How much does a fire extinguisher cost?

You can find flame arresters from leading manufacturers in the catalog on our website using convenient navigation.

You can also drive up to one of our car services, where they will select the flame arrester of the required model for you. Many car owners cannot decide what is better to put in their car - a catalyst or a flame arrester. Also often concerned is the issue of the legality of installing a flame arrester instead of a catalyst and the environmental standards established by the Government of the Russian Federation for the content of CO and CH in car exhaust gases (the possibility of legally passing exhaust toxicity control).

The use of flame arresters is permitted in the Russian Federation. CO/CH standards in Russia are significantly softer compared to European ones. Any car without a catalyst with a properly functioning engine easily meets the Russian CO/CH standard.

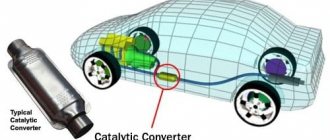

By its design, a flame arrester is a type of resonator. This element of the car's exhaust system primarily encounters the flow of exhaust gases emanating from the engine and therefore it must be durable and heat-resistant

Indeed, the speed and temperature of the engine exhaust gases are quite high and it is very important to cool and slow them down as much as possible before they enter the resonator

To reduce the cost of repairs, many car repair shops independently manufacture flame arresters based on the old catalyst housing. The technology for creating a homemade product usually looks like this:

- The catalyst body is cut and the remaining ceramics are removed from it;

- A perforated pipe is placed along the body;

- The gap between the pipe and the body is laid with sound-absorbing material, usually basalt wool.

Homemade flame arresters often do not dampen noise well, and the cheap filler used in their manufacture burns out after the first year of operation of the machine. As a result, a rattling sound appears, similar to the well-known sound of a Volga car engine running.

Factory products of the AWG and MG-Race brands are free from all of the above listed shortcomings. They have passed the necessary certification and time-tested in Russian road operating conditions.

If you have an old car with a rather worn-out internal combustion engine, then installing a new catalyst on it is unprofitable. In this case, it is impossible to avoid engine oil getting into the catalyst, and this significantly reduces its service life. Failures in the ignition system are also extremely dangerous for the converter. Unburnt gasoline begins to accumulate in the catalyst, where it subsequently burns, destroying it. In all such cases, it is more advisable to use flame arresters, which compare favorably in price and reliability.

Why install a universal flame arrester?

The main reason is saving money. Over time, the factory catalyst becomes clogged and fails. Gases are not able to leave the space due to melted or clogged honeycombs. All this affects the behavior of the engine and the car as a whole. Of course, you can install a new catalyst. But its cost ranges from 30 to 70 thousand rubles on average. Installing a flame arrester will cost 10 times less. And if we talk about homemade, then you can even spend a thousand rubles. Thus, the operation of the exhaust system does not change (except for more toxic gases). At the same time, money is saved significantly.

What kind of universal flame arrester can you buy? Bosal is one of the leaders in the production of these mechanisms. The dimensions of such an element will be as follows: diameter - 55 millimeters, length - 300. The cost of a universal flame arrester is about 4 thousand rubles.

Advantages of replacing a catalyst with a flame arrester

Installing a towbar socket on a Chevrolet Niva

This option seems very attractive, but has some nuances. Not every service station will do this efficiently.

The fact is that not every replacement of a catalyst with a flame arrester ends up being successful. Often an installed spare part breaks down within the first months of use, and even more often it does not perform its intended functions.

Fact! Often, as a result of replacing the catalyst with a flame arrester, interruptions in engine operation occur. This is not due to the new part, but to the old ECU settings. The fact is that many modern cars are equipped with exhaust cleanliness sensors. And if the catalyst contains a special filter, then the flame arrester does not. The sensors are going crazy. The ECU system does not know that you installed a flame arrester instead of a catalyst: it decides that the latter is broken and blocks the engine. To drive safely, you need to reflash the ECU.

Only the best qualified craftsmen can properly install a flame arrester in place of a catalytic converter. How to find them? We know such people - they work at the Muffler Master.

Why should we replace the catalyst with a flame arrester?

- Relatively inexpensive. At Master of Silencers you will pay from 2500 to 5500 rubles for the service.

- Fast. Usually the procedure takes no more than an hour.

- We know exactly how and what kind of flame arrester you need to install - and whether it can be done at all. After replacement, you will not be bothered by muffler malfunctions for a long time.

