provides services for repair and diagnostics of gas equipment. Our specialized service performs comprehensive installation, configuration and maintenance of gas equipment. If you encounter malfunctions or malfunctions in the operation of the gas equipment, please contact our company. The table below shows prices for basic services.

| Name of service | price, rub. |

| Replacing the gearbox with a similar one | 1500 |

| Replacing the gearbox with another one | 2300 |

| Gearbox overhaul | 2700 |

| Installation / dismantling of a toroidal cylinder | 1800 / 900 |

| Installation/removal of a cylindrical cylinder | 2500 / 1100 |

| Replacing the gas/petrol valve | 800 |

| Gas valve installation | 1000 |

| Installation/replacement of faucet (domestic car) | 1500 |

| Installation/replacement of mixer (foreign car) | 1500 |

| Switch installation/replacement | 1800 |

| Installation/replacement of VZU | 1800 |

| Installation of VZU in the gas tank hatch | 2200 |

| Replacing the multivalve | 1800 |

| Replacing the evaporated gas filter | 400 |

| Replacing the filter in the gearbox (without removing the ed.) | 800 |

| Replacing the filter in the gearbox (removing the ed.) | 1800 |

| Diagnostics and configuration of the 2nd generation | 1200 |

| Diagnostics and configuration of the 4th generation | 800 |

| Replacing the Valtek repair kit (1 injector) | 350 |

| Removing the manifold | 2200 |

| Dismantling of 2nd generation gas equipment | 3000 |

| Dismantling the 4th generation 4 cyl. | 3500 |

| Dismantling the 4th generation 6 cyl. | 4500 |

| Dismantling the 4th generation 8 cyl. | 5500 |

| Replacing electronics 4th generation 4 cyl. | 5600 |

| Replacing the engine compartment of the 4th generation 4 cyl. | 6500 |

| Replacement of electronics 4th generation 6-8 cyl. | 7600 |

| Replacing the engine compartment of the 4th generation 6-8 cyl. | 8500 |

| Maintenance 1.2 (replacement of 1 filter, leak test and adjustment) | 1200 |

| Maintenance 3 (replacing 2 filters, cleaning the gas valve and setting up) | 2500 |

| Replacing the 4 cyl. wire harness. | 3500 |

| Replacement of wire harness 6-8 cyl. (without dismantling the collector) | 4500 |

| Installation of gas equipment with customer equipment (new and used) 4 cylinders | 9000 |

| Installation of gas equipment with customer equipment (new and used) 6 cylinders | 11000 |

| Installation of gas equipment with customer equipment (new and used) 8 cylinders | 13000 |

Step-by-step instructions for removing HBO from a car

It is not difficult to figure out how to remove gas equipment from a car, but it is still recommended to trust specialists in such a matter. Dismantling work includes several main stages:

- "Getting rid of" basic equipment.

- Disabling control systems in the cabin.

- Installation of a plug on the conductive line in case of partial shutdown.

During a partial shutdown, the internal system remains intact. Only the balloon is removed. Plugs are placed in the main line and the control connector. To turn off the power to the battery, you need to pull out the fuse on the positive pole. Such manipulations take very little time, there is no need to visit a service station, these procedures can be carried out yourself. And if it is necessary to resume operation of the gas system, you will not have to pay for installation again.

From a passenger car

The easiest way to figure out how to remove the LPG from a car with your own hands is if an old-style system is installed. The dismantling of a modern model of the latest generation should still be entrusted to a specialist. The shutdown sequence is described below.

- The entire system is completely emptied of gas. If an old-style model was used, it is recommended to remove the cylinder and start the car, this will completely exhaust the remaining gas in the system.

- The system is completely de-energized.

- The tubes carrying the gas are disconnected.

- The gas cylinder is removed. When removing the cylinder, all valves must be closed. To ensure that nothing interferes with subsequent operation, the cylinder mounting system is also removed.

- Electronic elements and sensors, switches and injectors located in the cabin on the control panel are removed.

- The vacated holes are hermetically sealed with plugs.

- The cooling system pipes are replaced with new ones.

- The plug is placed on the neck.

- Corrosion or rust most often appears in places where parts are attached during long-term use. Such areas should be treated with an anti-corrosion agent and coated with a protective agent.

