In order to get maximum performance from a car engine, among other things, the most efficient valve timing must be set. It is impossible to achieve this without making changes to the timing structure due to fairly large fluctuations in the camshaft position, within factory tolerances. A split camshaft gear or a sliding timing gear will help solve the problem.

With its help, you can adjust the operation of the engine in accordance with your preferences, setting the position of the camshaft relative to the crankshaft, with an accuracy of up to tenths of a degree, but without weakening the timing belt tension. The procedure itself is not particularly complicated and can be done with your own hands.

Why install a split gear

There are two main reasons why it is advisable to replace the standard gear with a split gear.

First of all, during the manufacturing and assembly of parts at the VAZ plant, some deviations from the design dimensions are allowed. As a result, even in engines of the same series (for example, VAZ-2108 or VAZ-2112), the position of the camshaft relative to the crankshaft can fluctuate within 10 degrees (this corresponds to one tooth on a standard gear) both towards the earlier and towards the later ignition As a result, the power and dynamic characteristics of the power unit suffer.

Setting up a split gear on a VAZ-2108

On a VAZ-2108 or VAZ-2110 with an eight-valve engine, the split gear is installed and configured as follows:

- A standard mark is placed on the fixed and moving parts of the split gear, just like on the standard gear.

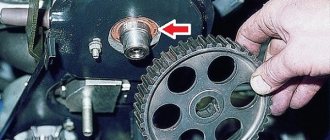

- The split gear is mounted in place of the standard one, and the timing belt is put on it. After this, you need to make sure that the marks located on the camshaft pulley and the rear belt cover match; The mark on the flywheel should be located opposite the middle scale mark on the clutch housing hatch.

- It is necessary to control the overlap of the intake and exhaust valves of the fourth cylinder. When the phases are correctly set, they must be open to a strictly defined amount. If the shaft is equal-lift, the degree of opening of the valves should be the same.

- If the required overlap cannot be achieved, you need to loosen the tightening bolts of the gear, and then, holding the moving part, rotate the camshaft in such a way as to obtain the required overlap. As a result of the operation, the camshaft is in the optimal position.

- If necessary, the valve timing can be further adjusted.

The correction is made depending on the driver's preferences.

- if the camshaft is turned ahead of the crankshaft relative to the crankshaft, the valves will open earlier and close earlier, and the gas-dynamic boost angle will decrease. Thus, traction at low and medium speeds is improved;

- when the camshaft is turned in the opposite direction (to retard), the angle of gas-dynamic boost increases, and at high speeds the filling of the cylinders with the working mixture improves, as a result the engine develops more power.

When making adjustments, you should not move too far away from the overlap point. You need to turn the camshaft no more than 3-4 degrees (on the pulley, this value corresponds to half a gear tooth). On carburetor engines, after making adjustments, it is necessary to re-set the ignition timing, since the distributor is rigidly connected to the camshaft via the ignition distributor sensor coupling.

Setting up split gears on a VAZ-2112 with a 16-valve engine

For 16-valve engines of VAZ-2112 cars, split gears are mounted and adjusted with your own hands as follows:

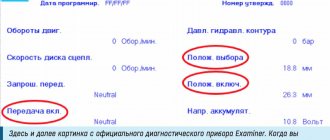

After installing the new camshafts, the valve overlap is set according to the marks of the standard pulleys, after which the pistons of the first and fourth cylinders are brought to top dead center, and the timing belt is put on. Then it is necessary to determine the movement of the camshafts and the TDC position; this is done using dial indicators installed on a special bar.

Next, you need to find the positions of the camshafts corresponding to the closed position of the intake and exhaust valves of the fourth cylinder, as well as their position corresponding to the position of the piston at top dead center. Then the bolts on the pulleys are loosened, and the required overlaps are set according to the indicators. After this, the bolts are tightened and the crankshaft is turned one revolution, after which the settings are checked. After a test drive, if necessary, the position of the camshafts is adjusted.

How to install and adjust the VAZ split gear on 8 and 16 valves?

