Common reasons for trimmers running at low speeds

The problem when the lawn mower does not pick up speed occurs mainly with gasoline units.

This affects equipment of various models, for example, Husqvarna, Champion, Stihl. Some of the structural elements that may cause problems can be visually inspected, but to check the functioning of the remaining components, you will need to disassemble the lawn mower.

The trimmer does not develop speed if it is filled with low-quality fuel. For this reason, the engine may not start at all or may run jerkily, changing the speed of rotation of the knife or fishing line.

To independently determine the quality of the gasoline used, perform the following steps.

- Use a special wrench to remove the spark plugs.

- Their working contacts are inspected for the presence of a red brick-colored coating: if there is one, then the fuel used contains significant inclusions of additives.

Spark plug

If deposits are detected, it is necessary to drain the fuel poured into the tank and replace it with high-quality fuel. The lawn mower used should only be filled with the grades of gasoline specified by the manufacturers in the operating instructions. It is also necessary to clean the spark plugs from deposits before reinstalling them.

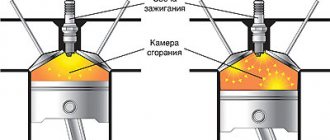

The next common reason for a decrease in the speed of the trimmer is contamination of its air or fuel filters. In the first case, the problem is that the fuel-air mixture entering the combustion chamber is not sufficiently saturated with oxygen, as a result of which not all of the gasoline is burned. This prevents the lawn mower from developing maximum power.

Air filter

In order to check whether the air filter is really at fault, you need to remove it (after unscrewing the cover for this) and turn on the lawn mower. If it works normally, then instead of the clogged filter element you need to insert a new one.

If the situation has not changed after the actions taken, then you need to pay attention to the fuel filter. The essence of the problem is similar to the previous case, only instead of a lack of oxygen, little gasoline is supplied for normal operation of the device. This problem can also be resolved by simply replacing the filter element. Air and fuel filters are inexpensive. It’s easy to change them yourself, and the whole job doesn’t take much time.

With constant use of lawn mowers, spark plugs become dirty and worn out over time. To check this, they are removed and inspected for the presence of carbon deposits. The problem can be resolved in two ways: if possible, restore the old spark plug, or simply install a new one in its place.

In the first case, they act like this:

- unscrew and wipe off the fuel from the spark plug;

- dry it without calcination;

- using a needle file or fine sandpaper, remove carbon deposits from the spark plug and check the gap between the electrodes (should be 1 mm);

- assemble the trimmer;

- start a lawn mower.

If the spark plug does not produce a spark after restoration manipulations at the required distance between the electrodes, then you will need to check the quality of the connections of the elements of the electrical circuit of the device. When the wires are in perfect order, you will definitely need to install a new part.

Replacing spark plugs is a simple process that is cheap, and if you can restore the old ones, it’s completely free. To work, you only need a spark plug wrench and a needle file.

If everything is in order with the fuel, filters and spark plug, then the next source may be a gasoline engine. It may have the following mechanical failures:

- problems with the carburetor;

- problems with the engine drive mechanism.

There is a small cable in the carburetor section. It may subside and lead to the problem in question. Therefore, when working on a carburetor, you should first check the condition of the cable and, if necessary, tighten it (but not to the limit). The main thing is not to overdo it with tension, so that it does not crack under load.

Cables in the carburetor

Afterwards, you need to check the operational settings of the carburetor, which must correspond to the parameters given in the instructions. If they are installed correctly, but there is no desired effect, then you should disassemble the part, rinse, clean, blow through all its strokes with a pump and put it back together. The carburetor itself must be free of mechanical damage.

If adjusting or replacing the carburetor does not give the required result, it is necessary to clean the drive mechanism and lubricate the cable located inside it with oil.

Carburetor

You can fix problems with the engine yourself if you have the required skills, but it is better to use the services of a service center for this. Its specialists will conduct a comprehensive diagnosis of the trimmer and determine the exact cause of the drop in speed.

