Running in the engine and its life after major overhaul

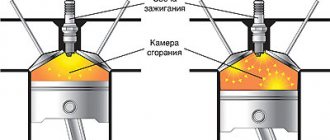

The main task of running in the engine is to grind in the installed parts. Since the engine is equipped with new spare parts (rings, pistons, camshafts, etc.), it is necessary to give it a little time so that all these components get used to each other, which is especially important when replacing rings that rub against the liner.

If you run-in the engine incorrectly, or neglect it altogether, the engine life will be reduced by at least 25%.

Also, two more important factors have a great influence on the resource of the restored power unit:

- Equipment and working conditions - any service station, even with the most modern equipment, is in no way able to compete with the manufacturer in terms of equipment and technical components. Consequently, the assembly accuracy is lower than at the factory;

- Engine mileage - the parameters of those components and parts that do not change during the overhaul can no longer correspond to the original ones, since during operation they were subject to a certain natural wear and tear.

If the running-in is incorrect, in addition to a noticeable reduction in engine life, it is quite possible that engine oil will get into the air cleaner, and fuel consumption (gasoline, gas, diesel fuel) may also significantly increase, and complications with starting are also possible.

Many car owners doubt the benefits of this measure and often neglect it, wanting to save money and relying on the quality of parts (which is not always the best, especially in cases with non-original spare parts). But it is worth remembering that properly carried out running-in will significantly extend the life of the engine.

What determines the duration of the run-in?

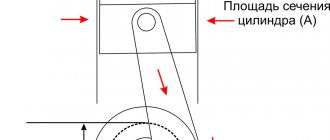

The larger the area of the rubbing surfaces, the longer they take to get used to each other. Accordingly, the duration of the gentle driving mode depends on the number of newly installed spare parts operating in friction mode.

First, it’s worth figuring out which major parts are replaced by a major engine overhaul:

- cylinder-piston group - rings, liners and pistons with pins;

- camshaft;

- timing elements - valves with bushings, levers or hydraulic compensators;

- crankshaft sliding bearings (liners).

Reference. Depending on the model of the power unit, the cylinder liners are bored out for repair pistons or replaced entirely. Replacing crankshaft bearings involves grinding the journals to accommodate thicker bearings.

If the cylinder-piston group or liners are not changed during the engine restoration process, the repair is considered current, and the running-in duration is reduced. How long does it take to break in updated spare parts in a gentle mode:

- After major repairs or purchasing a car at a car dealership, you need to drive at least 3,000 km.

- If work was carried out to install the main and connecting rod bearings of the crankshaft, and the pistons and liners were not changed, the grinding mileage will be 1000 km.

- The running-in period after current repairs is 500 km.

Article on the topic: When is it necessary to do a wheel alignment on a car?

European and American manufacturers are increasingly selling cars with run-in engines - this operation is done at the factory. Then, when purchasing a car, the service book indicates the mileage before the first maintenance is 10–15 thousand km.

In factory conditions, the so-called cold running-in of the engine is used on a special stand. The electric motor rotates the crankshaft at a certain frequency, and the computer monitors all indicators and controls the grinding duration. Such equipment is extremely rare in car services.

In what cases is it not necessary to break in updated elements through gentle operation:

- replacement of timing gear drive parts - pulleys, gears, belt or chain;

- installation of new valve rocker arms or hydraulic compensators;

- updating of oil reflective caps;

- replacement of main bearings and crankshaft oil seals;

- installing a new cylinder head gasket, replacing the pump;

- installation of a gear oil pump repair kit.

Note. It is assumed that these works were carried out separately. Simultaneous updating of the listed parts is usually done during complete disassembly of the engine and is equivalent to routine repairs.

Methods for running in an engine after a major overhaul

There are 4 ways to break in a car after an engine overhaul:

- Cold running on a special stand;

- Cold running without stand;

- Hot running;

- Natural run-in.

Cold running on a special stand

This is the best option for engines that have been overhauled - this is the only way to ensure full control over the running-in process.

To drive the engine (driven) mounted in the stand, a cardan shaft is used, connecting it to the shaft of the electric motor (drive). In this case, the rotation speed of the driving motor is controlled by a special device - an encoder. A tachometer can be used for the same purpose. The whole process is controlled by a computer program, which sets the rotation speed, focusing on sensor readings.

