Methods for eliminating leaks

If you find that the antifreeze level is dropping, you need to take measures as quickly as possible to get to the nearest workshop.

First of all, you need to determine the cause of the leak - the radiator itself is leaking or liquid is leaking from the pipes. If the leak is small, it is not so easy to detect it on the road. Without turning off the engine, try to visually determine the place where the liquid is dripping. If it is winter outside, steam will be released from the hole or crack.

Be very careful before pouring or pouring all this into the radiator - you can only unscrew the cap when the engine is turned off and cooled down, since high pressure is created inside the radiator and a stream of coolant can escape under pressure and burn you. Unscrew the radiator cap, pour one or two eggs inside, or add a small 10-gram bag of pepper, flour or mustard.

According to the testimony of many motorists, this simple method really helps. The leak disappears. However, then you will have to completely remove the radiator and wash it, since the tubes may become clogged and will not allow antifreeze to pass through.

What should I use to temporarily fix a leak?

Liqui Moly products are very popular, namely a product called LIQUI MOLY Kuhler Dichter - this is what experts recommend buying. There are many other similar products, but no one can guarantee that the same flour or mustard is not used in its composition. It’s even worse when dry construction adhesive or cement is added to such sealants. Using such a product will lead to blockage of the honeycombs and subsequent overheating of the engine.

If we talk about Liqui Moly sealants, they contain polymer additives in the form of sparkles, which will not clog the radiator tubes, but will settle precisely at the site of the crack. Although it should be noted that this is only a temporary measure, and the sealant will not clog quite large cracks.

Therefore, you will have to choose from several options:

- solder the radiator;

- glue by cold welding;

- buy a new one.

Radiators are usually made of brass, copper or aluminum. Aluminum cannot be soldered, so you will need cold welding - a special two-component epoxy-based adhesive.

To make this type of welding last longer, you need:

- let the engine cool down;

- detect a crack and mark it;

- completely drain the fluid from the radiator;

- degrease the damaged area;

- Apply glue and leave for 2 hours until it sets well.

If it is impossible to get to the place of the leak or it is not possible to detect the damaged tube at all, you will have to completely remove the radiator.

There are several ways to detect a crack:

- lower the radiator into the bath and bubbles will come out of the crack;

- connect the compressor and supply air - you will feel where the air is leaking from.

Copper or brass radiators are soldered with a special soldering iron - its power is at least 250 W. The soldering area must be completely descaled and degreased. Then you need to warm the metal well, apply rosin in an even layer, and then apply the solder itself. The solder should lie in an even layer without holes or irregularities.

Please also note that radiator pipes, which are made of rubber, can leak. In principle, a set of pipes can be bought in almost any store, especially for domestic cars

You can also seal them using special rubber patches, raw rubber or vulcanization. To ensure reliable contact between the pipe and the radiator outlet, you can use additional metal clamps, which are also sold at any hardware store.

Well, if none of these methods helps, the only option left is to purchase and install a new radiator.

Video showing the use of LIQUI MOLY Kuhler Dichter sealant.

In this video, a specialist explains what problems can arise when sealing a radiator, as well as what mistakes car enthusiasts most often make.

We calculate how many radiator sections we need for the room

How to flush a car radiator at home

People have a fairly simple formula for calculating the number of radiators per square meter - it comes down to one battery section per 2 sq.m. That is, if you have a room of 20 sq.m., then you need 10 sections in the battery. We also recommend adding another section in case the door in the room is open or the walls are thin and not insulated.

There is another, more complex formula. It is necessary to take into account many nuances; this is necessary in order to find out how much thermal energy is needed to heat the apartment.

Room type. Each room has its own amount of thermal energy that it requires for heating. To heat a room in a panel house, 1 cubic meter requires 41 W of heat energy. In a brick house (fully insulated and with double-glazed windows), the same volume requires 34 W of heat energy. Modern, insulated houses require only 20 W of heat energy.

For example, for a small room in a panel house, we determine its volume: 2.30*3.50*2.70=21.73 m3

Now we can find out how much heat is needed to heat this room: 41 W * 21.73 = 890.93 W. This is exactly how much heat energy we need to properly heat a room.