Let's consider this process on two VAZ engines: 2108 8 and 16 valve versions. First you need to remove the casing and valve cover. After this, remove the old gear and, using it as a guide, apply exactly the same mark on the split gear, then install it on the camshaft, match the marks and put on the timing belt. After tensioning the belt, you can proceed directly to the adjustment.

Next, we will need the valves of the fourth cylinder: check their position at the given settings of the camshaft and crankshaft flywheel marks. If the valve timing has been set correctly, the intake and exhaust valves should be fully open. Otherwise, loosen the gear bolts and rotate the camshaft to the required valve opening values. After this, tighten the gear bolts. Thus, it turns out that you have reached the nominal values of the GDF, which means that the motor will operate in nominal mode.

Read more: Vali tali online store

Setting up a split gear on a VAZ-2101

On a “classic”, for example, VAZ-2101, the split gear is installed and configured as follows:

- A new camshaft is installed.

- The valve overlap is set using the standard gear marks, then the pistons of the first and fourth cylinders are brought to top dead center, and the timing chain is put on.

- A bar with three dial-type indicators is installed, the legs of which rest on the rockers.

- For the first cylinder, it is necessary to alternately find the camshaft position corresponding to the closed position of the intake and exhaust valves, as well as the position corresponding to the piston being at TDC. After this, the indicators indicate the required overlap using a gear. It should be remembered that it matters at which point of the rocker the indicator leg rests, and also that the rocker has a gear ratio (if the camshaft is multi-lift). The gear ratio is not taken into account only for equal lift and equal phase camshafts. In this case, it is enough to simply align the shaft so that both valves are equally open.

- The fixing bolts are tightened, after which the crankshaft must be turned one turn and checked for correct settings.

- After a test drive, you can adjust the camshaft position if necessary.

Phase shift or strange games with a cut gear.

Related links:

A smart electrician dreamed of a 3-phase woman: a beauty at a party, a housewife in the kitchen, a courtesan in bed. Found. The lady found herself with a phase shift: a courtesan at a party, a beauty in the kitchen, a housewife in bed... No less problems can be encountered when checking the valve timing on a standard car.

The question of whether the motor works better with phases shifted forward or backward is not legitimate. It is the observance of effective valve timing (VDP) that ensures optimal performance of the power unit. The use of a cut camshaft gear, which came to us from sports, makes it possible, without weakening the tension of the timing belt, to change the position of the camshaft relative to the crankshaft. Moreover, the tuning step is calibrated to tenths of a degree.

The power and torque of an engine are determined by its mechanical part: displacement; flow sections of channels and length of intake and exhaust systems; FGR - periods of open and closed states of the valves, expressed in degrees of crankshaft rotation relative to the top and bottom dead centers (TDC and BDC). GDFs are usually depicted as pie charts. For simplicity, let’s consider the FGR of the VAZ 21083 engine with a volume of 1500 cc. with a standard camshaft 2108 and clearances of 0.2±0.05mm intake and 0.35±0.05mm exhaust valves (Fig. 1) Although all of the following is of great practical importance for any four-stroke internal combustion engine.

As we can see, the moments of opening and closing of the valves are somewhat earlier than the piston reaches TDC (at 33°), and closes much later than the piston passes BDC (at an angle of 80°). In the intake channel, in front of the valve, the flow rate of the air-fuel mixture is variable - from zero when the valve is closed to 100 m/s when it is open. Therefore, at the end of the intake stroke, the intake valve closes after the piston reaches BDC, when it is already going up, compressing the combustible mixture, while at high speeds the effect of gas-dynamic supercharging occurs - the inertial support of the flow of fresh mixture helps to compact the “charge”, improving the filling of the cylinder with fresh working fluid. mixture. Therefore, the closing delay angle after BDC of the intake valve (gas-dynamic boost angle Г=80°) is one of the main parameters of the camshaft. An equally important parameter is the valve overlap angle (P=33°+17°=50°). The intake valve begins to open before the piston reaches TDC, while the exhaust stroke is still in progress and the piston moves upward, displacing exhaust gases from the combustion chamber. In this case, valve overlap occurs when the intake and exhaust valves are simultaneously open and the vacuum that is created in the exhaust manifold “picks up” the fresh mixture into the cylinder, improving its filling. Moreover, the resulting effect of “purging” the cylinders is more pronounced the higher the engine speed. Mounting a cut gear is recommended for two reasons:

