In the modern market for automobile products, you can increasingly find not only popular know-how in the form of gel batteries, but also batteries with an incomprehensible AGM marking on the case. And this is not surprising: the mind of the average consumer does not always have time to understand the principles of new technologies that are moving far ahead. Car enthusiasts who do not yet know what an AGM battery is will do well to familiarize themselves with the advantages of this battery in more detail.

What is AGM technology

What is AGM? This abbreviation can be translated from English as “gasket impregnated with fiberglass” - “absorbent glass mat”. AGM technologies have been known abroad for quite some time. The first developments began in the 80s of the twentieth century in the USA. Initially, batteries of this type, like their gel counterparts, found their application in military aviation. These are practical and safe power sources that can withstand loads that other batteries simply would not be able to handle. An AGM battery is manufactured using a completely different technology than older lead-acid batteries. Its undeniable advantage is that it does not contain potentially dangerous liquid electrolyte, which can cause significant trouble and inconvenience during routine operation.

The inside of an AGM battery is structured like this: between its positive and negative plates there are gaskets (or mats) soaked in electrolyte. The gaskets are made of fiberglass, which absorbs electrolyte like a sponge. And it turns out to be, literally, “sealed” between the plates in a reliable fiberglass gasket.

It is this AGM technology that allows us to talk about the high degree of safety of these batteries. This form can be safely called a “briquette with electrolyte”. The fiberglass separator, being laid between the battery plates, performs a dielectric function. The plates are unable to come into contact with each other, which means that a short circuit will not occur between them.

This battery can be placed on its side or turned in any direction. The electrolyte will not leak or explode due to the fact that there is no evaporation of poisonous and dangerous gases such as hydrogen and oxygen. Of course, it is not recommended to subject it to extreme extremes by turning it upside down. But this in no way detracts from its obvious advantages.

The AGM battery is remarkable in that its plates are made from highly purified lead . This significantly reduces the degree of metal resistance and increases the efficiency of charge-discharge cycles. Such plates do not need desulfation, precisely because of the high quality of the metal.

Two plates tightly compress the separator on both sides using the sandwich principle, resulting in a very durable structure. The density of the plates is quite high, and a much larger number of them can be placed in one cell than in a liquid battery. Therefore, the capacity of such batteries is an order of magnitude higher.

A regular liquid acid battery needs to be charged on average 10-12 hours. An AGM battery can be fully charged with high currents in just 2-3 hours . The separator plate placed between the lead ones does not allow them to crumble prematurely. And that is why such batteries withstand deep discharge much better than many others .

As you know, desulfation of plates is a frequent manipulation that is most necessary for liquid “acidizers”. Precisely because both the quality of lead and the technology for arranging the plates often leaves much to be desired.

As already mentioned, due to the fact that much more fiberglass plates with electrolyte can be placed inside such batteries, AMG batteries can produce several times more capacity than conventional batteries. Large capacity and powerful starting currents are the main reason to purchase just such a battery. Especially in harsh operating conditions in winter.

A conventional battery produces inrush currents of at least 300, maximum 500 amperes. The starting current of an AGM battery starts at 550 amperes and ends at 900 . For obvious reasons, a battery with such a high capacity will start the engine in cold weather easily and simply. At the same time, the liquid acid agent may simply not “crank” the internal combustion engine.

The service life of the cheapest battery of this type is 5 years, and the record performance of the most expensive and capacious battery is 10 years .

If you traditionally try to sort out the “pros and cons” of AGM batteries, as you can see, there will be many more advantages. One of the few disadvantages of this particular battery is its price - from 6,500 to 10,000 rubles . However, if you compare them in cost with gel ones, gel ones will be much more expensive.

How to extend the life of your car battery

Basic definitions of camber adjustment. Camber adjustment technology.