- Qualitatively. We order flame arresters from the most reliable manufacturers. Our craftsmen know exactly how to ensure that the flame arrester serves correctly and does not cause any trouble.

- For a long time. We provide a guarantee of 6 months, which indicates the high efficiency of the replacement. Our new flame arrester will last for at least several years.

Make an appointment to have your car repaired by calling the phone number listed on the website, or use.

Flame arrestor, stronger instead of catalyst SUZUKI GRAND VITARA

Flame arrestor, stronger instead of catalyst SUZUKI GRAND VITARA

AWG universal flame arresters are the best solution for replacing the catalyst when building a sports exhaust system and more. All flame arresters are direct-flow, made of high-quality aluminized steel, and have a special internal design that allows you to achieve excellent sound solutions.

Replacing catalysts with a SUZUKI GRAND VITARA flame arrester

If you want to solve the problem of failing catalysts once and for all, then you can install a flame arrester (stronger) instead of the SUZUKI GRAND VITARA catalyst, but there are pros and cons. Pros:

- It will never burn out

- reflection and absorption of sound waves

- adds 1-5 hp power.

- low cost of the flame arrester (stronger) compared to the catalyst

- will not harm the turbine and engine (it does not clog)

Minuses:

- Afterburning of fuel occurs in the system, as a result the exhaust system fails faster (burns out)

- the sound increases (to varying degrees for cars with different engine sizes (the larger the engine size, the more sensitive the difference))

- on newer cars (2000s) a more sensitive electronic system for indicating the purity of exhaust gases is installed (2 or more lambda probes) - when installing a stronger, it becomes necessary to “deceive” it (mechanical tricks, “reflash” to Euro 2, etc.) d)

- High level of exhaust toxicity (this is for those who are concerned about environmental protection or travel abroad - the environmental standards of our country are loyal to this level).

Any catalyst will be an obstacle to installing a direct-flow exhaust system. In this case, there is only one way out: replacing the catalyst with a flame arrester (stronger). Essentially, a flame arrester is a high-quality resonator. It will never burn out, since its materials and operating principle simply do not allow this possibility.

Flame arrestors (stronegers) operate on the principle of reflection and absorption of sound waves. The combustion chamber of a car releases gases at high speed, heated to extreme temperatures. Once in the catalyst, they quickly cool down and their speed drops, and in the flame arrester everything passes further through the exhaust system. Thus, the car is reliably protected from destruction of the exhaust system with a catalyst, and the sounds of the exhaust are reliably muffled by the system.

Replacing the catalyst with a flame arrester SUZUKI GRAND VITARA

This option is profitable, but has completely different design features: the catalyst is removed from the car, and a flame arrester is installed instead, which, in fact, is a resonator that must withstand high loads (sound and temperature). The work of replacing the catalyst with a flame arrester (stronger) costs from 200 - 500 UAH depending on its installation location, but on cars with toxicity standards Euro 3.4 or more, after installing a flame arrester instead of the catalyst, the lambda probe begins to produce errors and, therefore, , it is necessary to re-flash the “brains” or install a “fake” on the second lambda probe (from 50 – 100 UAH).

Due to the simplicity of the design and the absence of a fragile filler, the flame arrester (stronger) has high reliability and a long service life, due to which the flame arrester is guaranteed. This option is also suitable for all cars.

Removing the catalyst for SUZUKI GRAND VITARA

Many motorists ask the question, why then can’t they simply cut out and remove the catalyst and weld a piece of pipe or muffler corrugation in its place? The fact is that, firstly, in addition to its main function, it reduces the noise level, therefore, in its absence, the exhaust system will work noisier, and also reduces the temperature of the exhaust gases and, in the absence of it, other parts of the exhaust system located after it will burn out quickly. Secondly, on cars with Euro 3.4 standards or more, another diagnostic lambda probe is installed after the catalyst, which checks the efficiency of its operation, and if it is missing, an error will appear and the car will operate unstably. Consequently, on cars with Euro 3.4 or higher standards, it is necessary to “reflash the brains” or install a “fake” lambda probe. Therefore, you cannot simply remove the catalyst. The question arises, what to do?

