The catalytic converter of exhaust gases is usually referred to by drivers and auto repair shop workers simply as a car catalyst. This device is installed in front of the exhaust pipe. It is needed to minimize the environmental damage caused by exhaust gases.

In a special chamber containing platinum, palladium, radium and other active components, chemical “burning” of harmful exhaust occurs. Thanks to a chemical reaction, aggressive carbon and nitrogen monoxide are converted into safer components: carbon dioxide, water, free nitrogen.

The design of a car catalyst is simple. It is a tube consisting of small ceramic or metal “honeycombs”. The walls of the cells are covered with an active mixture, which interacts with the exhaust. Passing through the tube, the air is purified, and much less toxic substances enter the atmosphere from the exhaust pipe.

Why does the catalytic converter fail?

The catalyst needs to be changed quite often - every 100-150 thousand kilometers. It is during this time that it manages to completely exhaust its resource. The fact is that a chemical reaction takes place in it, which binds certain compounds from the exhaust gases. Once the active reagents run out, the device becomes useless.

But other than that, there are several reasons why the catalytic converter will need to be replaced before the specified mileage. Accelerated wear of the device is possible under the following conditions:

- Regular driving on very bad roads. Constant shaking over rocks, potholes and uneven primers can cause the ceramic cells to simply break and cease to perform their function.

- Engine problems. If there are problems with the engine itself or the ignition system, unburned fuel and oil can enter the catalyst, clogging the small cells.

- The habit of constantly sharply pressing the gas pedal to the floor. In such a situation, the fuel mixture does not have time to burn completely; its residues also gradually clog the “honeycombs” of the neutralizer.

- Poor quality fuel or various winter additives. They contain impurities of lead and other heavy metals, which shortens the life of the exhaust purifier.

- Constant traffic jams. While the car is stuck in a traffic jam, its engine is still running, and accordingly, exhaust gas is being released. The catalyst resource is consumed faster than the recommended mileage.

How to extend the life of car catalysts

With the right approach to operation, the catalyst will last up to 150 thousand km. The negative impact of external factors leads to early failure.

In order for the neutralizer to work properly, you should follow a number of rules:

- use quality fuel. The lower the quality of gasoline, the sooner the neutralizer will deteriorate;

- keep an eye on the oil level. At high flow rates, some settles on the honeycombs, does not burn and clogs the channels;

- maintain the functionality of the ignition system;

- failed to start, take a break to allow unburnt gasoline to evaporate. Otherwise, an explosion in the catalyst and melted honeycombs are guaranteed;

- In case of electrical faults that require starting the engine to eliminate them, first disconnect the fuel pump relay. This will prevent fuel and lubricants from entering the exhaust system and prolong the operation of the catalyst.

How to tell if your catalytic converter is bad

Most often, catalysts are installed on cars that are already equipped with an electronic fault detection system. Therefore, if there are problems with the device, the “Check Engine” light on the panel will light up. In addition, manufacturers build in special oxygen sensors. If the exhaust gases are no longer cleared, some cars will automatically stop starting.

In addition, there are several other signs by which you can understand that it is time to change the exhaust gas converter. First of all, the engine power will decrease and the car will begin to accelerate worse. There may also be a rumble when starting the car. All this happens due to the fact that exhaust gases cannot exit normally through the clogged mesh and return back to the combustion chamber - the engine “suffocates”.

Ceramic catalysts

This device uses a mechanical method to reduce the concentration of harmful substances. The catalyst has a honeycomb structure, the surface of which is coated with an alloy of platinum and iridium. It is this coating of expensive metals, together with the increased contact area between the exhaust gases and the catalyst, that ensures the removal of harmful components to the established standards.

Where is the catalyst located in a car?

The ceramic catalyst works according to the following principle:

- When exhaust gases pass through the catalyst, additional oxidation of unburned fuel components with oxygen occurs. Thanks to the chemical oxidation reaction provided by the catalytic layer, exhaust gases are purified.

