Composition of alkyd paint for a car, its properties

Each car painting involves applying special enamels to the surface.

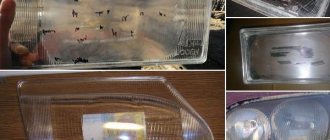

All types of car paints have both disadvantages and advantages. Alkyd car paint is a derivative of oil-based alkyd resin. The peculiarity of this type of enamels is rapid polymerization without creating any additional conditions. This means at normal temperature under the influence of atmospheric oxygen. To paint a car completely, such enamel is used very rarely, since it requires additional varnish and polishing. Fully matte enamel is also available; it is used for local repairs before varnishing or as an independent decoration of parts. It was the advent of synthetic paints that contributed to the dramatic improvement in the car painting process. Thus, alkyd paints are one-component paints that dry well in the open air. This type of car paint has high elasticity, shine, and high performance. But with prolonged exposure to atmospheric phenomena such as frost, heat, precipitation, such paint begins to lose its qualities. There are also some disadvantages: it takes a long time to dry and is difficult to polish. Special additives are used to speed up drying. Thanks to this, the evaporation of solvents is faster.

Today, alkyd enamels occupy a large market volume. Almost half of all car paints produced are made from them. Here are some brands: Vika, Helios, Sadolin, Mipa and others.

Advantages and disadvantages of alkyd paint

Alkyd paint for cars has the following advantages:

- good polymerization;

- low cost;

- excellent protective properties, resistance to aggressive environments, including;

- ease of use.

The disadvantage of that car paint follows from its advantages. Since polymerization occurs quickly, the paint dries actively, resulting in a thin film appearing on its surface, which prevents uniform drying.

Technology of painting cars with alkyd paint

If the question arises about which enamel is best suited for protecting a car without taking into account time costs, then alkyd-based car paint is one of the most reliable means of protecting metal. The resulting coating resists all exposure to the sun, atmosphere, and chemicals. The shine of such a film can be compared to the shine of an acrylic coating, only at a lower cost and without a hardener in the paint (the material is applied to the car in 2 layers).

The durable film that is formed by synthetic resins is also considered a disadvantage of enamel: the surface forms quickly, and alkyd enamel takes longer to dry. Professional use of an alkyd helmet requires a special drying mode with increased heating and good ventilation. Since alkyd enamel for cars forms thick layers, you need to apply 1-2 layers. But, despite their good protective properties against atmospheric influences, alkyd paints do not inhibit the formation of corrosion, so such paint should be applied to a primed surface.

If we are talking about painting a car in the garage, then it is rarely talked about a major update of the paintwork. But even with minor repairs, it is necessary to prepare the car body or its parts no less carefully. Professional application of alkyd paint occurs in three layers:

The backing is a thin layer that is needed only for adhesion to the surface (it sprays quickly, so it is difficult to maintain uniformity).

The base is a layer of normal thickness (it is possible to combine with the first).

The outer film is a layer on which the appearance of the surface depends (it is diluted a little more, and is more likely to be poured than applied).

The first and last layers are very important, since the first is able to provide adhesion, and the second is responsible for the appearance. Since the thickness of an individual layer is small, errors that were made when applying the first layer can also appear in the last. This effect is called “first layer memory”. The distance of the gun to the car surface depends on the pressure, viscosity of the enamel and the nozzle. The optimal distance is 15-20 cm, but since the last layer is liquid, it is better to increase the distance to 30-35 cm. You should move the gun quickly, you should carefully monitor the drying of the paint, since at high temperatures or with a solid solvent the paint can dry on the fly and form shagreen.

The opposite of this danger is smudges that appear due to too active use of solvent. In case of deviation from the norm, and especially with regard to humidity, it is quite possible to choose another solvent or change its amount.

Polishing and hardness of paintwork

The paints and varnishes used to cover a car can have different hardnesses. Acrylic enamels themselves are quite soft, so they can be easily polished. They already contain varnish, thanks to which they retain their shine after drying.

On a note

There is a separate type of acrylic paints that are specifically designed for varnish coating. Such enamels become matte after drying. Regular acrylic does not need varnishing.

In turn, car varnishes can be both soft and very hard. Usually, their own cars are coated with, if not the hardest varnishes, then something close to it. They wear less, which means they don't need to be polished as often. At the same time, polishing such coatings lasts several times longer.

