Lithium battery for cars is gaining more and more popularity. Lightweight lithium batteries are designed for a range of vehicles, from motorcycles to military vehicles. Rising demand for them has forced suppliers and scientists to focus on improving the energy density, operating temperature, safety, durability, charging time and power output of lithium-ion batteries.

The development of lithium batteries began in 1912 under the leadership of G.N Lewis, but the first lithium non-rechargeable power supplies appeared only in the early 1970s. In the 1980s, an attempt was made to develop a rechargeable power cell, but development failed due to instability in the lithium metal used as the base material.

A lithium battery uses lithium as the anode. Lion batteries use graphite as an anode and active materials in the cathode.

Due to the instability of lithium during charging, scientists began to use a non-metallic solution using lithium. In 1991, she patented the first Li-ion battery. Continuing to develop, it remains popular and promising in the global market.

Lead-acid power supplies are inferior to lithium-ion car batteries in many respects. The weight of lithium batteries is 80% lighter than lead-acid ones. The Lion battery retains its charge for a long time, with a service life of up to ten years.

On the other hand, the price of lithium car batteries is several times higher than the cost of lead-acid batteries.

The automotive lithium-ion battery is often used in electric vehicles. An electric vehicle is propelled using energy from a power source.

Electric Vehicle Battery Types

Electric vehicles use three types of batteries: lead-acid, nickel metal hydride batteries, and lithium-ion power supplies.

Lead-acid batteries were invented in 1859 and are considered a common form of power source. They were used in all types of road transport. This is a type of liquid battery that contains containers with a weak solution of sulfuric acid.

Lead electrodes and acid are used to produce electricity in the battery. The power source is easy to maintain and is low cost. But it contains dangerous gases that can lead to explosion if used incorrectly.

Nickel-metal hydride batteries have been used since 1980. This is a small, light and capacious battery that has a high density and does not contain any toxic metals.

Lithium-ion batteries have been used for automobiles since the early 1990s. They have a very high energy density.

Because of its lightweight and low maintenance requirements, lithium ion is used in electronic devices, often laptop computers.

This type of power supply is considered the best for powering electric vehicles.

Advantages of lithium batteries

This power source has its undeniable advantages:

- have significantly less weight, which significantly affects the weight of the car;

- retain charge for a longer time;

- have the ability to withstand multiple discharge/charge cycles.

In addition, the lithium-ion battery has a higher safe current output ratio relative to its rated capacity. Therefore, in comparison with acid batteries, significantly less energy is required to perform a certain amount of work. Based on the category, they can both absorb and discharge enormous amounts of current. However, lithium-ion batteries are not a panacea for cars and have quite a few disadvantages.

What are the types of lithium-ion batteries and where are they used?

There are currently three types of LIBs in use, which differ in cathode materials.

Lithium cathodes containing cobalt (Limo2).

This type is especially effective. The cobalt ion Co3+ is small, so the cathode is built in such a way that the lithium-ion cathodes move easily. This is important for high energy density and capacity to produce small and lightweight batteries. Used in portable electronics and electric vehicles.

Lithium cobalt oxide LiCoO2 (LCO) is a thin device that is sensitive to damage and is therefore only used in electrical appliances.

Lithium Nickel Cobalt Aluminum Oxide (LiNiO.8Co0.15Alo.05 or NCA) is a reliable compound. Providing good energy density and high power, these materials are used as 12 volt lithium batteries for automobiles.

Lithium Nickel Manganese Cobalt Oxides (NMC) – stronger and more durable than NCA type. Most electric vehicle manufacturers use this cathode material. However, there are several options in which the metals contain nickel, manganese and cobalt in various proportions. The higher the proportion of nickel, the higher the energy content.

Lithium iron phosphorus oxide (LiFePO4 or LFP) cathodes.

This type is also durable, but has a lower energy density than LiMO2 cathodes. Chinese manufacturers use urban electric vehicles. The charge lasts for short distances.

Lithium manganese oxide (LiMn2O4 or LMO) cathodes.

This type was previously used in electric vehicles, but cathodes containing cobalt are superior in stability and energy density.

This video describes the detailed characteristics of ion batteries, dimensions, composition and labeling.

Why Lithium-ion batteries are not installed on cars

Lithium batteries in cars

Lithium batteries are a rather difficult thing in the context of automotive topics. Their reluctant use is surrounded by many myths, but there are also quite objective reasons that make the installation of such batteries undesirable at the moment. At the dawn of the invention of lithium batteries, lithium metal was in the red, then it was replaced by coke, and today graphite is becoming more common. After adding cobalt oxide, the batteries lowered their lower temperature threshold and also increased the number of charge-discharge cycles. All lithium batteries are equipped with a special protective board and controller. Li-ion batteries are classified according to cathode material:

- Cobalt lithium – LiCoO2;

- Lithium polymer – LiPol

Advantages of lithium batteries

- Very high energy density. Four times superior to lead-acid power supplies.

- High cell tension. The lithium-ion cell replaces three NiCd or NiMH cells, which provide only 1.2 volts. Scientists are currently working to provide higher voltage in cells. The greater the voltage in the cells, the fewer cells are required. This makes it possible to make the battery lighter and more spacious.

