· 20.08.2013

This system provides the optimal intake timing in each cylinder for given specific engine operating conditions. VVT-i virtually eliminates the traditional trade-off between high torque at low revs and high power at high revs. VVT-i also provides greater fuel economy and reduces emissions of harmful combustion products so effectively that there is no need for an exhaust gas recirculation system.

VVT-i engines are installed on all modern Toyota cars. Similar systems are being developed and used by a number of other manufacturers (for example, the VTEC system from Honda Motors). Toyota's VVT-i system replaces the previous VVT (2-stage hydraulically actuated control system) used since 1991 on 20-valve 4A-GE engines. VVT-i has been in use since 1996 and controls the timing of the opening and closing of intake valves by varying the transmission between the camshaft drive (belt, gear or chain) and the camshaft itself. To control the position of the camshaft, a hydraulic drive (motor oil under pressure) is used.

In 1998, Dual VVT-i appeared, controlling both intake and exhaust valves (first installed on the 3S-GE engine in the RS200 Altezza). Dual VVT-i is also used on new Toyota V-engines, such as the 3.5-liter V6 2GR-FE. This engine is installed on Avalon, RAV4 and Camry in Europe and America, on Aurion in Australia and on various models in Japan, including Estima. Dual VVT-i will be used in future Toyota engines, including the new 4-cylinder engine for the new generation Corolla. Additionally, dual VVT-i is used in the D-4S 2GR-FSE engine in the Lexus GS450h.

By changing the opening moment of the valves, starting and stopping the engine is almost imperceptible, since compression is minimal, and the catalyst very quickly heats up to operating temperature, which sharply reduces harmful emissions into the atmosphere. VVTL-i (stands for Variable Valve Timing and Lift with intelligence) Based on VVT-i, the VVTL-i system uses a camshaft that also controls the amount of opening of each valve when the engine is running at high speeds. This allows for not only higher engine speeds and more power, but also the optimal opening timing of each valve, which leads to fuel savings.

The system was developed in collaboration with Yamaha. VVTL-i engines are found in modern Toyota sports cars such as the Celica 190 (GTS). In 1998, Toyota began offering new VVTL-i technology for the 2ZZ-GE twin-camshaft 16-valve engine (one camshaft controls the intake valves and the other controls the exhaust valves). Each camshaft has two cams per cylinder: one for low rpm and one for high rpm (large opening). Each cylinder has two intake and two exhaust valves, and each pair of valves is driven by a single rocker arm, which is operated by a camshaft cam. Each lever has a spring-loaded sliding tappet (the spring allows the tappet to slide freely over the high-speed cam without affecting the valves). When the engine speed is below 6000 rpm, the rocker arm is actuated by a “low speed cam” through a conventional roller tappet (see figure). When the speed exceeds 6000 rpm, the engine management computer opens the valve and oil pressure moves the pin under each sliding tappet. The pin supports the sliding pusher, as a result of which it no longer moves freely on its spring, but begins to transmit the influence of the “high-speed” cam to the swinging lever, and the valves open more and for a longer time.

I spent a long time choosing a car for my wife. I've been driving Toyotas for a long time and respect them. The Corolla fit almost perfectly. But to be honest, I couldn’t dare call her pretty. She reminded me of the face of unfortunate beauties after plastic surgery, when the bandages had just been removed. When I saw the photos of the updated one, the desire intensified significantly. I give the designers a 5+. It became at least clear what that surgeon meant. Well, that's not the point. The taste and color, as you know...

An honest 11.9% loan from TOYOTA Bank completed the defeat of doubts.

Now to the question of marketers.

Apparently I will never be able to understand the logic of these people. I can forgive the “oars” in the rear doors, the cheap standard radio, etc. But the lack of a stabilization system IN ANY EQUIPMENT is annoying, to put it mildly. Of course, I understand that you need to distribute the cars into different segments so that there is no internal competition for the manufacturer, etc. But BOSСH sells it to you for $200!!! And by the way, she saves lives. There is nothing worse than a head-on accident on the highway. And they often occur precisely because of loss of traction. I personally, without blinking an eye, will pay 10-15 thousand rubles for it. I'm sure I'm not the only one.

