The Niva family of cars differs from VAZ passenger cars in permanent all-wheel drive - they have two drive axles. In total, the VAZ SUV has three differentials in its transmission - one for each axle and another center differential.

The Niva transfer case is designed to distribute traction forces between axles, and operates on the principle of a 2-speed gearbox.

Design and functions of the VAZ 2121 transfer case

The VAZ 2121 transfer case is designed to properly distribute torque on the axle of an SUV and increase its output value. This device is correctly called a demultiplier.

The transfer case performs the following functions:

- 1. Allows you to lock the center differential;

- 2. Allows you to disable one of the drive axles;

- 3. Increases the torque of the drive wheels when using a lower gear;

- 4. Distributes torque along the axles of the SUV;

- 5. Allows the installation of a power take-off for operation of additional equipment.

Transfer case 2121 consists of a cast aluminum housing, inside of which the main parts are located:

- drive shaft;

- intermediate shaft;

- differential;

- rear axle drive shaft;

- front axle drive shaft;

- gear shift clutch.

There are two gears on the drive shaft, the larger of which is responsible for high gear, the smaller for low gear. Both gears sit tightly on the shaft, which is subjected to heat treatment in the most loaded areas to eliminate defects during operation.

Each gear has two rows of teeth - oblique and straight. The oblique row of teeth is in continuous operation with the gears of the intermediate shaft, and the straight row of teeth is with the clutch. When changing gears on the transfer case, the clutch moves along the hub in a horizontal direction, engaging with one of the drive shaft gears. The middle position of the clutch is neutral.

The transfer case intermediate shaft has two helical gears, of which the front one engages the differential gear. The speedometer drive gear is located at the end of the intermediate shaft. The center differential has a locking clutch, thanks to which the drive shafts of the front and rear axles are rigidly connected.

Signs of a broken transfer case

Chevrolet Niva transfer case, appearance

To prevent the transfer case from losing its functions prematurely, it is advisable to diagnose it periodically (approximately every 15,000 km). During this procedure, all its components and the level of transmission fluid must be checked.

Rapid wear of the RK on Niva can occur as a result of its aggressive use. Repair of the transfer case is necessary if the following are observed:

- jerks appeared;

- dynamics worsened;

- the car accelerates more slowly;

- difficulty changing gears;

- There were knocks and vibrations from the transmission.

In some cases, changing the oil helps solve problems. If it is deficient, a characteristic howling sound is often noted when moving at high speed.

If the rod or fork of the differential lock clutch breaks or wears out, difficult gear shifting will occur. In rare cases, the transfer case control lever has a mechanical breakdown.

Complete disassembly of the transfer case allows you to accurately determine the nature of the existing malfunction. It is recommended to entrust this procedure to professionals who have experience in carrying out this work. To restore the normal functioning of the gearbox, it may be necessary to adjust the gear shift drive and replace gears.

VAZ Niva transfer case: operating principle

The VAZ 2121 transfer case has only a few gears with gear ratios of 2.135 and 1.2. The SUV's axles are connected using a center differential, which redistributes torque to the wheels depending on their resistance to movement.

When driving a VAZ Niva on a flat, dry road surface, there is no need to use additional functions of the transfer case, since the wheels have good grip on the road. When road conditions worsen, it becomes necessary to engage a lower gear, which provides the car with a uniform and stable speed. In this case, it is necessary to switch to a lower speed limit only after the car has completely stopped.

In off-road conditions, it is possible to lock the differential, which ensures uniform rotation of both drive shafts of the vehicle and increases the vehicle's cross-country ability.

What is it for?

This unit is an indispensable element in all-wheel drive vehicles. The Chevrolet Niva transmission and transfer case redistribute torque between the drive axles (of which there are two in the car). This mechanism, if necessary, increases the torque when moving (the so-called lowering).

It is worth noting that the transfer case is installed not only on all-wheel drive SUVs. Car lifts, cranes and other special equipment are often equipped with such a system.

Major problems with the Niva transfer case

Over time, the car's transfer case parts wear out, which can result in the following problems:

- problems with engaging the front axle;

- transfer case overheating;

- excess consumption and oil leakage during operation of the transfer case;

- spontaneous shutdown of the front axle.

