Checking the battery starter

It is almost impossible to check a starter installed in its original place. You will not be sure of the true cause of the problem. Therefore, it would be better to remove it. Moreover, this is not at all difficult to do on any car. Before dismantling, we check the integrity of the wiring and the cleanliness of the contacts. In some cases, simple cleaning and tightening of the terminals helps. To complete the experiment, check the supply wiring. The voltage at the contacts of the connecting cables must be the same as at the battery terminals.

Before you remove the entire assembly, check to see if the starter can drain the battery. To do this, it is not necessary to connect an ammeter and record the leakage current.

- Disconnect the power cables from the starter

- Connect the multimeter to the battery, record the voltage value (if possible, do not turn on any load: external lighting, multimedia, interior lights)

- Connect the power cables to the starter. If there are no leaks, the voltage on the battery will not change. If the value decreases, there is a problem in the starter circuit.

Important! Before disconnecting the cables from the starter, disconnect the battery terminals. This can only be done with the ignition off, otherwise there will be problems with the immobilizer

The starter motor is very powerful, and the rotor has a large mass. When starting the engine, the loose housing may be pulled out of your hands. Therefore, to check, secure the assembly in a vice.

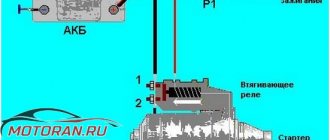

If you are not familiar with the starter design, carefully study the illustration. Then it will be easier to understand the principle of operation of the node.

Possible causes of battery failure. Details in this video.

Prevention for starter

If there is no time and opportunity to monitor the starter, and minor problems already exist, then it is recommended to carry out a little preventive maintenance. This will not help avoid significant damage, but will improve the condition of the device.

It is important to remember that during operation the car finds itself in various unfavorable environments. Due to such conditions, the metal used in mechanisms oxidizes and corrodes. Because of this, problems with the operation of the starter, as well as other elements, are possible.

To troubleshoot problems due to corrosion and oxidation, it is recommended to pay attention to the integrity of wires and contacts. To do this, you should regularly carry out the following actions:

- Disconnect the battery from the system.

- Clean all contacts with sandpaper.

- Treat all contacts with solvent or other special agent.

- Return the contacts to their place and securely fix them.

During the preventive maintenance process, it is worth checking the battery charge and the condition of the generator. If problems arise with the power system, this will affect the start and many other elements of the car. You can check the battery using a simple multimeter, and do not forget to pay attention to the wires. It is also worth looking at the condition of the crankshaft and other components of the car. This approach will allow you to detect problems at an early stage and eliminate them without significant time and financial costs.

With the onset of cold weather, many car owners experience all the “delights” of the cold season - difficulties begin with starting the engine. The reasons may actually be both the battery and the starter. This problem, when the starter turns poorly when cold, is quite common, regardless of the make of the car. As for the battery, the battery may be old or dead. And many people remember such a concept as “”. To understand what exactly is the cause of the identified problem, you need to understand where to “dig”, in what direction to move?

Wear of starter bushings

The starter armature rotates, supported by copper-graphite bushings, which are plain bearings. When starting the engine, the front bushing takes on the main load, so it wears out over time. The increased gap between the bushing and the armature shaft results in the armature being pressed against the stator during startup. This, firstly, makes it difficult to rotate, and, secondly, leads to an increase in the current in the windings. As a result, the winding insulation burns, which leads to complete inoperability of the starter.

You can read how to install a start-stop button instead of the ignition switch here

It is better to replace starter bushings in a car service - often reamers are required to adjust their internal diameter. If the starter has a front cover, usually made of aluminum alloy, then, in the absence of skills, it can be split when pressing the bushing. To replace the front starter bushing without a housing, you will need to remove it from the gearbox housing. In addition to the listed faults, defective spare parts may be found during repairs. So, for example, it happens that a purchased new bendix has a gear, teeth or housing made “out of size”, as a result of which the bendix “slips” a little further and rests against the gearbox housing. But such incidents, fortunately, are rare.

Mechanical problem

The starter spins idle if the bendix does not engage the flywheel teeth. The force from the relay when retracted is transmitted to the overrunning clutch through a special plastic element. If there is high resistance to the movement of the bendix along the armature shaft, then the plastic part breaks. The overrunning clutch cannot reach the operating position, while the starter rotates, since the contacts of the solenoid relay have closed.

An indirect reason why the plastic rod inside the starter may break is worn teeth on the starter armature shaft. The teeth on the back of the bendix may also be worn. To solve the problem, experts advise replacing the plastic lever or bendix completely.

Another mechanical reason for the starter to idle is wear and destruction of the teeth on the flywheel crown. The Bendix gear just spins and can't engage. As a result, the starter bendix turns to idle. In this case, repairmen recommend removing the starter from the engine and carefully inspecting the teeth on the flywheel, as well as on the gear. It is possible that both the flywheel crown and the bendix will have to be replaced.

How to properly test the starter on a battery

As can be seen in the illustration, the node consists of two separate components:

- The retractor relay - works on the principle of the clutch of a manual transmission - connects the Bendix gear to the engine flywheel to turn the crankshaft. After a successful start, the Bendix returns to the “parking” place so that the electric motor shaft does not rotate idle. A breakdown of the relay leads to the fact that a serviceable starter motor cannot crank the crankshaft, and the internal combustion engine does not start.

- Starter motor. The breakdowns are classic - the armature winding is burned out, the commutator is worn out, the brushes are worn out. The stator does not break because it has no winding.

There are also purely mechanical failures - for example, if the starter does not turn well when the battery is charged and the electrical part is in normal condition, it may be a matter of bearings or worn gears.

And if you removed the block from the engine, carry out preventative cleaning. The presence of dirt can make it difficult for the armature to rotate.

Let's look at checking electrical components. To do this, you need to directly connect the starter to the battery.

Checking the electric motor

Having securely secured the housing, we connect the negative terminal of the battery to the starter mounting eye (that is, we connect the negative terminal to the housing and ground). The cable must have a cross-section of at least 6 squares.

We connect the positive terminal to the engine power cable (a short piece of wire with a terminal that is attached to the contact of the solenoid relay).

The shaft should rotate vigorously. If the starter barely turns, we’ll deal with the engine. Check the condition of the brushes and commutator. The brush assembly is easily dismantled. Flexible wires must be without traces of melting, and the brushes themselves must have a margin of length. If there is visible damage, the elements must be replaced.

We inspect the rotor commutator (after removing the brush assembly, it is accessible from all sides). The rotor itself should rotate freely, and the copper lamellas should wear evenly. A short circuit between the contact plates is unacceptable (checked visually and with a multimeter).

There is another test - let the engine spin for 20-30 seconds. Then evaluate the heating of the housing and check for the absence of a burnt winding smell. The temperature should not be higher than 40-50°C.

Checking the solenoid relay

This element simultaneously closes the starter shaft with the internal combustion engine flywheel (via Bendix) and supplies power to the starter motor winding.

To check the starter solenoid relay from the battery, just connect the positive wire to the relay control terminal. It is easy to find - there is no threaded connection on the terminal, unlike power contacts.

When 12 volts are applied, a characteristic click should sound and the Bendix gear will take its working position.

