Today, gas is considered the easiest mineral raw material to use. Many people use this type of fuel every day in everyday household tasks such as cooking, space heating and water heating. In this case, it is necessary to somehow control gas consumption. For these purposes, a special measuring device was created. The operating principle of gas meters may differ depending on the design features of specific models, as well as the underlying mechanism.

General description and device

Such a device is connected to the main pipe supplying a private house or apartment. The connection can be either outdoor or located inside the building itself. A gaseous substance enters through the meter, and it, in turn, counts the volumes passing through. The display shows the user only the final information in the form of the number of cubic meters consumed. The operating principle of a gas meter may differ depending on the mechanism for calculating the flowing gas. The appearance of the devices will also be different. For example, mechanical meters may not have their own display to display information, but use a special counter with red divisions that indicate certain fractions of a cubic meter.

The design of a gas flow meter involves three main elements. The first of these is a completely sealed housing in which all other components are located. Others include the measuring transducer itself and the counting device. How the last of the listed elements will be affected by the device depends on the principle of flow conversion. An example is a mechanical device that uses different physical properties of gases to move the reading arm. If we are talking about an electronic device, then information is obtained by converting the flow into electrical impulses.

Device

There are several modifications of mechanical devices for the safe supply of gas from cylinders. In all cases, an identical basic device is used.

The gearbox consists of the following parts:

- spring lock;

- membrane element;

- reducing valve.

The functioning of the mechanism is reduced to a decrease in gas pressure during the transition from the container to the consuming device. The average pressure of the liquefied mixture is more than 150 atm. When it enters the pipeline or consumer chamber, the indicator decreases to a minimum (1-70 atm.). The exact value depends on the characteristics of the device.

The action of the spring inside the gearbox is aimed at closing the valve, and the membrane tries to open it. The membrane is exposed to reduced fuel with operating pressure. When this indicator decreases below a certain point, the force from the membrane outweighs and the valve opens. Along with the traditional equipment, the gas reducer sometimes includes a pressure gauge and valve. They make it possible to regulate the pressure of the supplied gas.

Main types of products

As a rule, a general classification of all meters is carried out into two types according to their intended purpose - household and industrial. The division occurs according to one criterion taken as a basis. We consider how much gas the device is capable of passing in one hour of operation. At the same time, the operating principle inside and the design of gas meters of both types in some cases may be completely the same.

- Appliances. The most common among them are products with a throughput capacity of no more than 12 cubic meters per hour. The measurement principles in such devices can be based on membrane, diaphragm and rotational methods.

- Industrial devices. This category includes all devices that can flow more than 12 cubic meters per hour. If this indicator does not exceed 200 cubic meters for a given time period, then rotational measurement methods are used. In more powerful models, the principles of turbine and vortex mechanisms already operate.

Operation after installation of the gearmotor

The set of documents includes two passports - the mechanism itself and the lubricant. They are needed at all stages of operation. In the lubricant passport, the manufacturer enters information about the frequency of replacement of the composition, the rules for its selection and refilling methods.

The gearbox passport contains recommendations for operation, installation, and first start-up. The following data is entered into it:

- based on inspection results (checking distortions and displacements);

- after an audit of security programs at the enterprise;

- based on the results of repair work (adjustment, elimination of backlash, overhaul);

- about TO.

Every employee who may find themselves at the installation site of a geared motor . What does this include:

- control of hatches (always closed);

- preventing dust from entering the device body;

- prevention of accidents due to foreign objects getting into moving parts (fasteners, tools, personal protective equipment cannot be placed on the equipment during work, repair, inspection, maintenance).

Use of lubricants

The recommended type of lubricant must be indicated in the lubricant data sheet. Lubricant replacement for most gearboxes is carried out 2-4 times a year during scheduled maintenance.

After 2 weeks of operation after installing the gearbox, it is necessary to remove the primary wear products of metal moving elements from its oil. This is done like this:

- the gear motor stops;

- the composition is completely merged;

- Gearbox oil is passed through a filter;

- After filtration, the composition is poured back into the container.