- During large-scale production of engines, deviations in the dimensions of parts from the specified drawings are inevitable. Due to deviations in the dimensions of the parts of the gas distribution mechanism and the crank mechanism, the actual GDF of an engine of one model may differ from the nominal ones by up to ±10° along the crankshaft, which amounts to an error within one tooth on the camshaft gear. To compensate for such an error, our laboratory practices the installation of a cut gear, which allows you to change the position of its ring gear relative to the hub in steps of 0, in contrast to the factory solid gear, which is fixed in only one position and you can move away from it only a tooth forward or backward in steps 17°o along the crankshaft. As a result, a noticeable loss in power and torque instead of the expected increase.

- The use of tuning and sports camshafts with increased cam lift and modified profile. Installing such a shaft with a standard gear gives an increase in power and torque. Setting this up for efficient FGR using a cut gear adds another 3% in power.

Lada 2114 8cl. combat atmosphere › Logbook › Adjusting the split gear in theory.

1 What is a split gear? It is also called a sliding timing gear (gas distribution mechanism). Structurally, the split gear is designed in such a way that it allows you to change the position of the camshaft relative to the crankshaft without weakening the tension of the timing belt. The adjustment step, depending on the need, can be made by a tenth of a degree. That is, the split camshaft gear allows you to set the most efficient valve timing, thereby achieving optimal engine parameters. 2 Reasons for installing a split gear In the opinion of experts, these are the two most significant reasons for installing a split camshaft gear. It should be noted that installing a tuning camshaft without a split gear simply does not make sense. So, the reasons: when assembling a standard car engine, the manufacturer allows certain deviations from the drawings. In this regard, the characteristics of engines of one model may differ from the nominal ones with a tolerance of ±10 degrees. This, accordingly, affects the engine power parameters. Installing a split gear allows for adjustment and optimization of torque. when installing a sports camshaft, engine power increases, and the use of a split gear, optimizing valve timing, adds 3-5% to power

The role of the split gear in the design of the engine camshaft

The camshaft gear itself is designed to transmit torque from the engine crankshaft to the timing camshaft via a belt or gear drive.

Such a gear is made of metal and has no moving parts, since it is itself. A split gear is made of two parts that can move relative to each other. It allows you to change the position of the camshaft without affecting the tension of the timing belt or chain, that is, it leaves all other parts motionless.

To understand the purpose of such a gear, you need to remember what factors influence the power of any motor. These factors mean: the cross-section and length of special channels through which fuel is supplied and exhaust gases are released, as well as valve timing. They are called those moments in time at which the valves are in the open or closed state. To make this definition easier to understand, a special pie chart is drawn up that depicts these phases relative to the crankshaft.

So, the split gear is installed in two cases:

- When designing engine parts, the errors of the equipment that manufactures them are not taken into account. The fact is that the dimensions of the final part may differ from the original drawing. This part is the camshaft gear. The fact is that it shifts the valve timing by an acceptable error of approximately 10%. However, these deviations affect the efficiency of the motor and in most cases reduce the rated power. This explains why many engines produced by the same plant may have different characteristics.

The split gear allows you to change the valve timing and reduce this error to a minimum, which means increasing the efficiency of the engine by increasing its power.

- Installing a sports camshaft already implies a rapid improvement in engine performance at various speeds, since it has a special design that affects the periods of opening and closing of the valves. The combination of such a camshaft with a split gear allows you to increase engine power by another three percent.

What is a split camshaft gear used for?

The split camshaft gear makes it possible, without loosening the tension of the timing belt, to change the position of the camshaft relative to the crankshaft. Moreover, the tuning step is calibrated to tenths of a degree.

What is it for?

