How to check the wear of brake pads?

Slowing down the speed of a car until it stops (braking) occurs when the pads rub against the discs or drums. These parts come into contact when the brake pedal is pressed. Motorists most often do not think about how to determine brake pad wear; this question usually arises when problems with the system become noticeable. The pads wear out faster because their main part during braking is friction linings, which are softer than metal and wear out faster. It is important to understand in time why the mechanism began to work worse and urgently carry out repairs. At what level of wear should you change brake pads and how to determine their wear, you will learn from this article.

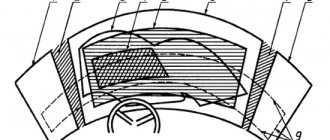

1 — brake disc; 2 — pad guide; 3 - caliper; 4 — brake pads; 5 - cylinder; 6 - piston; 7 — pad wear indicator; 8 - sealing ring; 9 — protective cover of the guide pin; 10 — guide pin; 11 - protective casing.

What causes pads to wear out?

For different car models, there is a certain service life of the brake bars. But this does not mean that they cannot fail before the car “runs” the kilometers indicated in the manual. There are several factors due to which the pads become unusable before the established service life expires:

- Riding mode. The urban driving cycle leads to wear and tear of parts faster due to frequent stops at traffic lights.

- Load level. The more cargo you carry in the trunk of your car, the faster the rear brake pads wear out. At the same time, this takes some of the pressure off the front brake pads, which means they will last longer.

The average service life for these elements is about 10,000 km, after which they are replaced. But signs of brake pad wear may appear earlier and are important to be aware of.

What indirectly indicates pad wear?

How do you know that these parts have become unusable without the hassle of inspecting them? Many modern cars are already equipped with an electronic brake pad wear sensor, which will promptly warn the car owner that the friction linings of the elements are no longer suitable for work. In addition to the electronic sensor, there are also mechanical ones, which are a metal strip and are attached below the lining. In this case, the abrasion of the friction layer can be recognized by a characteristic grinding and whistling sound, which will be clearly audible when you press the pedal. In this case, the operation of the brakes will be somewhat impaired, but not to a critical level, and the driver will be able to promptly change faulty car parts. Mechanical warning lights can be installed on one wheel (usually the front), two (front or rear), or all of them.

The presence of a brake pad wear indicator greatly simplifies diagnostics. If they are not there, extraneous sounds can be heard only when the linings are worn to the limit, and the quality of braking will decrease significantly: you will have to press the pedal with more force, and in addition, the braking distance will increase.

Brake pad wear sensor

If there are particles of road dirt between the disc and the pad, this will lead to accelerated wear of the brake components. Signs of such problems will be the brake pedal beating when you press it.

If there is uneven wear of the brake pads, in which the friction layer on one of the elements wears out faster, you can find out about this by the car skidding to the side when braking. Pressing the pedal sharply in this case can cause the car to be thrown off the road, especially on wet surfaces. Therefore, uneven wear is very dangerous, and if it is noticed, the car must be urgently repaired.

You can also find out about the maximum wear if the pressed pedal remains in the same position after being released. This happens when the friction layer is almost completely erased, and the metal of the bar, heating up during friction, grips the disk. But an accurate determination of the cause of the problem is only possible during inspection, since these signs may also indicate failure of other elements of the brake system.

Immediate signs of pad failure

If you notice any of the above signals, do not delay repairs - extreme wear of the brake system elements makes driving a car, without exaggeration, deadly. It is best if the diagnostics and, if necessary, replacement of spare parts are carried out by professionals at a car service center: this will guarantee the correctness of the check. But, if this is not possible, or you prefer to repair the “iron horse” with your own hands, then you can conduct a visual inspection to determine the cause of wear of the brake elements yourself.

The fact that the planks are unsuitable for further work can be determined by the following signs:

- The thickness of the friction layer has become below the permissible value established by the manufacturer.

- The thickness of the brake disc has decreased below the maximum permissible value (this parameter, as in the previous case, can be measured using a micrometer).

- Traces of mechanical damage in the form of cracks or depressions were found on the friction lining, on the base of the pad or on the disc of the braking mechanism.

- A protruding lip appeared on the outer edge of the block.

- The disc is skewed.