It is worth remembering that a modern double-glazed window reduces heat loss by almost 15% (this number can significantly affect the number of battery sections). The temperature of the coolant also affects the heat loss of the room (according to SNiP 2.04.01.-85, the temperature of the coolant must be at least 50 degrees Celsius, and according to SNiP 2.08.01.-89, the temperature in the apartment must be at least 18 degrees Celsius Celsius) When calculating, you also need to take into account what floor the apartment is on, corner room or not

It is also important to know that when you cover the battery with various types of decorative panels, you lose up to 25% of the heat. Many people do not take this fact into account when carrying out repairs, which leads to sad consequences.

Considering all factors, analyze the various options before changing radiators. If you are planning to replace your windows with double-glazed windows, then replace the windows and spend the winter; in many cases, the need to replace the batteries simply disappears. Well, if you decide to change, we recommend that you look at reviews in a “reputable” online store for the product you have chosen and beware of counterfeits and it is better not to mess with China - flooding will negate all your savings, which can cost you very dearly both financially and morally.

Tubular steel models

Steel sectional radiators are used much less frequently than panel radiators due to their high price. The design of tubular steel batteries consists of several rows of steel pipes (vertical or horizontal), which are connected by collectors. This equipment is very efficient: it heats up quickly and cools down quickly using a thermostat. Standard dimensions of the device: height - 19-300 cm, depth - up to 22.5 cm, and length - unlimited (when installed, it must be at least ¾ of the width of the window opening).

Table 5. Technical characteristics of tubular steel radiators

| Index | Description | Meaning |

| Operating pressure | The pressure in the system at which the system can operate normally and the radiator walls can withstand water pressure | 12 atm |

| Crimping pressure | Pressure that is acceptable for checking and starting the system at the end of summer. Indicator for testing for serviceability | Up to 25 atm |

| Limit temperature | Water temperature at which the system can operate normally (maximum value) | Up to 1200 degrees |

| Heat dissipation | How much heat does the section/panel give to the room? | 1200-1800 W |

| Center distance | Distance between bottom and top section | 12-293 cm |

| Life time | Time that the battery lasts without breakdowns | 20 years |

.

Tubular models made of steel are ideal for installation in apartment buildings: they withstand water hammer well, are moderately light, and have sufficient heat transfer. The only negative is the cost.

Radiators made of steel are highly susceptible to corrosion, chemical impurities in water, and moisture in general. If you leave the radiator without water for 2-3 weeks, the corrosion rate will only increase. Panel models are very sensitive to water hammer due to welded seams: it happens that during crimping the batteries become deformed and burst.

Table 6. Comparative analysis of four materials

| Indicators | Aluminum | Cast iron | Steel | Bimetallic | |

| panel | tubular | ||||

| Economical | + | + | + | + | |

| Light weight | + | — | + | + | |

| Possibility of temperature control | + | + | + | + | |

| Easy to install | + | + | + | + | |

| High heat transfer coefficient | + | — | + | ||

| Cute appearance | + | — | + | ||

| Possibility of water leakage | + | — | |||

| Uniformity of heat distribution | — | + | + | + | |

| High convection heat transfer | — | — | + | — | + |

| Long service life | — | + | + | ||

| Possibility of gas formation in the system | + | + | + | ||

| Anti-corrosion properties | — | + | — | — | — |

| Resistance to pressure drops in the system | — | + | — | + | + |

| Low cost | + | + | + | — | — |

| Where is it better to use | In autonomous systems where you can supply clean water and regulate the pressure | In central heating systems | In city apartments | In autonomous systems where there are no impurities in the water | |

| Where is it better not to install | In the apartment | — | In multi-storey buildings due to low pressure testing | In systems using contaminated water or antifreeze | |

.

Is it possible to close a car radiator in winter and why do it?

Clogged radiator symptoms

- The honeycomb fencing prevents the flow of cold air, which does not allow the coolant to heat up to operating temperature.

- When parked for a short period of time, the engine will take a little longer to cool down.

- When starting, the engine heats up faster.

A little theory

On machines where there is no ECU, and the cooling functions are performed mechanically thanks to a belt drive and a fan. Such a system is extremely dependent on the speed of the power unit. In practice, such cooling is not always effective in summer, and in winter it prevents the engine from warming up at atmospheric temperatures below -25°C. In such cases, the question of whether it is possible to close the car radiator in winter practically does not arise. The fact is that at this temperature, even with the fan turned off, it is extremely difficult to heat the coolant, not to mention driving with incoming currents of cold air. That's why drivers of old cars prefer to cover the radiator grille with cardboard. On more modern cars there is a viscous coupling that regulates the operation of the fan. This system is very effective at all temperature conditions. In winter, the fan practically does not turn on

But here it is important to consider the average temperature in your region. If it often drops below -20°C, then cardboard will not hurt in a modern car

Paired with engine insulation, this measure will help quickly get the car into working condition.