Please note Attention! Do not test the bendix with your fingers when applying voltage to the relay. You may be injured. You can check the closure of the power relay contacts that supply voltage to the starter motor

At the moment of operation, the resistance between them should be zero. If not, just clean the contacts (nickels)

You can check the closure of the power relay contacts that supply voltage to the starter motor. At the moment of operation, the resistance between them should be zero. If not, just clean the contacts (nickels).

If the relay does not operate, it should be replaced. This unit is purchased separately from the starter, is inexpensive, and can be easily changed. Restoring a burnt-out relay winding is impractical, although possible.

Having gained access to the “insides” of the starter, check the mechanical condition of the Bendix fork and gears. Wear may be present, but without tooth deformation. Play on the fork should not prevent reliable engagement of the Bendix gear.

After checking, the assembly is purged with compressed air and the bearings are lubricated. The contact junctions are treated with a special lubricant for contact groups.

Important! The terminals are connected to the battery only after the power cables are securely fastened to the starter.

Video “Causes of starter malfunction”

After watching the recording, you will find out what factors influence the malfunction of this mechanism.

The overwhelming majority of engine starting problems are caused by electrical wiring, because the current path from the battery to the starter is measured not only by voltage, but also by a large number of connections and wires.

And, as is known from chemistry, during operation, wires and contacts are subject to completely natural oxidative processes. In addition to oxidation, the wiring may also burn out, which also leads to extremely negative consequences, namely interruptions or complete loss of voltage supply to the starter.

You start the car and feel that the starter is working with heavy efforts. In the vast majority of cases, this is caused by contact damage. And the first thing you need to do is check the integrity of the wiring, especially at the collector, where they often get burned. Depending on the age of the car, the wiring may also simply rot or break. Check the copper “bus” that connects the ground on the engine and the car body.

Pay special attention to places where the wires have already been connected using electrical tape (if any). These “rewinds” are most often the culprits of tight starter cranking. The final points of wiring, that is, contacts, are no exception.

How to fix the problem yourself? If a break or breakdown is detected in the wiring, it is recommended to completely replace the damaged section. I do not recommend using electrical tape, since such a connection will not last very long.

Be sure to clean the contacts in areas of the starting system. It is heavily oxidized terminals that are malicious violators of adequate voltage supply. Cleaning is done as follows:

1) carefully disconnect the terminals of the battery (battery) and other components;

2) thoroughly clean all contact surfaces. Cleaning is done using very fine sandpaper;

3) all contact bolts and terminals must be treated with some kind of solvent (or at least gasoline);

4) when you install the terminals in place, before installation, lubricate them with lithol, and also do not forget to crimp them.

As a rule, after cleaning the contacts and replacing damaged wiring, the problem with difficult starting disappears.

But if cleaning does not help, then the problem should be looked for in the starter. In this case, pay attention to the starter brushes, the presence of soot (carbon deposits) on the “nickels” of the retractor relay, and also check the condition of the armature. And finally, don’t forget to check for a short in the starter winding. To do this, use an ohmmeter.

When using a car for a long time, various problems often arise. And often they affect the starting system, affecting its elements. Most often, motorists are faced with incorrect operation of the starter, which refuses to start the engine. But the condition of this element can indicate possible breakdowns of the car, which is worth paying attention to.

What to do

So, the symptoms are obvious: the starter does not turn when hot.

The most common breakdowns that need to be eliminated first:

- Battery discharge. The starter simply does not have enough electricity to fully start working. To do this, just forget to turn on any electrical device in the car - usually the headlights. This also includes battery failures. This reason is quite typical and understandable to any car owner.

- Incorrect connection of the stamps or insufficient contact to the body or engine. Operating conditions are such that there is increased contamination and favorable conditions are created for contact oxidation.

- Integrity of electrical system wires.

- Problems with the engine caused by failures when starting hot.

If no inconsistencies are found, then the problem is still in the starter itself, and it requires cleaning and diagnostics. To do this, this unit will have to be dismantled and disassembled. As a rule, a regular set of open-end and ring wrenches is sufficient. Different vehicle models use different layouts, and the starter is located in different places relative to the engine. After dismantling, it is advisable to immediately clean it from dirt that accumulates during operation.

Complete disassembly allows you to determine which parts have failed. Most often, this is:

- High wear of the brushes, which simply do not reach the commutator and cannot fully perform their function - rotate the shaft.

- High wear of the support bearings on the bushings caused by intense loads. This can lead to short circuits between the armature and the starter itself. In addition, during previous repairs, inappropriate bushings may have been selected, which begin to jam when heated.

- Ignition switch whose circuit is faulty. The presence of contacts creates the risk of problems with their connection. Even small discrepancies can lead to loss of performance.

- Relay. Its failure can often be determined by ear: when the key is turned, there is no characteristic click.

It is important to install spare parts with the corresponding level of quality that were available before. Components of dubious manufacture do not ensure reliable further operation. If the starter does not turn when hot, then you should not take this as a big difficulty

The intervention of professionals allows you to quickly eliminate the malfunction without leading to high costs.

If the starter does not turn when hot, then you should not take this as a big difficulty. The intervention of professionals allows you to quickly eliminate the malfunction without leading to high costs.

Electrical faults

Starter connection diagram

Let's divide possible breakdowns into two parts - those that relate directly to the starter, and those that are related to the supply of voltage to it.

No voltage supply to starter

The reasons for the lack of power supply to the starter may be:

- Low battery. Operating the car (including the battery) on short trips, with numerous consumers turned on (headlights, heated steering wheel and seats, heated rear window, etc.) does not help the generator fully restore the battery charge. And the battery itself is perhaps no longer in its first youth. During a cold start, a small force is required to crank the crankshaft since the compression in the cylinders of a cold engine is less, since on a cold engine the gaps between the parts of the connecting rod and piston group are larger. After the engine warms up, the gaps, due to thermal expansion of the parts, decrease, which causes compression (pressure) in the cylinders to increase, and the starter does not turn the hot engine.

- Some cars are characterized by “burning” of the ignition switch contacts when the car does not respond to the ignition key . This “disease” is especially typical for cars that do not have an additional starter relay - it is this that protects the contact group of the ignition switch, preventing excessive sparking of the moving contacts. But, even if such a relay is present, it may also fail. In any case, the starter power circuit can be checked by closing its “positive” contacts with a metal object (screwdriver). If even after this the mechanism does not show “signs of life,” then most likely the starter itself is faulty.

- Be sure to carefully check the power “positive” wire from the battery connected to the solenoid relay. It is quite possible that a poorly tightened terminal on the starter was burnt. Also check the negative wires and their connections to the body and engine.

Malfunction of the starter retractor relay

The main reason for the failure of this unit is the failure of contact between the copper “positive” bolts and the contact plate. Over time, carbon deposits appear on their surfaces (due to sparking), disrupting electrical contact. The defect can be eliminated by cleaning or replacing parts, but, unfortunately, the vast majority of solenoid relays have a rolled cover and are therefore practically non-separable. Quite often there is a violation of the contact between the terminal and the wire, as well as “rotting” of this contact.

Reasons for a cold or hot system

Since system temperature can affect the causes of starter problems, you need to test its operation in both states - cold and hot. In the first case, the following problems may appear:

In a cold system, such a set is extremely small, because the low temperature here is dangerous only for liquids. However, when hot, the following problems are possible:

- bushing wedge;

- crankshaft failure (rubbing of liners, axle displacement, etc.);

- bushing wear.

