What causes a variator to break down?

The main cause of known malfunctions of CVTs is violation of basic operating rules:

- the oil or filter element was not replaced on time;

- use of low-quality oil;

- aggressive driving style;

- prolonged driving at maximum speed;

- sudden braking.

Additional causes of malfunctions can be various defects in structural components (defects, ill-conceived design, poor-quality connection), as well as natural physical wear and tear of the constituent elements, which manifests itself after 150,000 - 200,000 km.

CVT malfunctions can occur both in its electronic control module and in mechanical components.

Electronics defects

In the first case, detection of a specific breakdown is carried out using computer diagnostics. A diagnostic code is assigned to each defect. Thus it is easy to determine:

- problems with the electronic control module board;

- defects in the speed sensors of both pulleys, operating oil temperature, pressure in the main line or pulleys;

- malfunctions of the stepper motor, defects in the blocking valves of the hydraulic transformer and control of the operation of the planetary gearbox, solenoid valves for pressure in the main line and the driven pulley.

The probable cause of a defect in the electronics may also be a violation of the integrity of the electrical wiring or unreliable contact in the connector.

Mechanical problems

Computer diagnostic tools are not the only tools used to detect mechanical problems. In this case, it is necessary to approach the problem in a comprehensive manner and monitor the parameters of the working fluid, conduct road tests, read the diagnostic code, and clarify signs of malfunctions.

When should you change the oil in a Nissan Qashqai CVT?

To check the condition of the oil in the variator, it is recommended to perform the following steps:

- Pull out the dipstick and place a drop of oil on a clean cloth. Cloudiness will tell you that there are a lot of wear products in the technical fluid. In addition, the presence of a burning smell will tell you about frequent overheating of the working fluid, which happens due to a malfunction of the variator cooling system or a drop in pressure in the lubrication system

- In the operation of the ECU of the Nissan Qashqai, there is a mathematical algorithm for calculating the remaining life of the working fluid. The calculation takes into account the total operating time of the variator, oil temperature and operating loads.

The methods described above are the only ways to check the condition of the oil. But color, smell, consistency, and even more so the aging counter, do not allow you to check the real physical properties of the transmission fluid in the variator. Therefore, we recommend adhering to the following rules:

General information about the variator

The differences between a variator and other types of gearboxes are fundamental. The defining feature is the ability to adapt to the current conditions in which the moving vehicle is located. The box also constantly determines the desired gear ratio. The gear range is limited by the design features of the transmission, but within it the number of variations is almost endless. It is this feature that helps save fuel and optimize energy costs.

There are V-belt and toroidal variators. The first ones are installed on most cars. .

How does a V-belt continuously variable transmission work?

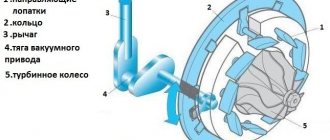

Structurally, the CVT V-belt box is represented by two pulleys - driving and driven. The master is connected to the car engine, the slave is connected to the wheel drives. The shafts are connected using a belt or chain.

Scheme of operation of a V-belt variator

The peculiarity of the pulleys is that they look like two halves of a conical shape, their vertices directed towards each other. The divergence and convergence of the cones changes the diameter of the single structure.

The operation of the CVT is as follows. When the car starts moving, the motor experiences a load. To reduce it, the cones of the drive shaft diverge and the diameter decreases. The opposite changes occur on the driven pulley - the cones converge, the diameter increases. As a result, the number of revolutions of the internal combustion engine becomes optimal.

Scheme of operation of a V-belt variator

An increase in speed has the following effect: the diameter of the drive pulley increases, and the diameter of the driven pulley decreases. The traction force is reduced, the operation of the motor is smooth. The electronic control unit (ECU) is responsible for the convergence/divergence of the bevel pulleys. The simplicity of the design makes the CVT powertrain less expensive than other transmission options.

Features of the variator

The CVT-type gearbox is fundamentally different from all analogues known today. The CVT technology itself has been around since the boom of subcompact scooters.

But in the case of a scooter, the continuously variable mechanism was quite easy to make reliable. A method was used to increase the safety margin due to the massiveness of the unit. And the torque that the variator on the scooter passed through was negligible.

How a variator works - video

In the case of the automobile, the slowdown in the adoption of this technology was partly due to the difficulties in creating a reliable and durable prototype of the CVT transmission. No one will buy a car in which the transmission life barely reaches 100 thousand kilometers.

Today this problem has been resolved. CVT gearboxes perform no less well than their automatic opponents, built according to the classical scheme, without any problems. But timely service is a very important condition here. Namely, changing transmission oil and filters.

In the Nissan Qashqai CVT, torque is transmitted through a metal belt stretched between two pulleys. The pulleys have hydraulically controlled movable walls that can expand and move. Due to this, the radius of these pulleys changes, and, accordingly, the gear ratio.

The hydraulic system in the Nissan Qashqai variator is controlled through a hydraulic unit, which is controlled by a computer. Fluid flows are distributed throughout the system by opening and closing valves actuated by solenoids.

Bearing wear

This is the most common defect in CVT cones. It manifests itself with a characteristic hum after a run of at least 50,000 km.

The belt is assembled from numerous plates interconnected by steel constrictions. With its side surfaces, with subtle oblique notches applied to improve adhesion, it comes into contact with the pulley cones. During operation, the notches wear out, which can ultimately lead to serious damage. Therefore, even the elimination of humming bearings should be accompanied by a preventive replacement of the belt, which guarantees the preservation of serviceable pulleys.

Bearing noise can also occur for several other reasons:

- Poorly manufactured bearings.

- Insufficient dynamic load capacity, as well as a low degree of bearing accuracy, lead to their overload and destruction.

- Penetration of wear products (small powder-forming particles) onto working surfaces, leading to destruction of the latter. This may be due to a large amount of metal powder clogging oil filters and weakening the field of the magnet installed to collect it. In some cases, this problem can be solved by changing the oil more frequently (approximately every 30,000 - 50,000 km).

There is no consensus among manufacturers on this issue. For example, Mitsubishi strongly recommends changing the oil every 75,000 km, while Renault-Nissan only allows monitoring its level and condition during the warranty period (100,000 km).

CVT oil is marked with the abbreviation CVT. Every car manufacturer has such oil. The original composition from Nissan is produced under the symbol NS-2. Mitsubishi is promoting the DiaQueen CVT-J1. The analogue from Renault is known as ELFMATIC CVT. Honda produces HMMF and CVT-F, VAG produces ATF CVT. All these fluids are recommended specifically for CVTs. It is absolutely unacceptable to use oils intended for hydromechanical automatic transmissions.

The amount of oil required for filling is determined by the type of drive and power unit. For example, for a front-wheel drive Qashqai with a 2-liter engine not equipped with an oil cooler, approximately 4.2 liters are required. A couple of liters will “get stuck” between the transformer elements and the hydraulic system components, since it is impossible to pump out these “drops” using the standard draining procedure. To completely renew the filling, they use the replacement method, using an appropriate installation and three times the volume of working fluid.

PryazhonovPodbor › Blog › Checking the variator (CVT) of a used car

Friends, hello everyone! First of all, I congratulate everyone on the new year 2017! Hurray! :)) And secondly, today I want to share with you information about CVTs, namely their testing on a used car.