Legends and myths

In fairness, it should be noted that among car enthusiasts, winter modernization of the cooling system is almost a universal panacea. Some of the myths are quite popular:

- The ability to reduce fuel consumption by 25% using insulation materials is a marketing ploy by manufacturers of insulation products. In reality, of course, there are savings, but their percentage is overestimated, because this occurs due to the rapid warming up of the engine in winter.

- Thermal insulation of the radiator will greatly facilitate the morning startup of the power unit in severe frost. This opinion is true when the car, after standing for 2-3 hours and retaining some of the heat, starts easier and faster. It’s another matter if the car was left all night in the cold, in which case the effect of the presence of insulation on starting is minimal.

Why do you need a cooling radiator in a car?

Car stethoscope

Every car, regardless of make and model, is equipped with a rather important and necessary mechanism, which is called a “cooling radiator”. This device provides the temperature conditions necessary for the full functioning of the engine. If there were no cooling system in the car, this would lead to instant overheating of the engine, and as a result, to its premature failure. Despite the fact that the radiator is an important and useful device in the overall design of the vehicle, many motorists do not understand at all , what it is and for what purpose it is used in a car. That is why in today’s article we would like to talk in more detail about the main purpose of this installation, as well as its types. First of all, let’s find out what it is. A cooling radiator is a kind of heat exchanger that cools antifreeze through a strong air flow. It is located at the front of the vehicle behind the radiator grille. It is in this place that there is an excellent opportunity to make the most effective use of the oncoming air flow during movement. If we talk about the slow movement of the machine, then the airflow is carried out by a special fan. Thus, the coolant in the car, after passing through many passages, is cooled to the required level, which in turn ensures the normal and uninterrupted functioning of the propulsion system. The modern market offers a large selection of cooling radiators that differ from each other in certain characteristics. If we talk about the very first devices, they were assembled mechanically. Of course, this significantly reduced the cost of the finished installation. However, as far as quality is concerned, such radiators in most cases turned out to be short-lived. And all because they needed the additional use of sealing gaskets that would help the device withstand fluctuations in temperature conditions. Over time, more advanced mechanisms began to appear on the market, with particular strength and a high level of heat transfer. Copper radiators could be repaired if necessary. However, due to the fact that this raw material gradually became more expensive, manufacturers began to use traditional aluminum for the manufacture of cooling radiators. A large selection is presented on the website of the Avtoradosti online store https://www.avtoradosti.com.ua/katalog-tovara/radiator_avtomobilnyj.html ultra-modern aluminum radiators that are particularly durable and reliable. This means that they can be easily used for cars equipped with more powerful power units.

Possible causes of the malfunction and ways to eliminate them

There are three main malfunctions of the radiator cap:

- deformation and wear of the rubber seal under the cover, which prevents the normal operation of the outlet valve to maintain excess pressure in the system, because of this the liquid can either simply boil or gradually boil away;

- breakdown of the exhaust valve mechanism, which can lead to a coolant leak;

- jamming of the intake valve membrane, which can cause air locks in the cooling system.

You can check the valve mechanism of the radiator cap with an open structure yourself by visual inspection and alternating pressure on the inlet and outlet membrane. When the mechanism is fully operational, the rubber membrane seals should not have any deposits on their surface and fit snugly to the seats.

And it is worth remembering that you can only open and remove the radiator cap when the engine has completely cooled down.

Device Features

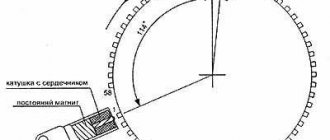

The coolant pump is a central type, driven by a V-belt from the crankshaft pulley. The fan has a four-bladed impeller, which is bolted to the pulley hub and is driven by the pump drive belt. The thermostat with a solid sensitive filler has a main and bypass valve. The opening of the main valve begins at a coolant temperature of 77-86°C, the stroke of the main valve is at least 6 mm. The radiator is vertical, tubular-plate, with two rows of tubes and tinned steel plates. The filler plug contains inlet and outlet valves.