It’s also useful to read: The shine of a car’s paintwork and polishing technology

Ceramic varnishes are considered the hardest. In addition, they know how to self-heal. There are fewer scratches on them, and those that exist “overgrow” over time. But polishing ceramics is very difficult, which means making a transition.

The best option is MS varnish, which contains a large dry residue and is highly polished. UHS varnishes are also good, but they dry too quickly, which is why they do not have time to spread in a warm room and form a pronounced shagreen.

On a note

High-quality car polishes are not cheap. In this regard, covering the car with an extra layer in order to have a reserve for polishing means increasing the cost of painting.

Thick varnishes are applied in one and a half layers, and this is enough. And HS needs to be applied in 3-4 layers, but it costs less. In general, the cost of a varnish coating with the same thickness is approximately the same.

Painting parts

The technological process of painting individual parts directly depends on their size. It is recommended to apply enamel to the roof, starting from the center, painting the vertical part from above. The distance from the gun and the viscosity of the enamel are greatly influenced. It is necessary to take into account that very diluted material will leak a little, and using a dry hardener and a small amount of solvent, the paint dries faster.

Sometimes the thickness of the layer can give a different shade, but in relation to materials based on alkyds, this is not so effective. Thus, the technology of painting parts with alkyd paint consists in their identical location in relation to the positions they occupy in the car. In this case, all changes that are associated with pressure and conditions are the same for all parts.

How to polish a car body manually? Complete instructions for carrying out work.

If the paintwork of your car has lost its former appearance and is covered with small scratches and chips, then you can try to restore the attractive and shiny appearance of the car by hand polishing the car body. In this article we will consider the option of working manually, without using a grinding machine, because it is not always found in a car enthusiast’s garage, and if you have free time and a desire to correct the situation, then you can achieve an even better effect manually. For example, in Soviet times there were no special polishing machines at all, but car owners using manual labor achieved the shine of their cars using the same goyi paste and other products that could be found in the store.

Today you have a wide choice of materials; for example, to manually polish a car body, you can use G-3 polish from. It's very easy to work with her. To do this, take a rag, wet it and apply polish. Next, use it to rub the car until it shines and periodically moisten the surface with a hand sprayer to avoid rapid drying of the material. After this, we wash the surface to be treated, rinsing off the G-3 paste, and apply the next brand G-10, from the same manufacturer. G-10 is a finely abrasive polish that removes even smaller imperfections and scratches while adding shine to the body. And as a finish, you can use any paste to preserve the surface and protect it from moisture, salt and chemical compounds that may fall on the machine during its operation. We took the manufacturer “Farecla” as an example; there are also analogs from other companies on the market, such as 3M, TURTLE WAX, ABRO, LIQUI MOLY, Willson and others.

The body surface treated in this way becomes dirt- and water-repellent. Which has a positive effect not only on the appearance, but also on the protection of the paintwork from destruction.

Related article: Acrylic car painting. Advantages of the material and complete technology for carrying out the work.

At the moment, polishing a car with your own hands is not often done by hand, because it requires a lot of time and effort, and city residents do not have time to allocate a day or two for this, so many people buy polishing machines or rent them. But you also need to be able to work with them. Monitor the surface temperature and speed so as not to overheat the paintwork and damage it. This point turns off many novice craftsmen, and they rub the abrasive and protective polish by hand.

Removing small scratches on paintwork

Restoration is possible primarily on minor scratches on the varnish of the coating. You've probably noticed small white or dark-colored scratches on the body, but when you wash them, they disappear and then appear again. This is due to the optical effect of light refraction. Scratched varnish displays a slightly different shade, but when washed, the pore is filled with water, which has similar display properties to varnish and visually this defect disappears, but as soon as it dries, it appears again. It is precisely such minor defects that you can eliminate by manually polishing the car, thus updating the paintwork and giving the vehicle a more presentable appearance.

Some car owners try to remove these scratches with the help of “pencils”, but this is nothing more than an oil or gel that fills these small pores, but they are quite expensive. Some people also use WD-40 lubricant, but it does not harden, thus collecting all the dirt and dust, resulting in greasy stains in the treated areas. There are also specially made optical polishes on the market, but they do not remove everything.

We would advise you to solve the problem in terms of actually eliminating the scratch by manually rubbing polish on a previously sanded surface. The essence of the process is to carry out several operations.

- Surface washing.

- Degreasing with anti-silicone. Do not skip this step, because resins and greasy stains will create clumps of paste and the process will be difficult, and you may even damage the surface.