- A carbon coating has appeared on the surface of the disk, which indicates that the surface has begun to deteriorate.

The need for urgent replacement of the braking system strips is indicated by the appearance of a dark-colored coating containing small metal particles under the wheel cap. This indicates complete erasure of the friction layer and that the base of the part has already begun to wear off.

Under no circumstances should repairs be put off if problems are discovered, since the safety of the vehicle, driver and passengers directly depends on the serviceability of the braking system.

If you find an error, please select a piece of text and press Ctrl+Enter.

We determine the wear of the brake pads ourselves

The brake pad consists of a frame and a friction lining.

The heaviest load falls on the friction lining, which serves to create friction against the brake disc to stop the wheels from moving during braking. Accordingly, the friction lining wears out first, and the driver must carefully monitor this and diagnose brake pad wear in time to avoid an accident. Different manufacturers have different service life requirements for brake pads. This is due to manufacturing technology and other factors. It is believed, on average, that after 10-15 thousand kilometers the brake pads are already quite worn out

But these are only approximate figures, since wear is influenced by many other factors, so it is important to be able to independently determine the wear of the brake pads on your car

Reasons for early failure of brake pads

1. Friction lining material. 2. Natural wear and tear. 3. Driving and braking style. If you are used to an aggressive driving style and often use emergency braking, then the brake pads are unlikely to last you even 5 thousand km.

If the brake cylinders on one axle are faulty, then the brake pads on that axle will wear out faster than the pads on the other axle. If the difference in the thickness of the pads on the front and rear axles is 1.5-2 millimeters, then you need to check how the brake cylinders work.

How to independently determine brake pad wear?

There are 3 definition options:

Option 1 – TECHNICAL.

Nowadays, many car models are equipped with a sensor that signals the wear of the brake pads. This is a plastic part with a core that is inserted into the friction lining. It works as follows: if the wear of the friction lining exceeds the permissible level, the core begins to touch the brake disc, and the sensor indicator on the control panel immediately shows this.

The disadvantage and inconvenience of the sensor is that its wires inevitably suffer from corrosion, since they are often exposed to water and dirt.

Brake pad kit with sensor

Option 2 – VISUAL.

Brake pad wear can also be determined by eye, by two signs: 1) by the amount of brake fluid - low level in the reservoir, 2) if you find coal dust with metal particles on the wheel rim or on the inside of the decorative cap.

Option 3 – DYNAMIC.

1) If you feel a distinct beating when braking sharply, then there are two possible explanations for this phenomenon: either the brake pads are worn out or the brake disc.

2) If during braking the brake pedal sinks unusually strongly, this may also indicate wear on the brake pads.

3) If the brakes are applied unexpectedly sharply, and a special sound is heard, it means that braking is already taking place by the pad frame, and the friction lining is completely worn out. This, of course, happens extremely rarely when the driver does not monitor the brake pads at all.

Another important thing is that the brake pads located on the front axle are subject to faster wear, since most of the load falls on them during braking

Therefore, closer attention should be paid to the degree of wear of the pads located on the front axle of the car. Which brake pads are best to choose? How to change brake pads?

Brake pad wear

Wear on the brake pads of a car depends on the intensity of their use, the driving style of the car owner, the operating conditions of the car, the quality of the materials from which the pads are made, the presence of an ABS system and even the type of transmission. However, atypical or uneven wear indicates some malfunction in the brake system.

Monitoring pad wear must be carried out periodically, every 2...3 thousand kilometers , as well as when performing preventive maintenance, for example, when replacing/adding brake fluid. The degree of wear of the brake pads can be checked in two ways - directly while driving the car, as well as by visually inspecting them and measuring the remaining friction material.

How often should brake pads be changed?

Automakers recommend changing brake pads on cars every 10 thousand km. This mileage figure is an estimate, as the degree of wear depends on many factors, so the recommended mileage is an average.

With an aggressive driving style and frequent off-road driving, the wear rate of the pads increases significantly, so replacement may be required after a short mileage of 5 thousand km, which is half the period recommended by the manufacturers.

With careful handling of the car and careful operation, the wear life of the pads can be doubled. A calm driving style allows the pads to last up to 20 thousand km without the need for replacement.

How to determine if the pads are worn out

Signs of brake pad wear can be divided into two types. First, let's look at the symptoms that can be identified when driving a car while driving a car.