Checking the level and density of the liquid in the cooling system

The correct filling of the cooling system is checked by the fluid level in the expansion tank, which on a cold engine (at 15-20°C) should be 3-4 mm above the “MIN” mark marked on the expansion tank.

Warning.

It is recommended to check the coolant level on a cold engine, because When heated, its volume increases and in a warm engine the fluid level can rise significantly.

If necessary, check the density of the coolant with a hydrometer, which should be 1.078-1.085 g/cm³. At low and high densities (more than 1.085-1.095 g/cm³), the temperature at which the liquid begins to crystallize increases, which can lead to its freezing in the cold season. If the liquid level in the tank is below normal, add distilled water. If the density is normal, add liquid of the same density and brand as is in the system. If below the norm, bring it up to it using TO-SOL-A liquid.

Cooling radiator design, principle of operation

radiator repair car defect

Every modern car has two main radiators in the engine compartment that perform cooling functions: the first is the main radiator, also known as the engine cooling radiator, and the second is the condenser (air conditioning radiator). Let's consider the design and principle of operation of an engine cooling radiator. There are two types of cooling of an internal combustion engine: air and water (liquid) cooling. Air cooling is used only on low-power engines and has many disadvantages. This type of cooling is used on some motorcycles and mopeds. The most popular due to its efficiency is the water (liquid) engine cooling system, which is equipped in every modern car.

The main part of the engine cooling system is the cooling radiator. The cooling radiator is designed to maintain the operating temperature of the engine, which ranges from 85 to 100 degrees (depending on the type of engine), and prevent it from overheating. When the operating temperature of the engine is exceeded, overheating occurs, which leads to engine seizure and, as a consequence, to its overhaul. The principle of operation of the cooling system is as follows. Using a liquid pump, coolant circulates in a circle and washes the hot cylinder walls and block heads, thereby removing heat from heated engine parts. The hot liquid then enters the cooling radiator and releases heat to the environment. Next, the now cooled coolant repeats the cycle. A cooling radiator is a heat exchanger or, in other words, a car radiator is a device for cooling liquid. For the most efficient heat transfer, a cooling radiator fan is installed in front of the engine, which forces air flow onto the surface of the radiator, thereby accelerating the heat transfer process.

The radiator cooling fan is switched on by a temperature sensor when the engine operating temperature rises. Depending on the type and size of the engine, radiator cooling fans are of two types: single-fan and double-fan.

The cooling radiator and condenser are installed at the front of the car, directly in front of the engine. This is shown in Figure 1.3.

Figure 1.3- Placement of the cooling radiator

Checking the operating mode of the pump for cavitation Condition of non-cavitation operation: Nvac. additional ≥ Nwak, where: Nwak. additional – permissible vacuum suction height of the pump (according to the passport); Nvac – vacuum-metric suction height of the hydraulic line, where: Nv – geometric suction height, determined by the condition of cavitation-free operation of the pumps, h...

Reducing fuel costs Finding and using reserves to reduce fuel costs is one of the most important problems of TEF, which is explained mainly by two reasons: a sharp increase in fuel consumption by sea vessels due to the growth of the fleet and an increase in the power supply of ships; growing energy crisis, cat...

Purpose and types of cooling system

The temperature of the gases in the combustion chamber at the moment of ignition of the mixture exceeds 2000°C. Such a temperature, in the absence of artificial cooling, would lead to strong heating of engine parts and their destruction. Therefore, air or liquid cooling of the engine is necessary. With air cooling, a radiator, water pump and pipelines are not required, and there is no danger of the engine “defrosting” in winter when filling the cooling system with water. Therefore, despite the increased power consumption for activating the fan and difficult starting at low temperatures, air cooling is used in passenger cars and a number of foreign cars.

The cooling system is a closed liquid type with forced circulation of liquid, with an expansion tank. Such a system is filled with water or antifreeze, which does not freeze at temperatures down to minus 40°C.

When the engine cools excessively, heat loss from the coolant increases, fuel does not completely evaporate and burns, which penetrates in liquid form into the oil pan and dilutes the oil. This leads to a decrease in engine power and efficiency and rapid wear of parts. When the engine overheats, decomposition and coking of the accelerating oil and carbon deposits occur, as a result of which heat dissipation deteriorates. Due to the expansion of parts, temperature gaps decrease, friction and wear of parts increase, and cylinder filling deteriorates. The coolant temperature when the engine is running should be 85-100°C.