- Next, use fine-grained P2000 wet-on-wet sandpaper to rub problem areas where there are scratches. As soon as the scratch visually disappears, the process must be stopped and proceed to the next processing area.

- Take the first type of polish with fine grain and apply it to a wet rag. Grind the composition, wetting it on the body using a spray bottle with water.

- After this, take a second type of polish, with even smaller grains, and repeat the operation.

- The finishing layer is a protective one. By type of liquid glass or film stickers.

Related article: Painting a car bumper yourself. All the details of the procedure.

Rub the polish with a fluffy rag in a circular motion. When working on your own, be careful not to get dirt on the rag, otherwise you may re-scratch the clear coat of your car.

Video example of carrying out work in your garage, without special equipment.

Is it worth polishing or is it better to do without it?

Despite the fact that polishing renews the appearance of the car, it also reduces part of the paint layer, which in turn makes it less resistant to various influences, both mechanical and chemical. Whether you need it or not, decide for yourself. We will only advise that after manually polishing a car without a machine, treat the top with a protective polish, like liquid glass or nano polishes. Yes, it is expensive, but such layers last quite a long time, it all depends on the nature of the machine’s operation and the number of washes. This will protect the paintwork from more intense wear and maintain the visual effect of polishing for a long period.

Have you polished your car by hand? If yes, then share the results in the comments.

Sanding and polishing paint

SANDING AND POLISHING PAINT

Nitrocellulose and acrylic varnishes require subsequent sanding and polishing. Without this treatment, the layer remains smooth, but has little or no shine and may have an “orange peel” appearance. All other paints can be sanded and polished if they use a curing catalyst according to the manufacturer's instructions. Other materials, such as synthetic and acrylic enamels, can be processed if a hardener has been added to them. Also consider using protective film https://autobezzabot.ru/uslugi/antigravijnaya-zashhitnaya-plenka/. Polishing enamel that has not been cured with a hardener may damage it.

Sanding paint

Sanding paint is similar to any sanding operation, but with a few differences. The point of sanding before polishing is to remove all the orange peel. All protrusions are removed and only a flat surface remains.

Types of polishing

Depending on the purpose and effect on the paintwork, there are three types:

- Abrasive. Helps eliminate serious defects after painting (deep scratches). It is carried out using sandpaper and paste with a gradual reduction in the size of abrasive particles. Can be done manually or using a grinding machine.

- Protective car polishing. To carry it out, pastes containing Teflon and wax are used, which clog the slightest irregularities and create a glossy, protective film. The latter, however, is destroyed after 3-10 washes.

- Nanopolishing. This procedure consists of applying a special multi-component varnish, which was invented by the Japanese and has unique properties to create a durable coating and a perfectly smooth surface.

General characteristics of alkyd coatings

When choosing a paint coating, you must first pay attention to how long the enamel will meet the required characteristics. If alkyd-styrene and urethane paints have a service life of approximately 5-6 years, then acrylic, glyphthalic, cellulose and other enamels will retain their properties for approximately three years.

Paint based on alkyd resins is a reliable protector of metal from the effects of corrosion. It withstands the aggressive influence of the atmosphere, sunlight, significant temperature changes, and resists chemical solvents. Alkyd urethane paint is used in temperature ranges that range approximately from -50 to +50˚C.

This allows you to expand the scope of its use in different climatic conditions without fear of premature wear. Resistance to minor mechanical damage will help avoid minor scratches of both the coating itself and the metal it protects.

When applied, urethane paint forms a thick layer of coating, which reduces the number of applied layers and material consumption. It is not recommended to mix this paint and solvent. Alkyd urethane paint has the following negative aspects of use:

- takes a long time to dry;

- difficulties arise during polishing;

- When tarnished, it is impossible to restore gloss without applying an additional layer of varnish or paint.

To achieve the maximum required effect, it is necessary to properly prepare the surface to be treated.

It is recommended to use products of the same chemical composition, so it is best to use alkyd primer. This additional layer of protective coating reduces the possibility of moisture penetration onto the car body to zero, and also compensates for the deficiencies in the corrosion protection of the main paint coating.

Why is it worth polishing?

High-quality car polishing should be done at recommended intervals because it helps:

- Restore the look of the car “like it came out of the showroom”, giving the coating its original shine;

- Remove looseness of the coating, small scratches, abrasions;

- Prevent the appearance of corrosion, microcracks and further destruction of the coating (more relevant to the non-abrasive type of polishing).