Sometimes it happens that after gas equipment (LPG) has been installed, it needs to be dismantled and returned to the original system, which involves the use of gasoline. In what cases are such actions justified?

Assembly

Before installation, wipe the seat and treat it with sealant. Be sure to replace the sealing rubber, having previously lubricated it with silicone grease.

- Adjust the float on the new “cartoon” so that the sensor shows the correct amount of gas in the cylinder. This should be done carefully, bending the float mount so that when the arrow on the gas level sensor is at its maximum position, the float is also in the highest position in the cylinder.

- We install the “cartoon” into the cylinder. After installation, the float should be in the lowest possible state (touching the bottom of the cylinder), and the gas level sensor on the multivalve should show “empty tank”.

- Paying attention to the quality of gas at our gas stations, it is a good idea to install a filter on the intake pipe.

- We install and secure the multivalve by carefully tightening all the fastening bolts crosswise. Tighten the bolts one at a time, avoiding misalignment. To avoid oxidation and rusting of the bolts, it is recommended to pre-lubricate them with thick lubricant.

- Reconnect the fuel line tubes and tighten them carefully.

- Prepare and take a soap solution with you. The easiest way to make it is using liquid soap and warm water.

- At the gas station, fill the cylinder with the minimum possible amount of gas . unscrew the multivalve valve, perform a “soaping” and check for gas leaks. If bubbles are detected, tighten the mounting bolts until the leak disappears. Do not overdo it so as not to break the thread!

This completes the replacement of the HBO multivalve. If you have any questions, ask them in the comments, we will be happy to answer them.

When to remove HBO

Firstly, this occurs if the vehicle (vehicle) must be registered with the traffic police. In this case, partial dismantling is selected, which involves removing the gas equipment and reinstalling it after inspecting the vehicle.

Secondly, if the car has a new owner who, for some reason unknown to us, does not want to use gas, but wants to return to traveling on gasoline.

Thirdly, if the gas kit fails and cannot be repaired. In this case, it is definitely necessary to return to the fuel system that was installed at the factory and restore its operation in full.

There is a serious difference between what actions will be performed in one case or another. The following parameters vary:

- scope of work (if the withdrawal is nominal, then it will be necessary to perform a minimum of operations, but if there is a return to the old system, then it will be necessary to perform the entire range of work);

- equipment that needs to be brought in (for example, will a lift be needed);

- the need to use additional materials (for example, we can talk about special plugs, re-painting places where corrosion has occurred.

Complete dismantling of the system

As mentioned above, if it is necessary to return to the factory fuel system, then the LPG system must be completely dismantled. In this case, all elements that were previously installed on the car are removed in full. Those holes that were made for the operation of the gas system are sealed, and the engine and injectors are calibrated. We should also not forget that the internal combustion engine must return to its original order of functioning, which means that the “brains” of the car should be cleaned.

The range of work that needs to be performed is quite diverse. First of all, you need to get under the hood and remove the gas reducer, work with filters and injectors, dismantle the ECU unit and hoses, remove the clamps and rack.

After this we move to the salon. This is where the fuel switch button is removed. If the cylinder was installed in the cabin, then it is clear that it should be dismantled.

The next point is the trunk. There, too, you need to remove the holder brackets, and also remove the cylinder if it was there.

In the body, it is necessary to remove the external filling device and the fittings in the bumper if they are installed in the bumper or fender.

The most difficult thing is the complex of works associated with the engine. There it is necessary to install plugs that close the entrance to the intake manifold, and after the LPG system is dismantled, it is necessary to carry out electronic diagnostics of the internal combustion engine and the required calibration. And the final stage should be to remove the line on the bottom of the vehicle.

All this work requires certain equipment, this could be a pit or a lift. If the car had a 2nd generation gas system, then do not forget about the gas valve (this is especially true for carburetors of the Gazelle brand). If the new, 4th generation LPG was dismantled, it is necessary to remove the ECU unit, which was necessarily installed for vehicles that have an injector in their design.

In order to complete the work associated with dismantling the equipment, it is necessary to install plugs in all places where technological openings were previously installed for the operation of the LPG system, and also make sure that there is no corrosion inside the trunk and along the body. If it is present, it must be removed.

Partial dismantling of the system

All of the above concerned complete dismantling, that is, the second and third options. But if it is necessary to carry out partial dismantling for a certain time, then the procedure will be slightly different.