The power and torque of the engine are determined by the displacement, the flow sections of the channels and the length of the intake and exhaust systems. Valve distribution phases (VDP) are periods of open and closed valve states, expressed in degrees of crankshaft rotation relative to the top and bottom dead centers (TDC and BDC). GDFs are usually depicted as pie charts. Installation of a cut gear is recommended for 2 reasons: 1. During the production of engines, deviations in the dimensions of parts from the specified drawings are inevitable. Due to the deviation in the dimensions of the parts of the gas distribution mechanism and the crank mechanism, the actual FGR of an engine of one model may differ from the nominal ones by up to ±10° along the crankshaft, which is an error within one tooth on the gear.

To compensate for such an error, it is practiced to install a split gear, which allows you to change the position of its ring gear relative to the hub in increments of 0°, in contrast to the factory solid gear, which is fixed in only one position and you can move away from it only a tooth forward or backward in increments of 17° along the crankshaft. As a result, there is a noticeable loss in power and torque. 2. The use of tuning and sports camshafts with increased cam lift and modified profile. Installing a sports camshaft with a standard gear gives an increase in power and torque. Split gear tuning adds another 3% of power.

Tuning method for a VAZ 2108 – 2110 engine, 8 valves

1. Take the split gear and mark it (on the fixed and moving parts) with a standard mark, comparing it with the standard camshaft gear. 2. Mount the cut gear on the camshaft, put the timing belt on the gear. We check the alignment of the installation marks on the camshaft pulley and the rear belt cover, and also whether the mark on the flywheel is opposite the middle division of the scale. 3. We control the intake and exhaust valves of cylinder 4 by overlap: when the phases are set, the intake and exhaust valves must be open to a certain amount specified when designing the shaft. If there is no required overlap, then loosen the outer bolts of the gear and rotate the camshaft relative to the outer part of the gear, aligning it. This way we get the zero (optimal) camshaft position. 4. Depending on the desired result, you can make additional corrections to the valve timing using test drives.

Tuning method for a VAZ 2110-2112 engine, 16 valves

- We install new camshafts and approximately set the valve overlaps, guided by the marks of the standard pulleys, bring the piston of the 1st and 4th cylinders to TDC and put on the belt.

- We install the bar for dial indicators (3 pieces are needed: to determine the movement of the intake and exhaust shafts and the TDC position) and the indicators themselves.

- We find alternately the zero (closed) positions of the intake and exhaust valves of the 4th cylinder and the position of its TDC. After this, we set the required overlaps according to the indicators using split pulleys.

- Tighten the fixing bolts of the split pulleys, turn the crankshaft 1 revolution and check the settings.

- We assemble the engine and start it. In the case where the manufacturer’s settings may not be optimal, the position of the shafts will have to be adjusted, monitoring the cyclic filling with control measurements on the road.

Introduction

Timing is an abbreviation for (gas distribution mechanism). Mechanism for distributing the intake of the combustible mixture and the intake of exhaust gases in the cylinders of an internal combustion engine. It is carried out by opening and closing the intake and exhaust valves of the cylinders using the camshaft (camshaft) and cam mechanism. The camshaft has rigid synchronization of rotation with the crankshaft, implemented using a toothed belt or chain drive. As is correct, on highly accelerated engines, a break or slippage of the timing belt or timing chain leads to engine failure.