The first signal that the Niva transfer case is failing is the appearance of characteristic noise and vibration when the SUV is moving. But you should distinguish the vibrations of the driveshafts from the noise of the transfer case.

It is for this reason that car owners install a third support, which dampens vibrations of the transfer case. This device can be purchased in specialized stores or made manually using welding. As for the design, the third support is designed to reduce vibration arising from the vibration of the VAZ 2121 transfer case levers.

Often, owners of the VAZ 2121 Niva, who have a third support installed, note a slight decrease in vibration and noise. This problem is solved by adjusting the transfer case height so that the rotation axes of the gearbox and transfer case are in the middle of the intermediate shaft CV joint.

It is important to adhere to the operating rules of the transfer case, monitor the condition of the oil seals and cardan shafts, change lubricants on time and not subject them to increased loads.

Transfer case VAZ 2121

The transfer case is designed to distribute torque between the vehicle's drive axles. The car is equipped with a two-stage transfer case, with a forced-locking center differential and manual control.

Two gears (low and high) with ratios of 1, 2 and 2.135 allow you to increase transmission ratios and double the total number of gears, which makes it possible to use the vehicle more efficiently in various road conditions. The center differential provides permanent drive to the front and rear drive axles.

Forced differential locking increases the vehicle's cross-country ability. Gear shifting and differential locking are performed using levers mounted on the transfer case.

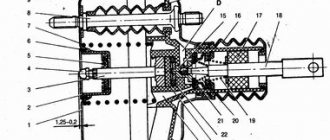

In the transfer case housing 19 (Fig. 32), cast from aluminum alloy, the drive 22 and intermediate 24 shafts, the drive shafts of the front 8 and rear 27 axles and the differential housing 25 are mounted on bearings. On the drive shaft 22, helical gears of the highest 17th and lowest 20th gears are freely installed, having toothed rims and being in constant engagement with the gears of the intermediate shaft 24, which is made in the form of a gear block.

Rice. 32. Transfer case: a — box assembly; b — box drive; 1 - driven gear; 2 — differential bearings; 3, 34 — spring washers; 4, 31 - retaining rings. 5 — differential lock clutch; 6 — gear ring of the differential housing; “7 — gear ring of the front axle drive shaft; 8 — front axle drive shaft; 9 - flange; 10 - oil seal; 11 - drain plug; 12 — driven gear of the speedometer drive; 13 — speedometer drive gear; 14 - filler plug; 15 - front cover; 16 — transfer case suspension bracket; 17 - high gear; 18 — gear clutch; 19 — crankcase; 20 — low gear; 61- bushing; — drive shaft; 23 — back cover; 24 — intermediate shaft; 25-differential housing; 26 — thrust washer; 27 — rear axle drive shaft; 28 — rear axle drive gear; 29 — satellite; 30 — satellite axis; 32 — rubber cushion; 33 - transfer case suspension axis; 35 — front axle drive gear; 36 — differential lock clutch fork; 37 — cover; 38 — lever spring; 39 — differential lock slider; 40 — lever axis; 41-differential lock lever; 42- gear shift blade slider; 43 — gear shift lever; 44 — gear shift fork; 45 — ball retainer; 46. — differential lock warning lamp switch

Between gears 17 and 20, a gearshift clutch hub 18 is fixedly fixed on the shaft, having external splines on which a sliding clutch is installed. When the highest gear is engaged, the gear shift clutch 18 stops the freely rotating gear 17 on the drive shaft 22, and when the lower gear is engaged, the gear 20 is engaged. The gear block of the intermediate shaft 24 is in constant engagement with the helical driven Gear 1, bolted to the differential housing 25, which consists of two parts. On the differential housing there is a movable differential locking clutch 5 on splines. Inside the differential housing there is an axis 30 with two satellites 29, which are in constant engagement with gears 35 and 28, which are connected to the splined ends of the drive shafts 8 and 27 of the front and rear drive axles of the vehicle. The front axle drive shaft 8, in contrast to the rear axle drive shaft 27, is longer and has a ring gear 7 for locking the differential. When the differential is locked, a movable coupling 5 connects the shaft 8 to the differential housing 25. The gear shift mechanism of the transfer case includes: shift lever 43, slider 42, fork 44 and ball retainer 45. Lever 43 is pivotally mounted on axis 40 in the eyes of the bracket. The lever has a shaped end, which fits into the groove of the slider 42 and is sealed in it by a spring 38. A fork 44 is fixed to the slider, which fits into the recess of the gearshift clutch 18. A ball retainer 45 holds the slider 42 in the neutral and engaged positions. The differential lock drive has a device similar to the gear shift mechanism. The drive consists of a lever 41, a slider 39 with a fork 36 and a ball retainer 45. The transfer case is attached to the car body on two supports mounted on axles 33. Each support consists of a bracket 16 into which a rubber cushion 32 is pressed. Under the transfer case suspension supports Adjusting shims are installed to ensure its alignment and correct installation in relation to the gearbox