The battery life recommended by the manufacturer can be extended if the following rules are followed during the entire period of use of the product:

Monitor the condition of the vehicle's electrical equipment

Particular attention should be paid to the generator, because if this part malfunctions, the entire load from electricity consumers will fall on the “shoulders” of the battery. The relay regulator also affects the operating mode of the vehicle's electrical equipment

If this element malfunctions, the battery may be constantly undercharged or severely overcharged. Change the alternator belt in a timely manner and ensure its correct tension. If this is not done, the generator rotor will rotate at a lower frequency, which will not provide electricity consumers with the required amount of electricity. If the battery is serviceable, then from time to time you should check the electrolyte level and its density. As the liquid level decreases, the lead plates are exposed and may crumble. Charge the battery using factory charger models. It is desirable that such devices have a special training regime that will significantly reduce the formation of sulfates on the surface of lead plates. All batteries need to be wiped from moisture and dirt from time to time, since liquid on the case can short-circuit the terminals. Check for mechanical damage.

In order for your car battery to last a long time, you should carefully monitor its condition.

A car battery, popularly called a battery, is one of the most important elements in a car. It is impossible to start the car without this battery. Depending on the type, model, manufacturer and compliance with operating rules, the service life of a car battery according to GOST may vary. Some samples do not require replacement for 10 years, others cease to cope with their responsibilities after 2-3 years.

How to charge an AGM battery

Charging an AGM battery is essentially no different from charging a regular battery.

It should be remembered that the charger must be able to regulate the current indicators, or with a charging mode for just such batteries. voltage is recommended not to exceed 14.8 V (AGM batteries, like gel batteries, are very demanding on the charging process, and high voltage can destroy them in a short time).

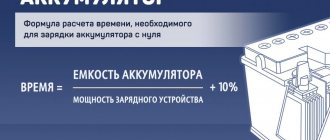

As for the current on the charger, it should traditionally be set to 10 percent of the battery capacity indicated on the case. When charging the battery with higher currents, the amperage should not exceed 30 percent. It is important to remember that only a properly charged power source can exhaust its resource so as not to lose it prematurely. And this is precisely what can serve as an answer to the frequent question of what current should be used to charge an AGM battery.

Since the lead plates in AGM batteries are made of higher quality lead, desulfation during charging occurs much faster and more efficiently: the white deposit of lead sulfate easily dissolves in the first hours of the charging process. If we remember how the plates of liquid-acid batteries are desulfated manually (rinsing with distilled water several times), we can conclude that the word “maintenance-free,” often applied to AGM batteries, also has its advantages.

Briefly about the main thing

Charging an AGM battery with a conventional charger is only possible in the charge replenishment mode from 75% to 100% level (12.45V). Deeply discharged copies are restored only with the help of automatic chargers. It is advisable to purchase models with intelligent control designed to perform the task of charging an AGM series battery from various manufacturers. Products with a built-in three-stage charging program on board are preferred.

The maximum voltage during charging should not exceed 14.8V. The current strength at each stage is different and depends on the degree of discharge of the battery, as well as the specific charging technology. A complete recharge is necessary when the terminal voltage reaches 12.2V.

Hi all. Dear electronics luminaries may not read this post, so as not to be irritated by the amateur’s reasoning, his terminology may be “crooked,” and do not judge him strictly. In it, he talks about his struggles and mistakes while creating this charger. I do this solely so that people like me, if they decide to take this path, do not repeat my mistakes. So, let's go.

As you know, AGM batteries are critical to the charging mode. Conventional chargers without charging voltage control can damage them. Inside an AGM battery, the lead plates are in a kind of bag filled with electrolyte in the form of a gel. That is why they are also called gel (not to be confused with helium). These batteries have many advantages over traditional ones, but they require a certain attitude towards them during operation. They cannot be used in high temperature conditions (therefore they are placed outside the engine compartment, in the passenger compartment or trunk of the car). Their charging voltage should not exceed 14.7 V. The manufacturers of these batteries recommend the following charging mode: Stage 1 - charge the battery with a current of 0.1C to a voltage of 14.5-14.8V. This point is very important because at this boundary the rapid splitting of water into oxygen and hydrogen begins, thereby creating excess pressure in the jars. Excess pressure escapes through the safety valves, increasing the acidity of the electrolyte. Battery life is significantly reduced. Stage 2 - when the battery voltage threshold reaches 14.5 - 14.8 V, the charging voltage is instantly reduced to 13.6 - 13.8 V with a current limit of 0.01C. The battery goes into saturation mode and can remain in this mode for a long time without harm to it. This is the device we will talk about.