Replacement with a new catalyst or universal catalyst SUZUKI GRAND VITARA

Ideally , you need to install an original catalyst ; its price will be from $1000 and above. Second option: you can install a universal catalyst , the price of which is from 1000 UAH and above, depending on the standards of exhaust purity that it provides (Euro 2, 3, 4, 5), filling (ceramic or metal). For example: a ceramic catalyst of Euro 4 standards will cost 2,400 UAH, and a metal catalyst of Euro 4 standards will cost about 3,000 UAH. When installing catalysts, everything remains as it was before, the same sound, the same engine operation, but you need to be prepared for the fact that after a while it will need to be changed again (catalyst service life is 80-150 thousand kilometers, although if you take care of your car, undergo maintenance on time, i.e. there are no problems in the operation of the engine, then the service life of the catalysts will double).

Selection of the SUZUKI GRAND VITARA stronger flame arrester

Selection of a flame arrester (stronger) instead of a catalyst.

The main purpose of a flame arrester is to install it instead of a catalyst. Unfortunately, based on the make of the car, we cannot say for sure which flame arrester is suitable for this particular car. Therefore, there are two selection options - you can come to our car service center, where they will select the required part, or take measurements yourself and select the part yourself, or by contacting our manager.

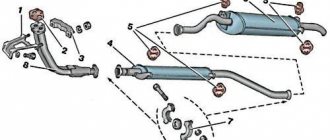

What dimensions should you measure? To accurately select a flame arrester, you need to measure:

1. Case size and length . If the part is round, then this is the diameter, if the part is oval, then the width and height of the part. The length is measured to the point where the catalyst is welded to the pipe.

2. The diameter of the pipe entering the catalyst . You need to measure the outer diameter of the pipe. When selecting a catalyst, the diameter of the flame arrester pipe should be either equal to or slightly larger than the diameter of the pipe suitable for the catalyst.

Delivery throughout Kyiv and all of Ukraine!

It's up to you to choose. Call!!!!

How to properly and competently remove a catalyst

Replacing the catalyst with a flame arrester

Many people ask the question “Is it possible to remove the catalyst yourself?” You can, if you have the necessary tool at hand, and not only a “cutting” or “welding” one, but also a full-fledged software package designed to disable (or deceive) the second lambda probe and the diagnostic function.

The Mastery service station, which specializes in solving any problems with the exhaust system, has everything necessary to remove the catalyst. With the help of its specialists, we will see all the stages of proper catalyst removal, including installing a flame arrester and disabling the corresponding errors and catalyst diagnostic functions.

How long does a flame extinguisher last? Pros and cons of the device

Rust removalLearning to remove rust from a car on your own

Flame arrestors installed separately usually operate successfully for five to ten years. Collective flame arresters last less (up to five years), since they have to work in the “hottest” conditions. The lifespan of this car part can be even longer if it is made by a reputable company using high-quality materials. It is also necessary to take into account operating conditions, vehicle characteristics and mechanical effects on the product.

Now a few words about the pros and cons of installing a flame arrester. The most significant advantage is the price of this device. By installing a budget flame arrester instead of an expensive catalyst, you can save a lot of money. The flame arrester is less demanding on fuel quality compared to the catalyst - this is its second absolute advantage. Since the quality of gasoline at our gas stations often leaves much to be desired, this advantage is quite significant. In addition, the flame arrester slightly increases engine power, since it has a direct-flow structure (and not a honeycomb, like a catalyst).

Of course, the flame arrester also has disadvantages (where would we be without them). The main one is environmental pollution. Without a catalyst, all outgoing exhaust gases go outside without any purification. So, if you care about clean air on the planet, then it is better to install a new catalyst.

To install a flame arrester, electric or gas welding is required, so doing it yourself is quite problematic. The installation of a manifold and a free-standing flame arrester is different because in the first case the exhaust manifold must be removed. However, it is hardly worth saving on this procedure: installing a collector flame arrester costs 6-8 thousand rubles, and a free-standing one costs 3-5 thousand rubles.

Differences between a resonator and a flame arrester

You can quite often come across stories from motorists who installed a flame arrester in the exhaust system of their vehicle. But not everyone knows what it is and how a resonator generally differs from a flame arrester.

Some argue that the only difference is the name. Others claim there is a significant difference between the two elements. It is necessary to understand the issue in more detail.

There is a device that for some reason in Russia and the CIS countries is often called a flame arrester. Let's start with the fact that the element does not extinguish the flame. This is where questions arise regarding the strange name. But the structure is actually installed in the exhaust system.