Such problems more often arise on a well-developed system where the temperature has risen. If such a tendency is observed, it is recommended to check the system at a car service center. There may be problems with the crankshaft, which can lead to expensive car repairs.

If there is no difference between the operation of the starter in both cases, then it is recommended to look for reasons among the general ones. Most often, the problem is in the starting device itself or the power system.

Why does the starter turn the engine slowly?

Previously, in previous articles we touched on a similar topic, but it sounded a little different. Why doesn't the starter turn? Today it's time to talk about another, but similar problem, with similar causes of malfunction. In general, most problems in a car arise from poor contacts. Contacts become such either due to mechanical action or under the influence of chemical processes (oxidation)

Therefore, if you have any problem (from non-working headlights to a car that won’t start), first of all you need to pay attention to the “MASS”. But we'll get there later

DIY diagnostics and repairs

So, if the engine refuses to start when hot, you need to diagnose the starter unit. We will tell you more about how to check and repair the device below. The starter mechanism is an electric motor that starts working, receiving energy from the battery. One of the main characteristics of this unit is the consumption of high current at the moment of starting the internal combustion engine, but this only happens for a few seconds. And even then, thanks to the ability of the battery not to discharge.

If the unit does not work well when hot, but all units, mechanisms and circuits are operating normally, it is necessary to repair it. This procedure is not a simple one, so you need to have certain skills and knowledge. As a rule, this unit is mounted in the most inconvenient place for the car owner - at the bottom of the engine. For repairs, prepare standard tools, including a set of wrenches. For greater convenience, you will have to use an extended socket wrench (the author of the video about malfunctions, as well as detailed repairs of the device at home, is the Exin Plus channel).

In any case, you first need to dismantle the mechanism; this procedure is individual for each car, so we will not describe it. After the unit is removed, you need to disassemble its structure. If you do not want to encounter assembly problems after repair, then before disassembling the structure, make the appropriate marks on the body.

When disassembling the mechanism, pay attention to the condition of the following elements:

- Nodes and contacts. If you notice that there is a bad contact somewhere, it needs to either be cleaned or replaced. In some cases, stripping can eliminate scorching or oxidation.

- Overrunning clutch or bendix, this component also needs to be carefully checked. Make sure that the component can continue to be used. If the Bendix splines are worn out, then it would be better to change it.

- Anchor. If this component fails, problems with the operation of the motor may occur. The armature is equipped with a commutator, which can burn out as a result of severe wear of the brushes. In addition, no burning of any kind is allowed on the collector, and the same applies to blue plates. At the same stage, the integrity of the windings along with the insulation should be diagnosed.

Also, when this unit is disassembled, it will be necessary to carry out preventive maintenance of all components. All parts without exception must be cleaned of dirt and dust, as this may cause the unit as a whole to malfunction. In the event that the cause of interference in the operation of the mechanism is due to burnt contacts, they must be replaced; if the brushes are worn out or sticking, then you can try to repair them. If the repair does not produce results, then the brush assembly is replaced; for this, you can purchase a special repair kit at any automobile store. In the event that the mechanism simply cannot be repaired, it will need to be replaced with a functional one.

If the need for repairs causes you difficulties, it is better to seek help from specialists. Even if you pay money, you will be confident in the correctness of the actions performed and the functionality of the node.

Problems with the fuel system

Even the most “vigorous” battery and a new, working starter will not be able to start the car if problems arise with the supply of fuel to the cylinders. For this reason, the next thing to check is the engine power supply system.

1.Fuel pump

For carburetor and diesel engines, this unit is located directly next to the cylinder head or block. Injection power plants are equipped with an electric pump, which is installed in the fuel tank. Their operation is judged by a short buzzing sound that appears after the ignition is turned on. As for fuel pumps in carburetor engines, they are mechanically driven by a cam mounted on the camshaft.

It is easy to check the functionality of the fuel pump - to do this, remove the hose from the carburetor inlet fitting and lower it into a suitable container. After this, you should pump up the fuel using the manual pumping lever or by turning on the starter. If the result is negative, check the passage of gasoline through the fuel line and clean the mesh located in the top cover of the pump. If this does not help, then inspect the membrane and valves of the fuel pump. After replacing damaged and worn parts, the functionality of the device will be restored.

2.Fuel filters

Along the path of fuel passing from the tank to the engine there are several filter units - coarse meshes located on the fuel receiver, in the fuel pump and carburetor, and in addition, paper filters located in the section of the fuel line. The intensity and even the possibility of supplying fuel to the internal combustion engine depends on their purity. If you find a blockage, clean or replace the filter elements.

Throttle and injectors

Gasoline internal combustion engines operate on a fuel mixture, which is prepared in the carburetor or in the intake manifold (for fuel-injected cars). In the first case, the fuel passes through a whole system of channels, jets and nozzles that are located in the carburetor. In the second, it is supplied by injectors according to signals received from the electronic engine control unit (ECU).

The air supply is metered using a throttle valve, which, depending on the engine design, can be mechanically or electrically driven. Clean the parts of this assembly and the throttle itself. Also check if fuel is being supplied to the cylinders. If you are dealing with an injection car, then press the fitting spool located at the bottom of the fuel rail - gasoline should flow out from there under pressure. If the stream is too weak, then check the filters, fuel line and pressure reducing valve of the fuel pump.

In carburetor engines, the fuel supply can be judged by sharply opening the throttle - in this case, a portion of fuel will be injected from the accelerator pump nozzle into the diffuser. In addition, for gasoline power units, inspect the spark plugs - they should not be dry. Otherwise, check for the presence of a control signal at the injectors. If everything is in order with this, then you should unscrew the ramp fastening and move it away from the manifold in order to inspect the spray nozzles when starting the engine. The absence of fuel streams or their weak intensity indicates the need to clean or replace the injectors.

This is interesting: Film for tinting car windows: manufacturers

As for diesel engines, fuel is supplied to them under high pressure, and a much more complex pump (fuel injection pump) and specially designed injectors are responsible for this. To repair these components, special equipment is required, so in this case it is better to contact specialists.

Something else useful for you:

- Why does the starter click after turning the ignition key, but the engine does not turn with the starter?

- Causes of alternator belt whistling and how to remove this whistling noise?

- How to check the starter when removed from the engine?

Video: The starter hums, but the engine does not turn over

Malfunctions of electronic systems

To check the ignition system, unscrew and remove the spark plug from one engine cylinder. Having installed the tip of the high-voltage wire on its contact nut, touch the spark plug skirt to the cylinder head and crank the engine with the starter. In this case, a powerful spark of a purple or blue hue should appear on the contacts. If the spark is too weak (or there is none at all), then we check the operation of the computer, ignition coils and distributor (for an old-style internal combustion engine).

Other reasons for difficulty starting when the starter is running

- The timing belt is torn, or is loose and has jumped several teeth - in this case, the valve timing turns out to be off, which is why the engine cannot start. It is enough to replace and mark the belt, unless such a nuisance ended with the pistons meeting the valves - in this case, a major engine overhaul will be required.

- The crankshaft rotates with noticeable force, which may be caused by various mechanical damage to the crank mechanism and the cylinder-piston group. Check whether the engine turns when you try to start it in top gear “from a tow” (for manual transmissions) or by turning the crankshaft pulley on cars with automatic gearboxes. Relatively easy rotation indicates that the cause of the malfunction is hidden elsewhere.