The duration of the procedure depends on the type and volume of repair work performed. For example, to break in a newly installed cylinder-piston group, about 2 or 3 hours of cold running are required.

Expected results:

- stable idle speed (no more than 600 rpm);

- no interruptions in the operation of the power unit when pressing the accelerator pedal at idle. In addition, the engine should not stall.

Not everyone can carry out a test run on a stand, if only because few service stations can boast of having such a device.

Cold running without stand

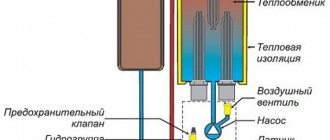

For cold running-in without a stand, you need to fill the engine with oil (which oil is best to pour into the engine), and antifreeze or antifreeze into the radiator. After this, the car needs to be towed, engaging 3rd gear, but without starting the engine. The duration of the procedure is up to 2 hours.

Experts do not recommend using this break-in method, although it is very common among “garage” craftsmen.

Hot engine run-in

During hot running, you can not only check the quality of the engine assembly after a major overhaul, but also eliminate possible inaccuracies in the manufacture of spare parts. By the way, for this you do not always need to take the car to a service station, since the technology for carrying out such an event is not very complicated.

- You need to start the power unit and set the engine speed to approximately the idle mark.

- The operating time is short - up to 3 minutes, but such visits should be repeated several times, allowing the motor to cool. Otherwise, local overheating is quite possible.

- After a cycle of short-term idling, the engine is started and allowed to run for about 50 minutes. The process begins at 1200 rpm and is gradually increased to half the maximum permitted value.

If the permissible temperature is exceeded, you need to turn on the interior heater, and if this does not help, you need to turn off the power unit and give it time to cool down.

During hot running, technicians monitor the level of technical fluids, tightness of connections and compression. After break-in, you need to recheck the ignition parameters and valve clearances.

Natural engine running-in

The duration of natural running-in depends on the work performed. In case of minor repairs (replacing a chain or camshaft), you can limit yourself to 500 kilometers. When a full overhaul is carried out (replacing rings, etc.), it is necessary to travel about 2000 km in a gentle mode.

If the car is equipped with new liners and rings (provided the old pistons are preserved), break-in should be carried out at the most gentle pace. This implies a speed limit of no more than 60 km/h (fifth gear is excluded), in addition, you need to move away as smoothly as possible, and it is also important to control the quality of the fuel being poured. The duration of the running-in in this case is up to 4000 km.

Methods for running in the engine

The algorithm described above is a classic natural run-in. But besides this, there are at least three more ways to grind in parts of a restored power unit:

- cold rolling method, performed using a special stand;

- cold running, performed without a stand;

- method of hot lapping of engine parts.

Let's consider the features of each of the listed methods.

Run-in on the stand

Of course, the stand itself is very expensive equipment. Only large service stations can afford it, but thanks to its use it is possible to gain complete control over all technological stages of running-in.

In this case, the power unit is installed on a stand and started by connecting to the driveshaft, which, in turn, is driven by an electric motor, which is considered to be leading in relation to the car engine.

A special device called an encoder controls the rotation speed of the drive engine, while the tachometer records slightly less accurate readings. The bench equipment operates under the control of a microprogram that regulates the operating parameters of the electric motor, based on sensor readings.

The total duration of operation of the driving/driven motor pair is determined by the scope of work performed as part of the vehicle's overhaul. In particular, normal grinding in of a new cylinder-piston group requires approximately three hours of continuous rotation of both engines.

The result of such cold grinding suggests that the following indicators were achieved:

- when the SA operates at idle (at speeds not exceeding 600 per minute), the speed stabilizes;

- pressing the accelerator pedal in the same mode does not lead to interruptions in the operation of the lead engine, and it should not stall.

Let us note that purchasing an expensive stand for cold running-in is not enough - you also need a specialist who is well versed in the nuances of reaching a certain mode, and in unquestioning adherence to the technology of grinding in parts.

Benchless cold running

It consists of towing the car in third gear, but with the engine turned off, for 2-3 hours. Before running-in, the car is filled with all necessary technical fluids, including oil and antifreeze/antifreeze.

