil that the pump supplies to the power steering system at increased engine speeds. The valve is designed in such a way that no more than 10 l/min of oil is sent to the hydraulic booster system.

Excess oil is bypassed inside the pump and goes back into the suction cavity.

The control valve is located at the front end of the tie rod.

Inside the valve body there is a spool, which is connected through intermediate parts to the steering arm pin.

The spool is sealed at both ends with rubber cuffs.

When the spool is in the middle position (the car is moving straight), the oil flowing through the discharge hose into the control valve is bypassed through the gaps between the ends of the spool journals and the channels in the body into the drain hose and returns to the pump reservoir.

When the steering wheel is turned, the bipod pin moves the spool, which, blocking the channels in the valve body, directs oil under pressure into one or another cavity of the power cylinder (depending on which direction the turn is made).

The power cylinder rod, connected to the tie rod, moves it, turning the front wheels.

After the end of the rotation, the spool is set to the middle position, the oil pressure in the power cylinder decreases, and the oil from the valve returns back to the pump without entering the power cylinder.

The double-acting power cylinder is mounted in a bracket on the front axle housing through a ball joint.

The rod piston is sealed with two elastic cast iron rings.

The cylinder rod is chrome plated to improve wear resistance and protect against corrosion.

The exit of the rod from the cylinder is sealed with a rubber cuff. To protect against dirt, brass washers and a felt seal are installed on the outside. The power cylinder, in addition to turning the front wheels, also absorbs impacts from the wheels when driving over various irregularities.

Power steering maintenance

The power steering pump drive belts are tensioned by tilting the pump housing. The angle of inclination of the pump housing should not be too large and should ensure that oil can be filled into the pump reservoir.

If tilting the pump housing does not ensure tension of the belts, move the pump to the holes in the bracket, and if the belts are stretched too far, move the pump brackets to additional holes in them.

With normal belt tension, the deflection of each belt between the compressor and power steering pump pulleys should be 15-20 mm when the belt is pressed with a force of 4 kg.

When checking the oil level in the power steering reservoir, the front wheels of the vehicle must be installed straight.

Add oil while the engine is idling to the “oil level” mark on the wall of the pump reservoir or, if there is no mark, to the filler filter mesh.

Before removing the tank cap to check the level, top up or change the oil, it must be thoroughly cleaned of dirt and washed with gasoline.

Fill the oil through a funnel with a double mesh and a filler filter installed in the pump reservoir.

If the filters are significantly clogged with tar deposits, additionally rinse the filters with solvent No. 646, used when painting a car.

During operation, regularly monitor the tightening of the bolts securing the pump and its brackets and the bolts securing the control valve to the longitudinal link.

Regularly check the tightness of the ball pin nut securing the power cylinder to the bracket. Loosening the tightening of this nut leads to the loosening of the ball pin in the conical hole of the bracket.

Periodically check the tightness of the power cylinder rod nut and the condition of the rubber pads through which the rod is attached to the rod bracket. When the rubber cushions wear out, they must be replaced.

Oil change

To change the oil, lift the front wheels of the car and open the lid of the power steering pump reservoir.

To drain the oil you must:

— disconnect the discharge and drain hoses from the control valve body and drain the oil from the pump through them;

— disconnect the hoses from the power cylinder fittings; and drain the oil from both the control valve;

drain the oil from the power cylinder by slowly turning the steering wheel left and right until it stops.

After draining the oil, flush the power steering system with fresh oil. The filter meshes are washed separately.

To add fresh oil you need:

— connect all hoses;

— pour fresh oil into the tank up to the “oil level” mark and pump the oil at a low speed of the engine crankshaft, turning the steering wheel 2-3 times all the way in both directions without delay in the extreme positions.

When pumping oil, monitor the level in the tank and add oil if necessary. The total capacity of the power steering system is about 1.8 liters of oil;

— install the tank lid with a sealing gasket, a rubber ring for the lid fastening stud and a washer and secure with a wing nut.

Tighten the wing nut only by hand. If oil leaks from under the cover, replace the cover gasket.

Driving a car with the power steering not working

The car's steering allows you to continue driving even if the power steering is faulty. It should be borne in mind that the force required to turn the car on the steering wheel will increase.

To continue driving with a faulty power steering, turn off the pump by removing the drive belts.

To reduce the force on the steering wheel, if the power steering is damaged, drain the oil from the power steering system.

If the power cylinder is damaged or malfunctioning, remove it.

Long driving with a faulty power steering is not recommended.

Checking the free play of the steering wheel. The free play of the steering wheel is determined by the adjustment of the steering gear engagement and the design features of the hydraulic booster.