- Tolerates high discharge currents. This allows the operation of automotive devices such as cold starters or drives for hybrid vehicles with a small battery capacity.

- Increase power and productivity, depending on requirements.

- They have fast charging capabilities.

- There is no memory effect - complete discharge does not affect the service life.

- Low self-discharge rate (from three to five percent per month, will remain operational for up to ten years).

- When the battery is charged 100%, it is capable of delivering current energy without technical damage.

Variations in the basic chemistry (eg, different anode and cathode materials) allow for varied performance characteristics for specific applications.

Small size batteries are also available. Electrode material and ceramic electrolytes can be separated into rigid (aluminum oxide/silica gel) or flexible (acrylic fiber) substrates to produce high-density energy for thin and flat-plate batteries.

Li-Ion and Li-Pol batteries

The first models of lithium-ion car batteries consisted of a cathode material on aluminum foil and anode material on copper foil, placed inside the case and separated by a special separator impregnated with liquid electrolyte.

The sealed battery case was equipped with an internal pressure relief valve. The anode and cathode were connected to the terminals using current collectors.

In lithium-ion car batteries, the charge is transferred by positively charged lithium ions, which are embedded in the crystal lattices of other materials - salts and acids of metals, graphite, forming a chemical bond with them.

Initially, the role of negative plates was performed by lithium metal, which was later replaced by coal coke and graphite. The use of cobalt oxide made it possible to increase the temperature range of the battery and increase the number of charge/discharge cycles.

Included with lithium-ion batteries for cars are BMS type protective boards.

Disadvantages of Li-ion Batteries

- Sensitivity to deep discharge, overload and too high temperature. But in practice this is rarely a problem. The batteries already have built-in electronics that protect against negative influences. When using a LIB without built-in electronics, it is recommended to use a charger that is designed for it.

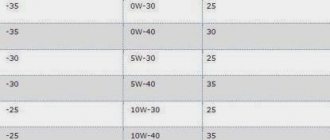

- Increased sensitivity to high and low temperatures. The optimal operating temperature is within 10–35 degrees. At low temperatures, battery power decreases. There are also dedicated low temperature ion power supplies that will maintain a charge at -40 degrees, with only limited discharge flows.

Charging LiFePo4 battery

The ability of such batteries to quickly accept the required charge is an advantage only at first glance. The speed of internal chemical reactions is far from instantaneous, as a result of which the state of the electrolyte during rapid charging will not be the same. The layers located in the immediate vicinity of the electrodes will be charged to capacity, while the peripheral layers will receive almost no charge. The more powerful the battery, the more noticeable this difference will be.

In practice, this means that you can quickly get the nominal voltage at the battery terminals, but it will take longer for the electrolyte to saturate.

Typically, charge current is measured as a percentage of the battery capacity. But if for conventional batteries this is 9–10%, then for lithium batteries it is from 50 to 100%. This is a lot, because the nominal capacity of such batteries can be up to 100 A*hour, so to charge them you need powerful chargers with corresponding amperage values.

For example, charging a lithium car battery with a capacity of 75–100 A*hour requires a current of 50–100 A. If during the charging process the temperature of the electrolyte begins to rise, the BMS will turn off the charger, but this will be evidence of a problem with the battery or an incorrect choice of algorithm.

Lithium Battery Safety

If overheated or overcharged, LIBs may be damaged. This will cause poisonous gases to leak, explode and fire. To avoid this, the lithium battery contains a fail-safe circuit that cuts off the power supply when the voltage is in a dangerous range.

A short circuit will cause overheating, fire and explosion. Lithium-ion batteries, unlike lead-acid batteries, are manufactured under high pressure and contain a flammable liquid electrolyte. Their quality is strictly controlled during manufacturing.

The lithium-ion battery for a car has many positive characteristics, but its use in gasoline and diesel engines is not effective and is not currently used. The generator that produces alternating current in a car is not suitable for charging this type of battery.

This video will talk about the use of lithium-ion batteries for gasoline and diesel engines.

Advantages and disadvantages of starting lithium batteries for cars

What is better for a motorist, to install a new generation battery on the car, which costs about 120,000 rubles, or to buy an expensive ($120) but familiar acid battery?

The advantages of a lithium battery include its light weight. But is ten extra kilos so important for a powerful engine? Yes, the charging capacity of a lithium battery is 2 times higher, and it will withstand 3 times more recharge cycles. The starter will receive a starting impulse reliably and stably if the operating conditions are met.

- First of all, a new battery cannot be charged directly from the generator. Remember, it does not tolerate overcharging and will fail very quickly. This means that you will need a converter that will convert the current from the generator to power the battery.

- The characteristics of any lithium batteries drop sharply as the temperature drops and in this they are inferior to lead batteries.

- Temperatures above +60 0 C are even more dangerous for the battery. Overheating can lead to fire and explosion.

- There should be no high current loads in the on-board system. Both the starter and the winch and other tools must accept the operating conditions of the battery. And this will result in an expensive modernization of the electrical circuit.

- The battery life depends on the uniformity of charge of the cans, constant vibration, which destroys contacts and contributes to corrosion of the housing. The capacity of cans in such conditions decreases sharply.

Adapting a car to a lithium-lithium battery will cost more than the cost of the energy source itself. However, you cannot count on long-term operation of the battery - a maximum of 3 years.