CVT, Continuously Variable Transmission

Everyone has long known that variators are structurally a system of two cone-shaped pulleys connected to each other by a belt drive. Each pulley contains a pair of cones directed towards each other, the mutual approach or distance of which during engine operation leads to a change in the radius of movement of the V-shaped closed belt or chain. Due to this, the change in gear ratio occurs smoothly.

CVTs are most widely used on cars of the Renault-Nissan concern. The unit is manufactured in Japan, and the most common model is JF011E. Among the Nissans, the X-Trail (T-31 body), Qashqai and Teana can boast of this CVT. Renault has Latitude, Koleos, Megan, Scenic and Fluence. In addition, Mitsubishi uses Jatko CVTs on the Lancer and Outlander models. They are also installed on the co-platform French crossovers Citroen S-Crosser and Peugeot 4008. But that's not all. "Suzuki-Kizashi", "Dodge-Caliber" and "Jeep-Compass" - they also have a Jatko variator!

Now closer to the point - what to look for when inspecting a car

with this type of gearbox?

The first thing that should make you wary is the jerking

of the car during acceleration. Ideally, the car should pick up speed smoothly (such as an electric car or trolleybus) at constant engine speed. If jerks or dips are clearly noticeable, then first of all you need to check... the engine itself. The variator may have nothing to do with it. But if the engine is known to be in good working order and runs smoothly, but the car still jerks when accelerating, then this most likely means that the variator is on its last days (months at best).

Next, we look at the engine speed during uniform movement: at a speed of 80 km/h, the tachometer needle should show approximately 2000-3000 rpm. If the arrow goes off scale beyond the 4000 rpm mark. per minute, then the variator is faulty. A clear indication of a breakdown will be an attempt by the engine to stall when braking. In this case, transmission repair is not far off and it is better to refuse to purchase such a copy. It would not be superfluous to check the level and condition of the oil poured into the variator.

Continuously variable transmissions are very susceptible (much more than automatic transmissions) to oil starvation. Therefore, the level must be normal. Black oil is unacceptable. This means that there is no point in changing it - the variator needs to be disassembled and repaired. To be sure, CVT experts advise dropping some oil onto a white sheet of paper and holding the resulting stain up to the light. It may be yellow or red

, but in no case brown or brown-black. Even if the seller (trying to hide signs of wear on the variator) changed the oil, the burning smell will still remain. It smells burnt - there is no need to continue the diagnosis.

Signs of CVT failure (for all types): noise, grunts, rumble (reminiscent of a faulty TAZ rear gearbox). How to diagnose: turn off the air conditioning and music at speed

60 from mode D to N and listen to the sound source. Most often, sounds are produced by bearings, being one of the most loaded elements. Be sure to check how the car moves at a constant speed, incl. in cruise control mode!

The most common malfunction of a variator is wear of the cone bearings, accompanied by a characteristic hum. Sometimes, during diagnostics, the noise of the variator is attributed to the front wheel bearings - and they are replaced with new ones, but the noise does not go away...

The first symptoms may appear already after a mileage of 50,000 km. Replacing four bearings with spare parts will cost 35,000 - 40,000 rubles. Most often, Nissan Qashqai suffers from this disease, less often - X-Trail, and least of all - Mitsubishi Outlander. With the latter, by the way, this happens at a much higher mileage: 150,000–200,000 km.

There are several reasons that lead to bearing noise. The first is that wear products fall on the working surfaces and accelerate their destruction. Two oil filters and a magnet for collecting metal powder are not able to provide a barrier to insidious wear products. Reducing oil change intervals to 30,000–50,000 km can extend bearing life. But there is no consensus even among experts, and the statistics on oil are ambiguous. There are many examples when one variator takes care of 100,000–120,000 km and remains quiet, while another in similar operating modes hums mercilessly after 50,000 km. This leads to the second reason - unstable quality of bearings. Third, bearings cannot withstand loads and are destroyed due to their low accuracy class and low dynamic load capacity.

The most serious and materially costly defect of the above is the defect of the variator transmission. It occurs when the belt slips between the pulley cones with the simultaneous formation of scoring at the ends of the belt segments and the working surfaces of the cones. This problem can only be eliminated by complete replacement.

Don’t forget to inspect the variator radiator (if there is one), check the oil level when cold and when hot (it should be different). Perhaps that's all I wanted to say in this entry. I am sure that you can buy a car with a CVT only after a good check and MANDATORY (!) computer diagnostics. It is necessary to take into account the indicator of the oil aging counter in the variator. This is a kind of indirect sign of the actual mileage and attitude towards the car.

Buy only proven used cars. Bye

Continuously variable transmission Nissan (Jatco)

The Nissan automobile concern has developed Jatco boxes, which are now installed not only on brand models, but also on cars from other manufacturers. There are quite a lot of cars on the Russian (secondary) automobile market with a Jatco CVT, so it’s not difficult to get information about the reliability of the gearbox and their service life.

CVT Nissan

Statistics from official and independent service centers allow us to evaluate the reliability and service life of variators, the cost and feasibility of repair work, and the availability of spare parts.

When considering boxes, the emphasis will be on the CVT Nissan Qashqai, other models will also come into view. This will answer the question of whether the Nissan CVT is reliable.

CVT Nissan Qashqai j10, X-trail T31 (T32), Murano (Z50 and Z51), Teana

Jatco models JF010E and JF011E represent the second generation of continuously variable transmissions. The second is combined with 2 and 2.5 liter petrol engines, the first comes with a 3.5 liter engine. There are no differences in design; the first variator only has reinforced elements for higher torque.

Jatco JF010E

The JF011E variator was installed on the Qashqai and X-Trail crossovers of the penultimate generation, as well as on the Mitsubishi Outlander (the last two generations). JF010E went to the Murano crossover (Z50 and Z51) and the Teana sedan.

The reliability of the Qashqai variator is beyond doubt, since the gearbox family in question is not distinguished by the presence of characteristic sores. The resource is about 150-200 thousand km. Once a Nissan CVT reaches the end of its life, its components are already critically worn out.

The advantage of CVTs is their maintainability. The cost of the latter is 150-180 thousand rubles. The concern produces a valve body or variator assembly for the spare parts market. You can find some spare parts on the market, others can be repaired. A new continuously variable transmission costs 200-230 thousand. If the resource allows, you need to choose this option.

Jatco JF011E

When compared with the first generation boxes, it turns out that the new generation is almost twice as inferior in terms of service life. Manufacturing savings and simplification play a role, which affects the reliability of the latest versions of transmissions.

Nissan (Renault) variator for small engines

Atmospheric internal combustion engines with a small volume received the JF015E power transmission. The specified CVT was installed on the Qashqai and Capture crossovers, as well as on Renault Fluence with a 1.6-liter engine. A design feature of CVTs for small-volume internal combustion engines is a two-stage planetary gear. The reduced cones were good in a theoretical sense, but in reality the result was a design that reduces its service life and affects reliability.

Jatco JF015E

Answering the question about how long the Nissan variator of this family lasts, it is worth noting that the natural wear and tear of elements due to ill-conceived technical solutions occurs earlier than planned. The resource of the variator is up to 120,000 km.