Although experts do not recommend using this method, it has become widespread among garage repairmen.

Hot running

It is carried out directly on the car, but immobilized. It is characterized by the ability to control the assembly quality of the power unit after overhaul and leveling of minor defects made during the production of parts and assemblies installed instead of worn ones. What’s good is that this technology can also be used in garage conditions. Cold running algorithm:

- start the engine, set the speed to idle speed;

- let it run for about 3-4 minutes, turn off the engine for approximately the same amount of time. We repeat the cycle 10-15 times. Stopping the engine is necessary in order to prevent local overheating of the power unit;

- we start the engine again, set the speed at 1200 rpm, gradually increase it to about 50% of the maximum level. We calculate the increase in speed so that the total operating time of the power unit is 45-50 minutes.

Frequency of oil changes after engine overhaul

After a major overhaul, the engine oil is changed 4 times or more. The use of low-quality oil is strictly prohibited.

- The first replacement is after traveling 500 km;

- The second replacement is when the 1000 km mark is reached;

- Third replacement - 1500 km;

- Fourth change - oil is added after 2000 km.

To summarize, it can be noted that running in the engine after a major overhaul is vital, because it can significantly extend the life of the power unit.

Running in the engine after a major overhaul correctly: rules and recommendations

Perhaps, when running in a repaired engine, you need to follow the same rules as when operating a new, recently purchased car. The engine oil must be mineral oil, otherwise the break-in period will double. The problem is after an engine overhaul, it smokes in the morning, then why did the caps come off? And in general, before the first start, it doesn’t hurt to measure the compression - it will become clear what to expect from the “new” engine. In general, after a major overhaul, only a specialist can properly break in the engine. All the answers to the question why does the engine smoke after a major overhaul? At otvetof.org. Come in quickly. Why does a diesel engine smoke | why 42. But using standard rules, you can carry out this process yourself, even with some difficulties...

It happens that after the capital, white smoke comes out of the chimney. Let's look at the video.

Oil selection and frequency of replacement

It is worth considering in more detail the issue of replacing lubricating consumables after a power plant overhaul. First, this must be done after 500 km. Then after 1000 and the last time after 2000 km. Use high-quality motor oil recommended by the manufacturer. After the specified kilometers have been covered, drain the used mixture and flush the engine. When running in, take into account the oil viscosity:

- in summer 15W40;

- in winter 5W30;

- in the intermediate season: 10

Case from practice

The engine “smoke” after repair, and the mechanic says something about grinding in the valves, about changes in the properties of the oil and that all problems will go away on their own... Such statements must be answered with the question: can a new car “smoke”? If oil is consumed, it means the valves are not ground in. But it’s not a fact that they will get used to it after the first “thousand”.

This shouldn't happen

As for oils, everything is clear: even on engines where only synthetics are suitable, during break-in they use material without modifiers. We are talking about break-in oils. And nothing should smoke when using them.

Ideally, everything looks like this:

- Replaced (rebuilt, repaired) the engine;

- When they started it, it “smoked”, and even a lot;

- The engine ran for 20 minutes, and the revolutions could reach up to 3000. And the problem gradually disappeared.

Anything else will be a “deviation from the norm.” And perhaps this deviation is caused by some defect.

Most car owners are aware of how the engine is broken in after a major overhaul or the purchase of a new vehicle - a necessity to make the engine more responsive and economical. Operation in a “gentle mode” (i.e., without heavy loads) increases engine life by approximately 15-20%. At the same time, the machine will achieve the performance stated by the manufacturer. Proper engine running-in after overhaul ensures restoration of 100% functionality of components and assemblies.

Tips for proper engine break-in

Firstly, let’s discard attempts to use the ECO mode with an automatic transmission: in order to save fuel, the transmission will engage high gears as early as possible! Sport mode, on the contrary, can be used, but there won’t be much difference with or without it. We are not going to spin the engine above 2500 rpm.

Let it be better “Sport”

A lean mixture is not needed during break-in. So it’s better not to use the ECO mode with a manual transmission either... In general, after a major overhaul, running in the engine will be easy: you need to do everything that you would do after buying a new car with the same engine.

The break-in period is usually 2000-2500 km.