An important parameter is the pour point of the lubricant composition; it should not be equal to or exceed the statistical ambient temperature. For bevel-helical gearboxes it is usually set at 60 degrees (oil bath).

Gas meter models

The required type of device is selected based on the maximum volume consumed. The cost of products with different throughputs can vary greatly. Each city has its own gas distribution company. Most often, its representatives strongly recommend the use of certain specific models. This approach simplifies life for both the gas consumer and the operating personnel at these enterprises. The fact is that the company’s specialists are trained to inspect and repair the very models that are recommended for purchase by the end user. Spare parts are always available in stock, and staff will be able to provide more qualified support in the event of a device breakdown.

Also, on the hotline, companies can suggest the appropriate operating principle of a gas meter for the existing infrastructure in the house. You should go shopping at any hardware or construction store in the city. In modern realities, it is also possible to purchase online from trusted suppliers, because any special performance check is not carried out at a regular retail outlet.

Water pressure reducer: how to adjust?

To configure the device correctly, you need to decide which model you will purchase. Most gearboxes are adjusted at factories (they already have a preset pressure). This is usually done by developers of relatively cheap brands of devices, for example, Italians.

The usual adjusted water pressure is 3 bar (3 atmospheres). As a rule, this pressure is quite enough for a country cottage or city apartment. However, this pressure is often too high (for a boiler) or too small (if the house has several floors). In such a situation, you can always change the fluid pressure.

In inexpensive models, a screwdriver or wrench is used for adjustment. But it is necessary to take into account that you will need a pressure gauge with scale coefficients an order of magnitude higher than what you plan to set. It is recommended to set pressure gauges to 10 bar. The adjustment is performed when the pressure reducer is already fixed, the pressure gauge is connected to it and there is water in the water supply.

Now slowly, using a wrench or screwdriver, you need to turn the central rod of the device clockwise if the pressure decreases, or against it if it increases. You need to look at the numbers on the pressure gauge. Usually 2-3 turns are enough to change the pressure range by 1-1.5 bar.

More expensive brands are adjustable without additional tools. The manufacturer took care of the convenience of consumers in advance. A special handle is already installed on the main rod. It is enough to turn it clockwise or counterclockwise a few turns. The result can be seen immediately.

Characteristics of gas meters

In addition to throughput, there are several other important parameters for such devices. They do not depend on the operating principle and design of the gas meter and are considered the same for all similar products. A list of other characteristics is presented below.

- Number of simultaneously supported devices. In some cases, it is necessary to keep records not only of a gas stove, but also, for example, of a heating boiler using this fuel.

- Distance between axles. Valid for all models with top connection. For devices with two gas devices, it is 11, 20 or 25 cm. If three sources of consumption are under control, then the distance can be 20 or 25 cm.

- Thread diameter. Depends on the same parameter for the pipe. In private houses, as a rule, the diameter of the main line is larger than in apartments.

- Intervalidation interval. The maximum period after which inspection of the device by specialists is required.

Basic rules for gearbox installation

The gearbox is installed only after removing all remnants of the packaging in which it arrived at the site. The equipment is placed on a prepared foundation - a rigid, strong foundation that will not sag under the weight.

When the base subsides, its shafts may become distorted: additional force will be placed on the bearings and moving parts, their wear will accelerate and the mechanism will fail ahead of time. To avoid the same consequences, it is necessary to strictly control the compatibility of the shaft axes (motor, mechanism) at each stage of gearbox installation.

Before installing a gearmotor delivered disassembled, you need to check:

- gear housing outside and inside (tightness, cleanliness, general condition);

- quality and availability of bearings;

- rigidity of supporting parts;

- parting plane;

- gaps.

If the gearmotor assembly contains mounted components (stars, couplings on a shaft or pulley), they must be heated (to 100–150 degrees minimum). This will help reduce insertion effort and ensure the tightest possible fit. Do not hit the coupling with impact tools during the process (this may damage the bearings or other components of the kit).