Repairing the box comes down to grinding the drive and driven shafts. The requirements for grinding equipment and the experience of the craftsman are high, so the life of the repaired part may not be long.

CVT Jatco JF15

The oil pump here is the same as on the JF010E and JF011E versions. In general, we can say that a continuously variable transmission for small cars is not very reliable, has a short service life and is prone to breakdowns.

CVT8 for Qashqai j11, X-Trail T32

The CVT8 series replaced the tenth family of Jatco CVTs. Models JF016E and JF017E are based on the technical solutions of their predecessors. The engine combinations also turned out to be inherited: the X-Trail and Qashqai CVT gearbox – JF016E. The JF017E model went to Murano and Pathfinder.

Jatco JF017E

In terms of design, the representatives of the series have acquired differences. Boxes for high-volume engines required a pin belt; for cars with a smaller volume, it was decided to leave the previous option - a plate one.

Malfunctions of the Nissan variator are associated with the complication of the control system in tandem with the hardware of the old base. The service life of the units has decreased, and their reliability has come into question. The advantage of the design is its maintainability. Restoring functionality costs 150,000 rubles, which is cheaper than it was before. The essence of the repair work is similar to that which was typical for CVTs of the tenth family. The similarity of the pumps used makes it possible to replace a failed pressure relief valve.

Jatco JF015E

Smooth ride

The next most common defect occurs in the form of jerking and jerking of the car. The responsibility lies with the pressure reducing valve located in the oil pump.

The latter begins to function when the engine starts. The pump is manufactured as a monolithic unit and in the event of a defect in the pressure relief valve, it must be completely replaced. During normal operation, the valve should move freely in a mating sleeve pressed into the pump housing. Constant contact of the valve working surface with abrasive particles of wear products falling on it leads to the formation of many longitudinal scratches. When worn, the valve begins to jam so much that subsequently it is difficult to pull it out even with pliers.

The result is abnormal pressure, leading to disruption of the coordinated operation of the pulleys. This causes the belt to slip. Timely contacting the service allows you to reduce financial costs. Minor damage to the cones can be corrected by grinding. The belt must be replaced.

The most famous CVT oil sold in car dealerships is the product from Nissan NS-2 in a two-liter tin. The container of the new issue is silver, the old one is painted blue. In no case should it be confused with the old, completely incompatible NS-1 oil, bottled in pink containers.

Extreme enthusiasts who are accustomed to pulling out a stuck car by rocking with instant alternate switching of the lever from position D to R and back run the risk of encountering another problem - unpleasant jolts during the process of switching from the “parking” position to D or R. In this mode, there is practically no pause when switching. between positions D and R, although ideally a complete stop of the car is required. As a result, increased wear of the coupling spline joints inside the planetary gear in contact with the friction discs occurs. The result is the need to replace the planetary gears.

Nissan Xtrail CVT repair

Nissan X Trail CVT repairs should be carried out by professional technicians. Problems with electronics are indicated by the Service required light, a glowing notification in the Slow Down panel (will appear if the temperature indicators for the use of working fluids are exceeded).

Important! Nissan X-Trail should be tested at the first suspicion of a malfunction. Otherwise, the breakdown will get worse over time.

If the problem is caused by the motor system, strong jerks will bother you during the trip. Other probable causes of their appearance are damaged motor mounts (only replacement will help). The cause of the noise is the failure of the bearings, which will also have to be replaced.

You will have to remove the Nissan X-Trail variator if there are mechanical problems - it will not be possible to understand what the reason is without analysis. In case of failures in the control system, the pan and hydraulic units are dismantled and serviced. It is also advisable to check pulleys and belts and replace them in case of excessive wear. Minor damage to the pulleys can be sanded out. Repressing the bearings should not be done - it is fraught with deformation of the housing and pulleys.

The housing landing valve can be restored. It breaks down due to iron dust, which gets on the working surfaces in large quantities. The best way to solve the problem is to replace the pump. The torque converters are repairable, the differential bearings only need to be replaced. After repairs, it is advisable to flush the box cooling system.

Step-by-step procedure for changing the oil in a Nissan Qashqai CVT

Well, now let's get down to the procedure for changing the oil in the Nissan Kaishkai variator:

- We unscrew the left wheel boot to make it easier to remove the variator fine filter housing and the filter itself.

- Naturally, we remove the plastic underbody protection.

- We unscrew the drain plug in the variator pan and wait for the first portion of oil to drain (about 1 liter).

- Next, unscrew several bolts that hold the variator pan. We wait until the second batch of oil begins to drain.

- As the oil drains, unscrew all the other bolts and remove the pan. As a result, about 4.5 liters of oil were drained.

- Using a so-called dryer, we clean all elements (magnets, variator pan, fine filter housing, coarse filter).

- Using the same dryer, we wash off oil stains from the suspension elements and the variator housing.

- And we begin to put everything in reverse order.

- Filling with new oil

How to check the CVT on a Nissan X-Trail

The operating principles of the Nissan X-Trail T31 and 32 CVT gearbox consist in moving a belt clutch made of metal alloys into the CVT in the direction of the tangent shaft pair. In order to correct the transmission data, the current diameter of the elements is modified. The primary type transmission shaft is connected by a coupling. The input pulley acts on the secondary, pushing it out with a strap. The surfaces in the intervals from pulley to pulley change under the influence of the modulus. Thanks to this design, the belt rotates at the desired speed.

Advantages of the CVT transmission X-Trail T 31 Nissan:

- frequency of processing refined to ideal;

- reducing the likelihood of adhesion and foam formation by the transmission.

The pump develops pressure up to 60 bar. The range of gear values is expanded, the hydraulic control system has been repeatedly improved and brought to almost perfection. Failures of the Nissan X-Trail variator are possible at any period of operation, although the operating time of the box declared by the manufacturer is at least 100 thousand km. After this period, scheduled repairs are usually required.

Important! Provided regular timely maintenance, repair of the X-Trail variator will not be required soon. It is advisable to test it from time to time and check the circuit every 12 months.

The procedure for checking the variator on the Nissan X-Trail will be described below. The main signs of failure, which indicate a problem and require in-depth diagnostics, are as follows:

- slipping when moving along perfectly smooth roads;

- the indicator activating the emergency lights began to work when it shouldn’t;

- The vehicle reduces engine speed, and the transmission hums;

- there are difficulties with gears, levers jam or shift with great difficulty;

- The power of the car has decreased significantly, the driver squeezes the gas, but the engine does not work, but hums loudly;

- vibration in the selector is disturbing, which can occur from time to time or constantly;

- jerking began when moving the gearbox selector.

The main causes of problems are incorrect operation and ignoring the basic principles of variator maintenance.

Signs of malfunction of the Nissan X-Trail variator

The first in terms of the frequency of occurrence of problems with the Nissan X-Trail T31 CVT is noise. It is caused by faulty bearing parts. The noise of the Nissan X-Trail variator appears when the working service life is almost exhausted. In practice, this happens after fifty thousand kilometers, but a lot depends on driving style and other factors. Bearing failure is often associated with the design features of variator boxes.

As a result of accelerated wear, if the driver cannot operate the CVT correctly, byproducts begin to clog the device's oil passages. A pair of variator filter elements with magnets are unable to attract all the accumulated dust from iron waste. Chips begin to settle in the transmission channels, clogging them. The result is the need to change bearing parts.