The history of the creation of VAZ is connected with the Deputy Minister of Automotive Industry V.N. Polyakov, appointed by the Council of Ministers as the general director of the future automobile manufacturing plant, and V.S. Solovyov. - chief designer of AvtoVAZ. In 1966, after analyzing 54 different sites of the CPSU Central Committee and the Soviet government, a decision was made to build a new automobile plant in the city of Stavropol-on-Volga, later renamed Tolyatti. Thousands of people were sent to build the giant plant, the bulk of whom were young people. An agreement was signed with the Italian company FIAT. The choice fell on FIAT mainly for political reasons: the Communist Party of the USSR supported the parties of other capitalist developed countries, especially Italy and France. The leaders of foreign communist parties needed new jobs, and the construction of a plant in Tolyatti solved their problems. Italian specialists and builders built the plant and provided all the necessary documentation. We consulted with VAZ engineers and participated in the development of new models. The first batch of logos was also produced in Italy, which increased interest among collectors. Thanks to the hard work and efforts of the Soviet people, the construction of the plant was completed three years earlier than expected, and already in April 1970, AvtoVAZ produced the first 6 Zhiguli cars - VAZ-2101. ". Since 1969, labor collectives began to be formed, and the installation of equipment produced at 844 domestic factories and 900 commonwealth factories by firms in Italy, Germany, England, the USA, France and other countries continued. The prototype of the VAZ 2101 was the FIAT 124 model of 1966 with a 1.2 liter engine and entry-level trim. In 1965 it won the title “Car of the Year”.

The purpose of the mechanism node on the selected topic.

The gas distribution mechanism is designed for the timely admission of the combustible mixture into the engine cylinders and the release of exhaust gases.

The gas distribution mechanism consists of:

1- Camshaft

2-Levers or pushers

3-Inlet and exhaust valves with springs

4-intake and exhaust valves

The camshaft is most often located at the top of the cylinder head. An integral part of the shaft are cams, the number of which corresponds to the number of intake and exhaust valves of the engine. In other words, each valve has its own personal cam. It is these cams that, when the camshaft rotates, ensure timely opening and closing of the valves, coordinated with the movement of the pistons in the cylinders.

The camshaft is driven by the engine crankshaft using gears, a chain drive or a timing belt. The tension of the drive chain is regulated by a special tensioner, and the toothed belt is regulated by a tension roller.

a) chain drive: 1 – camshaft sprocket; 2 – chain; 3 – chain damper; 4 – oil pump drive sprocket; 5 – crankshaft sprocket; 6 – chain tensioner shoe; 7 – chain tensioner

b) belt drive: 1 – camshaft toothed pulley; 2 – toothed belt; 3 – crankshaft toothed pulley; 4 – water pump toothed pulley; 5 – tension roller

Rice. Camshaft drive diagram

Let's return to the simplified engine diagram and understand the operation of the gas distribution mechanism.

Rice. Diagram of interaction of parts of the gas distribution mechanism

When the camshaft rotates, the cam runs against the lever, which, in turn, presses on the stem of the corresponding valve (intake or exhaust) and opens it. Continuing to rotate, the cam escapes the lever, and under the influence of a strong spring the valve closes.

And what’s next, you already know - the piston, through an open intake or exhaust valve, respectively sucks in the combustible mixture or pushes out exhaust gases.

2.3 Technical description (devices)

Gas distribution mechanisms are distinguished by the location of the valves in the engine. They can be with upper (in the cylinder head) and lower (in the cylinder block) valve arrangement. The most common gas distribution mechanism is with an overhead valve arrangement, which facilitates access to the valves for their maintenance, allows for a compact combustion chamber and ensures better filling of it with a combustible mixture or air.

The gas distribution mechanism consists of:

1) camshaft;

2) camshaft drive mechanism;

3) valve mechanism.

Let's consider the operation of the gas distribution mechanism using the example of the VAZ-2106 engine, with an in-line arrangement of cylinders.

The camshaft is located in the “camber” of the engine block, that is, between its right and left rows of cylinders, and is driven by the crankshaft through the block of camshaft gears. With a chain or belt drive, the rotation of the camshaft is carried out using a chain or toothed belt drive, respectively.

When the camshaft rotates, the cam runs against the pusher and lifts it along with the rod. The upper end of the rod presses on the adjusting screw installed in the inner arm of the rocker arm. The rocker arm, turning on its axis, presses the valve stem with its outer arm and opens the intake or exhaust valve hole in the cylinder head strictly in accordance with the valve timing and the order of operation of the cylinders.

Valve timing refers to the moments of the beginning of the opening and the end of the closing of the valves, which are expressed in degrees of the angle of rotation of the crankshaft relative to the dead points. The valve timing is selected empirically depending on the engine speed and the design of the intake and exhaust pipes. Manufacturers indicate valve timing for their engines in the form of tables or diagrams.