After installation, check that the gear axes are parallel to each other, and the distance between the central points of the shafts corresponds to the data sheet.

Electronic gas meters

Most suitable for measuring in apartments with central heating and hot water supply. Most models have low throughput, which will be sufficient in such conditions. Small-sized options like the Grand 1.6 product can measure flows of no more than 1.6 cubic meters per hour. This is considered the optimal value when connecting the device to a gas stove.

The operating principle of electronic gas meters is that the measurement is carried out by an indirect method. In this case, the flow speed has a direct impact on the frequency of automatic oscillations created using the built-in jet generator.

Varieties

Reducers are equipped with cylinders for storing various gases - acetylene, hydrogen, argon, oxygen, propane-butane, etc. For convenience, they are painted in different colors. Reducing devices are conventionally divided into models for flammable and non-flammable mixtures. Cylinders for flammable gases are equipped with a left-hand thread. On containers of the second type, right-hand threads are used. This prevents erroneous switching of the reducer for a different type of gas.

Reducing devices used to equip containers with liquefied hydrocarbons are supplemented with developed fins. This prevents freezing of the gas mixture inside the supply pipe. Gearboxes intended for use in industrial environments are usually equipped with 1-2 pressure gauges.

Similar articles

- Advantages of metal gas cylinders

- Cylinder gas installations: advantages and applications

- International requirements for gas cylinders

Membrane gas meters

As a household appliance it is one of the most common options. They are also called diaphragm. The principle of operation of a membrane gas meter is to alternately fill two measuring chambers. There is a special membrane between the compartments. It is from this fact that the name of such devices comes.

The volume of each chamber is strictly fixed. The connected valves at the inlet and outlet operate in asynchronous mode, that is, they alternately release and admit gas. The drive of the counting device is rotated thanks to a lever that converts membrane vibrations. Next, the consumption indicator is displayed on an external display.