- One of the mounted units is jammed, which creates increased resistance to rotation of the engine shaft. To find the “weak link,” you need to loosen and remove the belt, and then try to manually turn the pump, generator, air conditioning compressor or power steering pump. If the breakdown occurred far from the service station, then you can only get to the nearest car service center in those cars in which the pump is driven by a timing belt. On other engines, you can try to connect the crankshaft and coolant pump pulleys with something suitable - a rope, a rubber strip cut from a car inner tube, etc.

- Failure of sensors connected to the ECU - crankshaft position (CPCV), Hall, etc. Due to their breakdown or incorrect operation, the engine control unit incorrectly regulates the fuel mixture or injects and ignites fuel at the wrong time when it is necessary .

- Sometimes the cause of a failure or incorrect interpretation of signals from a particular sensor is electromagnetic interference from the starter and other electrical units. In this case, it is difficult to identify the malfunction, so it is possible that you will have to turn to specialists for advice.

Common Causes

Before checking, it is worth conducting a simple test for the operation of the starter, namely, checking its performance in cold and hot conditions. Based on this feature, you can exclude a lot of possible causes of problems. To check, it is enough to test the mechanism on a cold car, then start it and warm it up. Next you need to perform the same test.

Among the common problems it is worth noting:

- insufficient battery charge;

- thick oil;

- wear of bushings or brushes;

- problems with the solenoid relay;

- bad mass;

- Bendix failure;

- loose contact between brushes and commutator;

- short circuit of the element winding to ground.

The first point is the most common. Insufficient charge causes problems with the operation of the starter, due to which it cannot spin the shaft normally - there is simply not enough traction. Therefore, it is necessary to carefully examine the circuit with a multimeter. The check should affect not only the battery, but also all wiring elements.

The second problem is observed in cold regions when thick summer oil is used in the car. It is not designed for low temperatures, which is why it hinders the operation of various connections, including the crankshaft. In addition, during cold operation, the efficiency of the battery decreases, which also affects the operation of the starter.

Next comes wear on the bushings or brushes. Often the device wears out evenly, so this sign is a hint at replacing the starter. Damaged parts can be replaced, but other damage may occur.

Solenoid relay problems are also a common cause of starter problems.

This is often due to pin contacts, so it is important to check them immediately and replace them as necessary.

Often problems with the starter arise due to the “mass” of the battery

It is important to check its contact to the solenoid relay, as well as the integrity of the wires. If it shorts to the windings of the elements, this significantly reduces the efficiency of the device.

Breakage of the bendix, loose contact of the brushes and commutator, as well as some other reasons for the incorrect operation of the starter should also be checked in the process of solving the problem

It is only important to note that some problems occur only in a cold or hot system. This is also worth considering

Diagnostics

If the problem is not initially found, it is worth diagnosing the starter by disassembling it. To do this, you must first remove it from the system and carefully examine it.

My biggest distraction was that the horn - which replaced a horn that had not yet been invented - was fixed to the left of the windshield, causing some serious noise. Traveling along dark dirt roads was often very unpleasant due to the choking clouds of dust you passed as you passed another car or as you overtook or passed. In addition, frequent bumps and holes were further reduced, so suspensions were not as elastic as they are today. But what forced you to use lower speeds was the relative ineffectiveness of the brakes and road conditions.

Important! It is recommended to work on the car only when the system is cold. You also need to first disconnect the starter from the power supply before working with it.

During the removal process, it is worth checking adjacent parts. It is especially recommended to inspect the retractor relay, because this is where problems can arise. If there are oxidized contacts at the connection points, you need to clean them. It is also worth checking all connections for oxidation, because inappropriate operating conditions can cause destruction of the metal. This leads to wiring problems.

And this song rings in my ears From the cars climbing the sloping streets of Sinai. My father not only taught me how to drive it, but also initiated me into the secrets of its structure and mechanical functioning. This was one of my most adventurous adventures. This adventure, however, demonstrates how weak the road was at that time. This was my father's last car.

As a child, traffic in Bucharest was different from today's traffic. First of all, there were no paved streets when I was a child. It is true that in my grandparents' day there were no wood-panelled streets like the Mogosoai Bridge. In the center of the street were paved with cubic stone. Some of them were "paved" with boulders. On the outskirts, all the roads were like country roads, beaten or pebbled, filled with mud after each heavier rain.

- bushings and brushes;

- armature winding;

- stator winding;

- bendix.

The remaining elements are not so important, because checking them is difficult, breakdowns often occur due to these parts. It is important to carefully diagnose their condition and interaction with other elements in order to detect possible traces of problems.

At that time there were no traffic lights, no signs of crosswalks, parking spaces or others, and no signs of the traffic that pollutes the cityscape today. The most important difference today was the movement of horse-drawn vehicles along with automobiles. Its disappearance after World War II marked the beginning of a new era in the history of our capital. Electric horns came later and were rare. What remains of my memories is that all the car enthusiasts horned or tolled their horns all the time, creating a background noise that started at five in the morning and did not end until late at night.

In particularly severe cases such as massive oxidation, destruction of several parts and other malfunctions, it is recommended to completely replace the starter. Even after repair, the reliability of such a device will be low, and a comprehensive repair will be more expensive than purchasing a new part.

Causes of poor starter rotation

The reasons for the slow rotation of the starter when hot can be:

- Low battery charge. This is one of the first reasons for poor starter performance. It happens that a forgetful motorist, getting out of the car, forgets to turn off some of the electrical appliances, for example, daytime running lights. The battery is discharged and then, when you try to start the car, the starter either does not turn at all or turns very slowly.

- Incorrect ignition timing. To verify this, you can disconnect the wire from the relay coil and try to spin the crankshaft without a spark. If rotation occurs without much effort, this means that the ignition timing is too early.

- Natural wear of brushes or brass bushings (bearings). When the graphite brushes wear out, their contact with the engine commutator becomes poor. Due to poor contact, the starter rotor begins to rotate either too slowly or stops showing signs of life altogether. In the case of bushings, there is a violation of their alignment. The shaft warps, and the stator poles begin to touch the armature poles, thus forming friction. As a result of friction, the speed of rotation of the armature decreases and it becomes insufficient to start the car engine.

- It is quite possible that during the last repair work, the starter bushings were selected incorrectly, or even installed incorrectly. In this case, it is necessary to replace them.

- Ignition switch problem. This device also has its own problems of supplying a bad pulse to the excitation winding. This mainly applies to cars that do not have a starter relay installed. It allows you to reduce current losses as they pass through the contact group of the ignition switch.

- Solenoid relay malfunction. Usually manifests itself as a lack of a click when the starter is turned on. Usually, the relay is replaced. Check the wires going to the solenoid relay, they are probably broken. There may also be contact contamination that needs to be removed.

- Crankshaft problems. Its alignment is disturbed or one of the liners, which is pressed when the entire shaft is heated, has worn out. Jamming of the piston group also occurs. In any case, only engine repair will help here.

Starter diagnostics

Dismantling. Once we are convinced that this is the cause of poor rotation of the starter when cold, it will need to be removed from the car for diagnostics. It is advisable to carry out the procedure when the engine is cold, so as not to get burned on the elements of the exhaust system. Before dismantling the starter, you need to remove the terminal from the battery. Depending on what brand of your car it may be more convenient to first unscrew the mount of the starter itself, and then disconnect the power wires and the solenoid relay wire, and possibly vice versa.