Advice! You can increase the service life of bearings by reducing the transmission oil change interval to 30 thousand kilometers - this will be cheaper than repairing the Nissan X-Trail T32 and T31 variator.

When the Nissan X-Trail T31 variator growls, it is imperative to take action, but breakdowns associated with loss of power will be no less serious. The problem is disturbing when the transmission oil is not replaced in a timely manner. The main cause of the malfunction is clogged oil supply channels, the need to change consumables, and deep flush the unit. You need to test the box when you are sure that the motor is in order. If the problem is a loss of power in the engine, there is no point in restoring the variator.

You need to check the fuel filter and all sets of sensors. When changing the oil in the variator box, contamination and wear products should be removed so that the machine does not continue to lose traction.

Consequences of untimely replacement

Failure to adhere to transmission fluid change intervals may result in transmission failure.

The first symptoms that indicate that problems will soon appear in the operation of the unit and it’s time to change the oil:

- Difficulties arose when switching gear modes. When you activate the gearshift lever to a different position, shocks and jerks may appear.

- The transmission takes longer to warm up. When a lubricant loses its properties, it cannot handle all rubbing parts and mechanisms. It takes more time for it to enter all channels and lines of the transmission system.

- When switching modes, extraneous noise, hum, or rattle will occur. This indicates insufficient lubrication of the structural elements of the transmission.

- The appearance of vibration in the area of the gearbox selector.

- Engine power decreases. CVT transmissions operate without gear shifting. If the unit cannot develop enough power to activate the next position, this will also affect the power of the machine's motor.

- Due to lack of lubrication, rubbing parts will wear out faster. As a result, wear products in the form of metal shavings will begin to clog the channels of the transmission system. This will lead to a lack of pressure, which will affect the functionality of the unit as a whole.

- A lubricant leak has occurred.

- The lubricant in the Nissan CVT has become too dark, and traces of deposits and wear products have appeared in it.

- There is an unpleasant burning smell coming from the transmission fluid.

How to recognize CVT engine problems

Heat exchanger (oil cooler) of the Nissan X-Trail variator.

Traveling in a faulty car leads to the destruction of the mechanical part. This is especially true for CVTs. Bearing wear, belt damage, variator clogging with metal dust, overheating are a direct consequence of improper handling of the car. What signs indicate a malfunction of the Nissan X-Trail variator.

- Nissan X-Trail slipping out of the blue. Slipping occurs when you try to move away on a clear section of the road.

- Reduced power of the Nissan X-Trail, the engine hums as if in neutral when pressing the gas.

- Spontaneous braking of the car is a signal of serious problems with the mechanical part of the variator.

- The malfunction light on the Nissan X-Trail control panel, indicating the emergency mode of the gearbox, indicates problems with the variator.

- Any noise from the Nissan X-Trail gearbox.

- Transmission vibration.

- Characteristic shocks when changing gears.

Which is better: CVT or automatic

Taking into account the fact that today an automatic transmission can be selected by type, many car enthusiasts are interested in which type of automatic transmission is better and why.

However, it is quite difficult to give a definite answer in this case. If we consider the main pros and cons, the classic automatic transmission is the most reliable and least economical, while the CVT variator provides the best comfort, but the CVT resource is less than that of hydromechanical automatic transmissions.

Also, an automatic machine can be considered a more durable unit, which is less demanding on the quality of service. The automatic transmission is also quite repairable. A regular automatic transmission has fewer restrictions during operation; it needs to be serviced every 60 thousand km; all maintenance comes down to a complete change of automatic transmission oil and filters (sometimes additional flushing is required).

We also recommend reading the article on how to change the oil in a variator box. From this article you will learn when you need to change the oil in a variator, what kind of oil to fill in the variator box, and also what to pay attention to when servicing an automatic transmission of this type.

As for the variator, taking into account the design features, this box needs more frequent oil and filter changes (every 30 or maximum 40 thousand km). Also every 100 thousand km. you need to change the variator belt (chain). In the event of a CVT failure, repairs will be quite expensive, and given certain difficulties, difficulties may arise when searching for CVT repair specialists with a guarantee.

At the same time, unlike an automatic transmission, the CVT accelerates the car faster, the acceleration is smooth, without dips, the traction is constant (more like an electric motor). During acceleration, the motor does not spin up and there is less noise. When driving, the variator provides better responsiveness to pressing the gas pedal, taking into account constantly changing conditions, the pickup is always confident and “even” at any speed and speed.

However, despite all the apparent potential, sharply changing loads, active acceleration, driving at high speed, slipping, etc. This type of gearbox is contraindicated. If it is extremely undesirable to overload a simple automatic transmission, then doing this with a CVT variator is strictly prohibited. Otherwise, the box can fail very quickly, and repairing the variator is difficult and very expensive.

Nissan CVTs. CVT RE0F06A (Primera, Serena) - diagnostics

Home › Articles › Nissan CVTs. CVT RE0F06A (Primera, Serena) - diagnostics

DIAGNOSTICS CVT NISSAN PRIMERA, SERENA RE0F06A

Previous articles on the site discussed the design and operation of the NISSAN RE0F06A CVT transmission, as well as issues related to its repair. As practice has shown, more than half of the problems that arise among owners of cars with this type of transmission are caused by the complete ignorance of their owners and service centers that undertake repairs.

What is the main mistake : incorrect diagnosis, lack of diagnosis, neglect of diagnosis. It is impossible to understand the owner or service specialist when transmission repair begins with its disassembly without identifying the initial causes. There are hundreds of examples where the owner's SPORT or CVT indicator is flashing, however, he continues to drive. The psychology is that at speed or rpm to 5000 something will still switch in it. So, at 3000 rpm they can drive for an hour at a speed of 40 km/h, and then they wonder why smoke came out of the box - probably because the variator is a bad box. But to stop and make up your mind is not enough. In my opinion, this is the lack of consumer culture or neglect of operating rules, first of all. Somehow they don’t like to follow or read anything - everything is done in their own way, at random. Maybe he’ll switch gears, maybe I’ll get there.

But most cars have Russian-language owner’s manuals, in which it is written with pictures and in large font what to do in this or that case when turning on the diagnostic control lamps. The manuals were compiled by competent engineers at manufacturing plants, who certainly know why something is possible and something is not. Nobody knows better than them. And they have no goal of demanding a similar level of knowledge from the owners - this is impossible, and not necessary. A housewife who gets behind the wheel should not know how the car works. But you must follow traffic rules and operating rules. Abroad, such violations are subject to fines. In our country, everything is the other way around, so independent repairs lead to an increase in accidents on the roads . Either the wheel came loose, then the drive fell out, then the ball joint burst out of the blue, etc. So, to prevent this from happening, you need to do diagnostics .

Let's consider diagnostics of the RE0F06A CVT transmission installed on several types of NISSAN engines. First of all, there are two fundamental differences depending on what type of throttle valve is installed on the engine to which the CVT is mounted. This can be a mechanical throttle valve driven by a cable or an electronic one - to which no cables are connected. There is a “rare case” of an electronic damper on a NISSAN CEDRIC\GLORYA with VQ25/30DD Neo Di engines, in which the damper is electronic, but a cable is connected to it from the gas pedal from the passenger compartment. This is the first type of damper of this type; for reliability and implementation of an emergency mode, the APPS (gas pedal position sensor) was installed on the damper itself, and the cable mechanically allowed the faulty damper to be opened at a small angle for movement in the event of the drive motor failing. There was a lot of confusion about this, but it is still a fully electronic throttle. On new types, due to very high reliability, the possibility of emergency mechanical opening was removed.