The correct installation of the gas distribution mechanism is determined by the installation marks, which are located on the timing gears or the drive pulley of the engine cylinder block.

Deviation in the installation of phases leads to failure of the valves or the engine as a whole. Constancy of valve timing is maintained only if the regulated thermal clearance in the valve mechanism of a given engine model is observed. Violation of the size of this gap leads to accelerated wear of the valve mechanism and loss of engine power.

For proper engine operation, the crankshaft cranks and camshaft cams must be in a strictly defined position relative to each other. Therefore, when assembling the engine, the camshaft gears are brought into mesh according to the marks on their teeth: one on the crankshaft gear tooth, and the other between two camshaft gear teeth. On engines with a block of timing gears, they are also installed according to the marks.

The sequence of alternating strokes of the same name in different cylinders is called the order of operation of the engine cylinders, which depends on the arrangement of the cylinders and the design of the crankshaft and camshaft.

The camshaft serves to open and close the valves of the gas distribution mechanism in a certain sequence in accordance with the order of operation of the engine cylinders.

Camshafts are forged from steel, followed by case hardening and hardening with high frequency currents. On some engines, the shafts are cast from high-strength cast iron. In these cases, the surface of the cams and shaft journals is whitened and then ground. To reduce friction between the journals and supports, steel, coated with an anti-friction layer, or cermet bushings are pressed into the holes.

Between the camshaft bearing journals there are cams, two for each cylinder - intake and exhaust. In addition, a gear is attached to the shaft to drive the oil pump and distributor-distributor, and there is an eccentric to drive the fuel pump.

The camshaft gears are made of cast iron or textolite, the crankshaft drive cam gear is made of steel. The teeth of the gears are oblique, which causes axial movement of the shaft. To prevent axial displacement, a thrust flange is provided, which is mounted on the cylinder block between the end of the front shaft support journal and the timing gear hub.

In four-stroke engines, the working process occurs in four piston strokes or two revolutions of the crankshaft. This is possible if the camshaft makes half the number of revolutions during this time. Therefore, the diameter of the gear mounted on the camshaft is made twice as large as the diameter of the crankshaft gear.

1, 22 – valves; 2 – head; 3 – rod; 4, 20 – bushings; 5 – cap; 6 – washers; 7, 8, 17 – springs; 9 – plate; 10 – cracker; 11 – lever; 12 – flange; 13 – body; 14 – camshaft; 15 – neck; 16 – cam; 18 – bolt; 19 – nut; 21 – plate; 23 – ring; 24, 27, 28 – asterisks; 25 – chain; 26 – pacifier; 29 – finger; 30 – shoe; 31 – tension device

Principle of operation

The gas distribution mechanism (GRM) works as follows. When the camshaft rotates, its cams, in accordance with the order of operation of the engine cylinders, alternately run over the levers. The levers, turning with one end on the spherical heads of the adjusting bolts, act with the other end on the valve stems, overcome the resistance of the springs and open the valves. With further rotation of the camshaft, the cams move off the levers, which return to their original position under the action of springs, and the valves close under the action of springs.

When the engine is running, the camshaft rotates twice as slow as the crankshaft. This is due to the fact that during the engine operating cycle, which takes place over two revolutions of the crankshaft, the intake and exhaust valves of each cylinder must open once.

The normal operation of the gas distribution mechanism (GRM) largely depends on the thermal gap between the camshaft cams and the valve drive levers. This clearance ensures that the valves close tightly as they elongate due to heat during operation. If the thermal clearance is insufficient or absent, the valves do not close completely, which leads to gas leakage, rapid burning of the valve head chamfers and a decrease in engine power.

Camshaft drive.

A special feature of the camshaft drive is the use of a belt drive. The camshaft is driven through a toothed pulley mounted on it by a belt from the crankshaft toothed pulley. This belt also rotates the gear pulley of the oil pump drive shaft.