An excerpt characterizing the gas reducer

“If Bagration did not exist, il faudrait l'inventer, [it would be necessary to invent him.],” said the joker Shinshin, parodying the words of Voltaire. No one spoke about Kutuzov, and some scolded him in a whisper, calling him a court turntable and an old satyr. Throughout Moscow, the words of Prince Dolgorukov were repeated: “sculpt, sculpt and stick around,” who consoled himself in our defeat with the memory of previous victories, and Rostopchin’s words were repeated about the fact that the French soldiers must be excited to fight with pompous phrases, that the Germans must be reasoned logically, convincing them that it is more dangerous to run than to go forward; but that Russian soldiers just need to be held back and asked: be quiet! From all sides new and new stories were heard about individual examples of courage shown by our soldiers and officers at Austerlitz. He saved the banner, he killed 5 French, he alone loaded 5 cannons. They also said about Berg, who did not know him, that he, wounded in his right hand, took the sword in his left and went forward. They didn’t say anything about Bolkonsky, and only those who knew him closely regretted that he died early, leaving behind a pregnant wife and an eccentric father. On March 3, in all the rooms of the English Club there was a groan of talking voices and, like bees on spring migration, scurried back and forth, sat, stood, converged and dispersed, in uniforms, tailcoats and some others in powder and caftans, members and guests of the club . Powdered, stockinged and booted footmen in livery stood at every door and strained to catch every movement of the guests and members of the club in order to offer their services. Most of those present were old, respectable people with wide, self-confident faces, thick fingers, firm movements and voices. This kind of guests and members sat in well-known, familiar places and met in well-known, familiar circles. A small part of those present consisted of random guests - mainly young people, among whom were Denisov, Rostov and Dolokhov, who was again a Semyonov officer. On the faces of the youth, especially the military, there was an expression of that feeling of contemptuous respect for the elderly, which seems to say to the old generation: we are ready to respect and honor you, but remember that after all, the future belongs to us. Nesvitsky was there, like an old member of the club. Pierre, who, at the orders of his wife, had let his hair grow, had taken off his glasses and was dressed fashionably, but with a sad and despondent look, walked through the halls. He, as everywhere else, was surrounded by an atmosphere of people who worshiped his wealth, and he treated them with the habit of kingship and absent-minded contempt. According to his years, he should have been with the young; according to his wealth and connections, he was a member of the circles of old, respectable guests, and therefore he moved from one circle to another. The most important old men formed the center of the circles, to which even strangers respectfully approached to listen to famous people. Large circles were formed around Count Rostopchin, Valuev and Naryshkin. Rostopchin talked about how the Russians were crushed by the fleeing Austrians and had to make their way through the fugitives with a bayonet. Valuev confidentially said that Uvarov was sent from St. Petersburg in order to find out the opinion of Muscovites about Austerlitz. In the third circle, Naryshkin spoke about a meeting of the Austrian military council, in which Suvorov crowed the rooster in response to the stupidity of the Austrian generals. Shinshin, who was standing right there, wanted to joke, saying that Kutuzov, apparently, could not learn this simple art of cock-crow from Suvorov; but the old men looked sternly at the joker, letting him feel that here and today it was so indecent to talk about Kutuzov. Count Ilya Andreich Rostov, anxiously, hurriedly walked in his soft boots from the dining room to the living room, hastily and in exactly the same way greeting important and unimportant persons whom he knew all, and occasionally looking for his slender young son with his eyes, joyfully resting his gaze on him and winked at him. Young Rostov stood at the window with Dolokhov, whom he had recently met and whose acquaintance he valued. The old count approached them and shook Dolokhov's hand. - You are welcome to me, you know my fellow... together there, together they were heroes... A! Vasily Ignatich... is very old,” he turned to a passing old man, but before he could finish his greeting, everything began to stir, and a footman who came running, with a frightened face, reported: “You’re here!” The bells rang out; the sergeants rushed forward; The guests scattered in different rooms, like shaken rye on a shovel, crowded into one heap and stopped in the large living room at the door of the hall. Bagration appeared at the front door, without his hat and sword, which, according to club custom, he left with the doorman. He was not in a smushkov cap with a whip over his shoulder, as Rostov saw him on the night before the Battle of Austerlitz, but in a new narrow uniform with Russian and foreign orders and with the Star of St. George on the left side of his chest. Apparently, before lunch, he had cut his hair and sideburns, which changed his face unfavorably. There was something naively festive on his face, which, in combination with his firm, courageous features, even gave a somewhat comic expression to his face. Bekleshov and Fyodor Petrovich Uvarov, who had arrived with him, stopped at the door, wanting him, as the main guest, to go ahead of them. Bagration was confused, not wanting to take advantage of their politeness; There was a stop at the door, and finally Bagration still walked forward. He walked, not knowing where to put his hands, shyly and awkwardly, along the parquet floor of the reception room: it was more familiar and easier for him to walk under bullets across a plowed field, as he walked in front of the Kursk regiment in Shengraben. The elders met him at the first door, telling him a few words about the joy of seeing such a dear guest, and without waiting for his answer, as if taking possession of him, they surrounded him and led him into the living room. In the doorway of the living room there was no way to pass from the crowded members and guests, crushing each other and trying over each other’s shoulders, like a rare animal, to look at Bagration. Count Ilya Andreich, the most energetic of all, laughing and saying: “Let me go, mon cher, let me go, let me go,” pushed through the crowd, led the guests into the living room and seated them on the middle sofa. The aces, the most honorable members of the club, surrounded the new arrivals. Count Ilya Andreich, again pushing through the crowd, left the living room and a minute later appeared with another foreman, carrying a large silver dish, which he presented to Prince Bagration. On the platter lay poems composed and printed in honor of the hero. Bagration, seeing the dish, looked around in fear, as if looking for help. But in all eyes there was a demand that he submit. Feeling himself in their power, Bagration resolutely, with both hands, took the dish and angrily, reproachfully looked at the count who was presenting it. Someone helpfully took the dish out of Bagration’s hands (otherwise he seemed to intend to keep it like that until the evening and go to the table like that) and drew his attention to the poems. “Well, I’ll read it,” Bagration seemed to say and, fixing his tired eyes on the paper, he began to read with a concentrated and serious look. The writer himself took the poems and began to read. Prince Bagration bowed his head and listened. “Glory to Alexander forever And protect us Titus on the throne, Be a terrible leader and a good man, Ripheus in the fatherland and Caesar in the battlefield. Yes, happy Napoleon, Having learned through experiments what Bagration is like, does not dare to bother the Russian Alcides anymore...” But he had not yet finished the poems when the loud butler proclaimed: “The food is ready!” The door opened, a Polish voice thundered from the dining room: “Roll out the thunder of victory, rejoice, brave Ross,” and Count Ilya Andreich, looking angrily at the author, who continued to read poetry, bowed to Bagration. Everyone stood up, feeling that dinner was more important than poetry, and again Bagration went to the table ahead of everyone. In the first place, between the two Alexanders - Bekleshov and Naryshkin, which also had significance in relation to the name of the sovereign, Bagration was seated: 300 people were seated in the dining room according to rank and importance, who was more important, closer to the guest being honored: as naturally as water spills deeper there, where the terrain is lower. Just before dinner, Count Ilya Andreich introduced his son to the prince. Bagration, recognizing him, said several awkward, awkward words, like all the words he spoke that day. Count Ilya Andreich joyfully and proudly looked around at everyone while Bagration spoke with his son. Nikolai Rostov, Denisov and his new acquaintance Dolokhov sat down together almost in the middle of the table. Opposite them, Pierre sat down next to Prince Nesvitsky. Count Ilya Andreich sat opposite Bagration with other elders and treated the prince, personifying Moscow hospitality. His labors were not in vain. His dinners, fast and fast, were magnificent, but he still could not be completely calm until the end of dinner. He winked at the barman, whispered orders to the footmen, and not without excitement awaited each dish he knew. Everything was amazing. On the second course, along with the gigantic sterlet (when Ilya Andreich saw it, he blushed with joy and shyness), the footmen began popping the corks and pouring champagne. After the fish, which made some impression, Count Ilya Andreich exchanged glances with the other elders. - “There will be a lot of toasts, it’s time to start!” – he whispered and took the glass in his hands and stood up. Everyone fell silent and waited for him to speak.