Masters claim that in this case everything happens much simpler. At the first stage, you need to remove the cylinder, reducer, ECU and VSU. All other structural elements are stored on the car so that they can be easily connected after passing the technical inspection.

At the second stage, the dismantled gas equipment is returned to its place of operation, and the operation of the system is restored. It doesn't take long, about one hour for each stage. Moreover, these works are so simple that they do not even require the use of special equipment - a lift or pit is not required at all.

The most important task that the technician should solve is to ensure that when removing the gas equipment, it does not harm the engine and the standard power system. To do this, following safety precautions, observing connection diagrams, as well as knowing the order and sequence of all manipulations comes to the fore. That is, knowledge and experience come to the fore.

Estimated order of work

What needs to be done in order to deal with the gas in your car and get rid of the existing LPG once and for all? The procedure is not too complicated:

- First of all, you need to turn off the power supply;

- release the remaining gas that is present in the cylinder;

- close two taps located on the multi-valve - the so-called filling and supply valves;

- remove the cylinder from the place where it was previously installed - this could be the interior, engine compartment, trunk;

- dismantle the fuel line, ECU unit and injectors;

- carry out work in the intake manifold, apply sealant to seal technological holes;

- Remove the computer, taking into account the connection and gas supply diagram.

Only after this can you approach solving problems related to restoring the standard fuel system. The technician will have to start tuning the engine, electronic diagnostics of the DIS system and clearing it of possible diagnosed errors.

A reasonable question when removing the HBO system concerns the cost of such services. If complete dismantling is planned, then it is clear that the cost will be much higher than in the case of partial dismantling. Since the cost of such work directly depends on the brand of car and the generation of the LPG system that was installed earlier, we suggest contacting our managers to determine the exact price of the entire range of services. They will help solve your problem in full.

To be confident in the quality of the work performed, we suggest you contact our company. We will help you remove LPG in Moscow, and we will also help you legalize the relationship between your new car and government agencies (for example, the Ministry of Internal Affairs or the State Traffic Safety Inspectorate).

It would seem that there is a reason to remove the LPG if the cost of gas allows you to save more than 1 hryvnia per kilometer, but there are several reasons for dismantling the LPG

we'll call it anyway.

- The car was purchased knowingly with LPG, and the new owner wants to remove it because:

- is an ardent opponent of gas equipment, because he does not want to carry an extra bulky load in the form of a cylinder in the trunk, he considers gas equipment dangerous due to burnout of valves, he simply prefers gasoline out of habit;

- The installed gas equipment is definitely not of the quality that we would like, it does more harm than good, and in general it was installed somehow makeshiftly. It is cheaper to remove old equipment and install new one than to tinker with it.

- Moral obsolescence of gas equipment and its replacement with modern ones.

- Dismantling of gas equipment

that does not meet environmental standards (replacement of equipment, for example, before a trip to Europe).

It is difficult to come up with any other reasons, since in other cases it is easier to turn off the electronic control unit and temporarily “mothball the equipment”. For example, if gas is practically not used in winter.

Signs and possible causes of malfunctions

Symptoms of a malfunction of one or more injectors may include:

- high fuel consumption;

- deterioration of the dynamic characteristics of the machine;

- unstable engine operation, internal combustion engine is tripping (one or a couple of injectors do not work);

- dips when pressing the gas pedal;

- malfunctions of various sensors, appearance of “Check engine” errors (for example, MAP sensor);

- knocking in the injectors (they “click” loudly);

- gas leaks through injectors (pouring/poisoning);

- The car stops idling and the injectors do not turn on.

The reasons for this may be:

- wear of the damper rubber rings on the valve stems (this causes the injectors to knock);

- development of the seat (seat) of the valve or its locking rubber;

- wear of the rod (also called piston, anchor) or sleeve (also called core, cylinder, bulb);

- armature jamming in the cylinder;

- weakening of the elasticity of the piston return spring;

- failure of the electromagnetic coil (solenoid);

- violation of the integrity of the electrical wiring.

All of the above reasons can appear naturally or due to low-quality parts, untimely maintenance of gas equipment, or violation of the rules for installing injectors. For example, if gas filters are not replaced on time, gas condensate (oily liquid, water, dirt) can get into the injectors, which can cause them to jam or accelerate wear.