And one more sad thing.

I mean about the boxes. They have never been Toyota's strong point. Not in terms of reliability. There is just complete order here. And in terms of advancement. Toyota is hopelessly conservative on this issue. It is generally accepted that the “robot” that was originally equipped with this machine was not a success. Of course, I am very glad that it was replaced with a classic machine gun.

BUT WHY FOUR-STAGE?? Everyone has had five or even six gears for a long time now! To hell with the Corolla. How did you decide to equip the RAV4 with a 4-speed mortar?

And finally, the last fly in the ointment.

Heated seats. Why only two positions on/off?? Of course, I don’t pretend to have smooth adjustments like on Lexuses. But Hi/Lo is just what the doctor ordered. Hi - warmed up, Lo - drive all day. And then On and in a couple of minutes - your omelette is ready, sir! But turning these tiny buttons on/off all the way is inconvenient and unsafe, since both of them are located on the right behind the gearbox poker and it’s rarely possible to feel them without looking. And on the left in this place there is a plug. But why???

That's probably all that's unpleasant.

Hand on heart, I say - the car is great! Which is not surprising. This is the meat of Toyota sales. Engineers have no room for error in this model.

The 1.6 Dual VVTi engine is beyond praise! I give the mechanics a standing ovation. Excellent pull both from below and above. This must, to a large extent, smooth out the long gears of the box. By the way, despite 4 steps, the box, oddly enough, still deserves at least a 4+ mark. The lack of fifth gear on the highway and the not-so-great desire to jump down when overtaking are most likely just my imaginary quibbles. Everything is quite expected for a machine gun from the 20th century. But in the city the gearbox behaves like a solid 5! No extra kickdowns at the right time, when it’s too late to squeal the engine, the window in the next row has already been occupied.

I would like to end the alliance engine box with positive fuel consumption figures. On the highway computer showed 6.4, and judging by the gas stations, this is not far from the truth. I won’t write about city fuel consumption. It will be different for everyone. Based on my own experience, I can safely say that it depends on two important factors: the driver’s temperament and his honesty. Besides, there is discord between city and city. Some have avenues with traffic lights every 3 km. And someone gets stuck in traffic jams throughout their life

Now about the suspension.

In my opinion, an almost perfect balance of comfort and handling. I drove a Camry - it was too soft. Very rolly in corners. But it is understandable. It was made for the fat butts of hamburger and cola eaters. In fact, Russia is the only country other than the states where Camrys are sold. Apparently no one tried to remake it for us.

I went for a test drive of the new Avensis. It is tough. Especially from behind. It's a pity. The previous “broom” was very pleasant.

So the Corolla is the golden mean. Moderately energy intensive. It steers great. Certainly not BMW. but for its segment the handling is very pleasant

In terms of ergonomics, everything is for me. Maybe because I've been driving Toyotas for a long time. Or maybe just “Euromobile – 1 piece”. Nothing creaks or rattles in the cabin. The plastic, of course, could be softer, but looking at the price tag you understand that it’s normal. The seats are very comfortable. Nice lateral support. Of course, it’s a bit cramped in the back for three adults. But gentlemen! Have a conscience. This is a “C” class! The trunk deserves a rating of 4. It is quite roomy, BUT the lid hinges, of course, spoil the impression.

The budget option for restyling the rear lights is a little disappointing. Of course, I understand that remaking an iron trunk lid is expensive. But these inserts of white reflectors at the bottom on dark cars are like an eyesore. That's why it's just plain silver. By the way, the restyling of the American Corolla still affected this very trunk lid. The lanterns are already there. Again, a question for marketers - is it really cheaper for you to stamp different metal parts for different markets???

Managers claim that the ground clearance is one of the highest in the class. Let's take their word for it. Of course, in comparison with my Kruzak, this is hard to believe. Therefore, the next car for my wife is an SUV without any options. I am convinced that spinning two wheels on the road is wrong :)

Good luck to everyone on the roads!