Automotive engines use a forced (pump) liquid cooling system. Such a system includes cylinder cooling jackets, a radiator, a water pump, a fan, shutters, a thermostat, drain taps, and coolant temperature gauges.

The liquid circulating in the cooling system absorbs heat from the cylinder walls and their heads and transfers it through the radiator to the environment. Sometimes it is planned to direct the flow of circulating fluid through a water distribution pipe or a longitudinal channel with holes primarily to the most heated parts (convex valves, spark plugs, walls of the combustion chamber).

In modern engines, the engine cooling system is used to heat the intake manifold, cool the compressor, and heat the cabin or passenger area of the body. Modern automobile engines use closed liquid cooling systems that communicate with the atmosphere through valves in the radiator cap. In such a system, the boiling point of water increases, water boils less often and evaporates less.

How to clean an air conditioner radiator

Cleaning the air conditioner radiator consists of two stages:

- External cleaning of the air conditioner radiator

- Internal flushing of the air conditioner radiator

To the question of how to clean, the answer is quite simple. Cleaning is supposed to be external; first, large contaminants are removed, then the honeycombs are cleaned dry with a brush. After this, a special composition or detergent is applied, left for half an hour and washed off with a stream of water. It is advisable to use a high pressure washer for this operation. However, you should not set the pressure to maximum, since the honeycombs are quite fragile.

Radiator flushing

Flushing the radiator is not difficult. First, it is washed with water under pressure, then one of the specialized flushing liquids is poured in, after which it is washed again under pressure.

Radiator

To remove the radiator from the car: - drain the liquid from it and the cylinder block by removing the drain plugs in the lower radiator tank and on the cylinder block; At the same time, open the body heater valve and remove the radiator cap from the filler neck; — disconnect the hoses from the radiator; — remove the fan casing; — Unscrew the bolts securing the radiator to the body, remove the radiator from the engine compartment.

The tightness is checked in a bath of water. Having plugged the radiator pipes, supply air to it at a pressure of 0.1 MPa (1 kgf/cm²) and lower it into a bath of water for at least 30 s. In this case, there should be no etching of air. Solder minor damage to the brass radiator with soft solder, and if significant, replace it with a new one.

Purpose of the radiator, its types

Without starting the “heart” - the car engine, the car ceases to be a means of transportation and becomes a useless piece of iron. All parts in a car are interconnected, and one without the other simply ceases to perform its function. So, the radiator plays an important role in the smooth operation of the engine and is an integral part of it (Figure 1.1).

Figure 1.1 - Cooling radiator

The processes that make a car move begin in the internal combustion engine (ICE). With the help of an electric spark, the fuel inside the internal combustion engine self-ignites, and during its combustion, thermal energy is generated in the cylinders. It, in turn, is converted into a mechanical one, which creates the torque necessary to start the car moving. During operation, the engine reaches very high temperatures, which would be enough to heat two average-sized houses. If the operating temperature is exceeded, the engine overheats and, as a result, breaks down. In order to avoid serious problems such as overheating, there is an entire engine cooling system, which includes a cooling radiator.

In an internal combustion engine, the radiator is a heat exchanger that combines two circuits of the cooling system. Tubular-plate and tubular-tape radiator grilles are mainly used. Aluminum radiators are also used: they are cheaper and lighter, but the heat transfer properties, all other things being equal (dimensions, heat transfer area, etc.), and reliability are lower. The radiator has a tubular-tape copper-brass core with two-pass horizontal fluid movement (the right radiator tank is divided into 2 parts). Until November 1988, radiators with 2 rows of cooling tubes and stamped brass tanks were installed on cars. On cars of later production, radiators are installed with one row of cooling tubes of increased cross-section and plastic tanks. Cooling radiators come in different designs. The most common radiators are: tape and plate (Figure 1.2). Plate cooling radiators, having worse heat transfer characteristics and greater weight parameters compared to strip radiators, are confidently becoming a thing of the past.

a – device; b, c – tubular-plate and tubular-ribbon cores, respectively; 1 – side stand; 2 – steam pipe; 3 – plug; 4 – upper tank; 5 – rubber pad for mounting the radiator; 6 – lower tank; 7 – heat dissipating core.