What not to do

- Do not open the throttle even 1/2 – the gas pedal should move in the range of 0-50%;

- Acceleration will be slow: bring the gas to 50%, wait for a constant speed to be established, then engage the next gear;

- Don't use cruise control!

- If extraneous noise appears, overheating begins, or one of the light bulbs lights up, there is no need to despair. It will be enough to turn off the engine, cool it a little and continue the trip again.

First start of the engine after the “capital”

A very important moment. Before turning the ignition key, you need to ensure that all systems and modules provide support to the restored engine during the first break-in stage. Before starting the engine for the first time after a major overhaul, you must:

- fully charge the battery;

- check the functionality of the starter in advance (before installation);

- pour in the required volume of oil: this must be done slowly and carefully to prevent the formation of air pockets;

- Pump up gasoline in a carburetor engine and adjust the idle speed;

- If the start is carried out at sub-zero temperatures, warm up the oil and the engine itself.

When everything is ready, start the power unit and immediately pay attention to the oil pressure readings (if there is such a device). It should appear 3-4 seconds after the start of work and amount to 3.5-4 kgf/sq. see. If this is not the case, stop the engine immediately to determine the cause. At normal pressure, warm up the power plant to an operating temperature of 85-95 degrees while rotating the crankshaft at a frequency of 750-850 rpm. (it is not recommended to increase the speed by more than 60% of the nominal value). At the same time, inspect the engine from all sides for oil and coolant leaks.

The appearance of small and short-lived smoke under the hood should not cause concern: the process of combustion of oil that accidentally got inside during assembly of the unit is in progress. When the radiator fan turns on, turn off the engine and let it cool to 30-40 degrees. Then run it again and repeat 15-20 times. Only after this can you begin running in after the overhaul.

First engine start

This section is of interest to motorists who independently carry out repair work on the power unit in a garage environment. In order to successfully start the engine after a “overhaul” and not damage the newly installed parts, it is recommended to carry out the following preparatory steps:

- While assembling the cylinder-piston group, generously lubricate the inner walls of the liners with engine oil. To ensure even distribution, rotate the crankshaft several times by hand.

- Be sure to check the operation of the pump by immersing the oil intake screen in a container with lubricant and rotating the drive shaft by hand.

- Carefully adjust the timing according to the marks.

- Fully charge the battery.

- Install new spark plugs and wires.

- Fill with high-quality fresh oil without additional additives. Also fill the filter with grease before screwing it on.

- Make sure the cooling system, in particular the pump, is working.

Use the same type of oil for running-in as for operation.

For example, if you plan to use synthetics, then for grinding in, take a similar material (possibly cheaper). A repaired and properly tuned engine will start immediately. Let the power unit idle for 10 minutes, observing the instrument readings (especially oil pressure) and listening for extraneous sounds. Then follow the instructions:

- Cool the engine, check the lubricant and antifreeze levels.

- If no fluid leaks or suspicious noises are detected, start the power unit and leave it idling for 30 minutes.

- Monitor oil pressure, coolant temperature, and when the electric fan turns on.

- If the fan does not turn on when the temperature rises above 95 °C, immediately turn off and cool the engine.

Important point! Never turn off the engine while the fan is on or start it immediately after stopping. At this moment, the temperature in the cylinder head reaches its maximum; stopping the airflow and circulation of antifreeze will cause overheating. If you accidentally turn off the engine, wait until it cools down.

After making sure that the initial running-in at idle speed has not revealed any errors or malfunctions, start operating the car. Otherwise, fix the problems, otherwise the overhaul will go to waste.

Article on the topic: Checking the VAZ speed sensor, why it is needed and how it works

How long to break in the engine and how to do it

The first 1000 km are considered the most important. During this period, it is not recommended to travel at speeds above 60 km/h: it is better not to engage fifth speed at all. During the initial run-in, bluish smoke may appear from the muffler pipe: there is no need to panic: this is natural, since new piston rings are being broken in. Unstable idle is also not a reason to worry. Adjustment should be done after 500-1000 km. How long does it take to break in the engine in total? After the car has traveled 2.5-3 thousand km, increase the maximum speed to 85-90 km/h, gradually increasing the load. The engine can be considered finally run-in after running 8-10 thousand km.