VVTi Toyota what is it and how does it work? VVT-i is the name given by the designers of the Toyota automaker to the valve timing control system, who came up with their own system for increasing the efficiency of internal combustion engines.

This does not mean that only Toyota has such mechanisms, but let’s consider this principle using its example.

Let's start with decoding.

The abbreviation VVT-i sounds in the original language as Variable Valve Timing intelligent, which we translate as intelligent change of valve timing.

This technology was first introduced to the market by Toyota ten years ago, in 1996. All automakers and brands have similar systems, which indicates their usefulness. They are called, however, all differently, confusing ordinary motorists.

What did VVT-i bring to the engine industry? First of all, an increase in power, uniform throughout the entire speed range. Motors have become more economical and therefore more efficient.

Control of valve timing or control of the moment of raising and lowering valves occurs by turning to the desired angle.

Let's look at how this is technically implemented below.

Vvti toyota what is it or how does the VVT-i valve timing work?

Toyota VVT-i system, we understand what it is and what it is for. Time to delve into her insides.

The main elements of this engineering masterpiece:

- VVT-i coupling;

- solenoid valve (OCV - Oil Control Valve);

- Control block.

The operating algorithm of this entire structure is simple. The clutch, which is a pulley with cavities inside and a rotor mounted on the camshaft, is filled with oil under pressure.

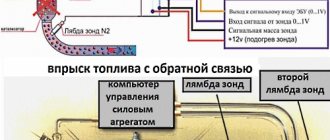

There are several cavities, and the VVT-i valve (OCV), which operates according to commands from the control unit, is responsible for this filling.

Under the pressure of oil, the rotor together with the shaft can rotate at a certain angle, and the shaft, in turn, determines when the valves rise and fall.

In the starting position, the position of the intake camshaft provides maximum thrust at low engine speeds.

As engine speed increases, the system rotates the camshaft so that the valves open earlier and close later - this helps increase output at high speeds.

As you can see, the VVT-i technology, the operating principle of which we discussed, is quite simple, but nevertheless effective.

How to clean the valve?

Many problems can be cured by cleaning the sensor. First you need to find the VVTI valve. Where this element is located can be seen in the photo below. It is circled in the picture.

To dismantle the sensor, remove the plastic cover of the power unit. Then remove the metal cover that secures the generator. The required valve will be visible under the cover. You need to disconnect the electrical connector from it and unscrew the bolt. It is very difficult to make a mistake here - this is the only bolt here. The VVTI 1NZ valve can then be removed. But you don't need to pull the connector to do this. It fits very tightly to the sensor. A rubber O-ring is also installed on it.

Cleaning can be done using carburetor cleaning fluids. To completely clean the system, remove the filter. This element is located under the valve - it is a plug in which there is a hole for a hexagon. The filter also needs to be cleaned with this liquid. After all the operations, all that remains is to assemble everything in the reverse order, and then install the generator belt without resting against the valve itself.

Development of VVT-i technology: what else have the Japanese come up with?

There are other varieties of this technology. So, for example, Dual VVT-i controls the operation of not only the intake camshaft, but also the exhaust camshaft.

This made it possible to achieve even higher engine parameters. Further development of the idea was called VVT-iE.

Here, Toyota engineers have completely abandoned the hydraulic method of controlling the camshaft position, which had a number of disadvantages, because in order to rotate the shaft it was necessary for the oil pressure to rise to a certain level.

This drawback was eliminated thanks to electric motors - now they turn the shafts. Just like that.

Thank you for your attention, now you yourself can answer anyone’s question “VVT-i Toyota, what is it and how does it work.”

Don't forget to subscribe to our blog and see you next time!

10.07.2006

Let us consider here the principle of operation of the second generation VVT-i system, which is now used on most Toyota engines.