Smart gas meters

This category belongs to electronic varieties and is considered the most modern. The main element for measurement is a block with a diaphragm. A special electronic adder calculates the total volume of gas consumed by any devices throughout the house.

The principle of operation of smart gas meters as flow meters is no different from conventional electronic devices. Nevertheless, smart versions are capable of providing more accurate data, and their additional functionality is expressed in the ability to notify the owner of a house or apartment about a leak or disruption of stable supply.

GOST and marking

According to GOST 13861-89 gearboxes for gas-flame

treatments are classified:

- According to the operating principle

: direct and reverse acting gearboxes; - By purpose and installation location

: balloon (B), ramp (R), network (C); - By reduced gas

: acetylene (A), hydrogen (B), oxygen (K), propane-butane (P), methane (M); - According to the number of reduction stages and the method of setting the working pressure

: single-stage with a spring pressure setting (O), two-stage with a spring pressure setting (D), single-stage with a pneumatic pressure setting (Z).

The gearboxes differ from each other in the color of the housing and the connecting devices for attaching them to the cylinder. Reducers, with the exception of acetylene ones, are connected with union nuts, the threads of which correspond to the threads of the valve fitting. Acetylene reducers are attached to the cylinders with a clamp with a thrust screw.

Gas meter "Grand-4"

The device uses a standard set of design components for its category. The body is made of metal. Inside there is a piezoelectric element, an analog-to-digital converter, a lithium battery, a liquid crystal indicator and other parts. All connections are made to be protected against short circuits or sparks. The established standards also require suppression of the danger from explosions of the second group.