Inspection. After dismantling the starter, we need to inspect it. If it is heavily soiled, we clean it. First of all, we check the solenoid relay. If we observe signs of severe wear or any visible damage, the relay should be replaced. Naturally, the new relay must be installed with the same parameters.

Disassembly. If everything is in order with the relay, we move on to the starter. It is worth considering that starters come in different designs. It is necessary to remove the rear cover of the starter, under which the brush assembly is located. The back cover at the same time protects the rotor. We evaluate the condition of the brushes and replace them if necessary. Brushes can be attached either with bolts or by soldering. In addition to the brushes, we pay attention to the bushings. If there is severe wear, the rotor warps at the moment of starting, a lot of force is created, the starter consumes a lot of current and therefore turns hard. If there is 0.5 mm play on the bushings, they should be replaced with new ones. To ensure good contact between the brushes and the rotor, the rotor must be cleaned of dust.

One of the important points is the correct diagnosis. Some people succeed easier, some more difficult, some don’t succeed at all. Much also depends on experience and whether the person has encountered this problem before. There are also car owners for whom such words as “starter” and “generator” are something completely incomprehensible. The article is intended for those who have decided to independently search for the causes of poor engine starting with a starter and eliminate them.

Friends, remember: despite the fact that a car is just hardware, it nevertheless requires periodic attention. Only in this case can we talk about reliability and be confident in your car. Good luck to everyone on the roads!

Why does the starter turn poorly when cold?

In this state of the system, the problems are not so significant and are mainly associated with the effect of low temperature on the working fluids. The starter does not work well for the following reasons:

- low efficiency of the battery due to loss of its capacity due to decreased temperature;

- Thickening of the oil inside the engine as it starts cold.

Note that if the starter works equally poorly in both modes, the reasons for this must be sought among the most common. They are often associated with a malfunction in the starting device, or a lack of contact in the vehicle’s electrical network. The causes of problems can only be identified by diagnosing the device.

What to do if the starter turns poorly

When the starter turns poorly, it is necessary to perform diagnostic and repair measures. You should always start with the battery and check the quality of the contact, and only then dismantle and possibly disassemble the starter for further diagnostics. So, first of all you need to do the following:

- Check battery charge . It doesn’t matter whether the gearbox turns poorly or the regular one, but the battery must always be charged. This is especially true in winter, when the air temperature outside at night drops below zero Celsius. Accordingly, if the battery (even if it is new) is at least 15% discharged, then it is advisable to charge it using a charger. If the battery is old and/or has exhausted its service life, it is better to replace it with a new one.

- Make sure there is reliable contact between the battery terminals and the starter power supply . If there are pockets of oxidation (rust) on the battery terminals, then this is definitely the problem. Also make sure that the clamping torque of the power wires is reliable and meets technical standards. Pay attention to the contact on the starter itself. It also makes sense to check the “ground pigtail”, which connects directly the engine housing and the car body. If the contacts are of poor quality, they need to be cleaned and tightened. If the wire is damaged, it is better to replace it with a new one.

Did the above recommendations not help? Then you will have to remove the starter to inspect and check its main elements. The only exception may be if the new starter turns poorly, then if it’s not the battery and contacts, then you need to look for the reason in the engine. Checking the starter should be performed in the following sequence:

Engine starting system problems. Slow starter rotation

According to the diagram, the starting system is a starter, to which two wires are connected. One originates from the battery positive, passes through the ignition switch and is connected to the corresponding contact on the starter housing. The second wire originates from the vehicle ground (negative) and is connected to the starter housing. A fuse is connected between the ignition switch and the starter contact. It protects the electrical circuit from possible short circuits.

During operation, all wire connections tend to oxidize or corrode. As a result, the contact disappears, and the starter begins to work with frequent interruptions: it turns slowly or does not always start. In this case, it is necessary to regularly clean the contacts from traces of corrosion and oxidation.

Procedure for cleaning contact connections:

- Disconnect the battery terminals and wires that connect to the starter.

- Clean the surfaces of the terminals and contacts with sandpaper.

- Treat cleaned areas with gasoline or alcohol solution.

- Apply lithol or graphite to the connections and connect all the wires back.

If there is a short circuit, a fuse is triggered, which will indicate a malfunction with a melted insert. First, find the short circuit, eliminate it and replace the fuse. All work may only be carried out with the battery terminal removed.

Main reasons and methods for solving them

Healthy! Maybe you are lucky and resetting the injector errors will help. To do this, you first need to remove the negative terminal from the battery. If after 5-10 minutes the car starts as well, then this is not the problem.

Difficulty starting the engine is influenced by a number of simple reasons, which you can eliminate yourself in the garage, having a standard set of tools with you.

Starter mechanisms (brushes, bendix)

In the process of rebuilding the starter. The arrow indicates worn brushes.

- On used cars, the brushes on the starter wear out. In this case, you need to remove the cover and replace them with new ones;

- A starter that has been in use for a long time can be sorted out, cleaned all the mechanisms, washed with WD-40 and filled with new lithol, since the old one is most likely coked and formed into balls;

Fuel problems

In the process of replacing the fuel pump grid. On the right is the old one, and on the left is the new coarse mesh

Small particles of debris getting into the gas tank

. This problem is treated by cleaning the fuel system and replacing the filter.

Incorrect sensor readings

Failure or incorrect signal supply from the sensors to the ECU (their diagnostics are required, and if a malfunction is detected, replacement with new ones):

- Speed sensor.

- Crankshaft position sensor.

- Phase sensor.

Wires, filter and spark plugs

Clogged air filter

- High-voltage wires are broken

, poor contact on the tips (oxidation). During a visual inspection, it is rarely determined whether the best option is to replace it with new or known good ones. Before replacing, you can clean (blow out) the contacts on the old wires. - The spark plugs are flooded

, mechanically damaged or. If necessary, the following is done: new ones are screwed in, the required gap is set, or the old ones are returned to their place. - The air filter is clogged

, causing the air supply to the engine combustion chamber to deteriorate. Recommended.

Gasoline pump

The fuel pump is located under the rear seat

The fuel pump does not provide the required pressure

, because of what, but they simply spray it. In order to discard this option, you need to measure the fuel pressure with a pressure gauge (the nominal one should correspond to the norm of 3.2 bar).

If the result is different, the situation requires replacing the fuel pump.

Engine failure

Bendix failure

Old and new Bendix

With each such idle start, voltage from the battery is supplied to the bendix, which begins to rotate the shaft until the engine starts. At this moment, it occurs, and the bearing may also crumble or hum.

In these cases, there is only one way out - replacing the starter with a new one.

Purpose and features of the starter

This element in the power unit starting system is necessary to spin the crankshaft, since without this procedure any vehicle simply cannot start. If for some reason the starting device stops spinning the crankshaft until it reaches the required speed, problems arise with starting the engine.

Do not confuse a non-working starter with a mechanism that does not turn the engine well, since these are two opposite states of the element. Therefore, every car owner needs to learn to distinguish between these conditions and diagnose their causes.