The VVT-i (Variable Valve Timing intelligent) system allows you to smoothly change the valve timing in accordance with engine operating conditions. This is achieved by rotating the intake camshaft relative to the exhaust valve shaft in the range of 40-60° (according to the crankshaft rotation angle). As a result, the moment when the intake valves begin to open and the amount of “overlap” time (that is, the time when the exhaust valve is not yet closed, but the intake valve is already open) changes.

1. Design

The VVT-i actuator is located in the camshaft pulley - the drive housing is connected to a sprocket or toothed pulley, the rotor is connected to the camshaft. Oil is supplied from one or the other side of each of the rotor blades, causing it and the shaft itself to turn. If the engine is stopped, the maximum delay angle is set (that is, the angle corresponding to the latest opening and closing of the intake valves). To ensure that immediately after startup, when the pressure in the oil line is still insufficient to effectively control the VVT-i, shocks do not occur in the mechanism, the rotor is connected to the housing with a locking pin (then the pin is pressed out by oil pressure).

2. Operation

To rotate the camshaft, oil under pressure is directed using a spool to one side of the rotor petals, while at the same time the cavity on the other side of the petal opens to drain. After the control unit determines that the camshaft has reached the required position, both channels to the pulley are closed and it is held in a fixed position.

| Mode | № | Phases | Functions | Effect |

| Idling | The camshaft angle is set to correspond to the latest start of the intake valves opening (maximum delay angle). The “overlap” of the valves is minimal, the back flow of gases to the intake is minimal. | The engine idles more stable, fuel consumption decreases | ||

| Valve overlap is reduced to minimize backflow of gases into the intake. | Increases engine stability | |||

| Valve overlap increases, while “pumping” losses are reduced and part of the exhaust gases enters the intake | Improves fuel efficiency, reduces NOx emissions | |||

| High load, below average speed | Ensures early closing of intake valves to improve cylinder filling | Increases torque at low and medium speeds | ||

| Allows late closing of intake valves for improved filling at high speeds | Maximum power increases | |||

| At low coolant temperature | — | Minimum overlap is set to prevent fuel loss | Increased idle speed is stabilized, efficiency is improved | |

| When starting and stopping | — | A minimum overlap is set to prevent exhaust gases from entering the intake | Improves engine starting |

3. Variations

The above 4-blade rotor allows you to change the phases within 40° (as, for example, on engines of the ZZ and AZ series), but if you need to increase the angle of rotation (up to 60° for SZ) - use a 3-blade or expand the working cavities.

The principle of operation and operating modes of these mechanisms are absolutely similar, except that due to the extended adjustment range it becomes possible to completely eliminate valve overlap at idle, at low temperatures or at startup.

Toyota Corolla engines have been considered reliable and unpretentious since 1993. The Japanese know how to create designs that, with a small volume, have high power, while boasting minimal consumption. These are technically advanced and practical units with a long service life.

Operating principle of VVT

The essence of the VVT system is to adjust the valve opening phases in real time, focusing on the engine operating mode. Depending on the design features of each system, this is implemented in several ways:

- turning the camshaft relative to the camshaft gear;

- activation of cams at certain speeds, the shape of which is suitable for power modes;

- changing the valve lift height.

The most widespread are systems in which phase adjustment is carried out by changing the angular position of the camshaft relative to the gear. Despite the fact that the operation of different systems is based on a similar principle, many automakers use individual designations.

- Renault -

Variable Cam Phases (VCP). - BMW – VANOS. Like most automakers, initially only the intake camshaft was equipped with such a system. A system in which hydraulic couplings for variable valve timing are installed on the exhaust camshaft is called Double VANOS.

- Toyota -

Variable Valve Timing with intelligence (VVT-i). As is the case with BMW, the presence of a system on the intake and exhaust camshafts is called Dual VVT. - Honda - Variable Timing Control (VTC).

- Volkswagen in this case acted more conservatively and chose the international name - Variable Valve Timing (VVT).

- Hyundai, Kia, Volvo, GM - Continuous Variable Valve Timing (CVVT).