The transfer case of the Niva car and some other SUVs is designed to distribute the torque of the wheels both between the axles and between different wheels of the same axle. This is done in order to increase cross-country ability on particularly difficult sections of the route. In the language of specialists, this device is called a “demultiplier.”

Standard Design Vulnerability

As a rule, in order to improve the off-road characteristics of their car, car drivers install wheels with a size of 31'' and replace the engine and main pair. In this case, the load on the transfer case increases, and more specifically, on the pinion axis and differential gears.

The standard differential of the transfer case of VAZ 2121, 2123 and other Niva modifications has two gears mounted on the satellite axis. The axis, in turn, is fixed in the housing using locking rings installed on the outside:

If this scheme works in a stock car, then in a Niva car prepared for off-road, under conditions of extreme loads, one pair of satellites becomes insufficient to “digest” the increased torque, which leads to their sudden breakdown.

This is the first drawback of the factory design of the RK differential.

The second , no less significant drawback is related to the geometry of the differential housing. The presence of beats in the housing, factory defects, and imbalance of the center differential is one of the causes of noise and vibration in the transfer case.

The presence of only one pair of satellites also causes imbalance, since such a design is not axisymmetric. Moreover, since the axis of the satellites is attached to the housing by means of external locking rings, it is subject to play, which also contributes to the overall imbalance of the structure.

It is impossible not to mention the problem we formulated in the first paragraph. It's no secret that to modernize the transfer case, nivovoda drivers install reduction kits with different gear ratios.

So, when it comes to installing a lowering kit in the transfer case, the center differential becomes the stumbling block. Or rather, its body, without modification of which it will not be possible to squeeze in a new shaft gear.

There is only one alternative to dancing with a tambourine and exercising with an angle grinder - replacing the differential in the RK with a new one of improved geometry.

Transfer case location and functions

Location of the transfer case in the Niva 21213

The transfer case occupies an intermediate position in the vehicle transmission between the gearbox and the driveshaft. It has its own body in which its components are located.

The transfer case helps to implement such SUV capabilities as:

- Center differential lock.

- Disabling the drive axle.

- Increased torque of the drive wheels.

- Distribution of torque along the wheel axles.

Transfer case purpose

transmission and drive of the KalinaReplacing the clutch and release bearing on the Lada KalinaLuK clutch on the Lada KalinaGearbox - automatic on the Lada Kalina

If you create a permanent all-wheel drive in a car and provide constant torque on the driveshafts of the rear and front axles, then such equipment is capable of overcoming obstacles such as off-road, but no more. However, the car will not be suitable for driving on the highway at relatively high speeds.

- There will be an excessive load on the parts that distribute the moment along the axes.

- Fuel consumption will increase.

- There will be a rubber eating effect.

The transfer case on a Chevrolet Niva car performs two functions at once. It ensures the distribution of torque along the axes with the possibility of supplying it to both axles simultaneously.

The transfer case also converts torque, increasing it by lowering the speed in gear. Here, transmission means a pair of gears that are in mesh and have a certain gear ratio. These two functions can be performed together or separately.

Self-repair of transfer case on Niva

There is nothing fundamentally complicated in the design of the multiplier, except that it itself is not attached to the main gearbox as on more modern all-terrain vehicles. Intermediate driveshafts extend from the transfer case to the manual transmission. The rest of the device is represented by gears, satellites and bearings. The design also includes a free differential with locking.