What is not recommended to do when running in

To avoid getting new problems when running an engine after a major overhaul, you should not do the following:

- start a trip without first warming up the engine to operating temperature;

- raise the crankshaft speed to 2000;

- fully load the car (with luggage and passengers);

- increase speed sharply (for example, “run away” from traffic lights);

- Drive for a long time in one mode: it is recommended to alternate low and high gears.

Methods for running in the power unit

In addition to running in natural conditions, there are several more ways to carry out this procedure, each of which is worth considering separately:

- Cold running on bench equipment. A good option for engines after major overhaul. To carry out the procedure, the shaft of the electric motor of the stand is connected through a cardan to the motor being tested. The engine crankshaft is rotated at a certain frequency, controlled by sensors installed on the engine and instruments on the stand. Operating modes are set by a computer program.

- Cold run-in without a stand.

It is not always possible to use special equipment. In this case, they use the “folk” option, in which the parts also rub against each other. What should be done? Fill the engine with oil and antifreeze, hitch the car to a tow (a friend's car) and drive in third gear for about a couple of hours.

After cold running of any type, you can expect the following results:

- stable engine operation at idle speed (maximum – 700 rpm);

- absence of “failure” when sharply pressing the gas pedal;

- the operating temperature does not rise to a critical level.

- Hot running. To implement it, it is not necessary to take the car to a service station. Start the engine and let it idle for no more than three minutes. Then wait until the unit cools down and repeat the operation several times. At the last stage, leave the unit running for 50 minutes. During this time, gradually increase the speed from 1500 to half the permitted maximum. If the BC temperature rises unacceptable, turn on the heater (if that doesn’t help, turn off the engine and let it cool). After completing the hot and cold running-in, re-check the valve clearances and correct ignition installation. Also tighten the cylinder head bolts to the engine block.

How to properly break in an engine after a major overhaul?

Experienced drivers know that after a major overhaul or purchase of a new car, the engine must be run in for some time. That is, for the first few thousand kilometers, optimal driving conditions must be observed, you must not press hard on the gas or brakes, and you must not allow the engine to run for a long time at idle or at high speeds. In this article we will try to convey to the car enthusiast as complete information as possible on how to run in an engine after a major overhaul.

Almost any engine will require major overhaul over time. Symptoms that your car’s engine requires diagnosis and repair are the following:

- gradual increase in fuel and oil consumption;

- exhaust of characteristic black or bluish smoke from the chimney;

- reduction of compression in cylinders;

- decreased traction at low or high engine speeds;

- The engine starts to stall when changing gears.

All these problems can be eliminated in various ways. For example, you can replace the cylinder block gaskets and use various engine oil additives. But such actions are only temporary measures that correct the situation for a short time. The most correct solution in this case is a major overhaul of the engine.

The very concept of “overhaul” of an engine implies a complete diagnosis of the unit and a complete replacement of all worn out and failed parts.

Engine overhaul usually consists of the following steps:

engine dismantling - removing the engine from the car using a special lift. To do this, first disconnect all components and systems associated with the engine - gearbox, clutch and cooling system;

cleaning the engine - in order to see and evaluate the actual level of defects and damage, it is necessary to completely clean all internal surfaces of carbon deposits and the remaining layer of oil. Only on a clean motor can all measurements be carried out correctly;

defect detection - mechanics assess the degree of wear of the engine, make a list of parts that need to be replaced, as well as upcoming work: boring, replacing rings, grinding, replacing connecting rods and crankshaft main bearings, etc.;

engine repair itself.

Of course, it is not difficult to guess that such repairs are a very expensive and painstaking pleasure, which can only be carried out by good specialists. Well, when it comes to foreign cars, then the cost of work increases many times over. That is why we do not recommend buying foreign cars with a mileage of more than 500,000 km. It’s better to buy a domestic car - their overhaul will cost you several times cheaper.

Running in the engine after a major overhaul.

After the experts have finished repairing the engine, you have installed it in place, replaced all the filters, connected everything necessary and started it to make sure that it is assembled correctly - that's it, your car is ready to use. But now you should know that you are dealing with a practically new engine, which needs to be run in for some time so that all the plain bearings, rings, and pistons get used to each other.