Figure 1.2 - Radiator and types of its core

Calculation and construction of an indicator diagram The indicator diagram (ID) serves as the source material for dynamic and strength calculations of the engine. Calculation and construction of ID were carried out according to the method of P.A. Gordeeva. The results of calculating the ID of the designed engine are presented in Table 2.2. Table 2.2 – Calculation for constructing an indicator diagram...

Calculation of ordinates of floor devices Inter-track width: 4.8 m (between side tracks) and 6.5 m (between the main track and side tracks). Rail types: P65 (main tracks), P50 (side tracks). Arrows with crosses of 1/11 grade are laid along the routes of passenger trains, on the rest - 1/9. The schematic plan shows the ordinates of the beginning of the acute ...

Elements of a transition curve Circular curves have a specified radius R and a specified elevation h. To ensure a smooth transition of rolling stock from straight to circular, transition curves are arranged. Within the transition curves, bends of curvature K, elevation and widening of the track are arranged, if required. Scheme lane...

Steel radiators

Steel batteries can be of two types - panel and tubular. All models are made from thick stainless steel 1.2-1.5 cm thick. Panel options are becoming the most popular.

About panel models: design

A steel panel radiator for a heating system is a device that operates on the principle of both a radiator and a convector. They are produced in the form of rectangular panels, the thickness and width of which can vary. Structurally, a steel battery consists of a panel - two profiled steel plates, which are connected to each other by welding around the perimeter. Inside the panel, vertical oblong channels are created by molding, through which hot water will flow. Also, U-shaped fins are sometimes welded to the back side (they enhance convection) so that heat transfer is more efficient. The material for the ribs is thinner cold-rolled steel.

One radiator can include up to 3 panels. After several panels have been combined into one unit, it is covered with side casings. Standard dimensions of a panel steel radiator: height - 30-90 cm, width - 40-300 cm, depth - up to 17 cm.

Types of panel steel models

The classification of steel panel batteries is based on the type of connection:

- models with bottom connection - most often a thermostat is built into them to control the temperature, so the price for these models is quite high;

- models with side connection;

- models with universal connection.

If the model does not have a built-in thermostat, you can connect it through a thermostatic valve.

Table 4. Technical characteristics of panel steel radiators

| Index | Description | Meaning |

| Operating pressure | The pressure in the system at which the system can operate normally and the radiator walls can withstand water pressure | 6-8.5 atm |

| Crimping pressure | Pressure that is acceptable for checking and starting the system at the end of summer. Indicator for testing for serviceability | Up to 13 atm |

| Limit temperature | Water temperature at which the system can operate normally (maximum value) | 110-120 degrees |

| Heat dissipation | How much heat does the section/panel give to the room? | 900-1200 W |

| Capacity | How much water does one section hold? | 2.3-3 l |

| Center distance | Radiator height minus 50-70 cm. | |

.

The problem with panel models is that the steel is thin and requires constant monitoring of oxygen in the water. This is only possible in autonomous systems, and it is difficult to use them for central heating.

Repairing small cracks in the radiator

Sometimes the damage is very small and not visible to the naked eye; you just have to constantly add coolant. If these microscopic cracks are not repaired promptly, they will grow larger over time and leaks will appear.

In order to remove microcracks several decades ago, they used dry mustard dissolved in water. This method was used by our grandfathers, and today there are chemical compounds on the market that have a similar effect. Not all of them do their job well, and when choosing this product you need to rely on reviews from fellow motorists or trust the seller.

One of the chemical means for eliminating microcracks in radiators

This method (both ancient and modern) has significant drawbacks: in addition to cracks and crevices, the composition can (and does) settle on other parts of the radiator and in the cooling system as a whole, which negatively affects the efficiency of its operation. In addition, this is only a temporary solution and all cracks will need to be either soldered or, as a last resort, cold solder-glue (cold welding) must be used.

Hauser cold welding - suitable even for emergency radiator repairs in the field

Using epoxy glue or the so-called cold soldering compound is a fairly effective and simple solution. Small cracks can simply be filled with the compound and wait for it to completely harden (the timing is indicated in the instructions for the product). Larger defects can be eliminated by gluing tin patches.

Filling the cooling system with liquid

Refueling is carried out when changing the coolant or after engine repair. Perform refueling operations in the following order:

1. Remove the plugs from the radiator and expansion tank and open the heater tap;

2. Pour coolant into the radiator, and then into the expansion tank, after installing the radiator cap. Close the expansion tank with a stopper;

3. Start the engine and let it idle for 1-2 minutes to remove air pockets. After the engine has cooled, check the coolant level. Jew. If the level is below normal and there are no signs of leakage in the cooling system, then add fluid.