Before performing a device test, it is necessary to check the charge of the power source, since the correct starting of the engine depends on it. If the battery is not charged well enough, the starter will no longer be able to spin the crankshaft.

Advice! You can check the battery in various ways, the simplest of which is to measure its voltage using a voltmeter. In addition, it is also worth checking the condition of the wires that supply voltage to the terminals of the starting system, since they can also cause poor operation of the element

It is very important to determine how often this condition occurs. If it occurs once, there is no cause for concern, otherwise it is recommended to install a new battery in the car

Crankshaft wear

The reason why the starter does not turn on a hot engine may also be the crankshaft bearings - liners. Due to wear, oil starvation, poor-quality assembly and increased longitudinal (axial) play of the crankshaft, the liners may wear unevenly, which will give them an “wrong” shape, especially as a result of scoring on the surface. As a result, when the engine cools down, gaps appear between the crankshaft bearing journals and the liners, which makes it easier to crank the engine. When it warms up, the presence of these defects, on the contrary, can lead to complete jamming of the engine. In any case, when operating a car, it is advisable to respond as quickly as possible to its seemingly random “whims”.

Once upon a time, car engines were started manually, spinning them using a special tool. The design of modern engines makes the driver's work easier. Now you don’t need to get out of the car and make great efforts to start the engine; just turn the key in the ignition and the starter will do everything.

With the advent of the starter, new problems appeared when starting the car. There are situations when you need to drive off, but the engine stubbornly won’t start because the starter refuses to rotate. In addition, there are a number of situations when the engine is well warmed up, but the starter still does not rotate. This leaves drivers with a serious question, one to which not everyone knows the answer. Let's try to figure out why the starter turns poorly when hot.

Messages 10

1 Topic by Djin 2014-05-03 22:13:33 (2014-05-03 22:15:12 edited by Djin)

- Djin

- New member

- Inactive

- Registration: 2014-03-20

- Messages: 14Thanks: 9

- Car: VAZ 21102

Topic: Resolved: Starter does not turn over when engine is warm (after driving)

Good day! The essence of the problem is that when the car is cold it starts, the starter always fires, but when you drive it (i.e. it warms up), turn it off, and start to start the starter does not work. Sometimes it starts 2 times, sometimes it takes 2 minutes to turn the key back and forth and then it locks. If the starter does not operate, the indicators on the instrument panel dim. This was done to solve the problem (it didn’t help): all the terminals on the battery are screwed on and cleaned well; The (+) wiring to the starter is also cleaned and tightly put on. I ask for help and advice. The retractors die.

2 Reply from igorek 2014-05-03 22:41:18

- igorek

- Brother-in-law

- Inactive

- From: Bryansk region g Starodub

- Registration: 2013-05-05

- Messages: 416Thanks: 191

- Car: VAZ-21102 1.5i-8V Bosch MP7.0H

Djin, look at the starter relay, perhaps the contact group in the ignition switch is also what the brain does. also the wiring of the connection point of the chips, the voltage drawdown from the poor contact somewhere, good luck in the search

3 Reply from Sergey VAZ 2111 2014-05-04 15:20:14

- Sergey VAZ 2111

- Connoisseur

- Inactive

- Registration: 2013-11-21

- Messages: 513Thanks: 145

- Car: VAZ 2111

check the wires when the engine is hot.

4 Reply from klimashov.roman 2014-05-05 09:26:41

- klimashov.roman

- Connoisseur

- Inactive

- From: Kasimov

- Registration: 2014-04-21

- Messages: 743Thanks: 143

- Car: GAZelle 33023 dv 405.22, 2.4 16kl 140hp

The contact group is unlikely since the problem is described during heating. The relay might be worth a look. Most likely the retractor or the entire starter itself. I had the same problem, no matter how I treated it, replacing the retractor only gave a temporary effect. Disassembling the starter is the only way you will find out the reason. I struggled with money for a long time, threw away half the cost of the starter and ended up having to buy a new one. If you want, disassemble the retractor itself and look at the spots, if they are burnt, clean them, put everything back and lubricate the starter itself with oil, just don’t pour too much without fanaticism. It should work out

5 Reply from Zloy 2014-05-06 22:01:29 (2014-05-06 22:10:18 edited by Zloy)

- Wicked

- New member

- Inactive

- Registration: 2014-01-20

- Messages: 7 Thanks: 2

- Car: VAZ-21102

And who’s stopping you (when it won’t start) to apply + directly from the battery to the starter control contact (after disconnecting the chip from the ignition switch or the starter relay - depending on the year of manufacture of the car). Do this with the ignition on and the gear off. If the car starts, then the starter is normal, look for a problem in the ignition switch or wiring, or in the starter relay if there is one (most cars did not have one).

6 Reply from Serg 2014-05-11 09:18:57

- Serg

- Lada2111.rf fan

- Inactive

- Registration: 2013-07-29

- Messages: 830Thanks: 363

- Car: 2111 dwg 2114 year 2008

The problem is trivial and as old as the world - a hidden defect of the manufacturer - modern starters do not have a starter winding; instead, powerful magnets are installed with a small gap between the armature and the stator; when cold, during further operation this gap is masked and therefore, when the starter is cold, the armature can rotate even to some minimum level. then with warming up the gap is selected by temperature expansion and the armature jams tightly - there are two options: the first is to disassemble and wash the stator (at the same time do maintenance), if the magnet(s) are unstuck then option two. new

- Jigull

- New member

- Inactive

- Registration: 2014-05-11

- Messages: 2Thanks: 0

- Car: VAZ 21124

The car won’t start – we check the main possible problems

The most common occurrence of problems with the engine or electrical system of a car is a lack of ignition. There are different options for the implementation of this breakdown, so you need to know the difference in order to determine the specific unit to blame for the failure to start the engine. The starter may spin, click or be silent, the engine may start and immediately stall, and also make sounds that are unusual for it. It is worth dealing with these manifestations so as not to make the breakdown even more complicated.

Firstly, if the car does not start, you should stop trying to start the engine until the problem is clarified. The timing belt may have broken on the car, and your successive attempts to start the engines will lead to valve failure. Let's look at the main possible manifestations of problems that cause poor engine starting.

Problems with the starter and electrical system of the car

Often the answer to the question of why the car won’t start lies on the surface. Poor performance of the starter or its complete failure is the cause of 80 percent of problems with starting the power unit. Therefore, first of all, check this unit for its correct operation.

Also, starting the engine can be complicated by a dead battery or a broken wire in the car's electrical system. The wire leading from the battery to the starter often breaks, and the car does not respond at all to turning the key in the ignition. Manifestations of problems with the starter are as follows:

- when turning the key in the ignition switch, only a click is heard in the starter area;

- the unit constantly makes clicking noises, but does not turn the engine;

- there is no reaction from the car to an attempt to start the car with the key;

- The starter turns, but makes strange sounds of rapid rotation.

In the latter case, the culprit of the problem will be the bendix, which should move out of the starter and turn the engine. This element often wears out and does not perform its tasks. The first types of problems are related to the solenoid relay. Replacing it can often solve this problem.

If your car's battery is dead, the starter will only turn once or twice without starting the engine. Lazy sounds under the hood also mean a dead battery. In all these cases, you can easily start the car from a pusher or with the help of a tow, and in the event of a battery failure, you can light a cigarette from the battery of another car.

Problems when starting the engine related to the power unit system.