The first type of mechanical throttle was installed on the SR20DE in two versions: with a linear idle speed control and with a proportional servomotor stepper. The model of the first is RNESSA U30, LIBERTY P12 of the first years of production since 1997. The second option is SERENA PC24 of all years and the above mentioned later releases.

An example of a LIBERTY, RNESSA damper from early years with a linear idle air control.

The second type is an electronic damper. Example - PRIMERA P12 and all other cars with a QR20DE engine. Let's just say that self-diagnosis is possible using the first type - mechanical, and the second type - electronic, without any tricks. On the SERENA PC24, the main obstacle is the vacuum throttle servo, which opens the throttle valve slightly for easier starting.

Now let’s determine how diagnostics differ from self-diagnosis for this type of machine. First of all, the CVT control unit has two memory sections for storing errors, the so-called CURRENT (current) and HISTORY (event storage). If there is a current error at a given time that is causing the CVT to operate in emergency mode, it will be displayed on the scanner display at that point in time or in the current error memory. In accordance with the logic of recording an error in the current error memory, it may or may not be displayed on the scanner display. In this case, the SPORT-CVT lamp on the instrument panel may flash a certain number of times - usually 16. This is not an error code, but simply information to the driver that there is an electronic problem with the CVT. The developers calculated that the duration of 16 blinks of the warning lamp is enough to attract the attention of an adequate driver before starting to move, but did not take into account that in Russia this is not enough for most drivers.

As a rule, this lamp blinking occurs when there is a CVT malfunction and subsequent stop-start driving. It looks something like this: the CVT stopped switching adequately, and after the next turn on the ignition and started the engine, it began to blink. If you turn off the ignition and turn it on a second time, the SPORT does not blink, but lights up properly for 2 seconds and goes out.

The instruction manual says that this lamp should light up for two seconds and go out - this means that the CVT electronics are working. After this you can start moving. Here, connecting the scanner in the mode of reading current errors may not show anything: that is, there are no errors. And this is correct: if all parameters are normal, the CVT works properly. But what if the CVT goes into emergency mode (inadequately selects the speed transmission), and when connecting a scanner, there are still no errors, even if the SPORT-CVT lamp is flashing? There is a HISTORY section for this, but it cannot be considered a scanner, and not at all: neither a dealer CONSULT, nor a Chinese one. This mode is only available in self-diagnosis. And to carry it out, you need to understand what type of throttle you have on the engine, because a necessary condition for its startup is the idle signal from this throttle valve. To do this, all types of motors must be warmed up to operating temperature, after which on the SR20DE with a vacuum servo drive it must be turned off before starting self-diagnosis.

Self-diagnosis procedure for RE0F06A

- warm up the engine to operating temperature

- secure the car with the parking brake

- turn on the ignition by turning the key to IGN ON, turn off to OFF for a second; repeat twice: IGN ON-OFF-ON-OFF

- press the brake pedals and move the gear selector to position D; hold down the brake pedal

- no earlier than 5 seconds after completing step 4, turn on the ignition IGN ON

- The CVT-SPORT warning light should light up for 2 seconds and go out

- immediately after the CVT-SPORT lamp goes off, release the brake pedal and move the selector lever to L

- Press the brake and gas pedals simultaneously (gas pedal all the way) and move the gear selector lever to D

- release both pedals at the same time completely

- read fault codes from the SPORT-CVT lamp

If all the conditions are met correctly and there is no empty beer can or rolled-up rug lying under the gas pedal, the SPORT lamp will light up for 2 seconds, go out, and then start flashing in 0.5-second flashes (short flashes). There will be 10 or 11 flashes in total - it doesn’t matter. If all 10 or 11 flashes are short or identical, then there are no errors in the HISTORY memory. This does not mean that they do not exist at all. This can only mean three things: either the CVT is working, or faulty, or someone erased them. You can erase the HISTORY and CURRENT memory by removing the negative terminal of the battery for a minute.

The most interesting thing is that it is faulty! Yes, there are cars like RNESSA in the back of the U30 from 97-99, with unique CVT control units that do not store HISTORY. This is a software defect in the unit. You can find a fault in such cars only by driving it with a scanner in current data mode. This has been installed experimentally on several machines. If you do not have such a machine, then all the impulses will be short or in a pack of short ones - some will be longer. What it looks like: suppose short pulses are I, long pulses are O, and the starting two-second pulse is S.

| Option 1 | everything is fine | SIIIIIIIIII |

| Option 2 | 4 are longer than the others | SIIIOIIIIII |

| Option 3 | 4 and 6 are longer than the others | SIIIOIOIII |

The procedure for displaying codes in self-diagnosis mode is cyclical, that is, everything is repeated in a circle until you turn off the ignition for 10 seconds. Why 10 seconds - this is how NISSAN does it, the control units have backup power to store various settings and calibrations, so they are turned off not by turning the key to OFF, but on their own, having completed internal recordings and calculations. Complete shutdown of the units occurs about 6 seconds after turning the ignition OFF, so the regulations require turning them off for 10 seconds before turning them ON again. Then the initial initialization of external circuits occurs, that is, their diagnostics. If this condition is not met, the CVT unit does not perform initial diagnostics and does not detect new faults.

Regarding 10 or 11 pulses in self-diagnosis mode, many copies have been broken on club forums for these car brands. There is only one reason: about 6 years ago, an article I wrote on www.autodata.ru with the given algorithm was copied to absolutely all RuNet forums without even indicating the authorship - many passed it off as their own. But time passed, other engines appeared, other CVT units and the developers added another code - 11. No one gave an explanation for this in the clubs (it’s easier to copy than to explain), they considered it a mistake for many years, then the passions subsided.

Diagnostic and self-diagnosis error codes are also in the first articles, we will not consider all of them, we will focus on a few. Let's start with self-diagnosis code 9. ENGINE SPEED SIGNAL (DTC: 0725) Its popularity on club forms was so high that a week I received at least two letters with this question, and sometimes collective club letters asking for an explanation. The battles there were apparently hot, but useless. Code 9 literally says: “The engine speed signal does not arrive at the CVT control unit.” How many people, with “nothing to do”, were “picking” serviceable machines in search of a malfunction - it’s terrible! And there are even more services. Without having done anything (without breaking it), they gave it back with the words: “Well, it goes - ride it while it goes.” In fact, self-diagnosis is carried out with the engine turned off. In other words, if the ignition is turned on, this does not mean that the engine needs to be started. In the self-diagnosis conditions, it is indicated only to turn on the ignition. Naturally, the CVT unit in this mode does not receive an engine rotation signal (it is not started) and can give the 9th flash longer than the others. It is clear that this is not a malfunction. And this error appears on units with old firmware. A full check can only be done by connecting the scanner in current data mode and viewing the line with engine speed parameters after starting it. Line 3 engine speed. Photo 2:

The next “interesting code” is 4 STEP MOTOR (DTC: 1777) – photo 3:

There was a time when on the forums, for any reason and for no reason, everyone advised and changed STEP MOTOR. The CVT is slipping - change the step motor, the CVT does not shift virtual gears - change the step motor, the CVT does not go back - change the poor step motor. Etc. But it is not cheap, and the procedure for replacing it involves draining the oil from the CVT, and then removing the pan and filter. There have been cases where they were installed incorrectly. We met - when they changed several times - “they say, it’s defective, maybe I got caught?” There was a problem, without doing diagnostics, they changed the step motor - no result, decided that it was bad, bought another one and changed it again, still no result - off we went, “burned” the box. We bought another box. And this is not the most “tragic option”.