For a long time I was looking for a circuit that would allow charging AGM batteries using the above algorithm with currents up to 5 A, but I found only low-current designs for small batteries. As a basis, I took the diagram from the site forum.cxem.net/index.php by the author “kurilka”, as the most suitable, from my point of view, for repetition. Here she is:

I replaced Q3 with KT815. It also has a saturation voltage of 0.6 V, like the 2N3409, but the current is 1.5 A max. I calculated the circuit as follows. R5 - 240 Ohm. The collector current on the KT815 is small, and no radiator is required. At the base of Q1 it became about 14 V and it opened. The charging current became 4.2 A. It is limited by the value of resistance R7, which is approximately calculated: J = 0.6/R7. 0.6 V is the saturation voltage of transistor Q3, which, when opening, shunts transistor Q1, forcing it to close and thereby limiting the current through it. I have R7 - 0.15 Ohm with a power of 10 W. The current is about 4 A. The battery is charged to the cutoff voltage, i.e. up to 14.7 V, as I set in the settings. Then timer 555 is triggered to turn off and the voltage at the base of Q1 will be determined by the voltage of the opened zener diode, i.e. 13.6 V - buffer mode.

And this is exactly the bias voltage of transistor Q1 at which the charging current with a fully charged battery (during the recharging process after switching on the buffer mode, the current gradually decreases, for me from 2.5 A at the initial moment when switching to the buffer mode) should be about 0 .5 A or slightly less than 0.01C. This is fine. This current does not harm the battery and compensates for its self-discharge. And everything would be fine, but... The fact is that in the main charging mode, resistor R5 provides a bias voltage to Q1. But when the circuit switches to buffer mode and transistors Q1 and Q3 are closed, and TL431 opens and current flows through the R5 - U3 circuit, this resistor is current limiting through the adjustable zener diode TL431 and its resistance is insufficient to provide a current safe for U3. The current is too high. U3 gets hot and may fail (I burned two like this). That is, in operating mode we need a resistor that provides sufficient bias on Q1 to obtain the charging current we need (in my case 4 A), and in buffer mode we need a much larger resistor to limit the current through U3 (its operating current is no more than 100 mA ). What to do? Introduce two resistors and a switching relay? We discussed all these issues in correspondence with the author of the original diagram, and the author of the original source convinced me to abandon the use of the relay because of its inertia. That is, it will work, no doubt, but there is no guarantee that during its operation the TL431 will not have time to burn out. The current on it may be momentary, but it will be lethal. On his advice, I introduced a KT814 transistor (complementary to the KT 815) into the circuit between the Q1 base and the ground, and connected a TL431 zener diode between its collector and the base, and a 1-component resistor between the base and the emitter. That is, I shunted TL431 with a transistor through which the main current flowed. This transistor is installed on a small radiator of about 20 cm2 (during operation it heats up to about 50 degrees Celsius). Resistor R5 is set to 150 Ohms. And finally the final scheme was born. Here she is:

Is it possible to restore an AGM battery?

The extent to which such a battery can be restored depends on its condition and service life. It happens that car enthusiasts come across old AGM batteries that were once produced abroad and somehow ended up in our country. It also happens that due to careless handling, a new battery may fail. There is nothing difficult in how to restore it, given that the composition of the electrolyte is the same acid as in liquid batteries, but it is enclosed in a different form.

Most often, videos are shown on the Internet about how a motorcyclist restores an AGM battery for his motorcycle. We are talking about filling the inside of a dried (or dried out) battery as much as possible with distilled water through a syringe . And when the separator plates are saturated with water, the battery can be charged at normal current: 10% of the rated capacity.

In the case of restoring an AGM battery for a car, you can try to “reanimate” the battery in the same way. According to stories from car enthusiasts on forums, sometimes this really helps.