- Changing pedal behavior . In particular, if during braking the brake pedal begins to fall down strongly, this may indicate a malfunction not only with the pads, which certainly need to be checked, but also with other elements of the brake system (brake cylinder, brake fluid level).

- Vibration when braking . If the brake pad or brake disc wears unevenly during heavy braking, vibration may occur, which will be felt both directly on the brake pedal and throughout the vehicle body. In this case, it is necessary to inspect not only the brake pads, but also the brake discs.

- Whistling or squeaking sounds when braking . Squeaking noise when braking can be caused by three reasons. The first is the work of the so-called “creaking”, which is an indicator of pad wear. The second is poor quality work of the friction layer of the pad and disc. The third is problems in the operation of the braking system.

- Indicator on the instrument panel . Many modern cars, instead of plate indicators, are equipped with an electronic pad wear monitoring system. Therefore, when the minimum permissible wear is detected, the pad wear lamp lights up on the dashboard. The operation of the system is based on the use of a sensor that begins to close the contact when it touches the disk.

However, the problem is that such an alert can be either false, when there is an error in the memory of the control unit or a short circuit in the sensor wiring, or it can be of little information content. The pad wear indicator lights up when the condition of the inner pad requires replacement, although in general you can drive more than one hundred kilometers. Therefore, to make sure how much wear the pads actually have, you always need to remove the wheel and measure it with a ruler.

- Reduced braking efficiency . As the linings on the pads deteriorate, braking becomes less effective. In particular, the braking distance increases. However, this fact is not easy to notice.

also always monitor the level of brake fluid in the system . If there is not enough of it in the expansion tank, then there are two options. The first is a leak, and you need to look for the place where the fuel fluid is leaking in order to fix the problem. The second option is significant wear of the brake pads . As the pads wear, the actuator (caliper) requires more fluid to protrude the operating piston to move the pad toward the disc. Therefore, the liquid level in the tank will drop.

This fact is a direct sign of pad wear. Those car owners who don’t know this rush to add fluid instead of changing the pads, and then, when replacing them, they are unable to press the piston and install the pads, since the fluid in the reservoir rises strongly!

Pad wear sensor is not 100% indicator

Owners of cars equipped with a brake pad wear sensor should understand that they should not wait for the icon on the dashboard to activate. Since many cars do not have electronic indicators on all wheels. Depending on the brake circuit design, the sensor is located on one front and one rear wheel.

This means that if there are problems in the operation of the calipers and wear occurs unevenly, then you may miss the moment when the thickness of the brake lining reaches its limit. The “pad wear” error will not appear and the outer and inner pads on one wheel wear out unevenly. Accordingly, it is necessary to perform a preventive visual inspection of the condition of the brake pads.

A brake pad wear error in the ECU memory followed by activation of a lamp on the dashboard can also occur due to a break/short circuit in the wire of the sensor itself. Many service technicians note that the sensor only works correctly if the car uses more or less new brake discs , that is, their thickness is large enough. If, for example, the third or fourth set of pads is already used with the disc, then there is a high probability that the pad wear icon will either not light up at all, or, on the contrary, will work falsely.

Thus, the wear sensor is, in fact, a safety net, a last resort that indicates that the pads on the car are completely worn out and relying on it to let you know when to change the pads is not worth it!

To better understand the problem, we suggest considering a specific example regarding the LAND ROVER Discovery car. Specific pad wear rates on other cars will differ slightly (± 0.5-1 mm), but the essence is the same.

So, the thickness of the new brake pad lining is 12 mm. The automaker indicates that the minimum allowable pad wear on this model is 3 mm. The distance from the edge of the friction lining to the sensitive element of the sensor is 8.5 mm. Thus, the sensor will work when the thickness of the pad is about 3.5 mm. That is, when the indicator lights up on the panel, it turns out that the pads already need to be changed, but in fact, you can still drive for some time, but the limit of wear is not far off and you should plan service visits or prepare for the replacement yourself.

How to replace brake pads with your own hands?

If you are convinced that the brake pads have become unusable, and you are not very knowledgeable about car repairs, then it is best to entrust this operation to professionals. However, the procedure for replacing brake pads itself is not very complicated. No special tool is required for this, except for a special key for unscrewing the so-called secret bolts, which every driver has.