The problem is that self-diagnosis alone is not enough here - you need to connect a scanner, look at the data in motion, check the windings with an ohmmeter. Depending on the year of manufacture and firmware of the CVT control unit, there may be two codes: P1777 and P1778. One of them indicates an electrical break - this is code 4, and the second indicates a mechanical failure of the step motor or CVT operation. There is no substitute for self-diagnosis; you need a scanner. But not every scanner displays errors correctly. The fact is that NISSAN has introduced a text description of the error - for example, STEP MOTOR. There is an OBDII code P1777, there is a self-diagnosis code 4, but there is also a STEP MOTOR text output. If you connect CONSULT, it will simply write STEP MOTOR in text on the screen. There will be no P1777 code there. Some multi-brand scanners can display P1777, and you will find an explanation for it in old repair manuals. In new manuals there may not be such a code - there will only be the text STEP MOTOR. The situation is worst with Chinese clones: there could be anything like 0001b - this is a diagnosis that leads to a dead end. Based on its results, you can only be guaranteed to spend money and not find the cause of the malfunction. Therefore, you shouldn’t do diagnostics with just anything, at least to obtain reliable data. Inaccurate data leads to erroneous repairs. The main problem with STEP MOTOR is a break in one of the winding phases or a change in resistance beyond the permissible limit. It is simply constructed and cannot be repaired. Reason for leaving: inadequate speed limit - racing. The oil in the box heats up over 100 degrees during intense driving, and the step motor itself also heats up due to the current flowing through its windings. At some point, for very passionate drivers, the sum of the oil and winding temperatures goes off scale, the windings become sintered or break off due to different thermal expansion of plastic and metal. Photo 4, 5:

Error 5 (P1791) – CVT FLUID PRESSURE SENSOR pressure sensor malfunction.

This CVT uses a single electronic pressure sensor to estimate secondary or driven pulley pressure. When the ignition is on, the voltage from the sensor should be 0.45 volts, at idle – about one volt. If a code 5 is received during self-diagnosis, this means that the voltage from the sensor is either zero or about 5 volts, which is usually a malfunction of the sensor itself. However, the CVT behaves quite adequately, changing the locking moment very slightly. Most drivers do not notice any deviations and, in general, such a CVT can be safely driven. The only negative is not assessing the pressure of the secondary circuit and the current error.

It does not affect the amount of pressure itself: if the pressure is good, the CVT maintains its service life, if the pressure is low and the box is slipping, then no amount of replacing the pressure sensor will help it. Just rebuilt with new pulleys and belt. The sensor itself is non-separable and cannot be repaired - only replaced. It costs almost as much as a step motor.

Error 1 (P0720) vehicle speed sensor (VEHICLE SPEED SENSOR CVT (SECONDARY SPEED SENSOR). Photo 6

The most common error that occurs on machines over 8 years old. This error is especially likely to occur among owners who like to exceed speed limits. The speed sensor itself is a self-contained pulse generator operating on the Hall effect. It includes a permanent magnet to create a magnetic field, a Hall element - a microcircuit that responds to changes in magnetic flux and external control circuits. When 12 volts is supplied to the sensor, it responds to changes in magnetic flux by producing a rectangular pulse. The sensor is located above the differential gear and reads the number of teeth of the main pair as it rotates. Based on this signal, the CVT unit receives information about the rotation speed of the secondary pulley, and since it is rigidly connected to the drive wheels, also about the vehicle speed. But this is not actually a vehicle speed signal. The speed signal in these cars is generated in two ways - through a separate speed sensor on the differential housing, or through the ABS system, which reads the speed from the wheel sensors, generating a common speed signal for the rest of the units. The reason for the failure is overheating and aging of components. The measuring part of the sensor is heated by flows of oil captured by the differential gear. The range of operating temperatures is very wide: outside -40 degrees. – CVT works; after warming up and in hot weather the temperature is above 120 degrees – the sensor continues to work. After 8 years of such fluctuations, disruptions occur in its work. At first, when it heats up a lot, the signal starts to disappear from it. The CVT goes into limp mode. The hydraulic and electronic parts of the control are designed in such a way that a virtual third gear is fixed, in which the car continues to move. But you can’t drive like this for a long time: due to the torque converter lockup being disabled, the oil quickly heats up to the upper temperature limit. This leads either to boiling of the oil and its combustion, or to a drop in pressure and slipping. All this irreversibly damages the CVT, causing pulley scuffing, and this effect is usually achieved by those drivers who are trying to get somewhere at any cost. Usually they don't arrive. If this happens, you need to stop as quickly as possible and turn off the engine so that the transmission cools down. After this, even if the SPORT-CVT lamp flashes 16 times, the car will move adequately and will drive until the next overheat. There is only one way out - change the sensor before it’s too late. The premature output of this sensor is caused by prolonged driving at high speed in hot weather (160 km/h for an hour). Photo 7

The sensor cannot be repaired; it must be replaced with a new one. There have been many cases where, precisely because of the failure of this sensor, owners changed the CVT box without understanding the reason. Due to a failure to move at a high speed of 160 km/h, after switching to third gear, the owners revved their engine over 8000 rpm. Those who realized it in time, reduced the speed to 100 km/h and got there, and those who, after the CVT cooled down, continued to drive in the same spirit, changed the engine due to a broken connecting rod. Well, there’s no point in even talking about broken chains and scuffs on the pulleys.

Error 2 (P0715) or PRIMARY SPEED SENSOR (I/P SPEED SENSOR) is a similar sensor that reads the speed of the CVT input shaft or drive pulley. Error 2 appears less frequently due to the lighter temperature regime of this sensor compared to the secondary one. It is located on the side cover, is better cooled by the oncoming flow and lasts longer. The reasons for refusal are the same. Based on exactly two sensors, the control unit is able to estimate the CVT gear ratio (at what radii the belt is located) and calculate the required gear ratio depending on the driving conditions. It differs from the secondary shaft speed sensor only in the rotation of the mounting bracket. Electrically fully compatible.

The message on the scanner screen INITIAL START is not an error - it means that the power to the CVT control unit was lost and the TCM was reinitialized. The control unit itself very rarely fails, but the owners help it very diligently. To be repaired. Photo 8

Conclusion

- In case of any malfunction, the car must be diagnosed before anything is removed or disassembled. A disassembled unit is subject only to visual diagnostics, and if the control lamps are blinking, then this is often a problem in the electronics, and not in the bolts with which the box is secured.