When the hydraulic booster is not working, the free play of the steering wheel is greater than when it is working. This is a design feature of the hydraulic booster.

The maximum permissible free play of the steering wheel with the power steering running is 60 mm around the circumference of the steering wheel (or 15°), with the power steering not working 120 mm (or 30°).

Repair of hydraulic pump ZIL-131

Disassembling and checking the pump

Before disassembling, the pump must be removed from the car, after draining the oil from the pump and cleaning and rinsing its outer surface.

The procedure for disassembling and checking the pump:

1. Remove the tank cap and filters.

2. Remove the tank by unscrewing the four bolts.

3. Install the pump so that its shaft is vertical and the pulley is at the bottom, and remove the pump cover by unscrewing the four bolts. When removing the cover, keep the valve from falling out

4. Mark the position of the distribution disk relative to the stator and remove it from the pins.

5. Mark the position of the stator relative to the pump housing and remove the stator (the arrow on the stator indicates the direction of rotation of the pump shaft).

6. Remove the rotor along with the blades.

The stator, rotor and pump blades are individually selected at the factory, so their completeness cannot be disturbed during disassembly. The blades cannot be swapped either.

When replacing the stator, rotor and blades, install them only as a complete set

7. If absolutely necessary, remove the pulley, retaining ring and pump shaft along with the front bearing.

If there is a large bearing (see Fig. 1, b), remove it only if necessary, since this may damage the oil seal and will need to be replaced.

When installing new bearings and seals, take precautions against damage to the seal lips.

8. Check that the bypass valve moves freely in the pump cover and that there are no nicks or wear.

The valve and pump cover are selected individually at the factory, so their completeness cannot be disturbed during disassembly. If necessary, clean out the nicks or replace the complete parts.

9. Check the tightness of seat 16 (Fig. 1) of the safety valve and, if necessary, tighten it.

10. Check for dirt in all channels of the pump parts and clean the channels.

11. Check for scoring or wear on the end surfaces of the rotor, housing and distribution disc. In case of minor scuffing or wear, rub these surfaces on the plate, then rinse the parts thoroughly.

12. Check whether the blades move freely in the rotor grooves and whether they are excessively worn.

Pump assembly

1. We perform assembly in reverse order.

2. Install the stator-rotor with blades and the distribution disk in accordance with the marks made during disassembly and the arrow indicating the direction of rotation. In this case, the chamfer of the spline hole should face the pump housing.

3. Install the cover with the bypass valve. The hexagon of the valve seat must face the inside of the hole.

4. The tightening torque of the M6 bolts securing the tank should be 0.6-0.8 kgm.

5. The tightening torque of the nut securing the pump pulley should be 5.0-6.5 kgm.

6. The pump shaft should rotate freely, without jamming.

Checking the pressure developed by the pump

The check must be carried out by installing a special device between the pump and the high-pressure hose (Fig. 2), which has a pressure gauge with a scale of up to 80 kg/cm2 and a valve that closes the oil supply to the hydraulic booster.

To check, you need to open the valve and turn the wheels all the way; The oil pressure at low engine idle speed must be at least 60 kg/cm2.

If the oil pressure is less than 60 kg/cm2, then you need to slowly close the valve, monitoring the increase in pressure on the pressure gauge.

If the pump is working properly, the pressure should rise and be at least 65 kg/cm2. In this case, the fault must be looked for in the steering mechanism. If the pressure does not increase, the pump is faulty.

If the pressure with the valve closed is greater than the pressure that was with the valve open, but below 60 kg/cm2, then both components are faulty.

When checking, do not keep the valve closed for more than 15 seconds and the wheels turned all the way.

The check should be carried out at an oil temperature in the tank of 65-75 ° C.

If necessary, the oil can be heated by turning the wheels from lock to lock and holding them at the stops each time for no more than 15 seconds.

Bleeding power steering gas 66

GAZ-66-11. Power steering (power steering)

Hydraulic power steering (power steering) reduces the force that must be applied to the steering wheel to turn the front wheels, reduces shock loads in the steering mechanism resulting from uneven roads, and improves driving safety by allowing you to maintain control over the direction of travel in the event of a front tire failure. wheels. The hydraulic booster consists of a pump (Fig. 139), a control valve (see Fig. 137), a power cylinder (Fig. 140) and oil lines.