Adjusting the pump drive belt tension

The belt tension is checked by deflection between the pump generator pulleys or between the pump and the crankshaft. With normal belt tension, deflection “A”

under a force of 10 kgf (98N) should be within 10-15 mm, and deflection “

B”

should be within 12-17 mm. To increase the belt tension, loosen the generator mounting nuts, move it away from the engine and tighten the nuts.

Advantages of bimetallic radiators

When flushing the system before autumn-winter operation, bimetallic radiators are said to be more convenient than single-component ones. The steel internal elements of the device respond much more reliably to washing before the heating season.

The low roughness of the steel surface prevents the formation of plaque on it and is better cleaned. This significantly extends the service life of radiators, taking into account the inadequate cleanliness, chemical composition and quality of the coolant of the centralized heating system.

Radiators manufactured by Grandini, Rifar, Global, Sira and some others are widely used. The Kraft trademark demonstrates interesting dynamics. Its radiators are increasingly used for new installations and replacement of old heating systems. The competitive struggle has led to a relatively equal level of prices among different companies with a fairly high level of quality of the product line.

One of the leaders on the market - Rifar radiator

When creating an estimate for the installation of a heating system, it may seem that the installation of bimetallic radiators significantly inflates the average cost of the system (especially if these are large objects), but such a calculation does not take into account the durability and maintenance-free period of operation. Bimetallic elements last much longer than their counterparts. The benefits of this application are felt over the years.

The use of high-strength coating allows radiators not to lose their appearance. Factory treatment of radiators makes painting work unnecessary in future operation.

Also, companies never cease to delight and surprise consumers with new designs of bimetallic devices that are sure to fit into the design of the most sophisticated interior.

Bimetallic radiators are also easy to install. The standard sizes of radiator connections are suitable for any fittings and serial fittings. The design of the devices at the production stage provides for the possibility of versatile connection to the system.

Possible schemes for connecting bimetallic radiators to the heating system

A wide range of bimetallic series radiators allow the replacement of existing devices of other types during reconstruction or repair without disturbing the design and hydraulic circuit. Based on a similar temperature flow (the production range of one model usually includes a large number of different-section devices) and hydraulic resistance, you can select the required bimetallic radiator without further negative changes in the operation of the system as a whole.

In a debate about purchasing a regular radiator or a bimetallic one, the choice is obvious and simple. Before purchasing, think about what is more important to you - initial minor savings or further long-term comfort and warmth without tedious and costly repair work.

Do-it-yourself methods for repairing car radiators

Do-it-yourself radiator repair can be done only if minor problems arise, for example, if you notice that coolant is slightly leaking in a certain place. Of course, if the radiator is seriously damaged as a result of an accident, it is better to buy the radiator without even trying to restore it. So, let's look at tips with which you can repair a car radiator yourself.

Internal radiator repair using “CHEMISTRY”

In those years when there were almost no various chemicals on sale, mustard was considered the most effective remedy for combating minor leaks. All you had to do was pour it into the radiator, after which it would swell (the result of the influence of hot water), eventually clogging various small cracks and holes in the device's pipes.

Today's chemicals work in the same way. They are known by various names: "reconditioners", "radiator sealants", and also "powdered restorers".

The “disadvantage” of using “chemicals” is that the place of production, as well as the specific composition of the product, are unknown to the car owner. As with ordinary mustard, in some cases the use of chemicals can lead to clogging not only of the radiator, but also of the entire engine cooling system.

External car radiator repair

Car enthusiasts often repair car radiators using special glue or “cold welding”. In such situations, external repairs to car radiators must be performed only after the radiator is removed from the engine compartment. Don't forget to drain the engine cooling system before doing this.

Cold welding kits are sold everywhere these days. First, the area to be restored must be degreased, and then the hole or crack must be “patched” using the purchased substance. If you have never used such products, we recommend that you read the instructions.

A similar method is often used to deal with relatively large holes. The method of external radiator repair using new adhesives is called quite effective.

Soldering and welding for car radiator repair

To perform professional radiator repairs using welding, you will need special equipment. However, such equipment can only be seen by specialists.