Regularly carried out high-quality polishing will cost less than painting 1 unit of car body. One service for polishing an entire car costs approximately 5 thousand rubles, while painting a small part costs 7 thousand or more, depending on the size.

Painting, for example, a wing may not match the color of the rest of the body, and this will no longer look profitable, especially when reselling the car. With a polished and well-maintained car, you can easily make more money, or at least recoup all the costs of polishing by selling it at a higher price compared to identical cars on the market. But it will most likely not be possible to reimburse the costs of priming and painting rotten parts.

Car polishing

The process of preliminary preparation of a car body before painting

The preliminary area of the surface to be painted is thoroughly cleaned of old enamel, dust, and dirt. To carry out this procedure, you need to prepare a weak solution of ordinary water and detergent. The surface is degreased using white spirit, although any other solvent can be used.

Next, all unnecessary parts are disconnected - we leave only the surface of the “bare” metal, which, if necessary, is defective (mechanical damage is eliminated). To do this, you will need a sharpened screwdriver or chisel, coarse and fine sandpaper.

Old paint and primer are removed, and scratches need to be removed using grout paper. After carrying out the damage removal procedure, you need to once again remove traces of abrasive from the surface of the car and degrease it using an alcohol solvent.

Next, if necessary, the required areas should be treated with a special putty for metal. This action is carried out in order to eliminate unevenness or deep dents on the body. After all the manipulations, you need to let the putty dry.

The final stage of preparing the car body for painting will be the final sanding of the required areas.

Painting a car with acrylic paint has its own nuances:

- The most important condition is the need to apply three layers of enamel due to the low covering power of the paint. The first creates a base for application and is covered with a very delicate and thin layer. The second, thicker one is the main layer. And to consolidate the result, apply a third, more diluted one. If you make mistakes when applying the first layer, then all the defects will be visible on the final painting layer. This effect is called “first layer memory”.

- Multilayer coating is carried out using the “wet on wet” method. However, in order to avoid possible smudges, before applying a layer it is necessary to allow time for the previous one to dry easily. Typically the time ranges from five to ten minutes.

- The recommended temperature in the painting room should be maintained at least 20 degrees Celsius. At low temperatures, it is recommended to add a quick solvent and a quick hardener to the acrylic primer. The exposure time between layers also increases, at least twice.

- Varnishing is not required, but some experts still prefer to carry out this procedure after painting to obtain a deeper color. In this case, it is necessary to wait a certain time for the acrylic coating to dry completely.

After applying all layers, allow the surface to dry for at least 24 hours and begin polishing. This stage will eliminate many of the defects that have arisen. Polishing a car consists of processing first with sandpaper and then with an abrasive polish. It can be carried out either manually or using a special machine.

Causes of defects after painting

There are several main reasons why certain defects appear after painting a car.

Dusty room

Among all paintwork defects, debris adhesion during operation occurs in 70% of cases. The reason for this: dust in the garage, a poorly washed car, insufficient ventilation of the room. Painting defects are eliminated by “wet” or “dry” sanding. Sandpaper with an abrasiveness of at least 2000 grit is used if sanding is done by hand. You can use a grinder. Polishing of the ground surface is required.

Shagreen

The reason for the appearance of “orange skin” on the body, instead of a beautiful shiny surface, is simple:

- Using too thick varnish or paint. Often a defect occurs due to the driver’s carelessness; each paintwork has an individual application technology, number of layers, and dilution parameters.

- Wrong choice of spray gun for painting. With low air pressure in the gun nozzle, the paint is sprayed unevenly on the surface of the body, and the density and thickness of the coating is not maintained.

The defect can be eliminated if the body is properly sanded and polished after the paintwork has completely cured.

Matte

The defect of a matte surface instead of gloss will be noticeable only on the fifth day after painting. If you wet the body with water, it will sparkle in the sun, showing the color that the driver would always like to see on his car. A defect appears if:

- High room humidity with complete lack of ventilation. If painting is done in winter, the garage should be well heated, the temperature should not fluctuate, falling below 15 degrees and not rising above 25.

- High pressure in the gun nozzle if painting is carried out with a spray gun (not a production paint cylinder).

- Incorrectly selected thinner with high cooling parameters and low drying class.