The power steering pump with reservoir 4 (see Fig. 139) is installed on the engine. It is driven by belts. The pump, with the exception of the pulley and calibrated hole in the cover, is completely unified with the power steering pump of the ZIL-130 car. The pump is a vane type, double acting, has two valves located in the cover .9. Safety valve 7, placed inside the bypass valve £, limits the oil pressure in the system, opening at a pressure of 65.75 kgf/cm2. Bypass valve 8 limits the amount of oil supplied by the pump to the control valve as the engine speed increases. A tank 4 for oil is installed on the pump. A breather 3 is screwed into the tank cap to limit the oil vapor pressure inside the tank. All oil returning to the pump passes through strainer 2. In case the filter becomes clogged, a bypass valve 5 is provided. In addition, a filling strainer is installed in the tank.

The operating diagram of the hydraulic booster is shown in Fig. 141. Pump 3 supplies oil under pressure to control valve 2, which is rigidly mounted on the longitudinal rod 5 of the steering control. Valve spool 1

control through the ball pin is connected to the bipod 4 of the steering mechanism.

Spool 1 can move relative to the control valve body 2 by 1.5 mm in both directions from the middle position. When the vehicle is moving in a forward direction, the control valve spool is in the middle position. In this case, the discharge line is connected to the drain line. When turning, the spool moves relative to the control body, thereby closing the gap between the spool and the body on the corresponding side of the central journal of the spool. As a result, the oil from the pump is directed to the corresponding cavity of the power cylinder 7, which moves the transverse rod 6 of the steering linkage, turning the wheels.

The oil is squeezed out from the opposite cavity of the power cylinder and returns through the drain line through the control valve to the power steering pump. The pressure in the power cylinder when turning is determined by the amount of resistance to turning the wheels. To move and hold the control valve spool when turning, it is necessary to apply a certain force to it, proportional to the oil pressure in the cylinder. Thanks to this, the driver gets a “feel for the road.”

Rice. 139. Power steering pump: 1—blade; 2—mesh filter; 3—breather; 4—tank; 5—filter bypass valve; 6—collector; 7—safety valve; 8—bypass valve; 9—pump cover; 10—distribution disk; 11—stator; 12—rotor; 15—pump shaft; 14—pulley

Rice. 140. Power cylinder of the hydraulic booster: 1-head fastening nut; 2—o-ring; 3—coupling bolt; 4—connecting coupling 5-cylinder; 6—piston ring; 7—rod with piston; 8—cylinder head; 9—rod cuff; 10—oil seal

Signs of malfunctions in the power steering system

There are several signs that the power steering system is airy, in which case it is necessary to bleed it. Among them:

- the appearance of strong noise in the area where the power steering or its pump is installed;

- increased pressure on the steering wheel , difficulty turning it;

- leakage of working fluid from the power steering system.

In addition, there are several other signs that indicate the system is becoming airy - the appearance of foam on the surface of the working fluid in the expansion tank, spontaneous turns of the steering wheel to one side. If you encounter at least one of the described symptoms, it means you need to bleed your power steering.

Do-it-yourself ways to fix breakdowns

One of the common problems is a lack of working lubricating fluid in the system or the use of low-quality oil. Therefore, every ZILovod should know how to replace consumables.

The system is equipped with a filter element that is washed with gasoline, but if there are deposits on it, the filter element should be washed with a solvent:

- To drain the oil, turn the steering wheel all the way to the left.

- Next, the drain hole is opened and the steering system housing cover is unscrewed. The container is inserted and the consumables are drained. When the liquid has stopped flowing and dripping, the draining procedure can be considered complete.

- When the draining is complete, remove the remaining consumable fluid from the tank; you can use a syringe with an extension tube for this. After these steps, you should wash the washer, sealing elements, and drain plug. It is necessary that all these components are clean and free from dirt. All mesh filters are also dismantled and washed, after which they are put in place.

- Using a funnel (preferably with a mesh), new oil, about one liter, is poured into the expansion tank, after which it must be drained from the system. When draining, the steering wheel must be turned in different directions until it stops.

- Next, the drain test is screwed in, and the steering wheel should be turned to the left until it stops. By closing the plug and turning the wheel, new oil can be added to the system, the liquid flows until the lubricant appears above the filter mesh. When filling, turn the steering wheel in different directions, this will allow the liquid to disperse evenly throughout the system. In total, the power steering system should include at least two and a half liters.

- Having done this, you need to start the power unit and let it run a little. During operation, the steering wheel must be turned left and right until it stops, while in the extreme right and left positions it must be held for three seconds with little effort. The lubricant will continue to spread throughout the system, so it will be necessary to add it little by little until it begins to appear above the mesh of the filler filter element. It is not necessary that the mesh be completely covered with liquid. Refilling the power steering system can be considered complete when bubbles no longer appear in the expansion tank due to air pockets leaving the lines.