Often problems with starting the engine are based on problems with the unit itself, and in this case you need to be much more attentive to extraneous sounds and other possible manifestations of the problem. If the engine knocks during startup, a possible problem is hidden in the piston group or in the valves. The ignition setting may also be lost.

Here everything depends not only on the operating characteristics of the car, but also on the type of engine itself. In some units you can try to find the problem yourself; in the case of modern foreign equipment, you will have to evacuate the car to a service station. The main problems that occur in the engine system and prevent the car from starting are the following:

- timing belt breakage or its displacement from the established marks;

- broken ignition timing setting, which often happens on carburetor cars;

- poorly configured valves that prevent the engine from starting normal autonomous operation;

- deformation of the valves due to impact when the belt breaks or other mechanical damage.

Also, the car may well not start due to low octane gasoline or poor fuel quality. Diesel engines can be difficult to operate in winter due to possible fuel freezing. The more technology and automatic solutions are present in a car, the more possible problems can be found.

If you understand that the problem of the power unit not starting is not related to the battery or starter, stop trying to start the engine, because you can only make things worse. It is better to invite a specialist or tow the car to a professional station to detect and fix problems.

See what a broken timing belt can lead to on some cars:

Let's sum it up

If your car refuses to start, you shouldn’t torture it with every second attempts to turn the key in the ignition system in an effort not to be late for work. Use the services of a specialist to identify possible problems and get more information about the problem. Then you can easily detect the breakdown and fix it.

If the engine does not start for more serious reasons, the service station will tell you possible ways to fix the problem. It is enough to find specialists who are well versed in your make and model of car. Are there any situations in your driving experience when it was very difficult to determine the reasons for the failure of the power unit to start?

The starter does not turn over either cold or hot, where to start looking for the problem?

Hello, dear motorists! The problem of starting the engine remains one of the most pressing and discussed. Agree, it’s a very annoying situation when we urgently need to go, and the starter, after sluggish attempts to turn the crankshaft, becomes silent and does not want to help in our intentions.

The question immediately arises as to why the starter does not turn well, because the car has been serviced, the battery seems to be charged, and just yesterday everything was fine.

We attribute everything to insufficient battery charging and forget about the problem, but after some time it returns again, but the engine no longer starts at all. If such a problem appears and the starter turns slowly for no obvious reason, it needs to be fixed urgently.

If the starter turns weakly, you need to understand the design of the starting system

To begin with, before the mounting bolts on the starter are unscrewed, you should decide what time of year it is and how long ago the engine oil was changed. If it’s a frosty winter outside and the starter doesn’t turn well when cold, the first thing you should do is change the oil to winter oil.

Just as with the onset of frost, we rush to “change” the car to winter tires, we should replace the engine oil with a less viscous one, even if the old one has not yet exhausted its service life.

As the temperature drops, summer oil turns into a sticky and viscous liquid, which tightly “glues” the entire piston system together.

The first culprit in the rating of poor engine starting is the battery. It just so happens that we rarely check how efficiently the charging system works.

Sometimes we allow ourselves to leave the ignition system and some electrical appliance in the car on. It is not surprising that by morning the battery is simply not able to move the starter.

The battery is fine, but the starter still barely turns, which means it is necessary to inspect (ring) the entire “ignition - starter” network in the following sequence:

- egnition lock;

- battery (terminals and ground connections to the body and engine);

- starter solenoid relay;

- starter.

The starter turns hard. How can I help him?

Any of us have witnessed when household electrical appliances began to work poorly due to poor contact in the wiring. The fact is that everything happens with the car exactly according to the same scheme. On the way from the battery to the starter there are many wires and dozens of connections.

As a result of operation, the metal oxidizes, becomes corroded, and burns, which leads to a violation of the integrity of the connections and, as a result, interruptions in the supply of electricity to the starter windings.

Very often the starter turns hard because of broken contacts.

You should definitely pay attention to the integrity of the wires themselves, which can burn on the collector, break or simply rot, as happens with the copper bus connecting the ground on the body and the engine

In order to revive the motor, it is necessary to clean the terminals and wire contact connections on all of the above parts of the starting system. To do this you need:

- disconnect the terminals of the battery and other devices;

- Clean contact surfaces with fine sandpaper;

- treat all terminals and contact bolts with solvent, alcohol or gasoline;

- Before connecting, carefully lubricate the terminals with lithol and press tightly.

If all these actions do not lead to a positive result, then you will have to remove the starter and look for a breakdown inside the unit

Particular attention must also be paid to the contact groups: starter brushes, the condition of the armature, the presence of carbon deposits on the contacts (nickels) of the retractor relay. Finally, you need to check with an ohmmeter whether the starter windings are shorted together

The starter turns weakly

A starter with a small mass has to turn a massive flywheel and set the entire piston group in motion.

Its operation is affected by all components included in the ignition system. The failure of one of them entails the failure of the others. For example, if the integrity of the electrical wiring of the engine is damaged. In this case, a spark jumps between the brushes, which burns out the commutator.

Before starting repairs due to the fact that the starter turns poorly, you need to rule out other possible causes of a bad start (video author Ivan Matieshin).

Possible reasons

One of the reasons may be engine oil, if the engine does not start well when cold. It may not have changed for a long time or may not correspond to the season. When it is frosty outside, you should use winter oil, which has components that take into account its operation at low temperatures. In frosty weather, summer oil thickens and becomes viscous, “gluing” the piston system.

If, then the reason is no longer in the oil. First of all, you should check the battery charge.

Solution

If everything is fine with the battery, and the starter turns weakly, you should ring the entire ignition system and check its functionality:

- ignition switch;

- solenoid relay;

- battery (ground connection to the body, terminals);

- starter.

Possible malfunctions in which the starter constantly turns, but the engine does not start:

- the collector is burnt out or a short circuit occurs between its plates;

- break in the winding;

- brushes are very worn or stuck;

- an interturn short circuit has occurred in the windings of the starting device or armature;

- short to ground.

If you hear a clicking sound at startup, and then it starts to spin with the sound of the flywheel gear grinding against the flywheel teeth, this may be caused by the following reasons:

- potholes in the flywheel teeth;

- the buffer spring is weakened;

- The ignition timing or gear travel is incorrectly adjusted.

After dismantling the starting unit, it should be cleaned, checked, brushes cleaned, and the corrector polished. If faulty parts are found, they must be replaced.

Before replacing the old grease, replace it with a new one.

Why do you need a starter?

Today, this device is used to remotely start the engine, eliminating the need for drivers to get out of the car and turn the starting handle. One can only imagine how unpleasant it is to do this at a time when it is freezing outside or pouring rain. Now you don’t have to be afraid of this. The engine starter is an electric DC motor, which, consuming current from the battery, rotates the crankshaft of the car engine. Its design contains devices such as a retractor relay and an overrunning clutch. Without their installation, the electric motor does not become a starter, so these devices also require proper care and maintenance.

The following two tabs change content below.

- Bio

- Latest Posts

admin1

I am a professional in the field of Auto Electrics and Auto Diagnostics. Work experience more than 10 years. I will identify and eliminate faults of any complexity. (Even with cars that Dealers and services cannot handle, as it were, of the highest class). We carry out all types of work on the installation of additional electrical equipment (xenon, multimedia system, special signals, etc.)