Air droplet breakthrough

The defect appears a few days after painting. Causes:

- Unsuitable brand of thinner that evaporates quickly;

- Applying thick layers of paint;

- Painting with a second or third layer occurs on an insufficiently dried first layer;

- High drying temperatures or using a hot fan.

The defect is completely eliminated after grinding and deep polishing.

Reducing shagreen with polishing

Shagreen is a paint texture that resembles an orange peel. It is formed due to the viscosity of the varnish, which is applied in small droplets sprayed with a spray bottle. These droplets create a bumpy texture on the surface of the body, but gradually, spreading, it smoothes out.

Car varnish or paint hardens quickly. At the same time, their viscosity increases every minute. The drops do not have time to completely spread, turning the surface into an ideal “water” surface. Often they freeze without reaching an equilibrium state.

Too noticeable shagreen is a disadvantage. You need to get rid of it, otherwise the car will not look perfect, especially upon closer inspection. And there is only one way to do this - abrasive polishing.

During the polishing process, the abrasive removes the tubercles that form shagreen. There is no need to be afraid to do this, because the thickness of the varnish is determined by the lowest point of the layer, and not the highest. Essentially, shagreen is removed by grinding, and only then the leveled and matted surface is polished.

When sanding, shagreens are guided by the pattern. If the surface being treated remains spotty (matte spots interspersed with glossy ones), then sanding should be continued. As soon as the spotting goes away, you can proceed directly to polishing with pastes.

The choice of polishing paste manufacturer depends on the personal preferences of the car painter. In other words, who is used to what! Some prefer 3M, others prefer Farecla, others prefer lesser-known products. The main thing is that the result is satisfactory.

After polishing the painted car, the shagreen should disappear. To check the “orange” without leaving the garage, you need to look at the reflection of the lamps. Their boundaries should not be torn.

Preparatory stage

Sanding and polishing is carried out no earlier than on the 20th day after painting. This is the optimal period when even a thick layer of paintwork dries out. In addition, in the third week all possible surface defects become noticeable.

The preparatory stage before polishing after painting takes a short time. You need to wash your car using car shampoo. The surface of the body is treated with a degreaser, all rubber bushings and car parts are sealed with masking tape.

Paintwork defects that occur during coating application

No matter how carefully the body finishing work is done, sometimes it is not possible to avoid the appearance of defects on the surface. Some of them are well known and include:

- Shagreen. Another name for it is the orange peel effect. The reason may be the use of too thick paint (varnish). Removed by sanding.

- Dirt or debris that gets onto the paintwork during painting. Quite a common occurrence. Eliminated by mechanical treatment.

- A matte surface is formed instead of a glossy one. The cause is most often high humidity affecting the painted car when drying it, high pressure in the spray gun during operation, or a poor solvent. Treated with deep polishing.

- Burst bubbles (appear after the paint dries). Their formation is caused by using the wrong solvent. Another reason for such a defect in paintwork can be thick layers of paint applied without intermediate drying.

As can be seen from the examples given, grinding and polishing are a mandatory stage of work when restoring a car body.

Required tools and materials

To sand the body yourself you will need:

- Sandpaper for sanding with abrasiveness from 2000 grit.

- Sanding machine if automatic sanding is used. You can use an electric drill by attaching sanding wheels to it and adjusting the speed of rotation.

To polish a car after painting, use:

- A set of polishes of varying degrees of abrasiveness;

- Felt or leather polishing wheels;

- Spray;

- Felt napkins.

How to polish a car after painting

Work to eliminate painting defects is carried out in several stages: grinding, polishing, applying a protective coating. Depending on the type of defect (if it is dull, for example), initial grinding is not used. The process begins with deep polishing. In other cases, the order of work does not change.

Grinding

Sanding is done using sandpaper. The wet method involves pre-soaking the skin with 2000 grit abrasiveness for 10 minutes. Then the surface of the body is polished in a circular motion, while the paper is constantly wetted.

Dry sanding can be done using a machine. Use sandpaper to remove possible sagging, making cross-shaped movements with the tool. Use sandpaper with an abrasiveness of 3000-4000 grit.

Abrasive polishing

The second stage will be polishing the car after painting, using an abrasive paste. Can be polished by hand or using a polishing machine.

The paste is evenly applied to the surface, choosing a working area of no more than 40 square meters. cm. Polish in a circular motion, gradually changing the composition of the paste, reaching a polishing composition without abrasive. After each paste change, the working surface of the body must be washed.