- The first thing you need to do before replacing the brake pads with your own hands is to “hang” the wheel on which we will replace the brake pads. This must be done with the help of a reliable jack and be sure to secure it with a support!

- Remove the wheel and use a screwdriver to move the pads to their original position. We perform the procedure with each of the pads separately.

- After the brake piston reaches its initial position, it is necessary to unscrew the bolt securing the brake caliper to the guide bushings. There are two bolts on the caliper that secure it to the bracket. It is necessary to unscrew the bolt that will allow you to tilt the caliper body along with the bracket to the side so that the brake hose does not interfere with this.

- After the caliper body has come away together with the bracket, turning on the guide pin, you need to remove the friction linings and evaluate the degree of uniformity of their wear. If one of the pads is worn down to the ground, and a decent layer of friction material remains on the other, this may indicate that the brake caliper is jamming along the guide bushings due to torn bushing boots; they must be replaced using the graphite-containing lubricant recommended for your car.

- After installing new brake pads, it is necessary to install damper tin pads. The set of new pads contains everything you need, right down to the package with lubricant.

- Next, in the reverse order, we manipulate the brake caliper bracket. Additional fixation may be required using an iron plate by bending it.

- We put the wheel in place, lower the car from the jack, having first removed the support. Let's move on to the next wheel.

After the front brake pads have been replaced, it is necessary to press the brake pedal several times to eliminate the gaps that have formed between the pads, brake discs and the brake caliper piston. Next comes replacing the rear brake pads.

It is worth noting that on cars with a disc brake system, the brake caliper piston is not pressed in, but is screwed into the caliper clockwise. It has special grooves for the key. You also need to understand that you need to change the brake pads as a set: rear brake pads, front brake pads.

How to determine pad wear

When servicing your car or experiencing signs of wear on the brake pads, you should always check their remaining thickness yourself. However, before performing the corresponding procedure, it is necessary to find in the technical documentation (service and repair manual) the maximum permissible wear of the brake pads for a particular vehicle.

When checking, it is necessary to visually assess the condition of the outer pad, as well as the brake disc itself. If there are scratches or dark marks on the disc, then most likely the pad is already worn out. Focusing on the thickness of the outer pad alone is not enough; always inspect, or better yet, remove both pads from the caliper and then measure the thickness with a ruler or caliper.

How to check front pad wear

To find out the wear of the pads on a car's disc brake, you need to dismantle the wheel, lift the caliper and evaluate the thickness of the pads (you don't have to lift them). Along the way, be sure to check the caliper guides and, by lifting the boot, check the external view of the working piston. If necessary, lubricate the caliper and guides.

A good guide will be the slot (longitudinal/diagonal) along the friction lining, which is designed to remove brake dust. If it is still there, then the block is in good condition.

How to check drum pad wear

Drum brake pads have a longer service life since they bear significantly less load, so they last 2-3 replacements of the front disc brakes. This pattern can already become an indicator of wear, but to find out for sure you need to look at them visually.

Monitoring pad wear in a drum is often a difficult task. The easiest way to find out the wear of the rear pads in the drum is to look through the inspection window . It can be either in front of the drum or at the back (under the rubber plug) . Therefore, this is often not very convenient, since you have to either park the car on an inspection hole or crawl under the car.

Through the window you can only see the wear of one pad, while the other may be worn out more or may not press well at all. By the way, the minimum permissible thickness of friction linings in drums is considered to be 1.5 mm.

It is best to remove the drum to visually assess the condition of the rear drum pads. This way you can also evaluate the operation of the mechanism that separates the linings, piston and wear inside the drum. When checking, you need to pay attention to the inner surface of the drum. If it is shiny and moderately worn, then most likely the pads are working.

2015-09-02 How to recognize brake pad wear

The braking system of a car is the most important component ensuring the safety of passengers and the integrity of the vehicle. Serviceable brakes allow the car to slow down and stop smoothly and in a timely manner in normal and emergency situations. For the safety of yourself and your passengers, it is necessary to monitor the condition of the entire braking system. Particular attention should be paid to brake pads, which are subject to wear more than other parts.