Moreover, flame arresters are placed directly behind the exhaust pipe. In fact, this design performs the tasks of an additional resonator. But here it is worth making some amendments.

In Russia, environmental standards are not nearly as strict as in Europe. Because of this, quite often on cars you can find situations where a flame arrester is installed in the rightful place of the catalytic converter, that is, the catalyst. Although the catalyst allows us to reduce the level of harmful emissions into our atmosphere.

In terms of its role in the exhaust system of a vehicle, a flame arrester really resembles a resonator in many ways. Its main functions include the implementation of the following tasks:

- partially compensates for the impulses that occur during detonation of the air-fuel mixture inside the combustion chambers,

- partially compensates for noise or sound waves in the low frequency range,

- regulates the movement of exhaust gas,

- reduces the temperature of the exhaust gas.

Now regarding the differences that directly interest us between the resonator and the so-called flame arrester.

The difference is in 2 main things:

- Flame arrestors must be made of high quality materials. This is due to its installation directly behind the exhaust pipe. Therefore, the absorber is subject to significant temperature loads and fluctuations. If the material is of poor quality, the element will quickly fail.

- A resonator compensates for sound waves more effectively than a flame arrester. After all, the direct responsibility of the resonator is precisely to compensate for peak sound waves, to organize the sound before it goes to the muffler.

Taking these factors into account, we can say that each element performs its assigned functions. The flame arrester and the resonator are not synonymous devices at all. These are slightly different elements of the exhaust system of a vehicle. But there really are similarities between them.

The principle of operation of the flame arrester

During operation, the flame arrester receives exhaust gases that enter the exhaust system, processes them and removes them. At the exit, the temperature of the gases becomes significantly lower, and their speed drops significantly.

In addition, the flame arrester breaks the primary flow of gases that come from the collector. This approach is used for the purpose of stable operation of the main resonator.

In addition, the flame arrester mixes all the unstable flows ufpjd from the cylinders into one stable flow. Thanks to the design of the body of the part itself, the flame arrester significantly reduces the level of noise that appears inside it due to the beating of gases.

Instructions for making a flame arrester with your own hands

So let's move on to the manufacturing procedure, for this we need two iron pipes, one with a diameter equal to the diameter of the exhaust pipe of the muffler, the second with a larger diameter and steel mesh brushes for washing dishes. On a pipe equal to the muffler pipe, we cut out (using gas welding or a drill) holes with a diameter of 3 mm along the entire circle and length. Then we insert this pipe in the center into a pipe of larger diameter and weld it on one side.

Then we stretch the mesh brushes in a circle in the form of a ring, put them on a pipe of a smaller diameter and push them tightly with a metal strip until it rests on the closed end of a pipe of a larger diameter. We continue this procedure until the last mesh brush reaches the free end of a larger diameter pipe. It took me 26 mesh brushes to fill the empty space.

After this, we bend the ends of the pipe of larger diameter, pre-cut with a grinder, and scald them in a circle. This procedure helps to avoid unnecessary ringing noises from the flame arrester during engine operation. For beauty, you can paint it with silver spray paint. Now, with peace of mind, we cut out the catalyst and weld the manufactured flame arrester in its place.

PS A flame arrester instead of a catalyst can be installed on cars with Euro standard 2. On cars with Euro standard above 2, there is an oxygen sensor lambda probe after the catalyst and removing it can lead to an error in the engine control unit, which in turn will increase fuel consumption and worsen dynamics car.

Alternatively, you can make a flame arrester with your own hands on a VAZ

We take an old resonator, it is 2 years old and 45t.km. For the flame arrester body we needed an old muffler. We cut the muffler into metal.

The outer casing of the drain muffler is 2 layers of metal - 0.6 mm on the outside; from the inside - 0.8 mm., by the way, well preserved, slight corrosion between these two layers of metal. Next, look carefully at the photo, everything is clear.

inside…

inside…

The outer diameter of the cut pipe is 80 mm, thickness 1.5 mm, will be used for the flame arrester body.