Also, the horizontal position during installation affects uneven wear (ellipse) of the liner body and rod. And simple non-compliance with the rules for installing wires (twisting instead of soldering, mixing, improper fastening) can cause problems over time. One way or another, injectors of this type rarely survive up to 70 thousand km. mileage without repair (repair kit change). It all depends on the conditions of their use.

Dismantling gas equipment: procedure

We are sure that the services of a car service

for dismantling LPG. The procedure for dismantling the gas equipment:

- bleeding gas from lines, reducers, cylinders;

- disconnecting the lines from the cylinder, removing the cylinder fasteners to the car frame, dismantling the cylinder with a multivalve and the filling hose. The hole for the neck can be closed with a plug;

- disconnecting the line from the gearbox, carefully removing them from the luggage compartment;

- dismantling the gearbox, electronic control unit, sensors, antifreeze hoses. Replacing the cooling system pipes, since the tee at the insertion point cannot be plugged;

- removing the injectors and plugging the holes for the injectors in the intake manifold.

This is a general procedure for completely dismantling the gas equipment, but we recommend going to a Kharkov car service center

, where they will either convince you that it is better to leave the equipment, or replace it with a new one, or simply disconnect the lines and turn off the equipment units.

Suddenly you decide to return to HBO again. On average, dismantling a 2nd generation LPG

takes literally 2-3 hours,

dismantling a 4th generation LPG

takes a maximum of 4 hours.

There are cases when the installer accommodates the client and removes the equipment free of charge provided that a new gas equipment is installed, but usually the cost of dismantling the gas equipment

is about a third of the cost of installation work.

By installing Italian PRIDE by AEB systems, you can be sure that you will have to remove the LPG only when it has completely exhausted its service life or becomes obsolete. These kits solve the problem of high gas consumption of LPG

(+5-7% to gasoline consumption is the maximum for this equipment), the problem of exceeding the temperature in the cylinders is eliminated. These are cost-effective kits that are provided with all the necessary functionality.

The best service station for installing gas on a car

PRIDE by AEB - KOSTA GAS.

After all, this is not only the official representative of AEB in Ukraine, but also a service for the repair and maintenance of gas equipment

, where real professionals work. Come see for yourself!

Reading time: 3 minutes

Millions of people enjoy the benefits of HBO, and the popularity of this solution is growing every day as the economic crisis continues. Today it is installed by automakers, specialized workshops and even homemade products - in garage conditions. The attitude towards gas equipment among motorists is ambiguous, although time has proven the effectiveness and durability of its work. Nevertheless, for various reasons, it is sometimes necessary to dismantle gas equipment on a car.

Dismantling instructions

If the decision to dismantle gas equipment is made, the whole process can be divided into several parts.

But no matter what the sequence is, safety measures must be taken first. In particular:

- use up the gas in the cylinder or vent it (you can learn how to do this correctly from this article);

- shut off the fuel supply from the cylinder by tightening the multivalve valve;

- drain the remaining gas by unscrewing the flow line from the evaporator reducer or multi-valve;

- release the gas from the supply hose by removing it from the fitting of the gas injector ramp or reducer.

It is important to exclude the presence of open flames and ignition sources.

Then find a lift or inspection hole. Be sure to remove the battery terminal/s .

Electrical part

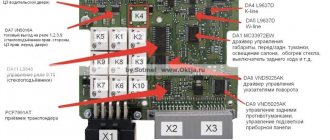

If you have no idea who installed the equipment and how, first you need to familiarize yourself with the electrical diagram for installing HBO 4. In 99% of cases, plus/minus it will coincide. The basic principles are the same, but there are exceptions. It is also better to have an idea about the HBO 4 device.

So, the first step is to remove the connectors from the following parts:

- solenoid valve coil of the shut-off valve block on the cylinder and fuel level sensor (if equipped);

- gasoline and gas injectors;

- map sensor;

- gas valve of the reducer (can be remote);

- variator UOZ (if available);

- Equipment ECU (electronic control unit);

- gas temperature sensor on the reducer.

Next, you need to disconnect the signal wire (often brown) from the ignition coil; it can also be connected to the camshaft position sensor.