- There is no need to remove the terminal from the battery after each CVT emergency condition - like “erase errors”. Until the cause is eliminated, it is useless to erase errors, since the source of this error, for example the sensor, has not been eliminated. And until it is replaced, the malfunction will be repeated hundreds of times, reducing the resource and wearing out the unit once again. To reset current errors, just turn off the ignition for 10 seconds; if this is not enough, then let the unit cool down. If this is not enough, take the car to a service center. And it’s completely stupid to remove the terminal from the battery before coming to the service center.

- Towing of modern transmissions is extremely undesirable. During any towing, a complete oil change is a prerequisite, but in any case of towing, it is damaged - at least, its service life is reduced.

- All electronic units of modern cars are interconnected by data exchange buses. It is impossible to diagnose a unit separately from the machine if it uses adjacent sensors and common signals.

GADZHIEV A.O © Legion-Avtodata Gadzhiev Arid Omarovich, Moscow, Ermakova Roshcha str. 7A, territory 14 TMP, www.nissan-A-service.ru tel. +79265256300, e-mail, Union of Automotive Diagnosticians

Diagnostics of the Nissan X-Trail variator

Diagnosis of the Nissan X-Trail T31 or T32 variator comes down to following the following recommendations. First you need to get behind the wheel and drive off. If the start was smooth, without extraneous noise, everything is in order with the Nissan CVT package. Growling and noises indicate that the package is not working correctly - it is not a fact that it is completely faulty, but there are defects. You will need to check:

- variator oil level;

- smell and color of the liquid.

The motorist or service station employee takes out the dipstick and evaluates the shade of the oil. Ideally, the technical fluid should be light-colored, without dark spots, streaks, or other impurities. The aroma of burning is unacceptable.

Important! Taking into account the condition of the car (heated or cooled), the oil level will change. A hot engine contains more fluid than a cold engine.

Now you need to drip the liquid from the dipstick onto a white blank sheet of paper. Assess the presence of compactions and black spots on the drop. If they exist, we can talk about various types of malfunctions and the need for a more thorough check of the X-Trail variator.

It is imperative to inspect and test the CVT box - no cracks, nicks, or chips. The measuring tool will allow you to accurately assess the unevenness and distortions of the Nissan variator. You need to understand that if there are chips or nicks, cracks may soon appear in the working parts of the mechanism, and the variator box will begin to gradually deteriorate. All this leads to the fact that the Nissan X-Trail T31 variator twitches, the mechanism jams and jams.

The next point that needs to be clarified as part of the diagnosis is the current state of the speedometer. If the unit is not working, the reason may lie in the transition of the belt part to the emergency position. When the car is moving at low speeds, belt deviation will go unnoticed, but for racing this situation is deplorable. The main unpleasant consequences are sudden emergency braking and breaks in the working parts of belt drives.

To understand the causes of vibration of the Nissan X-Trail variator and the occurrence of other problems, you need to:

- Warm up the car while driving.

- Disconnect battery power consumers.

- Insert the keys into the lock and activate the “ON” position. Repeat the “OFF-ON” switch several times, leaving the device in the on position.

- Turn on the ignition, wait for the light bulb to light up, then turn it off.

- Press the brake pedal. Activate the “drive” mode for the selector.

- Turn the ignition back on, release the brake pedal, and move the selector knob to position L.

- Depress the gas and brake pedals, move the selector to “drive”, release a couple of pedals.

At this point, the self-diagnosis of the Nissan X-Trail variator can be considered complete. If the emergency mode is not deactivated, it is worth checking the Step Motor windings at the variator box connector in the area under the battery. Through this connector you can access all electronic internal components.

Methods for checking the variator

The main disadvantage of a CVT transmission is its high technological and technical complexity and it is quite difficult to buy a car with a decent mileage at the same time with a live CVT and any repair of a CVT transmission is expensive. The main points and points that you should pay special attention to when buying a car with a CVT transmission and diagnosing the CVT.

Rules to follow

The check must be carried out on a flat surface; there should be no hum in the variator because this may mean wear of the bearings, and replacing them is a rather expensive procedure; jerking and jerking of the variator most often occurs due to a malfunction of the oil pump pressure reducing valve; this is also an expensive procedure.

Oil check

The first thing you need to do is check the color and smell of the oil in the variator; Dextron type oil is not poured into the variator; only special fluids for the variator are poured; they are mostly yellow. You need to take a white sheet of paper or a lint-free cloth and drip oil from the dipstick; if it contains metal particles such as dust or sediment, you should not take such a car. If the oil in the variator is dirty, then think about it because... The oil may not change color much during operation.

Checking the variator in different modes

After checking the oil level in the variator when it is cold, start the car and let it warm up, at the same time, no blinking of “D” should accompany the start and switching of the selector and, more importantly, if “D” does not light up, it is better to immediately refuse the purchase and not believe in that the light bulb in the dashboard has burned out. After the car warms up, check all selector positions in each mode “D, P, R, N, L”, they should all be present on the dashboard and not be accompanied by a jump in speed above 50 rpm; there should also be no extraneous sounds or knocks “in R mode there may be a rustling or similar extraneous noise - this is a feature of the variator.”

After you have checked all the selector positions, check the oil level on a warm engine and gearbox; the oil level on cold and hot should be different.

Checking the variator in motion

From the “N” mode, without pressing the brake pedal, move the selector to the “D” position; there are no strong shocks or sounds, which means we look further, in the “D” mode we gradually gradually pick up speed at 2000 rpm, the speed should pick up just as smoothly and the variator should work quietly and without shocks, if everything is in order, we check further, from mode “D” we go to mode “N”, we coast for a couple of meters and brake, then we put it in mode “P” if no jumps in speed have occurred and the variator still works very smoothly.

Test under load

In mode “D” and holding the brake pedal, you need to sharply press the gas pedal “hold for no more than 5 seconds”, the revolutions should stop within 2400 - 2800, if this does not happen and the revolutions have not risen to the desired level or, on the contrary, have risen much higher, then you can check further postpone.

When picking up speed and accelerating, there should be no jolts or sudden dips; the speed should be picked up smoothly without noise.

CVT design

Nissan

CVT cross-section The CVT (Continuously Variable Transmission) is distinguished by the ability to smoothly change gear ratios. This allows you to realize the traction capabilities of the engine with maximum completeness.

The transmission gears are replaced by a belt with two pulleys. The variator pulley is a cone of variable diameter. The convergence and divergence of the cones changes the radius along which the metal belt moves.

This is the main difference in the design, which allows you to abandon the usual gear shifting.

The steel belt is a vulnerable part of the system and must be replaced periodically.

Metal variable transmission belt

The oil pump is designed as a single unit with a chain drive and must be replaced if the pressure relief valve is damaged.

Oil pump for Nissan X-Trail variator

The first mass-produced CVT engines were installed on Nissan Qashqai cars. X-Trail models have new engines with a number of design improvements and protection against incorrect user actions.

How to change the oil yourself?

You can replace the Qashqai transmission yourself or with the help of specialists at a service station. We will tell you how to properly perform a complete lubricant change with your own hands.

Tools and materials

What you will need to complete the task:

- fresh oil, 2 cans are required for a full change;

- a set of wrenches and open-end wrenches;

- flat head screwdriver;

- a cut-off bottle or bucket into which used oil will be drained;

- clean rags;

- watering can;

- new sealing rubber for the CVT pan, the old one is damaged during dismantling;

- a special product or diesel fuel for cleaning the pan and filter device;

- a new coarse mesh filter, if the installed mesh cannot be washed.