We use the remaining piece for the end walls, then, due to the reluctance to cut the resonator pipe in half due to the further complexity of the joining, we did this: the flame arrester body was welded, cut lengthwise:

We put the halves on, scald them, then on the outside with a second layer we weld a 0.8 mm thick shirt onto the flanges of the end walls with a gap between the shirts of about 5 mm, the flanges are visible in the previous photos, the result:

On the end walls there is also an additional layer of metal 0.8 mm

then on the flame arrester body there is a noise-sound-heat insulator - a cover with flanges with asbestos fabric inside

We cook the lining from the bottom of the car

Similarly, on the bottom side there is a lining with asbestos for the resonator, we cook:

By the way, there is a decent stench when paraffins come out of asbestos... from heating. Now we clean with a cleaning disc and a metal brush

We degrease and paint with thermal paint (otherwise it will quickly corrode during welding, all welded seams should be thoroughly cleaned with a brush) thermal paint is stated to reach 538 degrees Celsius, we’ll see... By the way, one can was enough to paint three layers, there was one extra can left...

Now in a week I’ll install it somewhere, now I won’t have time, the plans are to remove the old (new) resonator, remove the thermal shields from the bottom, clean and cover the barrier with 2 layers of vibration-mastic, reassemble it in place, and by the way, reinforced suspension cushions of the resonator (weight -something has increased), I hope the metallic sound will go away, or it will become much less, in any case, I will approach the assessment of changes carefully and as objectively as possible, otherwise I somehow got into trouble with the SAAB... The original muffler is straight-through, and these Saab ones are for turbo- engines, the turbine itself dampens the sound quite well and the task there is to remove the exhaust as easily as possible. By the way, between the wall of the original resonator and the outer pipe 1.5 mm thick, I was afraid to shove stainless steel dish brushes, in case they start rubbing against vibrations and pressure and pour into the exhaust or even into the engine, write comments and we’ll discuss

Yes, I almost forgot - the stock silencer has stainless steel end walls and an exhaust tip, a mysterious Russian soul, if the 2 outer skins were made of stainless steel, it would be an indestructible silencer because Everything inside is practically new.

Source

Motorist's benefit

Using a flame arrester when tuning

When installing a tuning exhaust system of the direct-flow type, the sound requirements are somewhat different: you need a thoroughbred, loud sound with a predominance of low frequencies. Therefore, the direct-flow flame arrester used for tuning can be simpler in design. It must be reliable, have a two-layer casing and a flow area corresponding to the motor power.

Catalytic converters compress the exhaust too much. When exhaust gases pass through the catalysts, there is a strong decrease in the throughput capabilities of the route. Flame arrestors are free from this drawback and allow you to normalize the average gas pressure.

The appearance of the flame arrester is also important. The ability to use different colors and types of paints allows you to tailor the design of the flame arrester to the style of the car.

Unfortunately, even well-known brands for the most part do not have direct-flow resonators with a two-layer casing, since in the West control over the purity of exhaust gases is much stricter. Therefore, low-resistance metal-based catalysts are popular there. They consider it acceptable to leave a standard catalyst behind the tuned manifold. Lack of interest in parts that can be used instead of a catalyst is considered the main reason why Western manufacturers do not produce any parts of this kind.

How to make a flame arrester with your own hands

As we already know, removing the catalyst (cutting it out of the exhaust system) is not difficult. At the same time, the characteristics of the car will not suffer from this. The only thing that will change is the environmental component. There will be more harmful substances in the exhaust gases of the car due to the lack of additional cleaning.

What types of flame arresters exist, what are their features? Is it possible to build a flame arrester with your own hands? Let's consider these points in more detail.

Removing the catalyst without installing a flame arrester - is it possible?

Many car owners are interested in whether it is possible to remove the catalyst and not install a flame arrester in its place. Theoretically, this is possible. But you should be prepared for a number of problems, namely:

- Reduced muffler service life. This is explained by the fact that the catalytic converter (like the flame arrester) retains and cools the exhaust gases. Further, the already cooled exhaust gases are directed to the muffler and no longer cause harm to the product (“burning” of the metal does not occur). If the catalyst and flame arrester are missing, then the hot stream of exhaust gases flows through the pipes to the muffler. For this reason, the resonator “burns out” faster, and the device itself requires repair or replacement.

- The exhaust volume increases. Many people believe that when the catalyst is removed (without replacing it with a flame arrester), the engine volume increases and resembles the sound of a racing car. Not at all. According to statistics, the catalyst removes only 5-7 percent of sound. This means that the engine becomes louder, but not significantly. Only particularly picky drivers will feel discomfort.