How to run-in an engine after a major overhaul?

Run-in depends on the work performed. The run-in itself involves a certain set of activities:

- When driving, a gentle mode is used;

- The engine is flushed several times, filling and draining engine oil;

- filter elements are replaced.

So, if the repair affected the gas distribution mechanism, the camshaft, chain, valves were replaced, then running in the engine is enough to carry out the first 500 - 1000 km.

If liners, pistons and piston rings have been completely replaced, new connecting rod and main bearings have been installed on the crankshaft, and so on, then a gentle regime must be observed up to 3000 km.

The gentle mode eliminates sudden starts and braking, acceleration of more than 50 km/h, crankshaft revolutions of more than 2500. Sudden accelerations are prohibited and overloads are excluded.

Why is it necessary to run in an engine after a major overhaul?

Firstly, the piston rings must fall into place in the piston grooves, since with a sharp increase in speed, the rings can simply break and your engine will seize.

Secondly, during the grinding-in process of new parts, metal shavings inevitably form, which can only be gotten rid of by changing the engine oil.

Thirdly, if you look at the surface of the pistons under a microscope, then even after the most thorough grinding you will notice a lot of tubercles that should level out during the running-in period.

Another factor should also be noted - even after observing the full break-in regime during the first 2000 - 3000 kilometers, complete adaptation of all parts and components occurs only after 5000 -1000 km. Only after this can the engine be required to demonstrate all its capabilities.

Advice from experts for motorists.

When starting to run in the engine after a major overhaul, be sure to check the battery charge. Since the first start after repair is a critical step, and the crankshaft is quite tight, you will need all the power of the battery.

The second point is to replace the oil filter with a new one and fill only with high-quality oil. It is impossible to wet the filter in oil before installation, since an air lock may form and the engine may experience oil starvation at the most crucial moment.

Leave the engine running and idling until the oil pressure reading returns to normal - this will take no more than 3-4 seconds.

If the sensors show a low oil pressure level, turn off the engine immediately, as there could be some problems with the oil supply - the oil pump does not pump, there is an air lock, etc. If you do not turn off the engine in time, you may have to do a new engine repair .

If everything is in order with the pressure, warm up the engine to the desired temperature. As the oil heats up, it becomes more liquid and the pressure decreases to certain values.

Another problem that occurs when running an engine after a major overhaul is the leakage of technical fluids. This problem also needs to be solved urgently, as the oil or antifreeze level may decrease, which threatens to overheat the engine.

You can start the engine several times, warm it up to the required temperatures, idle it a little and then turn it off. If you don’t hear any extraneous noises or knocks, you can safely leave the garage.

Observe the speed limit - for the first 2000 - 3000 km, do not exceed the speed of more than 50 km/h. After 3000 km you can accelerate to 80-90 km/h.

At the 5000 km mark, you can change the engine oil - various foreign particles will appear in it. Fill the engine only with the oil recommended by the manufacturer.

After traveling 5,000 - 10,000 km, the engine can be loaded to its fullest.

Features of diesel running-in

There are no fundamental differences here from the same procedure with a gasoline unit. There are only a few nuances. First of all, this is the duration of the run-in: ultimately, it should be at least 10-12 thousand kilometers. Only after covering such a distance can the diesel engine be operated at maximum loads. Another important point when running in a diesel engine after a major overhaul is turning off the engine after stopping. This cannot be done right away: you need to let the diesel engine run for several tens of seconds - this requirement is especially relevant for turbocharged engines. As for changing the oil, this needs to be done every 500 km. After the first half a thousand km, replace the lubrication system filter, adjust the timing belt (including the belt or chain drive), and tighten the cylinder head bolts. When breaking in a car, do not use synthetics - it can only be filled in after the final grinding in of parts - after 3 thousand km. When running in summer, use oil M-10G2K (15W-30), in winter - M-10DM or M-8G2. It is worth noting that for a diesel engine, the best running-in option is to use bench equipment in a service station, where the process is “cold”. In this case, the duration of the run-in is at least 3 hours.

Use lubricants with low viscosity: this will improve the quality of lapping of parts. Sometimes in stores you can find special, so-called. “break-in” oil, which contains special additives that speed up the break-in process.