How phases affect engine operation

At low speeds, maximum cylinder filling will ensure late opening of the exhaust valve and early closing of the intake valve. In this case, valve overlap (the position in which the exhaust and intake valves are open at the same time) is minimal, so that the remaining exhaust gases in the cylinder are not forced back into the intake. It is precisely because of the wide-phase (“overhead”) camshafts on forced engines that it is often necessary to set higher idle speeds.

At high speeds, to get maximum performance from the engine, the phases must be as wide as possible, since the pistons will pump much more air per unit time. In this case, valve overlap will have a positive effect on the purging of the cylinders (the release of remaining exhaust gases) and subsequent filling.

That is why installing a system that allows you to adjust the valve timing, and in some systems, the valve lift height, to the engine operating mode, makes the engine more flexible, more powerful, more economical and at the same time friendlier to the environment.

Engine Toyota Corolla 1.6 1ZR FE

The Toyota Corolla 1.6 1ZR FE engine can be called the most popular and successful. This engine contains 4 cylinders, 16 valves, and a timing chain drive, which virtually eliminates problems with it.

The engine resource is quite long.

It will pass the first 200 thousand without any intervention, the main thing is to ensure that the oil consumption is not too high, change fluids on time (preferably after 10–15 thousand mileage) and fill in high-quality fuel, since the 1.6 1ZR FE engine is quite sensitive to impurities in gasoline.

How does this motor work?

The engine for the 1.6 1ZR FE is found in the E160 and E150 body styles; it was developed taking into account previous experience and created using advanced technologies. The gas distribution has a VVTI system, thanks to which the power supply is of the highest quality. In addition, the electronics control the lifting of the valves and the flow of air into the system, which makes the unit operate more efficiently.

1.6 VVT is equipped with two camshafts at once, the valve arrangement is V-shaped. There are hydraulic compensators, so valve adjustment is not required. It is necessary to monitor the quality of the oil; it is advisable to fill it with the original substance. If you do not do this, the hydraulic compensators fail; you can find out about this if there is a knocking sound in the engine.

Possible causes of valve failure

There are not many main causes of valve failure. There are two that are particularly common. So, the VVTI valve may fail due to breaks in the coil. In this case, the element will not be able to respond correctly to voltage transfers. Diagnosis of the malfunction is easily carried out by checking the resistance measurement of the sensor coil winding.

The second reason why the VVTI (Toyota) valve does not work correctly or does not work at all is jamming in the stem. The cause of such jamming may be simple dirt that has accumulated in the channel over time. It is also possible that the sealing rubber inside the valve is deformed. In this case, restoring the mechanism is very simple - just clean the dirt from there. This can be done by soaking or soaking the element in special liquids.

Technical data

The Toyota Corolla 1ZR FE internal combustion engine is distinguished by the following characteristics:

- Engine volume – 1.6 liters.

- 4 cylinders, power – 122 hp. With.

- Acceleration to hundreds is carried out in 10.5 seconds.

The engine is powered by AI 95, consumption on the highway is 5.5 liters, the combined cycle is one liter more, in the city - about 9-10 liters. The working life is 400 thousand km. A special feature is the absence of repair dimensions for cylinders. In addition, the engine suffers greatly from overheating. Such engines were installed in almost all cars produced before 2008.

Main characteristics

The motor has an injection power system, so it can be designated by the letter I.

There are 4 cylinders, volume is 1.6 liters, power – 190 hp. With.; urban consumption is the same as the previous version; on the highway consumption will be about 6 liters, with mixed use – 7.

The body is made of aluminum, which made the power unit lighter and eliminated overheating. Main disadvantages:

- A common problem is high oil consumption. If oil consumption is increased, the problem should be looked for in the oil scraper rings. You need to look carefully at what kind of oil filter is installed. When using non-original oil consumption, oil consumption may increase due to poor cleaning.

- The timing chain can stretch over time, which is why a characteristic knocking noise appears. Less commonly, it is caused by valves.

- The liner can become a big problem if the motor is not serviced regularly. The problem of overheating, although significantly reduced, was not completely eliminated.

The service life of this Toyota engine is at least 200 thousand km. Repairable cylinders allow it to be increased.