Disturbance in the normal circulation of fuel on the trimmer also leads to the fact that the lawn mower does not gain operating speed. This may be due to the following main reasons:

- air leaks, which are caused by cracks in the hoses;

- clogging of the gasoline pump, which occurred due to the use of low-quality fuel or due to the formation of sediment at the bottom of the tank and its entry into the system;

- contamination of the muffler or catalyst.

To resolve these problems yourself, you need to do the following:

- overhaul the fuel pump, removing contaminants;

- replace the tubes and hoses through which the fuel circulates;

- clean the muffler and the mesh on it;

- install a new catalyst, which will be expensive due to the precious metals it contains.

You can do all the work to troubleshoot problems in the fuel circulation system yourself. But it should be done carefully so as not to lose parts, or after assembling the braid there will be no “extra” left.

We invite you to familiarize yourself with zucchini seeds: benefits and harm for women

All trimmers are classified according to the type of power supply: gasoline or electricity (from the mains or battery). It should be noted that gasoline mowers are superior to their electric and battery-powered counterparts in many ways. Although they all perform similar functions, the differences in performance, maneuverability and efficiency are very noticeable.

However, the general principle of operation of all types of manual mowers is almost the same - the devices are equipped with engines (two- or four-stroke internal combustion engines or electric motors) that drive the cutting unit (a reel with fishing line or a metal disk). All elements are mounted on a straight or curved rod, including the handle for controlling the trimmer, on which the main buttons are located.

Since the problem of low speed is more typical for gasoline versions of trimmers, more attention will be paid to them. Thus, the brush cutter is very comfortable to use and unpretentious in maintenance. Moreover, most of its malfunctions are caused by the user’s ignorance of the basic things described in the instructions.

- turn on the ignition button;

- press the silicone button several times to pump gasoline;

- close the air damper;

- set the throttle lever to the high speed position;

- First make gentle jerks with the starter handle to feel the resistance of the engine, then pull sharply.

If the lawn mower starts but stalls, you need to put the air damper in the middle position and try again. When the engine starts, you need to slow down the gas and open the air damper, since the trimmer functions only on suction.

Air leak in the intake manifold

Another reason why the engine does not develop speed may be a banal air leak in the intake manifold of the power unit. Symptoms of such a malfunction are difficulty starting the engine, its “triple”, problems with increased fuel consumption and, of course, loss of speed. This all happens due to a sharp depletion of the mixture due to unaccounted air entering the combustion chambers.

Most often, system depressurization occurs due to wear of the intake manifold gasket. It is quite difficult to determine that an injection engine does not develop speed precisely because of air leaks, just as it is not easy to find the place of depressurization itself. It is better to entrust this to specialists. But there are some things you can try to do yourself. You can, for example, take a syringe with a needle, fill it with gasoline (or solarium for diesel units) and treat the perimeter of the junction of the manifold with the engine with fuel. If the gasket between them has become unusable, then gasoline will be sucked into the combustion chambers along with the air. If, after starting the engine, you notice positive changes in its operation, you can be sure that the reason lies precisely in the suction.

What could have broken

Problems with a lawn mower, related to the fact that this device does not start, are classified in a certain way by service specialists. They highlight faults with the following mechanism components:

- an engine in which the piston and bearings may wear out or fail, or the crankcase may crack;

- fuel supply system, in which case the filter may become clogged or there may be problems with the carburetor;

- mechanical damage to wires, tubes, hoses;

- ignition circuit.

Sensor malfunction

Compared to a carburetor engine, an injection engine benefits from the fact that its operation is controlled electronically, and if any problems arise, the driver will learn about them by an error signal on the control panel. All he has to do is connect the tester and read the code to determine which node has failed. This happens thanks to electronic sensors that control the operation of basic systems and mechanisms. But they are not eternal either.

If any of them refuses to work, the engine goes into emergency mode. Due to the fact that the electronic unit ceases to receive the necessary information, the operation of the power unit becomes unstable.

The best electric and gasoline trimmers

When using a trimmer with an electric motor installed, problems with speed also occur. But they are caused by completely different problems compared to fuel spits. The electric motor does not develop the required rotation speed in the following cases:

- if the voltage in the supply network is below the rated value for the electric motor by more than 10%;

- in case of problems with the soft start system (if this unit is installed);

- when there are problems with the brush assembly;

Electric scythe brush assembly

- in case of burning of the motor windings;

- if rotating parts become jammed.