After making sure that lambda regulation is involved in the operation of the HBO, carefully remove the insulation at the point where the wire (black) of the oxygen sensor breaks. Cut the wire (usually brownish-purple) and insulate the connection in reverse order.

Also disconnect the positive (red) wire from the ignition switch or it can be soldered to the supply wire of the first gasoline injector.

The most important part of dismantling is disconnecting the wiring from the gasoline injectors. There are two ways here:

- remove the old “braid” and install a new one in its place;

- leave the original tourniquet.

When choosing the second method, you must also refer to the connection diagram. Here you need to cut off two wires on each injector, soldered into the signal gap of the standard one. One plain one is directed to the engine control unit, the second with a stripe goes to the gas controller.

Then we solder the signal wire of the gasoline injector. We isolate the soldering points and put the chips on the injectors.

It is recommended to label the wires in order to simplify the possible installation of the removed harness.

Inside the car, remove the connector and dismantle the fuel selection button and buzzer.

Now you can carefully remove all the cables, freeing them from ties and clamps in advance. Also dismantle the gas equipment controller and variator.

Mechanical part

In this part, you should pay attention to dismantling the evaporator reducer. Since its heating is connected to the interior heater radiator, in order to minimize coolant losses, it is best to clamp the heater supply pipe with clamps, before and after the tee.

Then unscrew the clamps, remove the tee and in its place install a tube/adapter of a suitable diameter (preferably metal). In this case, you need to substitute a container, because the remaining antifreeze/antifreeze will pour out of the evaporator hoses. Carry out the same procedure with the return line.

Next you need to remove it from the car:

- a tube with a fine filter and a map sensor;

- a vacuum tube from the sensor to the intake manifold;

- reducer and hoses;

- gas rail with nozzles;

- flow line (under the bottom of the car);

- filling tube;

- VZU with bracket (filling valve);

- gas cylinder.

Then you need to carefully unscrew the fittings from the intake manifold and plug the holes. The plugs can be made from bolts with suitable threads. At the same time, cut them to the minimum length so as not to block the intake tract. It is advisable to apply a sealing compound to the threads.

If the vacuum tube is connected by tapping, proceed in a similar manner.

How to remove HBO from a car

It would seem that a fundamental decision should be made before installation, but there is no point in removing already installed equipment. But removing gas equipment from a car in some cases may become necessary. For example, before, or traveling abroad.

When the decision is ripe, two dismantling options are considered:

- Full.

- Partial.

In the first case, everything is clear. The machine is returned to its original condition. If the HBO is planned to be left, it will be deactivated. The cylinder is removed, the line is plugged, and a plug with jumpers is placed in the control connector. It is enough to simply turn off the power from the unit: that is, remove the fuse from the rubber chip on the positive wire of the battery. In this case, when selling the car, the value of the car will not fall.

From a passenger car

A little about how to remove a gas cylinder from a car. Let's start with the fact that this should be done by a specialist. The general operating procedure is as follows:

- The gas is completely released.

- Electrical switches off.

- The lines are disconnected, the cylinder, reducer, electronic control unit, sensors are removed,

- The injectors are removed and the holes in the intake manifold are plugged.

- The cooling system pipes are being replaced.

- The neck is plugged.

Now you know how to remove HBO from a car. We just don’t recommend doing this yourself. True, there are cases when you can still do everything yourself. We are talking about the equipment of the first generations, installed on old cars, most often Soviet-made.

How to remove gas equipment from a VAZ 2106? Nothing could be simpler. It’s better not to remove anything at all except the balloon. It is enough to turn off the tap and bleed the gas from the system. It’s even better to just start the engine and work out the rest. And then put a plug on the pipe, and that’s it. The process of installing LPG on a VAZ is described in detail in our separate section.

From GAZelle

Now about how to remove gas equipment from a GAZelle. There are no difficulties here either. The order is almost the same:

- gas is released;

- antifreeze drains;

- the balloon is removed;

- the heating system is cut out and the electrical wiring is removed;

- gas pipes are disconnected;

- the insertion points into the intake manifold are closed with rubber caps with sealant;

- The gearbox is removed.

Everything is done quickly and without financial costs. The only thing required is two straight pipe connectors with a diameter of 18 mm.

Of course, everything depends on the HBO itself. If there is a second generation, you will have to dismantle the gas valve.