The starter turns the engine weakly: causes of battery malfunctions

You turn the ignition key, but instead of the vigorous rhythm of the running engine, you hear that the starter is turning the engine, as if the battery is dead. Another attempt to start the engine. And further. Stop: until the battery really requires charging, and the car is not sent on a tow truck for service, it is worth remembering how to check the starter without removing it from the car, and even fix the breakdown. To identify the malfunction, you will have to remember the operating principle and design of the starter.

Units and design details

The function of the starter is to start the car engine by spinning its flywheel with an electric motor, creating temporary contact between the gears. Subsequently, the electric motor is turned off and physical contact with the flywheel gear is broken. The starter is located on the engine body closer to the battery and the cab.

Structurally, the device can be divided into two functional blocks:

- Solenoid relay. When 12 volts are applied directly to the control contact, the electromagnet pulls in the core. The core pushes the bendix through a lever to engage the gear with the flywheel teeth. At the final point of retraction, the armature, with a contact plate through the rod, closes the contact of the nickels, providing a direct connection of the electric motor to the “+” of the battery.

- Electric motor. When voltage is applied, it begins to rotate, spinning the flywheel through the Bendix to the operating speed of the car engine.

After starting the engine, the key is returned from the ignition position, de-energizing the relay. The relay opens the contacts, the spring returns the bendix to its original state. When starting, the electric motor requires several tens of amperes of current from the battery. After starting the car engine, the generator restores the battery charge.

The starter may have malfunctions, determined by the nature of the manifestation, visible signs, and tester readings.

Possible faults

The starter consists of more than 20 parts. The electric motor consumes hundreds of kW of power from the battery, converts it into rotational motion of the flywheel, overcoming the resistance of a car engine frozen on a winter night. In this mode, there is something and why to break. How to check if the starter is working - there is a method for finding out the location of the breakdown in order of complexity of the work - from diagnostics without removing the starter to its complete disassembly.

Low on-board voltage

A sign of a malfunction - the engine started and the car drove 5-10 kilometers. When trying to start, the starter turns weakly, the battery is charged before the trip. When you turn on the high beams, the headlights shine dimly. You can verify that the voltage is low by measuring it at the battery terminals with a tester with the key in the ignition switch and without it.

Probable reasons:

- the generator does not work;

- battery discharge due to a faulty on-board electrical appliance, including the starter.

The generator must power on-board consumers and provide charging current to the battery, otherwise the headlights and engine will quickly discharge the battery. With such a malfunction, the engine spins weakly when starting, although the battery was charged shortly before the trip. To check, you can disconnect the positive terminal of the battery after starting the engine by lighting it; if the generator is working, the engine will run. You can check other on-board devices without starting the engine - turn them off one by one by removing the fuses until the battery tester shows an increase in voltage.

Now it's time to start checking the starter itself.

Quality of contacts

Electrical malfunctions are caused by only two reasons - either the required contact is missing, or an unnecessary one has appeared. To check for current leakage through the starter, without removing it from the car, disconnect the power wire from its terminal. If the on-board voltage rises, then the starter is faulty, and why should be clarified after disassembly.

Bad contacts will manifest themselves as unstable operation - either the solenoid relay does not click when starting, or the rotation speed of the electric motor changes. Checking the battery starter will help identify the most common faults.

To check the voltage supply to the relay control electrode, remove the ignition key from the lock. Without dismantling the starter, remove the positive contact of the battery and the wire from the control terminal of the solenoid relay (it does not have a thread). Use a separate wire to connect the freed contact to the battery positive. A working relay will have a noticeable operation sound and the bendix will move into the operating position.

If previously there was no sound when starting with the key, but now it appears, you need to eliminate the faulty wiring from the ignition switch to the starter. If there is no sound, thoroughly clean the ground contacts on the housing and the control relay terminal. If after cleaning the sound does not appear, the solenoid relay is at fault.

In terms of frequency of failure of the retractor relay unit, it is less common than bad contacts. To check, you will need to dismantle the entire starter and remove the relay cover. The breakdown is manifested by the absence of a characteristic click of the retracted armature when the ignition is turned on. Visually, the Bendix gear will not move into the working position until it hits the limiter.

For all subsequent checks, the starter housing should be secured in a vice on a workbench, since the reaction to the supply of electricity will be a strong torque, at which it is very difficult to hold it in your hands.

Node diagnostics consists of checks:

- anchors;

- lever;

- relay windings;

- Bendix.

Having compressed and fixed the spring of the lever, you should try to move the anchor along the line of its movement. It should move freely. Possible dirt deposits should be washed off before moving smoothly. In case of physical deformation, it is better to take a new armature or relay completely.

The lever may jam at the connection points with the anchor, bracket or drive coupling as a result of dirt or metal wear in the friction areas. This means that you need to clean off the dirt, sand out scratches, or replace a worn-out part of the assembly.

The relay windings are checked with a tester. For a working winding, the resistance between the control contact and the housing will be shown by the tester to be about 1.5 Ohms. It is impossible to diagnose an interturn closure of a relay at home, therefore, if all the tests were successful, but when +12 V is applied to the relay, the armature does not retract, the relay should be replaced.

The gear can wear out, especially at the ends of the teeth. The gear cannot be restored. The bendix should be replaced.

Motor assembly

The malfunction is manifested by a click of the relay and full output of the bendix, but the rotation of the gear does not begin or may occur jerkily, slowly, with a weak torque.

Without disassembling or even removing, you can find out the functionality of the contact coins. To do this, you must first turn off the power to the on-board network and connect the plus of the battery to the starter wire that goes from the threaded terminal into the housing. If the engine begins to rotate much faster, to repair the starter, you need to remove the starter, disassemble the relay and clean the contacts of the coins and the contact plate.

To clarify other faults, the electric motor must be disassembled and the condition checked:

- brushes;

- collector;

- rotor windings:

- bearings.

A malfunction that requires replacement of the brushes is determined by their appearance - high wear, when the force and stroke length of the springs are insufficient for reliable contact with the commutator. It is possible that the brushes are simply dirty - washing will solve the problem. Be sure to measure the lack of conductivity between each brush and the body, in which case the part will have to be replaced.

A commutator that comes into direct contact with the brushes during rotation may have unacceptable wear or contamination. But sometimes the malfunction is in the nature of bridging nearby lamellas with conductive material - metal or coal dust. For repairs, you should clean the gaps between the lamellas and measure the resistance of each pore of adjacent contacts.

If the contact between the lamellas does not disappear, the electric motor will have to be replaced.

The rotor windings are checked with a tester for breaks, lack of contact with adjacent windings or with the housing. It is more difficult to check the interturn closure of the winding - you need a special device. Even having identified a winding malfunction, fixing it at home is a job that only a specialist can do.

Rotation of the electric motor rotor is possible only on non-jammed bearings holding its axis. If force is required to rotate the rotor by hand or uneven movement is felt, clicks are heard - the bearings have failed. You can try washing them and replacing the lubricant, but their wear will show itself in the near future. It is better to immediately install new ones, and if conditions do not allow, replace the unit completely.

Advice to a car owner

All external contacts of the starter should be cleaned before checking, since this is a fairly common malfunction and there is no need to remove it from the engine.

Even an initial check of the starter without removing it from the vehicle usually indicates a breakdown, reducing repair time, reducing costs and not taking much time.

pochini.guru