For the double pedal used by drummers, see Cardan (musical instrument)

For information about the rock band formerly known as Cardan Shaft, see Boni HEM

Cardan joint (Hooke joint)

Cardan transmission

(colloquially - “cardan”) - a mechanism that transmits torque between shafts that intersect in the center of the cardan transmission and have the possibility of mutual angular movement. Widely used in various areas of human activity when it is difficult to ensure alignment of rotating elements. A gear coupling can also perform similar functions.

General description[ | ]

The program received its name from Gerolamo Cardano, who described it in the 16th century. (but did not invent).

The cardan transmission has a significant drawback - non-synchronism of shaft rotation (if one shaft rotates evenly, the other does not), which increases with increasing angle between the shafts. This eliminates the possibility of using a cardan drive in many applications, for example, in the transmission of front-wheel drive cars (where the main problem is transmitting torque to the steering wheels). In part, this disadvantage can be compensated by the use of paired hinges on one shaft, in which the intermediate shaft forks are in the same plane. However, where synchronization is required, as a rule, it is not a cardan drive that is used, but a constant velocity joint (CV joint) - a more advanced, but also more complex design for the same purpose.

Advantages and disadvantages of a cardan

To understand which drive is better, you need to consider the pros and cons of each of them. Cardan is a variant of transmitting engine torque to the rear wheel using shafts and gears. Ideal for heavy tourists and cruisers. It has a number of advantages for which they love it:

- Does not require maintenance. Almost none. The mechanism is completely closed from dirt and dust - that is, sealed. User manuals sometimes write about changing the oil every couple of tens of thousands of kilometers, but this is required so rarely that most people simply forget about this procedure;

- The resource of the cardan can be equated to the resource of the motorcycle itself. In most cases, this part comes off without repairs from purchase to sale of the bike, and if it ever does “die”, then the cause will clearly not be the cardan. While you own the bike, you will simply forget about the existence of a drive gear.

But there are also disadvantages to the cardan that do not allow manufacturers to install it everywhere:

- Dimensions and weight. This is a really heavy, bulky part, which is why it is not used on sports and enduro motorcycles that chase every centimeter and weight to achieve the best results;

- If you decide to recall the BMW HP2 Sport as a counterargument, then do not forget to mention that the bike turned out to be so uncompetitive that it could only compete with others like it. Designers have repeatedly tried to lighten the cardan, which also repeatedly led to it simply breaking in half;

- The mass of the cardan is not sprung, which negatively affects the operation of the rear suspension. The analogy can be felt by first running with a 10-kilogram backpack on your back (it seems like nothing difficult), and then trying to do the same, only with 5 kg tied to your shoes;

- Price. The main argument against cardan transmission. Many people like to embellish everything to the point that “if the cardan is broken, then it’s easier to throw away the whole motorcycle and buy a new one.” In fact, the cost ranges from $300 to $600 (depending on the make and model of the motorcycle), and this is critical only for fans of “dockless bikes for $1000”).

One of the main myths about cardan transmissions is the supposedly large (up to 30%) loss of torque efficiency. In fact, this is not true. One gear pair has an efficiency of 96-98%, and when there are two of them, all losses amount to a maximum of 8%, taking into account friction and heating costs - no more than 10%. But not 30%. If a third of the total power were spent on generating heat, the structure would simply begin to melt. Of course, there are isolated cases of spontaneous combustion of the cardan, but this is only a direct result of the lack of lubrication in it.

Cardan adapter[ | ]

Cardan adapter for a wrench

An attachment for socket wrenches, the peculiarity of which is that the axes of the conventional cross of its cardan joint intersect, but do not intersect. This technical solution was used for simplicity and reliability, and the inherent increase in the non-synchronization of the angular movements of the connected tools does not have a particularly negative role here, due to the extremely low rotation speeds and the peculiarities of the motor skills of human hand movements. A cardan adapter of this design is not a double cross.

Design and principle of operation

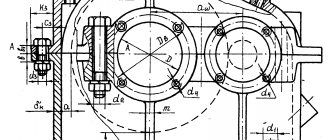

A cardan shaft consists of several elements: a shaft, two crosspieces, a sliding fork, seals, fastening parts and a number of other elements, depending on the design. The driveshaft can consist of one, two, three or more sections. The length, thickness and weight of the shaft depend on the dimensions of the vehicle.

