When do you need to change or sharpen brake discs?

We recommend reading: How to determine the permissible wear of brake discs

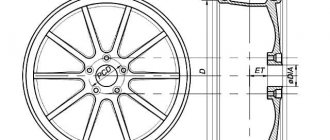

The driver must monitor the brake discs of his car so that their wear does not go beyond the limit. To do this, it is recommended to check the wear of the brake discs every 10-15 thousand kilometers using a caliper, comparing the measured values with the values recommended by the manufacturers.

But the problem with brake discs is that they wear down unevenly during operation. Over time, small “pits”, scratches, and grooves appear on them, which affects the quality of braking. At the same time, wear is still acceptable, which is why drivers do not want to spend money on buying new discs. In such cases, their groove will help.

Symptoms indicating that there are problems with the brake discs are:

- Uneven braking of the car with jerks;

- The appearance of extraneous sounds when braking - creaks, knocks;

- Beating of the steering wheel or brake pedal when braking;

- The brakes lock when you press the pedal.

If the symptoms described above appear, you should definitely take action as soon as possible to eliminate them and restore normal operation of the braking system.

Grooving brake discs: what is it?

The process of turning car brake discs is the elimination of irregularities on the disc by removing the “extra” layer of metal. Accordingly, when turning, the thickness of the disc decreases, so severely worn versions cannot be turned.

There are two options for grooving brake discs:

- With removal from the car using a special machine;

- Without removal from the car using special tools.

The second option is most often cheaper and takes less time.

Let's consider each of the options separately.

Independent work

If desired, you can do the grooving of the brake discs yourself. As indicated in the manual for domestic models, it is necessary to remove the disk and carefully process any defects that appear with a file.

Again, it is important not to overdo it and constantly monitor the thickness with a caliper.

If you don’t have time for such long work, you can do it easier. Raise the car on a jack and remove the wheel. Now start the car and put it in fifth gear.

As soon as the disk begins to rotate, you can use the same file to clean it. Often, experienced car enthusiasts use a special emery disc with a large “grain”.

Upon completion of work, it is necessary to clean the disk and degrease it with a solvent.

This grinding method is one of the best for all front wheel drive vehicles. In this case, the work can be done in 1-2 hours.

Timely pumping of brake discs is primarily your safety. Therefore, carefully monitor the condition of your car and visit a service station when the first symptoms of brake problems appear.

If you have confidence in your abilities, then you can always do the work yourself.

The main thing is to show a little patience, carefully read the literature and listen to the advice of experienced people.

Grooving brake discs without removing them from the car

If you do not remove the brake discs from the car, sharpening them is much easier. But the important point here is that you need to have appropriate equipment, which is not present in all services. In other words, it is unlikely that it will be possible to grind brake discs in a similar scenario “in the garage.”

Grinding of brake discs without removal is carried out as follows:

The car must be secured on a lift and the wheels removed;

- Next, access to the disk is freed; to do this, you need to unscrew the caliper (hanging it by the holder to the spring);

- After this, using tools, the approximate curvature of the disk blade is measured to determine how much metal needs to be removed from the part;

- Next, a special engine is attached to studs or fastening points. His task will be to promote the disk. A frame is screwed to the support, which will serve for the movement of the cutters. It is important to note that the cutters must simultaneously grind the planes above and below;

- After this, the actual grooving process begins.

Growing brake discs without removing them from the car does not take much time. It is important to note that two planes are machined. The area adjacent to the hub, since the disk is not removed, remains untouched. This is an important difference from the disc removal method.

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

When I removed the wheel I was surprised by the shoulder on the brake disc

I’ll start with the caliper bolt, and then I realized that you shouldn’t believe what’s written in the book on operating and repairing a car, since it says that holding the key at 17, unscrew the bolt at 13, at 17 it turned out to be only 15, and in the kit there is a 15 but thick one Well, in the garage I found a key for 14 and using a grinder I made a key for 15

Pressed out the cylinder with a screwdriver

Pulled the pads and everything else

The end of the disk has been tapped from scale

And he began to remove the shoulder on the disk. I chose the method of a file and a rotating disk (I looked it up on the Internet) 1st gear - slow, 3rd gear - too quickly even the file began to grind, I chose the middle and started grinding in 2nd gear. Moreover, when I ground the disc on the left, it didn’t beat, but on the right side it beat, but it creaked on the left.

Grooving brake discs with removal from the car

This grooving method also requires good equipment and accurate measurements in order for the work to be completed efficiently. Unlike the previous method, here it is necessary to completely remove the brake disc from the car and grind three surfaces, including those adjacent to the hub.

It is important that all three surfaces are machined at the same time with one attachment to the machine, otherwise the parallelism of the planes may be lost if the disk is “turned over”. Accordingly, for such work you need a specialized machine or a reverse cutter, otherwise it will be difficult to get close to the third plane.

Pros and cons of regrooving brake discs

Grooving brake discs is a procedure that has one obvious advantage over buying new discs and installing them, and that is the price. It is difficult to figure out the average cost of purchasing and installing new wheels on a car, since the price varies greatly depending on the car model. We can say that when purchasing high-quality parts, you will have to pay from 10 to 40 thousand rubles to replace brake discs. As for grooving brake discs, such a procedure will cost 4-5 times less.

But it is important to remember that regrooving brake discs is a temporary solution. Car service specialists do not recommend grooving more than once for a set of discs. This is due to the fact that when grooving, the thickness of the disk decreases. The smaller the thickness, the more fragile the disc becomes and, in addition, it heats up more during braking.

collage

After grooving, you need to change the pads, otherwise the friction linings that have worked on a crooked disc will kill the treated disc. For the sake of experiment, take such a block and rub it on sandpaper that lies on a flat plane - dangerous depressions will appear on the visually flat surface!

In Moscow, the cost of turning discs for one axle is no less than 2000 rubles. It is recommended to treat both discs so as not to shift the brake balance.

RISK AREA

Cast iron is the most common material for brake discs. And quite insidious: with sudden temperature changes, cast iron noticeably changes its physical properties - hardness, volume and even internal structure. This feature leads to excessive warping of the working surfaces of the disk. Of course, there are more durable analogues (for example, ceramic or composite) that provide better stability and braking dynamics, but their price is off the charts.

The brake disc shield does not protect against water: it gets abundantly on both its surfaces. If a cast iron disc is exposed to too much temperature change, its internal structure may be damaged. Processing on a machine will remove the bent top layer, but after a couple of intense braking (that is, heating and cooling), the surface will move again - this happens in five cases out of a hundred. Only an experienced turner can identify a damaged disk during turning - by the change in the tonality of the rustling sound from the cutters.

How to sharpen a brake disc yourself

Grinding brake discs “in the garage” without the right tools and necessary skills is strictly not recommended. On automobile forums you can find “collective farm” options for grooving - with a grinder, a file, or even with a piece of sandpaper placed on top of the disc. By engaging in such manipulations, you risk making the disc unsuitable for grooving even by masters, and, in addition, such a disc can fail at the most inopportune moment, not to mention the lack of symmetry during “collective farm” grooving.

( 398 votes, average: 4.49 out of 5)

Oil gets into antifreeze: what is the reason and how to fix it

The car cannot be removed from the handbrake: what is the reason and what to do