There is another original way to restore a “dead” AGM battery. In this case, you can try to “deceive” the charger by connecting it simultaneously to two batteries, one of which is “live” . If the battery that needs to be restored begins to draw current after some time, then it can be restored. After some time, you should disconnect the second battery from the charger and continue to charge the “waking up” battery in the normal current and voltage mode (10 percent current of the capacity and voltage no more than 14.8 volts).

If you purchase an AGM battery, you should take care of its proper operation so that you don’t have to think about whether it can be restored. Remember that even if the recovery of such a battery is effective, it is unlikely to work for a long time after that. And if you treat it correctly, it will “conscientiously” exhaust its resource, and it will not have to be opened again and subjected to actions that cannot promise one hundred percent effectiveness.

Battery types

“WET” refers to all types of liquid batteries, from serviced to maintenance-free options. After all, both batteries contain liquid electrolyte, only in some it is freely available - you can unscrew the caps and look inside. Usually these are so-called “antimony” and “hybrid” batteries; distilled water must be poured into them, because it boils away when charging.

But for others, the electrolyte is sealed hermetically, and there are only valves to relieve excess pressure. These are typically "calcium" batteries and have calcium and silver added to the lead plates. There is virtually no evaporation and they do not require the addition of water.

I wrote about the types in the article - about the choice of batteries, there is even a video, watch - read very useful information.

What it is?

AGM lead-acid battery technology was developed by Gates Rubber Company engineers in the early 1970s. The key feature of these batteries is that they do not contain liquid or gel electrolyte, as in classic or gel devices, but absorbed one. This design gives a number of new properties to this device.

Typically, this type of battery is used these days in premium cars, for cars with a high degree of energy consumption and for cars equipped with a start-stop system. Also, this type of device has found application where deep discharge is required, for example, in marine transport and in uninterruptible power supplies. AGM batteries have powered F-18 fighters and B-52 bombers from 1985 to the present day.

In the classic model of a lead-acid battery, the case is divided into compartments by microporous plastic separator plates. A solution of sulfuric acid, an electrolyte, is poured into these compartments, and positive and negative plates are immersed in it. Electric current flows between these plates with different charge poles.

Unlike classic lead-acid battery technology, AGM uses a porous glass fiber filler impregnated with a liquid electrolyte. The distribution of liquid in the filler is carried out in such a way that constant recombination of gas occurs in the system.

Thanks to this approach, the device body can be kept completely sealed, eliminating the leakage of caustic liquid during operation.

AGM battery configurations can be either spiral or flat. Devices with a spiral design are manufactured mostly in North America, while devices with a flat design are manufactured in North America and Europe.

Spiral cells have a larger surface contact area, so they can charge faster and deliver higher currents for a short period of time. On the other hand, compared to flat cells, spiral blocks have a lower specific battery capacity. Flat blocks are more widely used these days.

Spiral elements are patented by Johnson Controls and cannot be used without its consent, unlike flat models.

Attention! For stationary charging of AGM batteries, it is advisable to use a special charger with fixed output voltage.

Of the batteries with a service life of 5-12 years, AGM batteries are the cheapest. Such a battery can withstand up to 200 cycles of 100% discharge. Only these devices can be used in any position, for example on their side.

This is interesting: The design and principle of operation of batteries

Rules for using AGM batteries

To increase battery life, you should adhere to the following rules:

- As a preventive measure, before installing the battery on a car, it is necessary to equalize the product or the entire group. This will prevent possible deviations in component voltages from the average value. Charging with a constant voltage parameter of no higher than 2.4 volts for the component is carried out within 2 days, no more. This procedure will allow you to determine the presence of a defective product. The completion of the equalizing charge procedure will be indicated by the current consumption value, which will remain unchanged for two hours.

- One brand of AGM battery can be used in one group or system. Moreover, the products must be in the same series, and the nominal capacity must be identical. If these conditions are not met, the service life of individual batteries may be reduced. If there is a significant difference in the date of manufacture, the service life of all devices in the group decreases.

- When the product is deeply discharged, sulfation of the plates occurs, which leads to a decrease in service life. Sulfation is the process of the appearance of lead sulfate on the anodic and cathodic components, which is not removed in any way. The appearance of sulfation is due to the complete discharge of the product, operation under conditions of constant undercharging, long-term storage without recharging, and operation at elevated temperatures. If the battery has a function for adjusting the residual voltage, it must be used.