How to polish a car with your own hands

You need to start polishing the body by preparing the room and washing the car. The garage or box should be spacious and comfortable. It is necessary to maintain a comfortable temperature for work, but the most important thing is good lighting. A lot depends on him. The lamps should be located around the machine, but in no case on one side.

You need to wash your car very carefully (how to properly wash a car). It should be remembered that just a few grains of sand caught under a sheet of sandpaper can scratch the coating, so you need to be extremely careful. In addition to dirt, adhering resin should be removed, for which anti-silicone or gasoline is used. However, you shouldn’t pour it on the stain; it’s better to simply moisten the cloth generously and wipe it off.

Before polishing the body, it is necessary to seal all the plastic with tape, since the high temperature will cause the paste to “stick” to it. Notice how carefully everything unnecessary is taped over in the photo above and in the video at the end of the article.

Polishing a body with your own hands is a long process, so you should be thoroughly prepared for the work.

First, each part is cleaned with sandpaper. If large scratches appear, then sandpaper with index 1500 is used to eliminate them, but if they are all relatively small, index 2500 is also suitable. Cleaning occurs with water for 2 reasons:

- The paper will become softer in water;

- The “emery” with such a fine grain clogs very quickly if you rub it dry.

The paper should be regularly moistened with water and thus cleaned the surfaces. To do this, you need to make rotational movements and rub crosswise. If you use 1500 grit paper, you must use 2500 grit sandpaper to remove large scratches on the already sanded surfaces.

Important! You shouldn’t get too carried away with cleaning, as due to inexperience you can wipe off the varnish and then the part will have to be tinted. This problem especially often happens at the ends of parts, where the paintwork is wiped off very easily.

After this, you can start polishing with a machine:

- First, take the densest circle (as a rule, they are white),

- the paste is applied to small areas of body parts and polished,

- sometimes it is difficult for a beginner to choose the right paste, in which case it would be advisable to purchase a universal product,

- As for the grinding machine, it should have convenient speed adjustment, so it is better to choose one that has a dial control (tips on how to choose a polishing machine for a car),

- The same rules apply to working with the machine as when “sanding” - you don’t need to put too much pressure on it or rub the corners of the parts for a long time.

Polishing a car with your own hands is a rather long and monotonous process, so there is no need to rush here.

After finishing work with one part, it should be thoroughly wiped with a cloth or napkin, and then move on to the next body element. Sometimes the plane overheats, in which case the circle seems to get stuck. If this happens, you need to take a break and let the varnish cool.

After treating the paintwork with a dense circle, you should attach a softer one to the machine (usually they are black) and go over the entire body again, following the same recommendations.

The right combinations of materials

The right combinations of materials. The difference between acrylic and alkyd enamels and general recommendations for use.

Properties of one-component acrylic enamels

Unlike acrylic emulsions in jars, aerosol acrylic enamels have an organic rather than aqueous base.

Advantages (compared to alkyd aerosol enamels):

- high drying speed;

- rich colors;

- high elasticity and high adhesion to plastics (due to these properties, acrylic enamels are preferable for application to plastic surfaces).

Disadvantages (compared to alkyd aerosol enamels):

- moderate weather resistance;

- moderate adhesion to metals (preliminary priming is required);

- moderate resistance to solvents.

Properties of one-component alkyd enamels

The peculiarity of alkyd enamels compared to acrylic enamels is that after drying the chemical processes in them do not end. After the solvent has evaporated, the polymerization process continues in the alkyd enamel under the influence of atmospheric oxygen. The molecules are “stitched” together and, figuratively speaking, form one large molecule, making the coating more durable and resistant to various influences, but at the same time less elastic and more fragile. However, alkyds have been discovered for a very long time and are very well studied. Modern KUDO formulations take this fact into account, and even after complete polymerization, the paint film remains quite elastic. The polymerization process can last from several days to two weeks. During polymerization, the coating must not be subjected to mechanical stress. For example, a car body element painted with alkyd enamel cannot be washed or polished for two weeks. Also, during polymerization, alkyd enamel cannot be coated on top with other paints and varnishes, even those based on alkyd - the coating may be damaged. You need to coat either “wet on wet”, that is, apply the next coating immediately after drying “touch to touch”, or after waiting for complete polymerization. When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

Advantages (compared to acrylic aerosol enamels):

- high adhesion to metals;

- higher hardness;

- higher weather resistance;

- higher light fastness (less fading);

- higher resistance to solvents.