It is for these reasons that it is worth buying or making a flame arrester and installing it instead of the dismantled catalyst.

What types of flame arresters are there?

During the selection process, it is important to know about the types of devices available on the market. Today there are two types of flame arresters:

- Collector. Already by the name you can understand that such devices are mounted in close proximity to the collector. This type of product is used most often and is installed on 70 percent of cars.

- Trunk. The main feature of the flame arrester is its installation in the central part of the pipe. This type of device is suitable for cars with turbocharged engines. It's easy to explain. Engines with a turbine have special requirements: the pressure of the exhaust gases must be maximum. For this reason, a flame arrester is not installed on the exhaust manifold.

The mentioned types of devices also differ in design. Thus, the collector flame arrester has a simpler design, while the main unit has a more complex design.

How does a flame arrester work?

Flame arrestors come in completely different designs. Here's what a classic (“direct”) flame arrester looks like:

- Select a straight tube and drill a lot of holes in it (that is, make the product perforated).

- You make the body. It is desirable that the latter be done using two sheets of metal and a spacer (installed between the layers). Next, roll the blanks into an ellipse or cylinder.

- Insert a previously prepared tube with holes into the finished housing, and hammer non-flammable material into the spaces between them (basalt wool will do).

- Weld the upper part of the outer casing and leave only the pipe.

Video: DIY flame arrester for Ford Focus 2

If the video does not show, please refresh the page or » style=»color:#CC3333″>click here

That's all. Essentially, you made a fire extinguisher yourself. After its installation, exhaust gases will enter the pipe, pass through the holes made and remain in the material. At the same time, the flame arrester absorbs some of the extraneous sound and cools the exhaust gases.

Is it possible to make the device yourself?

From the considered algorithm it is clear that it is possible to make a flame arrester in a garage. In this case, the finished device is installed in place of the previously knocked out catalyst. But keep in mind that, to extend the service life of the flame arrester, use stainless steel as the starting material. The main advantage of this material is its resistance to corrosion and lack of reaction to road chemicals.

If you make a flame arrester with your own hands, using ordinary steel, the product is unlikely to last more than five years (it will be destroyed by corrosion). If you give preference to stainless steel, then the service life doubles or even more. The only difficulty lies in the special technology for welding such metal.

Components of the structure

As previously noted, the appearance of resonators is very similar to mufflers. Because of this, they are easy to confuse for a beginner. And more experienced motorists call resonators small or additional mufflers.

In fact, structurally this is a rather complex element, including several layers. Moreover, each of these layers is responsible for performing a specific function.

If you get acquainted with the structure of car resonators in cross-section, you can really notice a significant external resemblance to the standard standard muffler of a vehicle.

It is worth making some clarifications regarding how the muffler resonator is arranged in a car:

- the design is presented in the form of several chambers, which are separated from each other by a special mesh,

- This structure allows you to constantly narrow and expand the flow of exhaust gases. It is important to note that the gas comes out in sharp jerks. The resonator evens out these jerks, which allows you to get a uniform flow of generated gas exhaust at the output,

- the chambers inside are slightly offset, which allows you to change the direction of exhaust movement, thereby smoothing out uneven pulsation,

- Exhaust frequency damping occurs due to internal perforation. With its help, the noise level is reduced.

An automobile resonator performs its tasks thanks to a design that provides for the presence of a large number of closed cavities connected to each other using a pipeline and many perforations, that is, holes.

The holes provided by the design make it possible to cause multi-frequency vibrations that change due to friction.

As for the location, this element of the exhaust system is installed directly between the intake manifold or converter and the standard muffler.

But the location may be slightly different. This depends on the specific vehicle model and manufacturer.

It is important to understand that the gas produced in the engine during combustion of the air-fuel mixture has a high temperature. In this case, the function of the car resonator is to reduce it, reducing the thermal load on the muffler and the exhaust system elements coming after the resonator.

Now as for what temperature is at the outlet of the combustion chamber and under what thermal loads the small muffler operates. Depending on the specific vehicle system, temperatures can reach over 650 degrees Celsius. After combustion, the exhaust gas goes to the intake manifold at extremely high temperatures.

When reaching the car muffler resonator, the temperature does not drop so much. Therefore, it is extremely important that the resonator is made of high-quality and heat-resistant materials. When the resonator itself operates efficiently, it contributes to a drop in temperature, due to which the load on the muffler is significantly less. This extends its service life and preserves the integrity of the entire automotive exhaust system.