- If the battery is used in cyclic or buffer modes, the consumer must comply with the current and voltage parameters specified by the manufacturer. Therefore, when recharging, it is important that the charger has functions for adjusting the basic parameters. With chronic undercharging, the actual service life of the product decreases. When setting the basic values on the charging equipment, it is taken into account that the constant voltage value should be 30%. We are talking about the voltage from the total capacity of the device during a ten-hour discharge.

- If the battery is stored in a garage or indoors, the temperature conditions in it must be maintained. The optimal value for storage is 20-25 degrees. This will ensure all performance characteristics prescribed by the product manufacturer.

- It is not allowed to store the battery in a discharged state. If you plan to dismantle the product and store it for a long time, the device must be recharged before performing the task. The procedure for carrying out the task is carried out by charging equipment. It is important that the operating parameters of the product correspond to the battery charge of the required capacity.

- If the battery is stored for a long time in a garage or other premises, the consumer must periodically charge it at least once every six months. In this case, you must follow the manufacturers' instructions described in the service manual for the battery and charging equipment.

If the battery storage temperature is more than 25 degrees in the room, this will lead to an increase in the self-discharge value, and you will have to recharge more often.

Is it possible to restore an AGM battery?

The likelihood of battery recovery depends entirely on the service life and condition of the product as a whole. The principle of restoring the functionality of the device is similar to restoring the operation of traditional products. They use the same electrolyte, only in a slightly different form. It is necessary to fill all dried internal elements with distillate as much as possible, for which a syringe is used. After the separator elements are saturated with liquid, the product can be charged; the charging current will be 10% of the entire capacity.

There is one unique option for restoring the product. When implementing it, the consumer must “deceive” the charger by connecting two batteries to it at once, one of which must be known to be working. If a discharged product consumes current over time, it must be restored. A few hours after charging begins, the second battery is disconnected from the equipment, and the device will continue to charge the discharged product.

Channel 13 Sound presented the result of replacing the working substance inside a product developed using AGM technology.

Pros and cons of technology

The AGM technology used has certain disadvantages. These include the large weight of the product, and to charge such batteries it is necessary to use a special charger designed to provide stable parameters. It is not recommended to store a battery with a low charge for a long time so that the voltage in the banks does not drop below 1.8 V.

When determining the advantages and disadvantages, the negative aspects usually include the sensitivity of the power source to an increase in the charge voltage. It is unacceptable to supply more than 15.2 V to the terminals of a twelve-volt device. In cold weather, an AGM battery can produce a noticeably reduced voltage. When purchased in any store, the price tag will be higher than that of classic batteries.

If we consider the pros and cons together, the following positive parameters will outweigh the negative. After all, their self-discharge is significantly less, and the charging speed is 2–2.5 times higher. This ability reduces the negative effect of the generator not fully charging the battery in urban environments.

A short-term deep discharge turns out to be not so critical. Due to the sealed design and valve adjustment, acid leakage and terminal oxidation are prevented. The battery can be mounted in any position. Even in conditions of increased vibration, the service life of the device is not reduced.

Benefits of AGM technology

Advantages of this type of battery:

- there is no need for maintenance;

- the design is hermetically sealed (relatively, there is a gas emission valve), there is no possibility of damage to the terminals and body when acid fumes evaporate;

- at the time of a possible accident, electrolyte does not spill out, the probability of a battery explosion is minimal;

- the tightness of the structure makes it possible to mount the battery in almost any position, with the exception of “upside down”;

- stable operation when the temperature drops to minus 30 degrees Celsius (it is not recommended to use a weakly charged battery at lower temperatures, this is due to the risk of electrolyte crystallization in the separators);

- Batteries with AGM technology are less sensitive to strong vibrations;

- the ability to withstand full discharge-charge processes three to four times more than conventional batteries;

- increased charging speed (up to two times);

- the ability to remain at half-discharge for a long time without changing the electrochemical properties;

- increased service life;

- lower price than batteries using GEL technology (they belong to the same type of Valve-Regulated Lead–Acid battery VRLA).