How do brake pads wear out?

the brake disc together . Because of this, the rotation speed of the wheels decreases and the vehicle slows down. The harder you press the brake pedal, the tighter the pad block is pressed against the disc.

At these moments, the friction force wears off the coating of all parts of the brake system that are in contact with each other. Over time, the pads no longer fit tightly to the discs, therefore, braking worsens. For aggressive drivers who love quick starts and high speed, wear occurs much earlier than for those who favor a quiet ride. On average, pads are changed after 8–15 thousand kilometers, depending on the quality of materials and driving style. If you do not detect the wear of these important parts in time, you can not only get into an accident, but also lose your life.

Signs of Brake Pad Wear

The easiest way to recognize the wear of a block block is by sound. When braking, it will make a high-pitched sound, similar to a strong squeal. It can sound from one wheel or from several at once. As a rule, the drive wheel pads wear out first. If a malfunction is detected, these parts should be replaced as soon as possible on all four wheels, and not just on one.

Noticeable impacts in the wheel area. During use, the block of the block wears unevenly. It develops pits, potholes and cracks that increase with use. Because of this, when braking, uneven pressure on the disc occurs, resulting in shocks felt by the driver while driving.

Another important sign is an increase in braking distance. If you have to press the brakes harder to stop on the same section of the road, then it's time to replace the pads . This must be done as soon as possible.

Too harsh or weak braking. Drivers who know their car well and have a sufficient amount of experience will be able to determine wear by this sign. If the pedal drops down significantly when braking, and braking efficiency does not increase, then it is time for a replacement. If the wheels are clamped too sharply and smooth braking becomes impossible, the pad must be replaced due to a damaged friction pad.

Plaque on the wheel also indicates pad . If carbon deposits and metal dust were found on the wheel, then the gasket has worn out and now the metal is scratching the disc.

Visit to the service station. During maintenance or diagnostics, the brake system can be analyzed. Qualified specialists will determine the percentage of pad wear and make a decision on the need to replace the pads. The method will require financial investment, but it can guarantee you safety and a quiet ride.

Diagnosis of the cause by wear

As a rule, brake pads on different wheels wear unevenly on all cars. First of all, it is necessary to point out that the pads on the front axle always wear out faster than on the rear axle. This is explained quite simply. The fact is that during the braking process the front of the car body goes down, and accordingly, the rear part rises up (the car seems to “nod off”). Therefore, more force will be exerted on the front pads than on the rear ones. And the sharper the braking (the tilt angle of the car is greater), the greater the force on the front pads.

Many modern cars have an exchange rate stabilization system (ESP for short) . Its task is to maintain the vehicle's directional stability on the road during sudden maneuvers, that is, to prevent skidding. In practice, the system operates by braking one or more wheels in critical situations. Naturally, the operation of the ESP system will also affect the wear of the brake pads. Accordingly, the more often the stabilization system comes into operation, the higher the wear of the pads will be. Moreover, the pads on different wheels will wear out unevenly!

Otherwise, a separate type of uneven wear of the pads can also be caused by the reasons shown in the table.

How to easily determine brake disc wear by visual inspection

Hi all! I think every motorist is interested in maintaining his own vehicle in good condition. Moreover, special attention should be paid to the braking system. That is why the topic of our conversation will be how to determine the wear of brake discs.

People are also often interested in the question not only about the degree of wear of discs, but also pads. This is true more on cars, although the braking system is present on a motorcycle and even a bicycle. Let's immediately agree that the conversation will be about brake discs, not pads, and only strictly about cars. By the way, I separately talked about replacing brake pads in an article that you can read at the link.

The purpose of the brakes is to ensure timely stopping or reducing the speed of the machine. Moreover, the brake must respond instantly to the driver pressing the corresponding pedal. The speed at which a car brakes directly depends on the current condition and serviceability of the brake system components in the form of pads and discs. The stopping of the machine is due to the work of the friction force. To ensure that the discs do not wear out during friction, high-quality and durable materials are used for their production. But they are not eternal either. Wear and tear comes sooner or later.

What conclusions can be drawn?

So we figured out how to determine brake pad wear. This can be done visually, or using a ruler or caliper. If you do not have the time and desire to deal with this issue yourself, then entrust this matter to the specialists at the service station.