For this reason, before you start welding or soldering a car radiator, you need to make sure that you have the necessary equipment, experience, and filler material. If you have any doubts, it is better to entrust this work to professionals.

The choice of filler material depends on what the radiator is made of - aluminum or brass. To work, you will need a soldering iron or a gas torch. Don't forget to degrease the area you plan to solder.

Soldering or welding a radiator is an excellent solution in situations where damage of minimal size is detected. But if a large crack appears on the radiator tube, it is much easier to simply replace it. To do this, you will also need to use a soldering iron to remove the damaged tube and install a new one.

We hope that you were able to understand how ordinary car enthusiasts repair car radiators with their own hands.

By coolant type

Based on the type of coolant, electric radiators are divided into liquid and liquid-free. A liquid electric heater is a device where special channels pass through sections, which are filled with coolant. Just like in water batteries, heat here is transferred from the liquid to the metal, and then to the air - convective exchange - and to objects in the room.

The difference from simple batteries is that there is no circulation of liquid in the electric heater; heating occurs with the aforementioned heating element (electric coil). The design of the radiator is similar to water heating batteries: several sections, the presence of an upper and lower collector with through holes. A heating element is installed in the lower one, and a Mayevsky tap is installed in the upper one.

Liquid models can be connected to a water heating system or placed separately as a heating device. To do this, it is enough to install ball valves on the inlet and outlet pipes, which shut off the water - this is enough for the device to work autonomously. Either distilled water or an ethylene glycol-based antifreeze liquid is used as a coolant. If it is connected to a water system, then water is filled accordingly.

Distilled water is used in homes where people live permanently. But for non-residential buildings or buildings where people live intermittently, use a non-freezing liquid - there is a danger of freezing inside the device while the owners are away.

Liquidless electric radiators are devices where heat transfer from the heating element goes to the battery itself from several metal sections. This device heats up and cools down quickly, it is quite lightweight and can be moved from one room to another. There is no coolant as such here. These heaters are used as an independent heating device. They are most often installed in the country, in verandas, and garages.

Table 9. Comparison of liquid and non-liquid electrical models

| Criterion | Liquid | Non-liquid |

| Possibility of connecting to a water system in an apartment or house | + | — |

| Use for heating water | + | — |

| Using additional heaters instead | + | — |

| Light weight | — | + |

| Economical | + | — |

| Rated average power of the section | 0.13 kW | 0.13 kW |

.

Fastening

Liquid and non-liquid models are classified into several types according to the type of fastening:

- hanging on the wall with anchors - hung like a regular battery on the wall, which will support the weight;

- installation on a stand;

- installation on wheels, with the ability to be transported - the model can be transported from place to place, wheels can be purchased and mounted separately.

Any heater needs to ensure normal air exchange around it, so during installation the following parameters are observed: from the wall - 3 cm, from the floor and window sill - 5 cm.

Where are they used?

Most often, electric radiators are used where gas or water heating is not possible, or where heat is supplied intermittently. This is due to the fact that electrical appliances are more expensive to operate.

Advice: it is best to keep an electric heater in your house/apartment as an emergency, backup heating source. They can be moved mobile around the house by attaching them to a wall or floor.

No special conditions for operation are required; an electrical line with a voltage of 220 Volts and grounding are sufficient. Of all electrical devices, the most efficient are the convector type.

Electric heaters are an excellent heating option for a summer house, garage, or pavilion.

Common faults

The radiator can become unusable either due to the driver’s fault or due to obsolescence or incorrect operation of other vehicle systems. All faults can be divided into 3 types:

- blockages in the channel system;

- leaks;

- clogging in the cell system.

Product breakdown is always accompanied by significant discomfort inside the cabin. For example, leakage, which is the most serious type of failure, leads to failure of the product. There have been cases of unpleasant odors. Such a breakdown of the stove radiator occurs due to mechanical damage. Quite often the tap itself breaks down.

If such a problem is identified in a copper radiator, the problem is solved quite quickly. The product is removed and sealed at the hole site. Aluminum can also be soldered, but the cost of such a procedure is usually equivalent to purchasing a new device. This is the main disadvantage of products made on the basis of the presented metal.

Knowledge of the structure, purpose and main damage to the radiator of a heating device helps to avoid large repair costs. It also helps you identify the most suitable product for your income level. Thanks to the fact that you will be aware of how the presented device works and its types, you will choose the ideal option that combines the optimal price and high quality.