The operating principle of the Grand-4 gas meter is based on measuring the oscillation frequency of the gas stream. A piezoelectric element in the generator converts the received data into an electrical pulse signal. The final value is proportional to the entire volume of incoming gas. Afterwards, the pulse signal is displayed using an analog-to-digital converter in the form of numerical values on the device display.

Procedure for installing the gearbox

The algorithm of actions when installing a gearmotor depends on the state in which it arrived at the place of use.

- Installation of the assembled gearbox is carried out as follows:

- foundation slabs are installed;

- the equipment is installed together with the frame;

- the location and correct fastening of bearings and transmission gears is checked;

- the position relative to the main shaft is verified (until the shafts of the connected machine and the gear shaft are completely aligned);

- The gear bearings are finally attached, the covers are closed, and the bolts are checked for tightness.

- The installation of the gearbox, which arrives disassembled, before operation is carried out according to the manufacturer’s instructions, observing the sequence of prescribed actions and the completeness of the components. The order is:

- installation of a plate for mounting the gear motor and laying the support bolts;

- audit of completeness and condition of parts;

- installing the gearbox on the frame;

- centering the gear and drive coupling half;

- connection of coupling halves into a coupling;

- installing an electric motor on the frame;

- centering the engine with the main gear shaft;

- coupling fastening (reinforced by cement filling of the frame).

First start after installing the gearmotor

Putting the gearbox into operation after a test rotation of the gear (done manually). The first launch is carried out briefly. Its purpose is to detect defects in the installation of the gear motor and eliminate them (or identify manufacturing defects, if any).

A common defect that reveals itself during first use is overheating of moving elements (felt through the housing). Its reasons may be:

- incorrect installation;

- insufficient oil level;

- Incorrectly selected gear lubricant (too viscous composition).

These reasons must be eliminated point by point - first check the oil level and check the equipment data sheet regarding selection, then look for installation defects. Overheating due to improper installation of the gearbox is possible in cases of excessive load on moving parts due to subsidence of the foundation plate, clogging of the lubricant supply, or violation of clearances in the bearings.

If the oil is normal and selected correctly, the gearbox installation was carried out without errors, you should check the installation housing. It has heat sink channels; if they are clogged (there is a lot of dust on the site), this may cause the box to heat up.

Gas meter "Betar SGBM-1.6"

Another model widely recommended by companies and installed in apartments. The meter is designed for the main load in the form of a gas stove with four burners. The operating temperature ranges from -10 to 50 degrees Celsius, and the permissible humidity can be no more than 95 percent. The reading device is made in the form of a liquid crystal indicator. The measurement accuracy reaches thousandths of a cubic meter. The operating principle of the Betar SGBM-1.6 gas meter is based on changing the frequency of acoustic vibrations of gas strictly proportional to its flow. A certain flow passes through the sensor jet unit, and the counting device takes into account the number of pulses generated.

The instructions also note that when exposed to external electromagnetic interference, a short-term failure in the display of the flow rate may occur. This problem resolves itself within 10 seconds. The source of interference, for example, may be the activation of a piezo lighter. The operating principle of gas meters with electronic readers allows for the possibility of such an impact. It is worth noting that this is not a sign of a defective device.

Adjusting the VAZ rear axle gearbox

In 90% of cases when contacting a car service center with problems with the rear axle and, in particular, the gearbox of classic Zhiguli cars, the owners are refused. The maximum that most experts can offer is to buy a new VAZ gearbox. There is only one reason for this - basic technical ignorance, because only a few will be able to correctly diagnose and adjust the rear gearbox of a classic. A new gearbox can be bought for 6-7 thousand, it will be a branded factory mechanism, after disassembly the price of the unit will be about 3 thousand, and on hand or on the market a gearbox with traces of long-term use will cost about 2000 rubles.