- Next, the tank lid is put in place along with the seal, fixation pins and washer. Check for leaks in the system.

How to pump power steering

How to fill oil and bleed power steering

The procedure for replacing fluid and pumping power steering is carried out in strict accordance with the existing algorithm. Some automakers may add their own features to it. If you have a manual for your car, we recommend that you read the relevant section. In general terms, the steps must be performed in the following sequence:

- Raise the vehicle completely on a lift or with the front wheels off the ground.

- If necessary, drain the old fluid from the expansion tank. To do this, remove the return hose (going to the power steering system) from the expansion tank and put a plug on it so that liquid does not spill out of the hose. A hose leading to an empty bottle is connected to the released tap on the tank, where the old hydraulic fluid is supposed to be drained.

- It is most convenient to pump out the main volume of liquid with a syringe and pour it into a separate bottle. When there is very little liquid left, move on to the next point.

- Fill the expansion tank with working fluid to the top.

- Next, you should turn the steering wheel from side to side (from lock to lock) several times so that the old fluid remaining in the system flows out through the hose. Since the new fluid displaces the old, do not forget to monitor the oil level in the tank so that air does not get into the hose.

- If the fluid level drops, add it again.

- Start the engine for 2-3 seconds and turn it off. This is done so that the liquid begins to spread throughout the system.

Pumping out oil with a syringe

- Next, add working fluid to the tank to the MAX level and repeat the procedure by starting the engine. Repeat this cycle 3-5 times.

- The signal to stop pumping is the fact that air from the return hose stops entering the drain bottle. This means that there is no more air left in the hydraulic system and fresh, clean fluid enters the reservoir.

- After this, you need to reinstall the return hose (connect it to the expansion tank where it was originally installed).

- Refill the reservoir to the MAX level, then start the engine.

- To pump the hydraulic booster, you need to slowly turn the steering wheel 4-5 times from the left to the right stop. At the stop points, pause for 2-3 seconds. If there is any air left, it should escape into the expansion tank. During the inspection process, we make sure that the pump does not make any extraneous noise.

- An indicator that pumping has ended will be the absence of air bubbles on the surface of the liquid in the tank.

- After this, close the expansion tank tightly.

Bleeding the power steering system

can also be pumped without starting the engine , “cold”. To do this, just rotate the steering wheel from the left to the right stop . At the same time, old fluid and air leave the system. However, most automakers still recommend bleeding the system with the engine running.

The fluid level in the reservoir should be between the MIN and MAX marks . Remember that when heated, the liquid expands, so you should not pour it beyond the existing mark.

Rules for operating power steering

Power steering (power steering) ensures ease of rotation of the steering wheel when turning the wheels both on a stationary and moving vehicle.

On the first cars, power steering was not needed, since low driving speeds placed low demands on handling, and the tires were relatively narrow, with a small contact patch. Back then, large-diameter steering wheels were used to reduce steering effort. So the drivers turned the huge steering wheels 5-6 turns from lock to lock.

Power steering is a mechanism whose main element is a pump. The power steering pump is driven by a drive belt from the crankshaft or by an electric motor. The pump pumps oil from the reservoir and delivers it to the distributor under high pressure. The distributor monitors the force on the steering wheel and helps turn the steered wheels in a strictly dosed manner. For this purpose, a tracking device is used, the determining element of which is a torsion bar built into the section of the steering shaft. When the car is stationary or driving in a straight line, there is no force on the steering shaft and the torsion bar is not twisted. Accordingly, the metering channels of the distributor are blocked, and the oil is drained back into the tank. When the driver turns the steering wheel, the wheels resist, the torsion bar twists the stronger, the greater the force on the steering wheel, the channels open and oil under pressure is directed to the actuator, which will set the wheels in a position corresponding to the position of the steering wheel. The actuator, as a rule, is made integral with the steering mechanism. ATF oil is used as a working fluid in power steering of foreign cars - the same as in automatic transmissions.-

Power steering has another useful property - it weakens the transmission of bumps to the steering wheel from road irregularities.

The driver should remember that most cases of failure of power steering systems are not due to manufacturing defects, but to violations of the required operating conditions.

Required:

— regularly check the oil level in the tank;

— monitor the tightness of the system and eliminate various leaks as quickly as possible;

— check and, if necessary, adjust the tension of the drive belt;

— replace the filter element and oil in a timely manner (once every 1-2 years, as well as when its color changes).