To eliminate a voltage problem, you need to use a multimeter or tester to check its value in the outlet from which the electric braid is powered. If it is less than the minimum permissible value, then to increase it you will need to turn off all electrical appliances or install a stabilizer.

To repair the soft start unit, you will need to have appropriate knowledge of electronics, so it is better to contact a service center. There they will determine whether it is repairable or whether it needs to be replaced. You can check the button yourself or find a block diagram and try to figure it out.

Soft start block

The brushes may wear out, resulting in loss of contact, which leads to the motor stopping. The brushes are easy to replace. The features of the process are determined by the model of brush cutter used. At the same time, you will also need to clean all contacting surfaces.

If the windings burn out, if you continue to mow grass or bushes, the electric motor will quickly burn out. This will be accompanied by the appearance of a burning smell, up to the melting of individual parts. The electric motor will need to be replaced.

Wedging of rotating parts occurs for various reasons. To identify and eliminate them, you will need to sort out the drive unit. There are models in which the number of revolutions is automatically adjusted depending on the load, increasing as it increases - their rotation speed drops at idle.

Trimmer Huter GET-400 on Yandex Market

Trimmer STAVR TE-1700R on Yandex Market

Trimmer Makita UR3502 on Yandex Market

Trimmer Husqvarna 128R on Yandex Market

Trimmer Makita EBH341U on Yandex Market

Trimmer Huter GGT-2500S on Yandex Market

When you press the gas

If the lawn mower stops when you press the gas, the reasons may be the following.

- The most common option is a failure of carburetor adjustment, which occurs when there is significant load on the drive, after prolonged inactivity of the mechanism, or when it is used under difficult conditions.

- Clogging of the fuel valve, which can be eliminated by loosening it, as a result of which gasoline begins to flow normally through the system.

- Loosening and hanging of the cable located in the carburetor. The fuel hose may also stretch to the point of breaking due to significant load.

- The breather (check valve) is clogged, resulting in no fuel flowing into the tank.

If the problem is related to the carburetor unit, then it can be recognized by the appearance of vibrations from the lawn mower. When a hose bursts or a cable stretches, these components are replaced.

Carburetor trimmer

At high speeds

When the scythe stalls at high speeds, this is due to the following problems:

- clogged or stuck valve located on the gas tank cap;

- the carburetor has become misregulated due to vibrations that occur during operation of the mechanism;

- problems with the circulation of the fuel mixture;

- atmospheric air suction;

- the fuel intake hose is cracked or loosely connected.

The carburetor is adjusted based on the operating instructions for the trimmer. To adjust it, it is often enough to loosen the tightening of its housing. If there are problems with the circulation of the fuel mixture, then it can gradually enter the carburetor. After it is exhausted, the engine stalls at high speeds.

At idle

At idle, common reasons for the trimmer stopping are the following:

- contamination, misadjustment or incorrectly adjusted carburetor adjustment;

- air filter clogged;

Replacing the air filter of a brush cutter

Trimmer air filter

- reduction in gearbox speed when it heats up, which is a consequence of using an unsuitable fuel mixture;

- throttle valve clogged;

- air entering the system;

- There is not enough fuel to operate the trimmer.

Often, when the speed is reduced, the brush cutter engine stalls and does not maintain idle speed when restarted. The main reasons for such a breakdown include contamination or misadjustment of the carburetor, as well as clogged air filter.

Gasoline trimmer stalls when idling

If the optimal carburetor settings are violated, it is necessary to clean it and readjust it. A clogged trimmer air filter can be dealt with by soaking it in a solution with regular household detergent for several hours. If self-cleaning does not help to cope with the blockage, then it is better to purchase a new filter element in accordance with the instruction manual.

After carrying out the activities, the user for a long time will not encounter a situation where the trimmer stalls at idle and functions only when gas is supplied.