Tools

- Spanner 13.

- Flathead screwdriver.

- Key for 10.

How to remove a box from a car

Installation, centering and adjustment

- Install the engine mount brackets correctly.

- Install the transfer case without fully tightening the bolts of its fastenings.

- The flanges of the drive shaft of the box must coincide with the intermediate driveshaft.

- Install the transfer case supports and secure the fasteners.

- Connect the transfer case to the front and rear universal joints, and reinstall the differential lock sensor.

Centering the range multiplier can be done in different ways. The classic version of alignment is that the car is installed on a lift or inspection hole, and all operations are performed by two people, one of whom is sitting behind the wheel. The procedure is performed as follows:

Removing the Niva transfer case

To repair the transfer case on a VAZ 21213 (21214), the unit must first be removed. We carry out removal in the following order:

- in the cabin we dismantle the plastic lining of the gearbox and gearbox levers;

- unscrew the knobs of the transfer case shift levers, remove the casing under them;

- disconnect the speedometer cable, for RK 21214 you will need to additionally disconnect the speed sensor;

- we unscrew the bolts with nuts securing the elastic coupling of the front and rear propeller shafts; in order to remove the bolts, the cardan shafts must be turned - they are removed one at a time in one specific position of the shaft;

- We install a jack (or other support) under the transfer case and mark the places where the side supports of the RC were attached. This is done in order to minimize the alignment of the transfer case during installation;

- unscrew the 4 nuts securing the gearbox to the gearbox;

- unscrew the 4 fastenings of the RC supports to the car body;

- Now all that remains is to dismantle the transfer case.

The all-terrain vehicle VAZ 2121 is a reliable universal SUV. Unlike vehicles with one drive axle, it is equipped with all-wheel drive and has high maneuverability. The Niva 2121 transfer case provides conditions for operating the vehicle both on difficult roads and on city streets with heavy traffic. Thanks to the all-wheel drive wheel arrangement, a series of cars produced by AvtoVAZ became known as “Niva 4x4”.

Video: Aligning the Niva transfer case without a lift

Repair and alignment of the transfer unit must be carried out subject to the presence of experience and knowledge in the field of design and repair of the specific transmission of all-wheel drive vehicles. The range-multiplier needs to be centered after each reinstallation. The correct position of the box is judged by the presence of vibration.

For hunting and fishing, the Niva is an indispensable car. It is famous for its maneuverability and simple design. Of course, over the years the model has become significantly outdated. But there is an option to buy a Chevrolet Niva. This is a more modernized car with a pleasant appearance and no less good off-road performance. What is the secret of cross-country ability? It's simple - a transfer case is installed on a Chevrolet Niva. Its structure, principle and modes of operation are discussed further in our article.

Varieties

There are several types of these elements:

- Equipped with coaxial drive shafts. This type is used on many SUVs. It gained such popularity due to the use of a single main gear for both axles.

- With a misaligned driven shaft. There is no intermediate shaft here. The advantages of this system are high efficiency and noiselessness. Also, this box has a low curb weight.

- With drive axle drive blocking. It is also installed on the Chevrolet Niva. Here it is possible to use all the torque without slipping the wheels, which is very important when driving off-road. The front axle engages only on difficult sections of the road. On asphalt surfaces, the SUV has a single-wheel drive (only this works. This allows you to reduce fuel consumption and, if necessary, increase cross-country ability (when the drive “locks”). There is also a forced inter-axle locking.

About the device

Despite the difference in varieties, the structure and operating principle of these boxes are the same. How does the transfer case (Niva Chevrolet) work? This node includes several elements:

- Drive shaft.

- Center differential locking mechanism.

- The differential itself.

- Chain or gear transmission.

- Drive shaft of the rear and front axle.

- Downshift.

All this is controlled from the interior. There is a transfer lever for this. "Niva Chevrolet" has both locking and downshifting. The torque that goes from the main transmission to the transfer case is transmitted through the drive shaft.