Only a few can correctly diagnose and adjust the rear gearbox of a VAZ 2106

It’s easier to sell a new one than to adjust or restore an old one, especially since this requires certain knowledge, and it costs the same as a qualified adjustment. Therefore, we decided to theoretically educate the owners of classic Zhiguli cars, so that if something happens, you can confidently remove, adjust, repair and install a full-fledged working unit with your own hands. But first, a few words about the design of the gearbox.

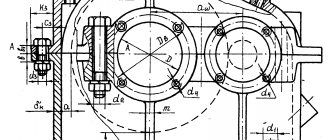

The rear axle gearbox in all classic VAZ models is installed in the rear axle housing and consists of two main components:

- bevel main gear of hypoid type;

- cross-axle differential.

The differential has the same design on all rear-wheel drive vehicles, with the exception of the all-wheel drive Niva. A self-locking differential is sometimes installed there. But he’s of no use at six, so let’s leave him alone for now.

Video tips for replacing the rear axle gearbox on VAZ cars

The main gear is of the hypoid type, made in the form of two helical gears - driving and driven. The drive gear is rigidly connected to the driveshaft of the car, mounted on the shaft on bearings pressed into the crankcase. The drive gear shaft is connected to the cardan mounting flange by a splined joint and is locked with a nut, which regulates the bearing play, but more on that a little later. The driven gear is mounted on the differential housing and rotates with it on bearings. They are secured with adjusting nuts, which adjust the gap between the teeth in the main gear engagement. Rotation on the axle shaft is transmitted through bevel gears, which mesh with the differential pinion gears. It's a little confusing, but if you look at the diagram, everything will become clearer.

Technologically, it is easiest to transfer rotation from one bevel gear to another when they are on the same axis. But in the gearboxes of rear-wheel drive cars, a gear with axles shifted by 31.8 mm is used. This complication of the design is caused by the fact that, along with the transverse slipping of the teeth, the hypoid gear causes the teeth to slip longitudinally.

The photo shows the rear axle gearbox of a VAZ 2106, the cost of which is 6-7 thousand rubles

And this, in turn, gave the following advantages:

- long gear life;

- quiet operation;

- quick grinding of teeth;

- increased ground clearance.

If both main gears are severely worn or damaged, replace them only in pairs. The fact is that in preparation for sending ready-made sets of spare parts, pairs are selected using special precision equipment, taking into account the tolerance, the correction of which is applied to the drive gear shaft. On the driven gear you can read all the necessary information about the gearbox model - gear ratio (on the VAZ 2106 it is 11/43), model 2106, serial number and production date.

In principle, one of four sets of final drive gears can be installed in the gearbox of any Zhiguli model. They differ only in the number of teeth, and this dictates the gear ratio. There is no need to say what importance this parameter has when choosing a gearbox. It affects both the maximum speed of the car and the implementation of engine torque. As garage tuners say, “it either pulls better or goes faster.” In some ways they are right.

However, as we have already mentioned, there are only four options for final drive pairs:

- VAZ 2101 - 43/10 with a gear ratio of 4.3;

- VAZ 2102 - 40/9, the most high-torque gearbox with a gear ratio of 4.44;

- VAZ 2103 - 41/10, this is the most popular medium balanced version of the gear ratio - 4.1;

- VAZ 2106 - 43/11, is the fastest gearbox, especially when paired with a five-speed gearbox, and its number is 3.9.

This set gives classic car owners unlimited possibilities to customize the car's dynamic characteristics. No “tuning” can change the dynamics of a classic as much as a rear axle gearbox.

So, for certain purposes you can buy a specific gearbox, which will change the maximum speed of the car, acceleration dynamics, fuel consumption, and traction force. The most “cargo” gearbox from 2102, pennies in a station wagon. Its maximum speed is low, about 145 km/h, but the car confidently drags quite serious loads and trailers without overloading the engine. The limit needs to be known, but the fact remains a fact. If you need a small tractor in the back of a Zhiguli, there is a 2102 gearbox with a gear ratio of 4.44 and a number of teeth of 40/9. This gearbox has become a rarity, but if you wish, you can find the main pair both new and used. The other extreme is the gearbox of the VAZ 2106. It will give the car a high maximum speed, but it will not take off from a standstill, because the traction force as a result is less than that of a two.