Cardan cross.

A single-section propeller shaft consists of a central part and tips with crosses attached to it. The central part is made of steel pipe. The use of a pipe is due to the need to reduce the weight of the shaft and save metal. Only very short shafts are made solid.

Single-section shafts are mainly used in sports cars. For example, a single-section cardan is used in the design of the Nissan GT-R.

The driveshaft is one of the most repairable parts. It is easy to remove from the car, and the repair consists of replacing the crosspieces and the suspension bearing

Cardan joint.

The operation of the cardan transmission is ensured by hinge mechanisms based on crosses. Crosses allow two mating shafts to rotate at varying angles to each other. The highest efficiency is achieved when the rotation angle is between 0° and 20°. When this figure is exceeded, the crosspiece is subjected to heavy load. In addition, the shaft loses balance and begins to vibrate.

Another important element is the sliding spline joint of the cardan. Its use is due to the fact that the car’s suspension, especially when overcoming obstacles, significantly stretches in height. The gearbox or transfer case, to which one end of the shaft is attached, is rigidly fixed inside the body, and the axle gearbox (the second point of attachment of the cardan) is connected to the suspension. As a result, when moving over an obstacle, the distance between the gearbox and the axle gearbox increases. In this case, the driveshaft must “stretch”, and the sliding spline joint helps it do this.

Another important component of the driveline is the suspension bearing. It provides additional support for the composite shaft, holding it in place and not preventing it from rotating. The bearing bracket is attached to the body. The number of bearings depends on the number of sections that make up the shaft.

Cardan shaft[ | ]

Cardan shafts in the bogie of a rail vehicle.

An element of the transmission of vehicles. At least one end of the driveshaft is connected through a driveline to another element of the transmission, and the shaft itself consists of two half-shafts connected to each other through a gear coupling that allows axial movement of one shaft relative to the other. The canonical purpose of driveshafts is to transmit power from the gearbox to the final drive of the rear axle on front-engine, rear-wheel drive vehicles. In fact, they can be used wherever power transmission is required between two transmission elements, in which either the axes of the rotating connected parts are not coaxial, or their mutual mobility in space is possible. For similar purposes, shafts without universal joints and couplings (for example, with CV joints) can be used. Shafts with cardan drives can be used in wheel drives and in safety or adjustable steering columns, but such shafts are not usually called cardan shafts in common parlance. Often, the cardan joints of transmission driveshafts use not a single, but a double cross.

Driveshafts must be very precisely balanced and carefully weighted as they rotate at high speeds and apply torque to the wheels. If there are any problems with the drive shaft, this will affect the vehicle's handling. They usually cause the appearance of symptoms that clearly indicate to the driver that the drive shaft needs to be repaired. One of the first symptoms of drive shaft failure is vibrations in the lower part of the car. If the universal joint or bushings are worn, severe vibration of the drive shaft may occur. Another sign of a faulty drive shaft is the presence of extraneous noise. If the bushings, support bearing, or universal joints are worn or damaged, the rotation of the drive shaft may be difficult or impaired. In this case, extraneous noises (clanging, rumble or grinding) may be observed in the lower part of the car. If such noises occur, it is necessary to diagnose and repair the driveshaft as soon as possible.[1]

Cardan shaft

To be more precise, today we are looking at a mechanism that is designed to transmit rotation from the gearbox to the gearbox of the front or rear axle of the car. This is an intermediate, but extremely important part of the transmission.

What type of driveshaft is there? In fact, the classification is quite diverse. For example, some groups can be distinguished depending on its purpose, type, and the presence of a compensation device.

Classification by purpose

- the main one is directly responsible for spinning the wheels in the car;

- auxiliary - such cardan shafts drive various optional mechanisms, such as winches and pumps.

Types of cardans

- open cardan - is an independent and separate mechanism in the car;

- closed cardan - hidden from prying eyes or integrated into some other element of the car.