The minimum thickness of brake pads should be 2-4 mm, but values such as 1.5 mm are allowed. If the pad is smaller, we change it. If it is within the acceptable range, but is already suitable, we are preparing to replace it soon. It is also worth regularly checking the brake discs for wear and overheating. The latter leads to the disc warping, and the system works less efficiently - the braking distance increases and runout appears. So we figured out when the brake pads are replaced. The price for them differs depending on the manufacturer and varies between 800-3500 rubles. But you don’t need to take the cheapest “musical” friction linings.

Post Views: 140

Wear limit

Each brake disc has its own limited resource. It is set by the manufacturer from the factory, and resource wear is affected by mileage, braking intensity, the condition of the entire braking system, the characteristic features of the vehicle itself, etc.

When buying a new set of brake discs for his car, the driver must always follow the recommendations of the car manufacturer. Therefore, first we look at the instruction manual, or according to convenient catalogues, based on the characteristics of our particular machine, we select a part via the Internet. If you take a high-quality kit from a trusted manufacturer, you can be sure that wear will not occur very quickly, and when braking hard, the car will definitely stop, as you expected. The same applies to buying new pads.

There are international norms and standards for the production of such components for passenger cars. They oblige all manufacturers to make appropriate engravings or markings on products.

The essence of the engraving is to indicate information that relates to the maximum permissible degree of wear.

There is such a thing as the thickness of the brake disc. And it has a certain maximum wear limit.

To obtain the relevant information, you should look at the end part of the product. It is there that, according to international standards, all manufacturers of certified parts are required to display data regarding the wear of the brake part. Information about the initial thickness, as well as what thickness is considered minimal, should be located here. As soon as the disk reaches this value, it must be replaced. In fact, the manufacturer thereby relieves itself of responsibility. If a driver wears a disc below normal and causes an accident, he will not be able to blame the brake manufacturer or auto company for this.

Determining the degree of wear

You have received basic information about the maximum and permissible wear. Now you need to find out exactly how the wear of a part is determined and what is required for this.

Not a single specialist or auto parts manufacturer can say 100% exactly how long a brake disc will last or how many kilometers it can travel. There is only a calculated resource, which is influenced by many additional factors. Yes, for starters it’s worth focusing on the quality of the disc itself, the raw materials used and adherence to technology. This is a question for the manufacturer. It's definitely not worth saving on brake discs. It is better to give preference to more expensive, but reliable and proven parts from leading manufacturers.

But there are other factors that provoke gradual or rapid erasure of the disk, exceeding the calculated values. These are driving style, condition of the brake unit, pad wear, climatic conditions, road surface condition, etc.

All this suggests that diagnosing discs is the task of the car owner himself.

It is unlikely that it will be possible to carry out an accurate diagnosis without removing the wheel. You can only visually try to take a closer look at the condition of the element through the wheel rim and roughly assess its current condition. But it will not be possible to check the disk for curvature or accurately determine the degree of wear.

And it doesn’t matter what kind of car we’re talking about. Brakes wear out everywhere, be it:

The first step is to remove the wheel from the side where there is a potentially problematic part.

Another feature is that it is recommended to replace both wheels at the same time, even if the second disk is in better condition and has not completely worn out.

Measurements are taken first and then a visual inspection is performed. Then an appropriate decision is made. You may need to groove the discs, which in theory can be done with your own hands.

Stages and features of diagnosis

The measuring stage of the test involves the use of a caliper, which will help make thickness measurements. At approximately 5-8 points, moving around the disk, measure the thickness. If it varies along the radius of the part, there are signs of curvature and uneven wear.

Check the information from the manufacturer to understand whether the wear limit has already reached or not. I cannot say which indicators are correct and which are not, since different discs have their own wear limits.

Then a visual inspection is carried out. The disc should be examined for cuts, chips, dents, scratches and other defects on its surfaces. If they are, the spare part will have to be replaced.

Do not forget about the rule of pairwise replacement on the same axis. That is, when the left front disc is changed, the front right one also changes at the same time.

If you want to assess the condition of the elements without removing the wheels, this can be done by checking while driving. With severe wear, characteristic signs appear:

- the car brakes jerkily;

- a grinding sound appears;

- there is a squeaking sound when you press the brake;

- other extraneous sounds are heard;

- the driver feels a beat on the steering wheel;

- the beating is also felt in the gas pedal;

- When the brake pedal is pressed, the braking system is locked.