Reasons for low trimmer speed

If users complain about a trimmer that does not gain speed, this means that at idle it works fine, but when you press the gas it does not develop the necessary power. This can happen as a result of the device being idle for a long time without activity. These problems are typical for gasoline devices, including Husqvarna 128r, Stihl FS 38 and Hitachi of various modifications.

When working with a trimmer, you need to constantly monitor its behavior - a drop in speed and unusual noises indicate problems with the unit. Sometimes you give it gas, but the trimmer floats. In such cases, work should immediately be suspended, the mechanism should be allowed to cool, and the search for possible problems should begin. They can be of a different nature, both technologically and external factors associated with the conditions and characteristics of the operation of the device.

External factors

The reduction in the speed of a lawn mower is influenced by several factors not related to its breakdown:

- filter contamination due to dirt and dust particles entering it;

- use of low-quality fuel;

- incorrectly prepared mixture (relevant for trimmers with two-stroke gasoline engines);

- contamination of the muffler mesh with particles of vegetation, soil elements and other objects.

In this case, in the second and third cases, carbon deposits form in the combustion chamber and the carburetor elements become clogged.

Technical problems with lawn mowers mainly occur in the fuel supply and ignition system. You can deal with them yourself.

- When a walk-behind mower won't start or stalls, the problem may be the spark plug. Dark carbon deposits indicate poor carburetor adjustment and low quality gasoline.

- The cause of the trimmer not working correctly may be a clogged fuel hose. Filters also often become clogged.

- Another internal problem is that the muffler is covered with carbon deposits. This causes the trimmer speed to drop significantly. The solution is to clean the muffler.

Symptoms of a problem

It is not difficult to determine that the engine does not develop the speed it should develop, especially if you have driven the car before and know its original characteristics. Those drivers who have encountered a similar problem in their practice know that a decrease in power is characterized by sluggish acceleration, loss of dynamics, traction, as well as engine overheating and increased fuel consumption. Sometimes these processes are accompanied by bluish or even black exhaust.

Do you press the accelerator pedal and the engine revs poorly? Pay attention to the tachometer. A working engine should immediately respond to an increase in the amount of fuel supplied to the combustion chambers by increasing the number of crankshaft rotations. And if this does not happen, you need to urgently look for the problem.

Immediately after starting

The unit may stall immediately after starting if the carburetor is misaligned or incorrectly configured - this causes uneven fuel supply. The result of this is that the device begins to vibrate distinctly. To troubleshoot problems, the carburetor is reconfigured following the instructions for the mechanism.

The engine also stops when the fuel supply valve becomes clogged. In such cases, simply cleaning it is enough. If the lawn mower started working at first, but then immediately stalled, then fuel may be supplied to the carburetor unit with some difficulty. Loosening the valve helps solve the issue, which ensures free circulation of the mixture in the system.

A stop can also be caused by air leaks if there is mechanical damage to the hose (holes, cracks) that takes in fuel. In this case, you should increase the drive speed to quickly expel air bubbles from the system.

- Many owners of garden equipment face the problem of the trimmer engine stopping after it has started. Petrol tool repair technicians are confident that the problem lies in the fuel system, or, to be more precise, in the carburetor. As a result of violation of its settings, uneven fuel supply occurs and, as a result, increased vibration and engine shutdown.

- Trimmer ignition module

Another reason why the trimmer starts and immediately stalls is a clogged fuel valve. To restore the circulation of gasoline in the fuel system, it is enough to dismantle the valve and remove contaminants.

- The problem may be a malfunction of the ignition module, but in case of such a malfunction it is best to contact a specialized center.

The trimmer stalls: causes and troubleshooting was last modified: July 22nd, 2020 by Administrator

see also

Comments 47

hose for the vacuum tank, how is it doing intact or with holes, look

good idea, thanks)

please ask the author of the topic to share with others how he solved the problem

so I shared it seems that 2 injectors were clogged, and since I was not there I don’t remember which ones (by count), they replaced the injectors and everything became fire)))

then sorry, I must have missed it

This also happened, it turned out that the fuel filter at the bottom was clogged, could not stand it and all the debris got into the injectors, at first it jerked, and then completely stalled. But after it started twitching, I drove another 300 km. Upon arrival home, I changed the filter, cleaned the tank and injectors and forgot about it.

replace the filter that is under the bottom of the car and drive on

How many people, so many opinions. Look at all engine systems one by one from simple to simple. If the check light does not light up, then it is unlikely to be a camshaft sensor, and it does not look like it. Also, if the crankshaft sensor doesn’t work, you won’t start the car. Look at the crankshaft pulley, it was somehow loose, just at speed it got into resonance and the DPKV could not get a normal signal from it. Relevant if you recently climbed into the timing belt. Check the air and pressure in the rail.