— to prevent the power steering from breaking, avoid holding the steering wheel in the extreme position for more than 5 seconds. This may cause the oil to overheat;

— long-term operation of the vehicle with the pump not working leads to rapid wear of the steering mechanism and distributor parts, since they are not designed for this mode;

— avoid sudden impacts on the curb, stay in a position with the wheels turned to the limit for a long time.

When you quickly hit an obstacle, a very unpleasant thing happens: the power steering reduces the information content when steering, and the driver does not feel what conditions the wheel is in. Jumping onto the curb, he will only feel a slight push on the steering wheel. On a car without power steering, the steering wheel would respond with a very hard jerk, which could easily cause injury to your fingers. With power steering, the driver does not feel any load on the steering wheel, but this does not mean that the car easily overcomes any curbs. The power steering pump, as already mentioned, is capable of developing high pressures and thereby maintaining the specified position of the steering rack shaft. In the event of a reckless collision with a curb, the system will try to keep the wheels in the position specified by the steering wheel, which will actually provoke a hard impact on the curb. In such a situation, damage to the steering rods, steering rack, tire and wheel rim is very likely. Similar consequences can occur when the steering wheel is rotated when the car wheel is pressed tightly against the curb or track. The power steering system will strictly carry out all the commanding movements of the steering wheel, and if the wheel is limited in movement, persistent steering will inevitably damage the steering mechanism. You cannot accelerate with the wheels turned too far.

Increasing engine speed with the steering wheel turned will cause a significant increase in pressure in the power steering, which may damage the sealing elements and the pump.

At low temperatures, the viscosity of the working fluid increases significantly, which makes it difficult for it to flow through valves and calibrated holes and generally increases the load on all elements of the system.

In this regard, in severe frosts, you should not start driving in a cold car, and when leaving a parking lot, avoid intensive taxiing if possible. Based on materials from: auto-master-com-ua.1gb.ua

Typical power steering malfunctions

Malfunctions in the operation of the hydraulic booster can be easily identified by characteristic signs. Among them:

- The steering wheel turns hard . Probable causes are failure of the power steering pump, use of unsuitable working fluid, sticking of the spool mechanism channels.

- , a high-frequency sound (similar to a whistle) is heard while driving The probable cause is a loose drive belt.

- The steering wheel turns jerkily . Probable causes of the malfunction are the working fluid not meeting the specifications declared by the manufacturer, a malfunction of the fluid distributing mechanism, or a pump malfunction.

- The presence of intense foaming in the expansion tank. Probable causes are mixing of different types of fluids, failure of the power steering pump.

- When the engine is running, the steering wheel spontaneously turns in any direction . The probable cause is malfunction of the spool mechanism, most often, clogging of its working channels, incorrect assembly (for example, after installing a repair kit).

Recommendations for operation and maintenance of power steering

In order for the power steering and its system to operate normally, as well as to extend their service life, you must adhere to several simple rules:

- use working fluids recommended by the automaker , and also replace them in a timely manner (most automakers recommend replacing power steering fluid every 60.120 thousand kilometers, or once every 2 years, it depends on the driving style and intensity of use of the car);

- carry out bleeding of the power steering system in strict accordance with the algorithm described above (or observing individual requirements, if any are set by the car manufacturer);

- monitor the condition of the steering rack boot , because if it is torn, dust and dirt will enter the system, which leads to the power steering pump exiting. A sign of a problem that has already occurred is the hum of the power steering, which is not eliminated even by replacing the fluid.

Cost of replacing fluid and pumping power steering

If you plan to carry out work on replacing the fluid and pumping the power steering yourself, then you will only need to buy oil in a volume of 1 to 3 liters (including flushing, while the volume of the power steering system of a passenger car is up to 1 liter). The price of the liquid depends on the brand and store. It is within $4.15 per liter. If you do not want or cannot carry out such work yourself, contact a service station for help. Approximate prices for January 2020 are:

- fluid replacement work - 1200 rubles;

- power steering pumping - 600 rubles.

How to bleed the power steering with your own hands: simple instructions

Hi all! The article was created specifically for owners of cars with power steering and those who plan to make a corresponding purchase in the future. We’ll talk to you about how to bleed the power steering, what is required for this and whether it is possible to do the work yourself.

Practice clearly shows that pumping is done in cases where the working fluid is being replaced, when signs of air congestion and malfunctions are detected. Typically, such a need arises as a result of breakdowns or after standard repair work affecting the power steering system. For example, bleeding is often carried out after replacing the rack.

If you do not expel the air that has entered the system, this will lead to a decrease in the efficiency of the hydraulic booster and provoke further malfunctions. In particular, you may encounter the fact that the pump will need to be replaced, and there will be no way to restore it.