Split gear adjustment technique

Of course, you understand that within the framework of one topic it is impossible to describe the methods for adjusting the split camshaft gear for all types of engines. But the principle will be very clear. We will present to you a technique for setting up a split gear on a VAZ 2108 - 2110 8V engine.

- We put a mark on the moving and stationary parts of the split gear, comparing it with the standard camshaft pulley;

- We install the gear on the camshaft, put on the timing belt. Next, check that the marks match: on the pulley and the back cover of the belt, on the flywheel, so that it is opposite the middle division of the scale;

- control of the intake and exhaust valves of the 4th cylinder by overlap. Both valves should be open the same amount. If this is not the case, then you need to loosen the bolts and rotate the camshaft relative to the outer part of the gear, obtaining the zero position of the camshaft.

For low and medium speeds - turn the camshaft relative to the crankshaft in the direction of rotation. By doing this, we increase the opening angle of the intake valve, reducing the angle of gas-dynamic boost.

For high speeds, turn the camshaft relative to the crankshaft against the direction of rotation. By doing this we increase the angle of gas-dynamic boost, and accordingly, the power.

Important! When adjusting the valve timing, you must remember to set the initial ignition timing after rotating the camshaft.

Good luck adjusting the split gear.

What is a split gear and why is it needed!

- Split camshaft gear - what is it?

- What is a split gear?

- Reasons for installing a split gear

- Adjusting the split camshaft gear

Many people today often hear the term split camshaft gear. You have also probably come across the definition of camshafts with a changed angle of attack of the cams. A sufficient number of car enthusiasts see in this a large increase in engine power and maximum speed of the car, also praising other wonderful consequences of these miraculous units after their installation. Let's shed light on this and determine whether everything is really so fabulous? And what exactly is a split camshaft gear and what is it used for?

What is a split gear?

Many modern engines are equipped with phase shifters, which allow car owners and experimenters to adjust engine operation based on the crankshaft speed. All this is needed in order to fully squeeze out the engine torque in the highest speed range.

Each information source about a particular car specifies its maximum power, measured in horsepower “hp.” and maximum torque at such and such number of revolutions per minute “Nm”. For example, let’s take the fairly common Renault Laguna car. Its engine power at 6000 rpm is 170 hp, and the maximum torque is 270 Nm at 3250 rpm. As can be seen from this, maximum torque is achieved already in the middle of maximum crankshaft speed, and peak power is available only after almost 3000 rpm. And if this or a similar engine is equipped with phase shifters, then this will greatly expand the range of application of the maximum torque than what was already set at the factory.

Well, for example, expand it from 2000 rpm. up to 4000 rpm. What will it give? And the fact that from the very bottom the entire maximum possible torque will be available, which will have a positive impact on the acceleration characteristics of the car. When the engine reaches its highest speed and the cylinders require more powerful filling, the intake camshaft rotates at a certain angle. This is achieved using a special coupling. The phase shifter promotes earlier opening of the valves and, as a result, better filling of the cylinders, which gives the engine powerful pickup even at high speeds.

The design of the split camshaft gear is made in such a way that the camshaft can be rotated at a certain angle forward or backward. For example, the split camshaft gear of VAZ cars allows the camshaft to rotate five degrees in the forward or backward directions. What you need to understand here is that changes occur only in engine settings in certain modes, namely at the top or bottom. If, along with replacing the split camshaft gear, the shaft itself is replaced with another one with a different cam profile, then it will be possible to “play” with changing the angle of overlap of the valve phases and the angle of delay in the opening and closing of the valve. When a regular gear is replaced with a split gear, you can only vary the mounting angles of the valves in their closing or opening.

Let's say the maximum torque shifts from 4000 rpm to a lower zone at 3000 rpm. This is achieved due to the additional rotation of the camshaft during the rotation of the crankshaft, that is, the phases are set ahead, which affects the reduction of the retardation angle of the closing of the intake valves. In this case, you need to know that when maximum speed is reached, the filling of the cylinders will not be dense enough, which will adversely affect maximum power and speed.

The split gear is divided into two parts: a ring gear, which is bolted to the hub.