User Evgeniy Lipovka showed in his video how the procedure for changing the lubricant in a Nissan Qashqai CVT transmission is performed.

Stages of work

Replacing consumable fluid is done as follows:

- The vehicle is driven into a garage with a pit or onto an overpass. To make the lubricant more fluid, the car engine warms up to operating temperature.

- Get under the bottom of the car and remove the crankcase protection. Please use the service book before performing the procedure. The protection is fixed with bolts or special fasteners.

- Unscrew two more screws located on the front part in the subframe area. The procedure is performed with an open-end wrench.

- Remove the four pistons located on the sides and one on the front. To dismantle, pry up part of the part in the middle and pull it down, so you can remove the lock.

- Check the lubricant level in the transmission unit. We talked about level control above. Volume diagnostics must be carried out during a change. This is done so that in the event of a leak, the car owner knows that there is a problem. If there really is a leak, the gearbox housing, oil seals and seals are diagnosed. All damaged items must be replaced.

- If the lubricant level is normal, crawl under the bottom of the car and find the drain plug. Before draining, place a container underneath to collect the waste substance. Unscrew the plug with a wrench and wait until the oil drains from the gearbox.

- If it is necessary to replace the pallet gasket, dismantle the product; to do this, unscrew all the screws that secure it. There may be some oil in the pan. When dismantling it, be careful not to spill the lubricant on yourself.

- There are two magnets installed inside the tray. Assess their condition, as well as the condition of the used lubricant in general. The magnets must be cleaned of wear products in the form of metal shavings. For cleaning, you can use a special cleaner or acetone.

- Remove the filter and clean it. The filter device is replaced if the cleaning procedure does not produce results. Reinstall the filter, as well as the magnets in the tray. Get rid of the remnants of the old seal around the perimeter of the pan. Install a new rubber band, treating the seat with sealant. Reinstall the tray, securing it securely with the bolts.

- Place a funnel in the hole and pour fresh lubricant through it. When the oil is filled, check the level of the substance and take a test drive. Measure the amount of lubricant in the system again.

Not so long ago, newly produced cars began to be equipped with completely new types of transmission - CVTs. The name comes from the English phrase Continuously Variable Transmission, which means “continuously variable transmission”.

This type of gearbox is often called by its abbreviation from its name in English - CVT. The very concept of this technical solution is not new and has been used on some types of equipment for a long time.

The technology of continuously variable speed control became widespread only when it was possible to achieve an acceptable service life of the CVT transmission.

The car, in addition to the standard automatic, was also equipped with a CVT gearbox. In this article, we will consider in detail the procedure for changing the oil in the variator of a Nissan Qashqai car.

Problem areas of bearings and replacement

The most common problems with CVTs are abrasion of worn-out bearings.

If you hear noise or hum from the gearbox, the cause of the malfunction is most likely worn bearings. The bearing life is about 80 thousand km with proper handling. Since most problems with Nissan CVTs are related to driving errors, you need to take 50 thousand km as the starting point. CVT cone failure

Repairing Nissan X-Trail CVTs with replacement of bearings will cost about a thousand dollars, often more, since repairs cannot be done by replacing bearings alone.

Worn metal parts produce abundant metal shavings, which clog everything and lead to further and progressive damage...

The procedure for changing the oil in the Nissan Qashqai variator

Before starting the replacement, it is recommended to warm the fluid in the variator to operating temperature. To do this, depending on the time of year, you need to drive 10-15 km or let the car idle for 15-20 minutes. Thanks to the heat exchanger, the oil in the variator will warm up even without load.

After placing the car on a viewing hole or lift, the pan is cleaned of adhering dirt. Carefully remove the drain bolt. An empty container is inserted.

- The bolt is unscrewed completely and the spent fluid is drained. You need to wait until the stream of oil turns into droplets. After this, the plug is wrapped back into the hole.

- Carefully remove and unscrew the bolts securing the pallet. The pallet is carefully separated from the box. There is still some oil left in it. This oil is also sent to a waste container.

- The bolts securing the coarse filter are unscrewed. The mesh is carefully removed.

Important! Be careful not to lose the o-ring. It does not always come with a new filter.Some car owners wash the mesh on the old filter, thereby saving several hundred rubles. But it will not be possible to wash it completely, since fine shavings are firmly clogged between the layers of mesh material. Therefore, saving on this element is a very dubious activity.

- A new coarse filter is installed.

- The tray and two magnets are cleaned of sediment and small chips. At this stage, it is important to pay attention to the amount and structure of the chips. Sometimes it is during the process of changing the oil that it is possible to detect and eliminate serious malfunctions in the operation of the variator before the limiting state occurs. Additionally, the geometry of the pan is checked and the contact surfaces for the gasket are cleaned.

- The front left wheel is removed.

- The air duct, the plastic protection of the left front arch, the battery and the stand under it for access to the heat exchanger are dismantled.

- Carefully disconnect the antifreeze and transmission oil supply hoses. The holes can be plugged with a clean rag or other available means.

- The heat exchanger is disassembled and the fine filter is changed.

- A new O-ring is installed in the housing. The heat exchanger is assembled in the reverse order. The dismantled parts are installed in their places.

- The tray is installed in its place. When tightening its fasteners, it is important to remember that the CVT gearbox housing is made of aluminum alloy, the diameter of the bolt thread and its length are small. Therefore, under no circumstances should you use excessive force when tightening the bolts.

You can roll the thread. If you have a torque wrench, it is better to use it. The tightening force is 30 Nm. - A new copper ring is placed under the drain plug. The plug is screwed into the pan.

- New oil is poured through the dipstick channel in an amount approximately equal to the drained oil. The level is checked. The fluid is added to the COLD mark on the dipstick.

- The engine starts and at idle speed the oil warms up to operating temperature. The level is checked again. It should be at the HOT mark. If there is sufficient supply, topping up is performed.

This completes the procedure for changing the oil in the Nissan Qashqai variator.

For those who don't like to read. Detailed video of changing the oil in the CVT of a Nissan Qashqai

Conclusion

As can be seen from the instructions for changing the oil in the CVT gearbox of the car in question, there is nothing complicated about it. You just need to carefully and one by one follow the instructions. Change the oil more often than scheduled - and the variator will serve for a long time and trouble-free.

The Korean manufacturer's regulations state that the oil change in the Nissan Qashqai gearbox with a CVT must be done at least every 60 thousand kilometers. However, the Qashqai has an overly sensitive transmission.

It endures especially “painfully” poor-quality road surfaces, as well as off-road conditions. Such operating conditions negatively affect the condition of the mechanical transmission components and lead to their rapid wear. Therefore, owners of Kashkai cars with a CVT are advised to change the gearbox oil every 30 thousand.

Qashqai 1.6

- RE0F11A 1/1

- Volume 7.1 liter

Qashqai 2.0

- Gearbox in block with final drive, variator

- RE0F10A 1/1

- Volume 7.5 liter

- Set of pan gasket with internal filter

- External filter cartridge

- Bearing

- Pan gasket

- Drive belt

- Oil filter

- A couple of seals

Note:

For cars with 2.0 l and 1.6 l, the gasket and filter are different