If the gearbox is properly adjusted, it will serve for a very long time.

A gearbox made according to technology and properly adjusted can serve for decades without reminding itself of anything at all. No noise, no hum, no ringing. This was the case until recently, but two popular products appeared on the market - fake gear oil, and a few years later, fake VAZ rear gearboxes. In most cases, everything that is sold in car dealerships and looks like a gearbox is actually just a pile of metal, unsuitable for use. The fact is that for high-quality adjustment of the gearbox, which is necessary, serious skills and sophisticated measuring equipment are needed. There can be no talk of any adjustment by eye here. And most service stations do just that, without realizing that they are simply killing a healthy gearbox. After replacement, you can check the performance of such a unit only on the go. Therefore, they are washed, painted with beautiful paint and placed on store shelves next to counterfeit lubricants. We will talk about lubrication separately, but now a little about the main malfunctions of the VAZ 2106 gearbox.

As with all units that have a closed lubricated volume, the shank oil seal can leak in the gearbox. This is noticeable right away, because after parking, drops of the transmission under the rear axle will speak volumes about it. It may also be that the oil leak is not caused by the oil seal, but by loose bolts securing the gearbox to the rear axle housing. But the most common symptom of gearbox failure is noise. The unit can make noise in different ways and in different modes, so no specialist can give any specific recommendations without listening to it personally. Nevertheless, there are the most common noise manifestations, which we will briefly discuss.

The main source of noise is a worn main pair. This sound cannot be confused with anything else, but it appears under load. As soon as you let off the gas, the noise disappears, and the active phase begins again after pressing the gas pedal. This malfunction can only be cured by replacing the main pair. Those who like to experiment can add magical additives to the lubricant, but, as a rule, these dubious means do not restore the main pair, cannot adjust the gaps, and do not change the bearings.

Gearbox bearing noise is quite easy to identify. They hum under any load, and in the most advanced cases they can even crunch at low speeds.

There are no options other than replacement to fix the problem. Except in cases where the noise was caused by improper tightening of the shank nut after replacing the oil seal. Incorrect adjustment of the gearbox can also cause a hum, but it is almost impossible to describe this noise, because it manifests itself differently in each gearbox. Gear adjustment is carried out only if you have measuring instruments, torque wrenches, the necessary probes and, most importantly, experience in this matter. An incorrect adjustment can ruin a good gearbox literally a thousand kilometers away.

A common sign of a gearbox malfunction is unit noise.

Another source of noise from the gearbox is the loosening of the shank tightening nut. It appears due to the fact that the spacer sleeve sags, the play in the bearing increases, and the nut becomes loose. The reason is insufficient tightening torque of the nut when replacing the oil seal or the disgusting quality of the metal of the spacer sleeve. In order for the gearbox to serve for a long time and happily, only certified transmission lubricants must be poured into it, preferably those specified by AvtoVAZ, observing a replacement frequency of 10-15 thousand kilometers.

Materials: https://sutkin24.ru/regulirovka-reduktora-zadnego-mosta-vaz-2106-v/

Gearbox operation

There are two main types of devices: vacuum-controlled and electronically controlled. The second option is used on the fourth generation, the most common, since it is installed on injection cars. It is worth noting that in the fifth generation there is no such mechanism; instead, an electric pump is used. The Tomasetto gas reducer or any other electronically controlled one supplies fuel under the following conditions:

- The switch is in the gas position.

- The vehicle ignition is turned on.

- There is a signal from the engine speed sensor.

The vacuum type evaporator reducer analyzes data from the fuel switch, the presence of the ignition switch, and the intake manifold vacuum. The last parameter indicates that the car engine is running. Such designs are used in conjunction with a carburetor injection system.