Varieties

- universal cardans - able to compensate for large axial movements;

- simple cardans - without any such tricks.

The design of the cardan shaft and the principles of its operation

It was noted above that the driveshaft is a torque distributor between the axles and half shafts of some cars. Before the advent of constant velocity joints (otherwise known as grenades), the “cardan” was one of the most popular transmission elements of all vehicles without exception. However, due to the design features of front-wheel drive cars, the driveshaft was forced out of their structure, and the previously mentioned grenades came to replace it. Despite this, the “cardan” is still used in the design of many rear-wheel drive and all-wheel drive cars today.

A standard type cardan mechanism can be represented in the structure of a car by two elements:

- The front driveshaft, which often extends on both sides of the gearbox and each part interacts directly with the axle shafts (wheels);

- And the rear driveshaft, which is either also connected directly to the gearbox, or extends directly from the front of the mechanism through a special distributor (middle “cardan”). The rear driveshaft has a significant difference from the front one, namely, a special structure, which involves the use of a thin-walled pipe that transmits rotation to the axle shaft through connection with the previously noted nodes. In the case of using a front “cardan”, a similar approach is not required, since the drive mechanisms are connected directly to the wheels.

Front driveshaft

Rear driveshaft

If with the rear driveshaft everything is extremely simple - it consists of a thin-walled pipe, hinges and a connector with the gearbox, then with the front driveshaft the situation is slightly different. This part of the mechanism in its standard version has the following structural elements:

- suspension bearing (less commonly, other torque distributors);

- double hinge necessary to transmit rotation to the axle shafts;

- one or more sliding forks that distribute rotation between the axle shafts or axles after receiving it from the gearbox;

- intermediate seals and protective components (seals, gaskets, etc.);

- fasteners of parts.

Considering the principle of operation of any part of the driveshaft as simply as possible, it is worth highlighting three basic stages of its operation:

- A thin-walled pipe or sliding fork connected to a source of rotation (gearbox) on one side receives this same rotation from it;

- Connecting to the axle shafts on the other side, these elements transmit torsion directly to the wheels;

- In the process of implementing the two previous stages, it is possible to correctly distribute torque between the axles through the use of some bearings, hinges and similar elements of the device. In addition, the mentioned joints in the driveshaft design are used to transmit rotation at an angle. The greatest effect and efficiency from such a rotation transmission is achieved in the angular range of 0-20 degrees. Of course, most “cardans” can transmit rotation even when the wheels are turned more, but in this regard they will in any case be inferior to the grenades of front-wheel drive cars.

Depending on how competently and intelligently the “cardan” distributes rotation between the axle shafts, the complexity of its design is determined. An extremely simple principle applies here - the more complex functions a given mechanism performs, the larger the size and weight it will be. Note that most cardan shafts are made of high quality steel. This approach allows not only to achieve maximum strength of the assembly, but also relatively small dimensions and weight, in contrast to the case with the use of alloys or replacing steel with other metals.

Destruction of anthers

It would seem that this malfunction is quite insignificant, but it can lead to serious consequences. Those who know what a driveshaft is on a car carefully monitor the condition of the anthers. The fact is that the shaft is located directly under the machine, which means it is exposed to dirt and dust. The hinges and crosspieces are protected by anthers. When they are destroyed, the hinge bearings are not lubricated, and their increased wear begins. It is necessary to carefully monitor the condition of the anthers. This will help extend the life of the crosspieces and the driveshaft in general.

Cardan shaft

, also known as

a cardan

, is an integral part of the transmission of many cars. Transmits torque from the gearbox or transfer case to the front or rear axle gearboxes. The design of the driveshaft is extremely simple; its design has remained virtually unchanged for more than a hundred years. No all-wheel drive system is complete without a cardan drive.

Main HF malfunctions and their manifestations

Below are their possible external manifestations and the reasons for the appearance of each of the signs. Extraneous knocking in transmission units; at the beginning of movement, sudden acceleration or changing gears of the vehicle’s transmission. May result from:

- Loosening of the threaded connections of the flanges and the universal joint coupling;

- The HF in the splined part has an over-permissible gap;

- Excessive clearance in the bearings of the cardan shaft crosspiece.