Many people are interested in the question of how to remove 4th generation gas equipment. In exactly the same way, it is only necessary to dismantle the ECU.

Attention, gases!

As an alternative to gasoline, methane (natural gas) and propane-butane (petroleum gas is a by-product of oil refining) are used. Methane is more expensive and its physical and chemical properties force the use of thick-walled cylinders, because natural gas is stored and transported under a pressure of 300 atm. In addition, in order to have an adequate supply of fuel, several cylinders are required.

In a word, there is no space in a passenger car for a methane plant, and its price is so high that during normal “civilian” use the equipment takes a long time to pay for itself. Long runs are needed - hundreds of kilometers a day, which is the norm for commercial trucks. It’s easier with propane: firstly, the pressure in the cylinder does not exceed 16 atm, and secondly, the gas is liquefied, which simplifies its transportation and storage.

The supply of propane on board a gasified car is comparable to the supply of gasoline in the tank, while its consumption is only 15–20% more than gasoline.

The increased consumption is due to the lower density of the gas, which is why 1.19 liters of propane-butane (summer mixture) is equivalent to 1 liter of gasoline. And the price of gas equipment for propane, although fixed in euros, because it is produced in Europe, allows you to recoup the costs of purchasing and installing equipment in a short mileage. Once upon a time it was 15–20 thousand km, but with the latest price changes at Ukrainian gas stations, the budget LPG “beats back” for 10 thousand km. Note that here we are talking about modern 4th generation installations for injection machines. Installation “under the carburetor” costs less, which means it pays off even faster.

Gas instead of gasoline: operating principle

The operation of a car on gas looks like this: the engine starts and warms up using gasoline. After the gearbox temperature reaches 40°C, the electronics (electronic control unit - ECU) switches the machine to gas mode: the gasoline supply is shut off and the gas valve opens. Warming is necessary for the high-quality conversion of propane from a liquefied state to a vapor state. If you start immediately on gas (there is such a function, but it belongs to the emergency start), then the load on the evaporator reducer increases.

Injection occurs through gas injectors. The program stitched into the gas ECU regulates the opening time of the injector rod, thereby dosing the amount of fuel supplied.

The role of the “gas brain”: firmware and settings

Unlike previous generations of gas equipment, where the evaporator reducer ruled the roost, in modern gas equipment the key role is played by electronics. The ECU's task is to intercept signals from the car's on-board computer (BC) and adjust gas injection in a timely manner, sending signals to the injectors and gearbox. Binding to the BC is necessary because it “knows” about the current operation of the engine thanks to impulses from the sensors. In addition, the “gas brain” monitors the remaining gas in the cylinder and turns off the gas mode if there is something wrong with the gas. It turns out that the driver’s role is to fill up with gas on time and not to forget to replenish the supply of gasoline that is needed for warming up.

Most of the programs programmed into the ECU are considered universal, so after installation the specialist configures the system for a specific car. First of all, you need to create a fuel map, which is based on gasoline indicators. The cooperation between the BC and the ECU is based on the master-slave principle: the “gas brain” removes gasoline algorithms and generates gas ones using a correction coefficient. The car is adjusted while moving, in all modes.

After receiving the settings, the adjuster checks the correct operation of the system during diagnostics. In cars without feedback (gas ECU without OBD adaptation function), the correctness of mixture formation is checked with a gas analyzer. That is why untrained technicians are not recommended to install and configure LPG on their own. However, it is also better to entrust the selection of gas equipment to a specialist.

Where are dismantling services provided?

Equipment can usually be removed in the same place where it is installed - in specialized centers.

How much does the service cost?

Typically, the cost of dismantling gas equipment is approximately a third of the cost of installation. It directly depends on whether the equipment is removed completely or partially. In the first case, for a four-cylinder engine the price will be on average 4 thousand rubles. In the second, such a service costs from one thousand.

It also happens that the client is accommodated and the equipment is removed free of charge if a new one is planned to be installed in the future.

How long does it take

On average, dismantling a 2nd generation LPG takes literally 2-3 hours, dismantling a 4th generation LPG takes a maximum of 4 hours.