The holes for the bolts in the hub are made in such a way that they allow it to be rotated relative to the crown at a given maximum angle in different directions. The hub is attached to the camshaft using a key, which allows the camshaft to be rotated while turning the hub, which ensures a change in the valve timing.

Reasons for installing a split gear

According to experts, there are two reasons for installing a split camshaft gear, which are the most important. Consider the fact that it makes no sense to install a “bare” tuned camshaft without a split gear. So let's look at these reasons.

1. When assembling a standard car engine, the manufacturer allows you to deviate from the drawings. Because of this, the main characteristics of engines installed on one model may differ from the prescribed ones by ±10 degrees. And this, naturally, affects the power characteristics of the motor. By installing a split gear, drivers can adjust and optimize torque.

2. By installing a tuning camshaft on their car, drivers significantly increase the power of its engine, and installing a split gear adds another 5% of “horses” to the “herd”. Not bad, you'll agree.

Adjusting the split camshaft gear

Split gears for engine tuning are currently produced for absolutely all VAZ car models. Of course, with all our desire, it is simply impossible to fit into one section, or even the entire article, a complete description of the methods for setting split camshaft gears for all types of engines. But we will try to explain the principle using the example of some engines.

We present to you a methodological description of setting the split gear on engines of VAZ models, namely from 2108 to 2112.

1. To adjust the split gear on eight-valve VAZ 2108-2110 engines, you need to take this part in your hands and draw marks on its moving and stationary parts. The marks are necessary to install the split gear in the same way as a standard one. Next, after marking the gear, install it on the camshaft, then put the timing belt on it.

2. Be sure to check all the marks, especially the installation marks, to ensure they completely match. To obtain the optimal camshaft position, it is necessary to check the following: the degree of opening of the intake and exhaust valves must be a certain value, which is specified during the design of the shaft.

If this is not the case, then loosen the split gear bolts on the outside slightly and rotate the camshaft so that it is aligned with the outside of the split gear.

3.When the zero position of the camshaft is set successfully, additional correction of the valve timing should be carried out. When you turn the camshaft as the crankshaft rotates, you can improve engine thrust at low and medium speeds.

By turning it in the direction opposite to the rotation of the crankshaft, you get an increase in power. When performing this procedure, the main thing is not to move away from the starting point by more than half a tooth along the pulley. If you are adjusting a carburetor type car, then after each rotation of the camshaft you will have to set the ignition timing again.

4. To tune the split gear on engines with sixteen valves in the VAZ-2110-2112 models, install tuning camshafts with split gears. Based on the marks of the factory gears, it is necessary to approximately set the valve overlaps. Bring the pistons of the first and fourth cylinders to TDC, and then put on the timing belt. Install dial indicators that determine the movement of the valves. Find the closed positions of the intake and exhaust valves of the fourth cylinder. Then, using the split gears and indicators, adjust the valve overlaps. Tighten the locking bolts on the split gears. Once you have assembled the engine, take it for a test drive.

5. In order to adjust the split gears on classic VAZ cars with eight valves, do the following. Install the split camshaft according to the marks of the standard gear. Next, adjust the valve overlap. Bring the pistons of the first and fourth cylinders to TDC, then put on the timing chain. Place the legs of the dial indicators against the rockers, having installed them correctly in advance. Set the valves of the first cylinder to the closed positions one by one. Set the exact position of TDC and the required valve overlap using the tuning gear. Do not forget the gear ratios of the numbers on the rockers and the point on one of them to which the indicator adjoins. This will make changes to the floors. Lock the tuning split gear, assemble the motor and start.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

- © 2020 Auto.Today

- This email address is being protected from spambots. You must have JavaScript enabled to view it.

- Confidentiality

- Advertising on the website

- Editorial

The use of any materials posted on the site is permitted provided there is a link to auto.today.

The portal's editors may not share the author's opinion and are not responsible for copyright materials, for the accuracy and content of advertising

Materials: https://auto.today/bok/2808-razreznaya-shesternya-raspredvala.html