You need to be careful about changing the oil; it needs to be done every 10 thousand km, for which you need to purchase 4.2 liters.

vvti coupling. Replacing the vvti coupling.

Home > REPAIR and maintenance > Engine > Replacing the vvti coupling

A short report about replacing the WWTI coupling, Toyota car, 1AR - FE engine.

A traditional disease of Toyota, and not only Toyota engines, is wwti clutches. They work, but they make such a noise that it sounds like a diesel engine. But the performance of the motor is not impaired. This annoys the owners and they fix their engine themselves or turn to a car service center. Toyota itself does not consider this a malfunction, but still provides for replacing the wwti coupling without any special material and physical costs, with your own hands or with the help of a car service center. In the depths of the Internet there is a report on replacing the coupling, which describes the procedure and some nuances. The job is completed in two hours and no problems arise. But this is in theory or when you do it with your eyes closed for the 350th time.

In fact, there are nuances and some difficulties. The circle took 4 hours and a little swearing. If there were tools available, the process would go faster. Unlike previous engines AZ, NZ and similar ones, it is no longer necessary to remove the camshaft; the engineers have provided for this detail. You can also bend your arms in seven places, the chain tensioner is located under the cover, and in general it’s a pleasure to work with this motor.

We begin the replacement procedure. We remove the wipers and the piece of hardware in which they are located. Unhook the connectors and remove the coils. Wires and other accessories to make it easy to remove the valve cover.

Everything usually doesn’t go well; the engine was developed by Japanese engineers, who also learn from their Russian comrades. Now it’s also good for the Japanese when the mechanic is bad. A bundle of wiring was laid along the top of the valve cover and fastened with nuts. But having unscrewed the nuts, the joy from what was done does not increase; the wiring harness stubbornly does not want to come off the valve cover. To do this, remove the air filter housing, find the hidden bolt, unscrew it, and get the opportunity to lift the wiring.

Remove the upper engine mount.

Remove the valve cover. We see that the engine is clean, the oil was changed on time, there is no dirt. There are marks on the couplings and chain with a marker - this means they have already climbed here, I wonder why?

We remove the wheel and plastic protection and get to the chain tensioner cover.

We set the knee to TDC and look at the marks. There must be a certain number of links between the marks. We put our marks and remove the tensioner.

We unscrew the plug,

and fixing the intake camshaft with a 22 key, unscrew the wwti coupling. It is pulled off the shaft and removed with some difficulty. In this case, the chain jumps 1-2 teeth from the exhaust camshaft clutch. To prevent this from happening, it is advisable to prevent this by all possible means.

We read the manual and look at the marks on the coupling itself and install it in place. We tighten it with a torque wrench to 8.5 kg, and start dancing with a tambourine.

The first dance is to return the chain to the correct marks on the exhaust camshaft clutch. With a little jumping you will be able to do this. The second dance is to reinstall the chain tensioner. In principle, it’s also nothing complicated, but the process is a little painful, especially if there are no devices or a third hand. Otherwise there are practically no difficulties.

After this, we check the marks and begin reassembly. Before starting work, do not forget to purchase the entire set of gaskets so that you do not have to disassemble the engine again later.

Well, a little parting word, if you do not have experience in carrying out serious engine repair work, do not try to do this work yourself, entrust it to car service specialists. Don’t be fooled by posts that say the job can be done with two keys in two hours.

Engine Toyota Corolla 1.6 VVT I

The VVT I engine is often found on cars manufactured for the Russian Federation. They have 4 cylinders, an aluminum body, 16 valves, an injection power system and a timing chain. It was possible to improve the characteristics of the unit thanks to the use of VVT-I technology. The valve timing is adjusted almost perfectly, so the engine turned out to be quite dynamic with economical consumption (below 10 liters).

Cars from 2011–2014 received hydraulic compensators, which eliminates the need to adjust the valves. A serious disadvantage of VVT-I is its poor maintainability; the cylinders almost cannot be bored. The characteristics of the engine model are similar to the 1ZR FE.