The most common reasons for dismantling gas equipment

- a car whose design has not been officially modified must be registered with the traffic police or submitted for technical inspection;

- an order was issued to eliminate the changes made to the design;

- it is necessary to carry out maintenance of the gas equipment or replace non-repairable system elements with new ones;

- the new owner of the car, for some reason, does not plan to use gas equipment; the car is rented out at Trade In;

- It is planned to install this HBO kit on another car.

In the first three cases, as a rule, partial dismantling of the gas equipment is carried out. To successfully pass the technical inspection and verification procedure at the traffic police, it is usually enough to remove the visible elements of gas equipment - the cylinder, reducer, air intake and nozzles (in some cases). Inspectors usually do not pay attention to lines and fittings in the intake manifold neatly laid in the engine compartment or under the bottom. There is no point in completely dismantling the gas equipment even if maintenance and repair of its individual components are required.

It is necessary to completely dismantle the LPG if it is not planned to re-install and use it on this vehicle in the future. This service is in demand mainly by new car owners who consider gas fuel unsafe or simply want to return the full volume of the trunk, as well as by previous car owners when selling their car. Complete dismantling of gas-cylinder equipment involves not only removing all additional elements of the system, but also bringing standard components back to their original form, and therefore is a more labor-intensive and time-consuming operation, taking up to four hours. The cost of complete dismantling of gas equipment is also naturally higher than partial dismantling.

Benefits from switching to gas fuel

Modern Gazelles are equipped with Euro-3 engines. The average cost of installing the system is 25-30 thousand rubles. In urban conditions, fuel consumption will be approximately 15 liters per 100 km. If the car is used intensively for transporting goods or transporting passengers, the difference in cost between gas and gasoline will cover the cost of installing LPG in just 2-4 months.

Even when using a vehicle exclusively for personal purposes, the full payback period is on average one and a half to two years. In addition, gas-cylinder equipment has a long service life and requires much less maintenance costs.

How to remove HBO from a car?

First of all, when dismantling the LPG, for safety reasons, the power supply to the vehicle is turned off.

by removing the battery terminal. Also, during work, smoking and the use of open flames are strictly prohibited. This is due to the need to bleed off remaining gas in the line.

- the filling and supply valves on the cylinder are closed;

- the gas cylinder, filling fittings, VZU (if equipped), lines are removed;

- the injectors, gearbox, ECU (4th generation) or gas valve (2nd generation) are dismantled;

- the standard cooling system line is restored;

- The fittings are removed from the intake manifold, and the technological holes in it are plugged.

To speed up the process of removing HBO, work is often carried out in the engine compartment and at the location of the cylinder and lines at the same time.

After removing the gas equipment, it is recommended to reconfigure the standard controller and calibrate the gasoline injectors. These actions guarantee stable engine operation and no errors.

Avtogaz 36 carries out professional partial and complete dismantling of gas equipment in Voronezh, as well as work on replacing gas equipment or reinstalling it on another car. Everything you need is provided.

The procedure for installing LPG yourself on a Chevrolet Niva

We already know what all types of HBO generations are and what properties they contain. Now it is important to focus directly on the independent installation of LPG on your Chevrolet Niva crossover. The most common and well-represented equipment is the fourth generation of HBO equipment, as a result of which we will use this equipment as an installation on our Niva.

Installation of the cylinder and line

In practice, only two types of cylinders can be judged to perform well: toroidal and cylindrical.

Toroidal gas cylinder

The essence of the toroidal one is that, as a rule, it should be placed in the trunk in a place provided for a spare ear. The Chevrolet Niva does not have such free space; as a result, purchasing a cylindrical cylinder is more suitable for such a car. Such a cylinder can be placed both in the trunk and under it. But as for placement, the method of securing it under the trunk is the most used, as well as the best today for such a car, which will save the already small trunk space. In this regard, it will be necessary to modify the tow bar during the final installation of the LPG. It is the location of the cylinder under the trunk that must be correct and accurate, so as not to perform installation manipulations over and over again. In this regard, as a rule, craftsmen use rubberized tapes in their work. The filling valve is important and most conveniently located directly near the place where gasoline is poured.

It will be most convenient to place the filling valve near the place where gasoline is poured.

The line refers to the brass tubes placed under the bottom of the Chevrolet Niva. This line must have a route from the cylinder to the engine compartment. To secure the lines, they are already used to tie them to the gasoline pipeline; this method is the most effective and widespread in relation to this type of machine.