Next, the torque force is distributed between the axes. This is where it comes into play. This unit allows you to rotate the wheels at different angular speeds. By the way, the differential itself can be of several types:

- Asymmetrical (distributes torque in different ratios).

- Symmetrical (distributes forces equally).

Device

The VAZ 2123 transfer case is installed at the rear of the gearbox and is attached with brackets to the bottom of the car. It is driven by an intermediate shaft. Torque from the drive shaft to the drive axles is transmitted by cardans, which are screwed to the flanges of the transfer case drive shafts.

The transfer case body is made of aluminum alloy. In its upper part there is a hatch with a lid.

The transfer case consists of the following parts:

- RK Corps.

- Drive shaft.

- Control levers.

- Bearings.

- Gears.

- Drive shafts (front and rear).

- Flanges.

- Differential mechanism housing.

- Axles.

- Satellites.

- Clutches for gear shifts and differential locks.

- Oil seals.

- Retaining and thrust rings.

- Housing covers.

- Breather.

The Chevy Niva transfer case has three speeds:

- The first one, with a gear ratio of 1.2.

- Neutral.

- Low (second), with a gear ratio of 2.135.

Neutral allows you to temporarily disengage the gearbox from the transmission. It is used when connecting a winch and other units to a vehicle.

The first speed is intended for on-road driving, and the second is for off-road use where high torque at low speed is required.

Important: there are no synchronizers in the transfer case. Therefore, it is necessary to switch the locking and speed of the RC only after stopping the machine. If you cannot switch the transfer case, you need to try turning the steering wheel or moving slowly. In this case, the gears will change their relative position, which will make it possible to switch the mode.

Blocking

It is worth noting that on domestic SUVs the transfer case (including Chevrolet Niva) has a differential locking function. Thus, torque transmission can occur either symmetrically or asymmetrically, depending on the position of the shift lever in the cabin. To connect the front axle, a chain drive is used. This unit consists of gear links (driven and driven) and a drive chain. On modern SUVs, all-wheel drive is engaged automatically. But here the transfer transmission is made in the form of a bevel gearbox.

Transfer case operating modes

This mechanism can operate in five modes:

- Neutral is on.

- The differential is unlocked when the "lowering" is turned off. In this case, the torque is distributed in a ratio of one to two.

- The differential is locked when overdrive is engaged. Here, torque distribution is carried out automatically, depending on the quality of wheel grip on the road.

- Downshift is engaged and the differential lock is disabled. The transfer of forces occurs in the same ratio as in the first case.

- The differential is locked and the gearbox is engaged. In this case, all axles are rigidly locked together, including the axle shafts. Torque is produced unevenly, depending on the type of road surface (dirt, sand, etc.). In this mode of operation, the best cross-country ability of the vehicle is achieved. But driving with a constantly engaged downshift and with locks will not work. This increases the load on the transfer case bearings. The Chevrolet Niva will soon require serious intervention in the transmission. Fuel consumption also increases significantly, which greatly eats up the tires.

How to use it correctly?

There is a diagram on the shift lever. To turn it on, you need to move the lever to the right, up. To lock the differential, pull it all the way to the left. There are also Latin letters on the lever. So, L is a low gear, N is neutral, and H is high. Now let's find out how to use all this so that we don't have to repair the mechanism and change the transfer case bearings.

The Chevrolet Niva is a universal-purpose vehicle that is actively used not only on asphalt surfaces, but also off-road. So, if you have to overcome a ford or a puddle, you should stop completely and turn on a lower set of steps. Please note: it should only be turned on after a complete stop. Even at 5 kilometers per hour you will have problems with the transfer case. But you can lock the differential even while driving. This won't bring any surprises. Unless due to the constantly working two bridges and axle shafts.

In what cases is it necessary to turn it on on a Chevrolet Niva? Its work will be needed when crossing “diagonals”, fords and during a long climb, which you climb slowly. Motorists often ask: is it possible to drive for a long time with a lock? Please note that it should only be enabled when absolutely necessary. Otherwise, the load on the teeth and shafts increases. If you drive like this on the asphalt at high speed, you will soon need to replace the transfer case on your Chevrolet Niva.