Diagnostics and elimination of problems of gasoline engines

Before starting to repair a particular unit (part), it is necessary to determine the nature of the malfunction. Step-by-step diagnostics and troubleshooting below.

Carburetor

This mechanism is an important component of the gas trimmer. In order for the carburetor to work properly, several conditions must be met:

- disassemble and clean it from time to time;

- adjust the idle speed according to the instructions;

- seek the help of a specialist when making adjustments.

If this unit breaks down, you can repair it yourself, but only if you have certain knowledge.

One of the reasons for poor carburetor performance is a loose cable. To fix the problem, you first need to disassemble the entire assembly, and then, after thoroughly washing all the parts, lubricate and tighten the cable, but not too much, so as not to tighten it.

If there are problems with the spark plug, sometimes it is enough to dry it or clean it with sandpaper and return it to its place, setting the gap correctly - it should be 1 mm. If the spark plug is heavily covered with soot, it is better to replace it with a new one. When the trimmer operates optimally, the spark plugs do not fail so often.

Filters

A clogged air filter is another reason for unreliable operation of the device. To check whether this element is involved in the malfunction, you need to start the lawn mower without it. A dirty filter can be washed in gasoline, dried, or replaced with a new one.

A clogged fuel filter does not allow fuel to enter the cylinder, and the engine stalls at full throttle due to a simple lack of gasoline. This element is located inside the tank on the intake hose. To fix the problem, you should replace the old filter with a new one on the hose or thoroughly rinse the one that was removed.

The engine is the most important part of any unit. There are several reasons for engine failures:

- incorrect proportions of oil and fuel (for two-stroke);

- old fuel mixture;

- wear and destruction of the piston ring;

- traces of scratches on the cylinder and piston;

- operation of the device for wear and tear.

All this leads to the fact that the engine either does not start or stalls.

Fuel system

For trouble-free operation of the gas trimmer, the functioning of the fuel system is of great importance. Gasoline passes through all its components and parts, so they must be cleaned regularly. In addition, only high quality fuel must be used. To prepare the flammable mixture for a two-stroke engine, motor vehicle oil cannot be used, as it has insufficient qualities.

Malfunctions of electric trimmers can be as follows:

- insulation failure or cable break;

- malfunctions in the cutting tool area;

- Damage to the socket or plug.

To cope with these breakdowns, you do not need to disassemble the entire device.

If the engine has serious problems, it will have to be disassembled. To do this you need to unscrew several screws. Having gained access to the engine parts, you need to do the following:

- check the degree of wear of the brushes - unsuitable parts will need to be replaced with new ones;

- ring the motor winding - the resistance should be high;

- check the stator and rotor - to test the rotor winding with a multimeter, measure the resistance: large deviations from the norm indicate a malfunction, the absence of resistance on the stator winding also indicates a breakdown (the stator housing is diagnosed in a similar way).

The most common breakdowns in which the washing machine does not pick up speed

The rotation speed of the drum depends on many components in the washing machine. Therefore, only a specialist can determine on their own what exactly is responsible for the fact that the machine does not want to gain the required speed.