It is no coincidence that some military aircraft (B-52, F-18) are still equipped with AGM batteries.

Gel technology

The design of a gel battery is similar to AGM, but the electrolyte is not absorbed by glass fiber, but thickened with silica gel (SiO2). The gel retains the electrolyte in its structure, maintaining the integrity of the lead plates. The movement of electrolyte molecules occurs through the micropores of the gel structure.

Now let's compare the characteristics and cost of similar batteries made using different technologies. Based on data sheets (performance characteristics) and an interview with an engineer, we will compare the characteristics using the example of Delta and Challenger batteries.

1) Charge

The classic charge current for lead-acid batteries is 0.1C or 10% of the battery capacity, but the maximum permissible charge current for AGM and gel batteries is different:

- AGM – 0.3C (for example, for battery Delta HR 12-100 (100Ah) – charge current 30A)

- GEL – 0.2C (for battery Delta GX 12-100 (100Ah) – charge current 20A)

Charging with maximum current slightly reduces the battery life (by 5-7%), but can be very useful in cases where the battery needs to be charged quickly. For example, when working in hybrid systems with a generator. Thus, the minimum possible charging time (taking into account efficiency) for a completely depleted AGM battery will be about 6 hours, and for a GEL battery – 8 hours.

2) Number of cycles

Let's compare the number of cycles for different types of batteries in two different series

Delta HR 12-100 (AGM) : 100% DOD - 275 cycles, 50% - 575 cycles, 30% - 1325 cycles

Delta GX 12-100 (GEL): 100% – 325 cycles, 50% – 700 cycles, 30% – 1850 cycles

Delta DTM 12-200 L (AGM): 100% – 275 cycles, 50% – 550 cycles, 30% – 1200 cycles

Delta GX 12-200 (GEL): 100% – 325 cycles, 50% – 700 cycles, 30% – 1850 cycles

So, the difference in cyclicity between the HR (AGM) and GX (GEL) series at DOD 50% is 21.7% in favor of the latter; between DTM and GX: 27.2% in favor of the latter.

For objectivity, we present a graph and data on Challenger batteries series A (AGM) and G (GEL) at a discharge of up to 80%

Challenger A12-200 – 80% DOD – 525 cycles Challenger G12-200 – 80% DOD – 645 cycles 19% difference.

3) Current retail price and cycle cost

Due to the unstable exchange rate, I had to indicate in the hated dollars. In relation to the number of cycles at 50% discharge:

- Delta HR 12-100 – $223/575=0.406

- Delta GX 12-100 – $240/700=0.343

- Delta DTM 12200 L – $390/550=0.709

- Delta GX 12-200 – $467/700=0.667

For Challenger:

- Challenger A12-200 – $475/525=0.91

- Challenger G12-200 – $550/645=0.85

4) Deep discharge

Thanks to the use of an electrolyte thickener, a gel battery is more resistant to deep discharges, in other words, a discharge up to 1.6V/el (9.6V) causes less harm to the battery. Deep discharge of batteries is inherent in alternative energy (solar panels, wind turbines); in buffer modes, UPSs and inverters do not allow the battery to discharge below 10.5V.

5) Lifespan

The lifespan of a battery is a relatively abstract thing due to the fact that it is difficult and costly to conduct a professional study with parallel operation of a sample of two types of batteries from different series lasting 10-12 years and compare its results. The documentation indicates the same battery life. In view of this, we must rely on indirect data that is given to us by production engineers, whose opinion is based on the features of manufacturing technologies. So:

- DTM – standard AGM battery

- HR and HRL - differ in the composition of the electrolyte, to which special additives have been added, which increase energy output and slow down the process of sulfation and corrosion of the lead plates of the battery, significantly extending its service life

- Gel – electrolyte thickened with silica gel

Based on a survey of experts, the rating of the viability and timing of work in the buffer mode, from least to greatest, is built as follows:

- GX – a guide to cyclicality

- DTM L – Long Life additives

- HR – additives + high energy efficiency