Gear Modes

Let's take a closer look at how to use the transfer case on a Chevrolet Niva. It serves to switch to a lower gear and also blocks the center differential; this can be done at the same time. In order to engage a lower gear, you need to shift the lever to the right and up; to lock the lever, you need to pull it to the left all the way. The handle has the following designation:

- Low(L) - decrease;

- N-neutral;

- High(H) - normal, increased.

The figure below shows a diagram of the operation of the transmission levers, gearbox and transfer case:

You can switch the transfer case from low to high while driving. To do this, you need to squeeze the clutch twice.

Low gear is engaged at a speed of no more than 5 kilometers per hour, or after a complete stop. In order to overcome a steep climb, or when driving where there is soft ground, so that the vehicle speed is minimal and at the same time stable, a lower gear must be engaged in advance. For example, if you are driving on a flat road in second or third gear, and a bad section of road appears in front of you, you need to stop and shift to a lower gear.

Forced unlock

Sometimes it happens that the lock jams - it cannot be turned off even when the car is completely stopped. The situation is quite common for the Chevrolet Niva. How to solve it? There is a sure way. To do this, turn on reverse gear, accelerate a little, and turn it off while driving. At a certain speed, you can easily “knock it out.” But if a similar lamp continues to light on your instrument panel, as in the photo below, the lock has not been turned off.

What to do in such a situation? It is necessary to turn on the first speed and try to turn off the unit again. Moving back and forth will solve the problem of a stuck differential. In general, it is recommended to turn on the center lock only in serious off-road conditions. At the intersection of dirt roads and sand dunes, a downshift is sufficient.

A few words about the Chevrolet Niva transfer case

I think it’s time to talk about the transfer case of the Chevy Niva, because those who just bought this car, at the very beginning of use, do not really know how to use the transfer case, what the rules are, and in general, when to lower the gear and when to lock it. Let's figure it out now. It’s a pity, of course, that I didn’t record a video on today’s drive along a fairly washed-out road. Well, never mind, I’ll record it and show it clearly on video. For now, in words.

In general, the transfer case switches to a lower gear, as well as to lock, and it is possible and even necessary to do this at the same time. It’s convenient on the Shevik - this is done with one lever.

Turn it down - right up. Add lock - Pull the lever all the way to the left. Look at the switch handle, it's written there. Letter designation - L(low) - low, N - neutral, H(high) - high, that is, normal.

How inter-axle locking works - read this article. There you will also learn about self-blocks - a real cool upgrade for the Chevrolet Niva, which will allow you to drive even further.

Well, now we’ll figure out when it’s better to turn it down, and when to also lock it. And how to do it correctly.

It looks something like this - we are driving across the field in normal second/third gear. Suddenly there is a terrible puddle ahead. We stop and turn down the car.

This is the first rule - when you engage the lower gear, you must definitely stop, that’s how the Shevik differential is designed. But the lock can be turned on and off without stopping. But do you need to always enable the blocking? It’s an interesting question and I’ll tell you what - I use it in exceptional cases, when the dirt is not out of the blue, but there are all sorts of potholes and where there is a risk of catching the “diagonal”.

You may ask - how long does it take to turn on the blocking and then turn it off? There is another nuance here - very often, many owners of the Chevrolet Niva have a problem with the blocking - it does not turn off. It just jams and that’s it, you have to drive on the highway with the blockage. This, you understand, is very harmful for the machine and in such cases you must turn it off.

How to turn off the interaxle? There are several options - turn on reverse, accelerate a little and try to dislodge the lock while driving. You need to do this at speed; it works quite often. Moreover, you can accelerate forward and also try to turn off the lock. I also got stuck once, but even then I didn’t notice it right away and it’s not a problem. Therefore, look at the on-board computer - when the lock is turned on, the following combination will “burn”:

In bright sunny weather it is sometimes difficult to see. Be careful. Well, about turning off the center wheel - I managed to turn it off just when reversing. Needless to say, now I turn it on only in the most dire cases. In the rest of the others, lower gears are quite enough for me.