| Breaking | What is the problem | Repair cost * ** |

| Malfunction of the water level sensor (pressostat) | The water sensor is faulty , which in normal condition tells the control module what the water level is in the machine. Based on these data, the “brain” of the washing machine turns on draining or spinning. If the sensor thinks that there is still water left in the machine, the spin cycle will not actually start: the machine will try to drain the non-existent water. In this case, the speed will be significantly lower than during spinning. The sensor needs to be replaced. | From 1200 rub. |

| Malfunction of the tachometer (speed control sensor) | Failure of the tachometer - the unit that controls the speed of the washing machine - leads to the fact that the machine loses control over the speed and does not give the command to accelerate the drum. The sensor needs to be replaced. | From 1300 rub. |

| Malfunction of the “brain” of the washing machine: the electronic module (in devices with electronic control) or the programmer (in models with electromechanical control) | Failures in the control board lead to the fact that the washing machine does not give the correct commands to other components of the unit - in our case, the spin does not turn on at the required speed. The board needs to be re-flashed or replaced. | From 1500 rub. |

| Washing machine motor malfunction | The motor—the physical driving force of the drum—has broken down. As a rule, most often the reason lies in an interturn short circuit: in this case, the engine runs, but only at half power. It has enough power to rotate the drum at low speeds - during washing and draining, but it is not possible to accelerate the drum to the specified speed for spinning. Also, wear on the graphite brushes of the motor can lead to insufficient rotation. The engine needs to be inspected, repaired or replaced. | From 1500 rub. |

| Drive belt failure | Drive belt abrasion and deformation leads to the fact that the traction weakens, and at high speeds it scrolls “idle”. Because of this, the overall rotation speed of the machine drum is significantly reduced and does not reach the set speed. The drive belt needs to be replaced. | From 700 rub. |

* The table shows the approximate cost. The technician will provide an accurate estimate for repairs after inspecting the washing machine, taking into account the nature of the breakdown, as well as the manufacturer and model.

** Prices are indicated only for the work of the master, without taking into account the cost of spare parts.

In addition to the above cases, sometimes the problem lies in the fact that for some reason the machine cannot drain the water: in this case, there is also no need to talk about spinning. If you find that the machine not only does not develop the required speed, but also does not drain water, refer to our article “”.

However, with or without water - if you find that your washing machine is not picking up speed - you should not put up with spinning it manually. Contact "RemBytTech":

7 (495) 215 – 14 – 41

7 (903) 722 – 17 – 03

Our technician will arrive as soon as possible, carry out free diagnostics and give the exact reason why the unit does not want to produce the specified 800 or 1200 rpm. An hour or two for repairs - and you can forget about damp laundry!

Contact us!

- Read more:

If the engine of your car does not pick up speed, or does not cope well with it, stops pulling, sneezes, hiccups, you will agree that this is very unpleasant. Let's try to figure out what are the reasons for such unhealthy behavior of the motor, of which we assure you, there are a great many, ranging from some kind of wiring or pipe, to very troublesome problems with hardware or electronics.

When opening the air damper

It happens that the unit stalls when the air damper is opened, idling normally. This is due to air leaks from the system caused by cracks in the fuel hose or problems with the seals. The carburetor metering system may also malfunction, and the lawn mower will stop after opening the damper.

Fuel hose in carburetor

All possible reasons why the lawn mower stalls and how to eliminate them are contained in the following video

There are many reasons why a lawn mower stops, but the most common are malfunctions associated with its carburetor. They can arise in any case. The most problematic option is when a serious breakdown occurs and you will need to purchase new parts or replace the lawn mower.

Cold engine

It would be wrong to demand full power from the power unit until its temperature reaches its operating temperature (90 0 C), especially if we are talking about an engine with carburetor injection. A cold engine does not develop full speed, even with the choke fully closed. The fuel mixture must be warmed up before entering the combustion chambers. Otherwise, the car will “twitch” and the engine will stall and detonate. So, if your car is equipped with a carburetor engine, do not rush to drive it until it warms up.

When to contact the workshop

If the device is under warranty, at the first sign of incorrect operation, you can safely take it to a specialized workshop. Repairs will be made free of charge, regardless of the nature of the damage, if it was not the fault of the owner. If there is a breakdown in the engine, it is better for a person ignorant of technology to immediately contact a specialist. In any case, the severity of problems with the unit is determined by the user himself.

Summarize. Both gas and electric trimmers are designed to provide years of reliable service. Most of the problems described above occur due to insufficient attention of the owner to his assistant. Subject to strict adherence to the manufacturer's requirements and regular maintenance, the manual mower will work rhythmically and without interruption.