The driveshaft crosspiece requires special attention.

. It is the crosspiece that is the main source of noise and rattle in the cardan transmission, and is subject to the most frequent replacement (it is recommended to change it every 10 thousand km). A little less often, the outboard bearing fails or a gap may appear in the universal joint.

Increased noise and vibration of the car when driving. The reasons may be the following:

- HF bending;

- Incorrect installation of the HF, installation marks were not followed during installation;

- the balance of the shafts is disturbed;

- destruction or wear of the bushing (centering) of the intermediate coupling flange or the ring (centering) of the secondary gearbox shaft;

- excessive clearance in the outboard bearing;

- destruction of the HF suspension support;

- loosening of the threaded connection of the transverse support;

- excessive clearance in the needle bearings of the crosspiece;

- the connecting nut of the gearbox fork is loose;

- there is no lubrication in the shaft splines.

Lubricant leakage can occur due to:

- destruction of the stuffing box seal of the splined part of the shaft;

- Damage to the oil seal of the gearbox cross bearings.

The main reason for the rapid failure of the driveshaft is imbalance

, imbalance increases the load on the cardan parts several times.

Famous models

You can argue endlessly about which is better, a cardan chain or a belt. But only powerful motorcycles of significant cubic capacity are usually equipped with a cardan drive, since this unit itself is expensive to produce, and besides, it “eats off” part of the power from the engine when transmitting torque to the rear wheel. Therefore, it is installed specifically on expensive equipment, powerful and responsive, and of various classes, from cruisers to sports tourists. But some manufacturers began to gradually abandon it - for example, Yamaha has no longer produced choppers with a cardan drive for the last fifteen years, preferring belts, but at the same time retains the FJR 1300 cardan sport tourer in its lineup. This type of drive can be seen on Honda motorcycles on the VFR 1200 sports tourer and on the famous Gold Wing GL1800 tourer. Suzuki still puts it on its cruisers (Boluevard M190R, Boulevard C1800), but Kawasaki abandoned it a long time ago. In the USA, most belt-driven motorcycles are produced, for example, all Harley-Davidsons.

What to prefer?

It all depends on your personal tastes. Many motorcyclists believe that a chain on a solid bike looks frivolous, forgetting that all heavy-duty sportbikes are equipped with it. But a cardan made from “honest iron” is considered extremely reliable , and there is some truth in this, and it does not need to be serviced often. But modern belt drives also do not require frequent maintenance, while having a huge resource, up to 30-50 thousand kilometers or more! Therefore, when choosing a bike, you don’t need to focus on any particular type of drive.

All models with a cardan shaft have one thing in common - a huge service life and high reliability . But many owners believe that nothing will happen to the cardan, and reduce its maintenance to regularly changing the oil in the gearbox. This should not be done, since even the most reliable part requires attention. It is necessary to monitor the condition of the oil seals and boots that protect the shaft from dirt entering the bowels of the mechanism, it is necessary to check the condition of the splines on it (in the place where it connects to the gearbox and gearbox), and also clean and lubricate it from time to time. This is a rather labor-intensive operation that requires hanging the motorcycle and removing the rear wheel, so many bikers simply forget about it. And in the future, this can lead to a reduction in service life and possible breakdown, so when servicing your steel horse, you need to be guided by the manufacturer’s manual, and not your own opinion.

Above you will find a complete list of motorcycles on a cardan with reviews of them and reviews from owners.

From the history of the cardan

The cardan shaft was named after the Italian specialist in medicine and mathematics, Gerolamo Cardano. It was he who developed and described the principles of operation of hinge mechanisms that connect two shafts rotating in the same direction. By the way, historians claim that Leonardo da Vinci already had something similar.

What is a cardan and when did it appear? This element was first put into practice by Louis Renault. It was he who first used a driveshaft in the design of his cars in 1898. This drive is extremely simple, which contributed to the fact that at the beginning of the 20th century it became practically no alternative. Despite the development of modern technologies, it is still impossible to do without cardans. They are used in motorcycles, mining SUVs, in transmissions of all-wheel drive vehicles, and in rear-wheel drive models.