Just today I went to the lake to check if the ice had melted. The road was washed out, the snow had already melted and turned into liquid mud, and it’s not safe to drive through such mud on my AT tires. It feels like it’s being dragged in all directions, but the most important thing is that I’m driving, I don’t get stuck, and sometimes the ruts were almost to the very bottom; when you shuffle, it always becomes unpleasant)) After some short drives, the car looked “military-like” - all covered in mud , went to the city - people look around))

Overcoming a deep puddle

Often a dispute arises between motorists about how best to cross a ford with a transfer case. Some people prefer to “fly” into a puddle from acceleration, others prefer to downshift. If you get into a mud pit, there is a high risk of water hammer - water enters the cylinders through the filter, and the engine “chokes.” To exclude this, many install a special snorkel. But you can do without it. A deep puddle should be overcome in second low gear. This is done so that in case of trouble (when the car starts to fail) you can switch to first gear in time and not stall. If you enter the water from acceleration (which is a better decision), remember that the wheels may get stuck in the middle of the journey. The engine power is not enough to turn the wheels - the car stalls, and the engine experiences a hydraulic shock.

"Niva Tuning 24/7" - values every client

Applicability:

The installation kit of parts “Synchronized transfer case” is installed in a modernized, small-modular transfer case of LADA 4x4 (21213-2131M), Lada Urban, Chevrolet Niva, Niva Lynx cars and cars created on their basis (Lada Niva Pickup 2329, VIS Pickup), for easy engaging a lower or higher gear both when the vehicle is stationary and while the vehicle is moving.

Purpose:

Motorsport, difficult road conditions, normal driving. The use of a synchronizer also ensures movement without slipping and without stopping on steep and slippery slopes, even with a heavy trailer (boat).

What’s great about the Niva, besides its main purpose of conquering off-road terrain, is that it always offers the opportunity to improve, modernize and customize itself.

We are upgrading the transfer case with 5 pluses :

First! Increased cross-country ability due to non-stop movement.

When switching the serial transfer case of a Lada 4x4 car, you need to stop, which means you may not move, get stuck, or “burn the clutch” on a steep climb. Second! You can use a synchro transfer kit in the city, for example, while driving in a traffic jam in a lower gear, slowly, without jerking the box and clutch, and when it becomes possible to simply squeeze the clutch and shift the transfer case lever to a higher gear. This gives you a few more gears in your arsenal.

Third! Two reverse speeds, this particular kit allows you to shift while driving and in reverse gear.

Fourth! Installs without any modifications, instead of serial parts, does not require special tools. All necessary parts are supplied complete with instructions, and can be installed at any car service center that has experience working with gearboxes.

Fifth! The manufacturer provides a 12-month warranty on the kit.

And a little more about the well-known:

The difficulty of switching down and up gears of the transfer case is invisible to some, but to those who use the car for its intended purpose, this is an extremely serious inconvenience for the vast majority of nivavods. Stopping to shift off-road often leads to difficulties in starting and unnecessary loads on the transmission, or you can simply get stuck. Climbing with a trailer on a dirt road, you need to go downhill, and to do this you have to stop, everyone knows how difficult it is to start with a trailer on a wet dirt hill. And how I would like to switch while coasting, but the manufacturer does not recommend this, and it is problematic to turn it on.

Easy switching on the move! Now there is such an opportunity - a built-in transfer case synchronizer, easy, comfortable upshifting or downshifting without stopping the car and without interrupting traction when switching.

Plus a good video!

Installation

The kit is installed without modifications, using the transfer case repair technology of car manufacturers. A kit is produced for self-conversion of the transfer case.

DELIVERY SET CONTENTS:

1. Intermediate shaft - 1 pc.;

2. Gear ø83 (low) gear (assembled with synchronizer, spring and retaining ring) - 1 pc.;

3. Gear ø108 (overdrive) (assembled with synchronizer, spring and retaining ring) - 1 pc.;

4. Clutch 21010-1701116-10 - 1 pc.;

5. Shift fork 21010-1702024-00 1 pc.;

6. Bolt 21010-1702028-00 (modified) - 1 piece or bolt washer (without spring washer);

7. Spring washer ø6 - 1 pc.

8. Box

9. Instructions

Guarantees

The warranty on kit parts is 12 months from the date of sale or 18 months from the date of production.

WARNINGS:

1. Switching from upshift to downshift is not recommended at speeds over 40 km per hour . This can lead to sudden braking of the car and its skidding.