I strongly do not recommend waiting for such symptoms to appear. It’s better to periodically do simple diagnostics in your garage through visual inspection and measurement. This is usually done every 10-15 thousand kilometers, if wear symptoms do not appear earlier.

That's all for me.

Thanks to everyone who reads us! Subscribe, leave comments and ask relevant questions!

(

2 ratings, average: 5.00 out of 5)

Symptoms of wear

Among the main danger signs you should pay attention to the following:

- The occurrence of beating during sudden braking is the main sign of excessive wear.

Uneven abrasion during operation, chips and cracks are the main reasons for the occurrence of such malfunctions.

In the first case, squeezing the pedal below the normal position does not give the desired effect, in the second there is a clear contact of metal surfaces with each other due to absolute abrasion of the friction layer.

The presence of brake dust with metal filings on the wheel rims is also a characteristic symptom for immediate inspection of the condition.

Looking under the wheel caps, carefully examine the dusty coating - if it is uniform, with a dark charcoal color, then the lining is still left, but the presence of metal inclusions signals an urgent need to urgently contact a car service center.

Timely maintenance is a sure way to avoid problems.

The experts will inspect:

Having found small flaws in the entire system as a whole, they will quickly and efficiently eliminate them.

By what signs can you determine that it is time to change the brake pads?

Ford Focus Wagon Family Turbo Barn Logbook Replacing rear brake pads Ford Focus 2-disc brakes

Everyone knows that the braking of a car's wheels occurs due to the friction of the brake pads on the brake discs when the brake pedal is pressed. Friction naturally causes wear on the brake pads. The rate of pad wear largely depends on the driving style of drivers. Fans of fast driving often use sharp braking and wear out the pads faster, and those drivers who prefer calm and smooth braking can count on slower wear of the brake pads in their car. It is believed that on average brake pads need to be changed every 8-12 thousand kilometers. Prompt detection of wear and tear and replacement of brake pads will help keep your vehicle's braking system in good working order.

Let's look at 6 main signs of wear:

- An obvious sign of worn brake pads is a high-pitched sound called a squeal that your car makes when stopping. This sound is created by worn brake pads.

- When braking hard, you may feel a knocking sensation. As the pads wear out, they wear unevenly. Chips and cracks may occur on the pads and discs. Therefore, worn brake pads and rotors create noise and clatter when braking.

- The length of the braking distance and braking time also allow you to determine the wear of the brake pads. If it takes you a while to stop, it means your brake pads need to be replaced.

- Brakes that are too weak or too harsh can also cause pad wear. If, when you press the brake pedal, you notice that the pedal drops even lower, and the braking is not very effective, then the pads need to be changed urgently. And vice versa, if the wheels lock too abruptly, then the friction lining is worn out and the metal of the pads rubs against the disc.

- In some cases, pad wear can be confirmed by plaque on the wheel. When the friction lining wears off on the wheel, a uniform carbon coating can be detected. If it contains an admixture of metal dust, this means the lining is abraded and the pad scratches the disc.

- And finally, the most expensive, but most reliable way to determine pad wear is to undergo a technical inspection at a service station. A service station specialist will inspect the condition of the brake system and make a qualified conclusion about the need to replace the brake pads. It's up to you to decide whether to change the pads or not.

Why does pad wear accelerate?

Severe operating conditions lead to the beginning of grinding of the inner pad faster than the outer one.

However, it is advisable to ensure uniform wear of the parts so that it does not lead to scuffing on the brake discs!

The smaller the thickness of the lining, the faster it “melts”, since portions of thermal energy are absorbed by the less massive element.

Features of front and rear brake pads

The front brake pads are subject to greater load and their service life is much shorter.

Installing sensors that monitor the condition of the clutches helps to notice problems in time, but if they are not there, sometimes inspect the problem areas yourself.

Rear brake pads last three times longer, but once they become unusable, do not delay repairs.

If you regularly carry out diagnostics, the car will fully meet all established safety requirements and the worry that something will go wrong while driving will be reduced to a minimum. If necessary, drive the car to the nearest service center without waiting for irreparable consequences.