What to choose: flame arrester or catalyst

Almost the most popular work with the exhaust system on modern cars is replacing the catalyst with a flame arrester.

This procedure causes a lot of controversy as to how safe it is and whether the game is worth the candle. Let's consider the following points:

— Catalyst content

— Flame arrestor content

- Process

— Results of replacement

Catalyst

The internal filling of the catalyst is multilayer and consists of several fractions. One of the main elements is a part consisting of honeycombs and coated with platinum group metals. This is necessary to burn out harmful substances from the exhaust gases, thereby cleaning the part that goes into the environment.

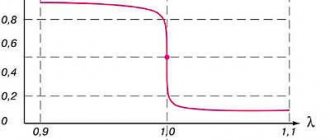

Thanks to total control, performed using two oxygen sensors installed on both sides and regulating the readings of both the incoming mixture and the outgoing purified one. If the readings differ from the specified parameters, then the operation of the power unit, and in particular its fuel system, will be adjusted or stopped.

Flame arrestor

Flame arrestor, there are 2 types. Intracollector and main. In addition, they are divided by type of production, into factory-made and handicraft-made.

However, the meaning of their use does not change, as does the interior decoration. When manufactured using a homemade method, the flame arrester is a barrel similar in size to the catalyst, inside of which there is an elbow, with holes drilled around the perimeter.

In simple terms, a flame arrester is not an alternative to a neutralizer in its full sense, but is often a successor. After installation, the control system is reprogrammed to a lower emission class in order to eliminate errors.

Replacement

When replacing one part with another, there are several methods. Provided that the catalyst is in the collector, there is a method in which the filling of the collector is removed in a barbaric manner by knocking it out.

Then, using a homemade method or selecting the required factory one, the flame arrester element is inserted inside and the integrity of the collector surface is restored. With this design, there may be a little more noise than usual, but the problem will go away after flashing the control unit.

The second method involves a similar procedure, with the catalyst located between the manifold and the middle part of the muffler. To pierce and remove the insides of the neutralizer, they use brute force and improvised means. In the end, you need to reflash the system for a lower fuel class and emission class.

The third option is the simplest and does not require much effort. The factory flame arrester is made in the form of a can, so using the necessary dismantling method, be it cutting off the old one or simply unscrewing the flanges, we remove the failed catalyst.

Bottom line

The cheapness and availability of this method are the main criteria for selection. If the flame arrester is made in a homemade way, then its main negative quality will be louder operation and a decreasing service life of the entire exhaust system.

The hot mixture will now reach the exhaust pipes faster, and accordingly, its wear will be increased.

When installing a factory flame arrester, the exhaust sound will not change one iota. It should also be noted that installing such a system, in principle, changes the factory settings and lowers the car’s requirements for both environmental friendliness of the exhaust and a higher octane number. Therefore, you can save money and use cheaper fuel.

To summarize, we note that such an operation has enough pros and cons; whether to do it or not is up to your locksmith and you personally to decide. And do not forget that replacing the catalyst with a flame arrester is required in specialized services that have not only experience in such repairs, but also qualified automobile mechanics.

Assembly of the flame arrester

A large pipe should be 30-40 mm larger in diameter. After holes are made around the circumference of the small pipe, it must be cleaned with a metal brush and inserted into the large pipe (strictly in the middle). The larger pipe must be placed with the same indentation on each side relative to the smaller one, and then the pre-cut parts should be folded and welded (the seams are also welded hermetically).

Article on the topic: Which tires to choose for the winter

Next, turn the pipes with the unwelded side facing you: you will need to put dish brushes on the smaller pipe, after which they need to be compacted tightly inside the resulting “glass”. After this procedure, you need to bend the petals to the smaller pipe and weld it to it in the same way (do not forget about the seams). Welding must be done carefully to avoid leaking joints. The finished flame arrester must be thoroughly cleaned with a brush to remove dirt and rust, and then coated with silver paint (spray cans can be used).

Now it's time to reassemble the old exhaust system. A newly manufactured flame arrester must be welded to the place where the catalyst was previously installed. Then the exhaust system is installed in its original place. It would be a good idea to treat its surface and coat it with a heat-resistant anti-corrosion compound.