2. Switching to a lower or higher gear must be done by squeezing the clutch and switching first to neutral of the transfer case, then to gear. This will preserve the durability of the parts.

Please note (for owners of Lada 4x4 with a car produced before 2000):

In connection with the modernization of the LADA 4x4 transfer case carried out by the car manufacturer (transition to gears with a small module and a changed number of teeth on the drive shaft gears):

Drive shaft: high/low gears were 35/26, now 39/29.

Intermediate shaft: high/low gears were 28/37, now 32/42.

Differential gear: was 42, now 47

All cars with four and five-speed gearboxes produced before 2000 require replacing the transfer case differential driven gear with a serial fine-module gear 21213-1802180-00 with a number of 47 teeth.

Box repair

Often the transfer case cover (Niva Chevrolet is no exception) begins to leak oil through it. At the same time, its level in the box begins to fall slowly but surely.

In this case, the transfer case seals should be changed. Chevrolet Niva is equipped with three sealing elements. To replace these seals, you need to take the box out. It is best to do this on a lift or inspection pit. So, first we clean the box from oil stains and thoroughly blow it out. Next, we dismantle the driveshaft. An important point: when removing the bolts, inspect their condition. If the threads are “licked”, such bolts can no longer be used. And to eliminate imbalance of the driveshaft, make a mark on it at the dismantling points. Next, insert two bolts into the holes of the shaft flange and screw the nuts onto them. Use a small spatula to keep the element from rotating. Using a 24 mm socket, remove the nut and take out the flange washer. We also take the last part out. Next, take a flat-head screwdriver in your hands and remove the transfer case oil seal. The seating surface must be wiped with a dry cloth and a little new oil applied to the sealing element. Using a mandrel, press it into place. The remaining seals are installed in the same way. After completing the repair work, add oil to the transfer case. Niva Chevrolet loves gear lubricant with a viscosity of 80W90.

Other problems

Sometimes there is a knocking sound in the transfer case. The Chevrolet Niva is a more reliable car than the VAZ-2121, but such malfunctions should not be ruled out. The first thing you should pay attention to is the driveline. Previously, Nivas had crosses, the play in which caused a lot of noise and vibration.

If you have an old generation Niva, first inspect the crosspieces. As for the new versions, constant velocity joints are used here. There are no backlashes here. Therefore, we look for the reason in the alignment of the gears, which are located in the transfer case itself. If there are any backlashes or gaps, the gears must be replaced. It is also recommended to change the oil in the transfer case. An important point is that if the car overcomes a deep puddle, the lubricant in the box should be replaced as soon as possible. The presence of water in the transfer transmission oil reduces the life of gears and bearings. By the way, the latter also need to be checked and replaced. Perhaps the knocking is due to weak bearing seats. Motorists recommend using anaerobic sealant. They should treat the outer race of the bearings before installing the element into the grooves.

Another reason is the so-called helicopter. This is the splined part that secures the breakout with an elastic coupling. If such symptoms occur, check the wear of the splines. If there is play, replace it with a new one.

Transfer case malfunctions

The transfer case is a complex unit, so it is important to correctly diagnose the malfunction and be able to quickly fix it. The most common sign of its incorrect operation is increased vibration. If it is observed when driving in various modes, then the cause may be wear of the elastic coupling. A visual inspection will help verify this. Vibration under direct load (acceleration) indicates a loose attachment of the transfer case to the body, a faulty CV joint on the intermediate shaft, or a jammed joint on one of the cardan shafts. If vibration is observed at a constant speed, then there is a problem with the balancing of the cardan shafts themselves or the differential.

Malfunctions associated with difficult mode switching often occur. Here attention should be paid to the hinges of the control mechanism, as they usually become clogged with dirt. The fork or stem may be deformed. Over time, nicks appear on the splines of hubs and gears. They can be easily removed by grinding, but to identify the defect you have to remove and disassemble the entire assembly.

Preventive maintenance includes timely replacement of transmission lubricant. It is performed every 45,000 km. It is important during operation to follow the rules for switching modes, and also to carefully monitor the timely unlocking of the differential.