Gearbox installation

The installation of the gearbox can be carried out both at the beginning of the work on installing gas equipment, and at its final stages. We will consider installing the gearbox at the very beginning of the installation, since it is with this method that you can understand the whole essence of the direct operation of gas equipment.

The gearbox itself, as a rule, should be located to the left of the engine compartment. It is attached to the body of the car, but not to the engine, this is very important! Care must be taken to ensure that it is always easily accessible.

Following its installation, it is important to make a connection in the cooling system. After installing the gearbox, a high pressure line and a vacuum pipe must be connected to it.

Gas train

It is easier to insert fittings with the manifold removed

Already immediately proceeding to the next stage, it is necessary to make an insertion of the fittings on the intake manifold. It is easier and more efficient to do drilling work with the manifold removed. It is important to carry out drilling work as accurately and carefully as possible, observing all safety rules, without causing harm to the collector. It is important that when drilling, the gas fittings are the same as the gasoline injectors, that is, they must have the same angle and be located next to each other. The thread is made on the holes that were drilled earlier. Before we screw in the fittings, it is necessary to lubricate their threads using a special high-temperature sealant.

Then you need to install the collector in its original location. Now we proceed to one of the difficult stages of the whole work - this is the installation of a gas train, which must be fixed to the upper area of the collector.

The gas train must be fixed to the upper area of the manifold

After installing the ramp, another pipeline must be laid before it, which will supply gas from the reducer, and it is also important to install a fine gas filter. With the completion of this stage, the entire technique of work is completed.

Then we move from technology to electrics, which pose a certain challenge to professional electromechanics involved in the production of wiring in Niva Chevrolet cars.

Reworking the towbar and muffler

It is important to note that when installing LPG, it will also be necessary to redo the towbar and muffler on the Chevrolet Niva, since the installation of gas equipment entails a modification of this type of device.

We have two methods of installing a towbar in our arsenal:

- Directly purchasing a new tow bar with a body kit from Bertone;

- Just remaking the towbar.

If the remaining option for you is the second, then we will briefly talk about the rework, which, as a rule, is not always successful. It can be converted like this:

- We take a tube whose diameter will be 34 millimeters and make a bend on it, similar to the rounded shape of a balloon;

- We move and trim the mounting plate, then remove the auxiliary bracket in order to avoid it from resting on the neck of the filling part.

Tow bar for Niva Chevrolet

When remaking a towbar, it must be tested for reliability.

With the completion of redoing the tow bar, we begin to redo the muffler, which also needs it. To remake it, you need to install a muffler. Two mufflers must be welded together. The second muffler should output a pipe that has a bend for the cylinder.

If you are aware of the entire procedure for installing LPG on a Niva Chevrolet crossover with your own hands, this does not yet guarantee its correct and high-quality installation. Such a process is dangerous; it requires at least the supervision and advice of a professional.

Prices for dismantling and removal of gas equipment

| Name of works | Cost of work |

| Adjustment of HBO 2nd generation | from 200 rub. |

| Computer gas adjustment 4th generation | from 500 rub. |

| Issuance of a passport for HBO for technical inspection. inspection (during installation, a passport is issued free of charge) | 600 rub. |

| Dismantling of 2nd generation gas equipment | from 2000 rub. |

| Dismantling 4th generation gas equipment | from 3000 rub. |

| Replacing the gearbox | from 500 rub. |

| Replacement of gas EMC (+ cost of EMC) | from 300 rub. |

| Replacement of the EMC gas filter (+ filter cost) | from 400 rub. |

| Replacement of gasoline EMC | from 200 rub. |

| Replacing the VZU | from 500 rub. |

| Removal - installation of the cylinder | from 600 rub. |

| Replacing fastening tapes | from 400 rub. |

| Replacing the multivalve | from 800 rub. |

| Replacing the main copper tube d = 6 mm | from 600 rub. |

| Replacing the filling copper tube d = 8 mm | from 400 rub. |

| Replacing antifreeze hoses | from 400 rub. |

| Replacing the PVT button | from 500 rub. |

| Replacement of electrical equipment (wiring) | from 600 rub. |

| Carburetor insert | from 1000 rub. |

| Installation of gas equipment 2nd generation | from 4000 rub. |

| Installation of 4th generation gas equipment | from 6000 rub. |