Disadvantages (compared to acrylic aerosol enamels):

- longer drying time;

- long polymerization process.

Table of correct combinations

The alkyd base cannot be coated with paints and varnishes during its polymerization - the alkyd base may swell! The alkyd coating must be applied to the alkyd base either “wet on wet” **, that is, immediately after the base has dried “touch” (no later than 1.5 hours after applying the base), or after waiting for complete polymerization. *

When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

Alkyd coating can be applied to an acrylic base ** by waiting until the base is touch dry. *

You can also apply the coating after the base has completely dried.

Attention!

Do not apply aclide-urethane coatings, in particular yacht varnish, to one-component acrylic primer - the base may swell.

The alkyd base cannot be coated with paints and varnishes during its polymerization—the alkyd base may swell. An acrylic coating on an alkyd base must be applied either “wet on wet”, that is, immediately after the base has dried “touch” (no later than 1.5 hours after applying the base), or after waiting for complete polymerization. *

When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

Acrylic coating can be applied to an acrylic base by waiting until the base is touch dry. *

You can also apply the coating after the base has completely dried.

* Intermediate drying time between layers, touch-drying time, complete drying time and the time for the base to gain full mechanical strength are indicated in the instructions for use of each specific product.

** We recommend using a primer color as close as possible to the enamel color.

If the acrylic base is brightly colored, then when a thick layer of alkyd coating is applied to it (especially light colors), the bright pigment of the base may “rise.” The same is possible when applying an alkyd coating to an alkyd base “wet on wet”. For example, if a brown-red acrylic primer is painted with white alkyd enamel, then there is a high chance of getting a pink finish.

How to apply acrylic coating to acrylic base.

Acrylic coating can be applied to an acrylic base by waiting until the base is touch dry.

You can also apply the coating after the base has completely dried.

How to apply alkyd coating to acrylic base.

Alkyd coating can be applied to an acrylic base by waiting until the base is touch dry.

You can also apply the coating after the base has completely dried. Attention! Do not apply aclide-urethane coatings, in particular yacht varnish, to one-component acrylic primer - the base may swell.

How to apply acrylic coating to an alkyd base.

The alkyd base cannot be coated with paints and varnishes during its polymerization—the alkyd base may swell. An acrylic coating on an alkyd base must be applied either “wet on wet”, that is, immediately after the base has dried “touch” (no later than 1.5 hours after applying the base), or after waiting for complete polymerization, when the coating has gained full strength.

When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

How to apply an alkyd coating to an alkyd base.

The alkyd base cannot be coated with paints and varnishes during its polymerization - the alkyd base can swell even if the same composition is applied as the base. An alkyd coating on an alkyd base must be applied either “wet on wet”, that is, immediately after the base has dried “touch” (no later than 1.5 hours after applying the base), or after waiting for complete polymerization, when the coating has gained full strength.

When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

The intermediate drying time between layers, touch-drying time, complete drying time and the time during which the base will gain full mechanical strength are indicated in the instructions for use of each specific product.

How to properly care for the protective coating?

Caring for your car after polishing is not that difficult. It is enough to follow just a few simple recommendations.

Be careful when washing. Improper washing is the most common cause of premature damage to the protective coating. Firstly, do not wash the body during the first three weeks to a month after polishing. Moreover, regardless of what protective composition you used. The coating must acquire sufficient hardness and durability.

After this period, the car can be washed again, but you should resort to a professional two-phase washing - when a detergent composition (with a gentle concentration of alkali) is first applied, after which the foam is carefully removed with a soft sponge. The sponge should be carefully squeezed out of dirt before each new wipe, and the washing itself should be done in the direction from the roof to the bottom.

Avoid abrasive mechanical impact. In addition to driving carefully and being careful when parking, you can also stop using hard brushes and sponges. When washing and dry cleaning, do not rub the coating too hard - then it will delight you with a mirror-like shine and rich color of the car body for a long time.

It would also be a good idea to have the protective coating regularly maintained. Depending on the need, it may include the following operations: restorative polishing to eliminate mini-damages, clay cleaning to more effectively remove dirt and dust, restoration of water-repellent properties using special compounds.

Caring for polishing is a measure that will allow you not only to avoid the reappearance of defects on paintwork over time, but also to save a lot of money, because preventative procedures are not as expensive as full polishing.