- During oxidation, the working elements of the catalyst heat up significantly, which makes it possible to significantly increase the rate of chemical reactions. This is what makes it possible to ensure cleaning in accordance with current regulations. The CO content when using ceramic-type catalysts will meet even stringent European standards.

Manufacturers claim a service life of 100 thousand kilometers. But, given the quality of domestic fuel, in most cases the catalyst can last 70-80 thousand kilometers, after which it will need to be replaced.

What does a catalyst look like?

In addition to low-quality fuel, the resource of a ceramic catalyst may decrease for other reasons. In particular, such catalysts are sensitive to:

- Strikes;

- Sudden temperature changes or overheating;

- Ingress of unburnt fuel due to ignition problems;

- Contact with oil or coolant;

Devices of this type are installed on the majority of cars entering our market.

When to remove the catalyst and how to drive without it

It is imperative to remove and replace the faulty part after the exhaust gas neutralizer has exhausted its service life. This is done either after a certain mileage, or if there are already clear signs of its malfunction. If this is not done, the car will begin to consume more fuel, start and accelerate worse, and some models will stop starting altogether.

The easiest way out is to simply buy a new catalyst and install it in place of the used one. But such a part is expensive due to the precious metals it contains. Therefore, many car owners simply install decoys and use flame arresters.

Reprogramming sensors

This is the easiest way to do without an exhaust gas converter. Car manufacturers install two oxygen sensors called lambda probes that monitor the level of pollution in the exhaust air. To make it possible to drive without a catalyst, these sensors are turned off, and the on-board computer is reflashed taking into account the changes made to the design.

Using a flame arrester

This is a more affordable device than a catalytic converter. The flame arrester works as a muffler and also separates the exhaust gas flow. It does not have such a fine mesh grid as in the catalyst, so the flame arrester is not so sensitive to the quality of the combustible mixture and various additives. In addition, it allows air to pass through much more freely, which increases engine power by 5-10% and also reduces fuel consumption.

"Decoys" for probes

After installing a flame arrester or completely removing the catalyst, additional “decoys” for lambda probes will be needed to avoid flashing the car’s on-board system. What are these “deceptions”? These are additional spacers that move the second lambda probe further from the exhaust. As a result, a lower level of contamination is detected, and the on-board computer does not generate any error messages. “Dummy tubes” can be empty or with a mini-filter inside to obtain the necessary data on contaminants.

Why do you need a catalyst?

The main purpose of a catalyst in a car is to reduce the content of carbon monoxide (CO) and nitrogen monoxide (NO and NO2), as well as hydrocarbon group compounds (CH), in the exhaust gases. This is realized through more complete combustion of fuel or by changing the physical and chemical properties of the fuel used.

Operating principle of the catalyst

In Europe, the amount of harmful impurities emitted by a car is regulated by the European emission standards, which provide the following permissible values for cars with less than 8 passengers and weighing less than 3.5 tons (category M1):

| Stage | date | CO | HC | HC+NOx | NOx | P.M. | PN |

| g/km | #/km | ||||||

| Diesel | |||||||

| Euro 1 | 1992.07 | 2.72 (3.16) | — | 0.97 (1.13) | — | 0.14 (0.18) | — |

| Euro 2, IDI | 1996.01 | 1.0 | — | 0.7 | — | 0.08 | — |

| Euro 2, DI | 1996.01 | 1.0 | — | 0.9 | — | 0.10 | — |

| Euro 3 | 2000.01 | 0.64 | — | 0.56 | 0.50 | 0.05 | — |

| Euro 4 | 2005.01 | 0.50 | — | 0.30 | 0.25 | 0.025 | — |

| Euro 5a | 2009.09 | 0.50 | — | 0.23 | 0.18 | 0.005 | — |

| Euro 5b | 2011.09 | 0.50 | — | 0.23 | 0.18 | 0.005 | 6.0×10 |

| Euro 6 | 2014.09 | 0.50 | — | 0.17 | 0.08 | 0.005 | 6.0×10 |

| Petrol | |||||||

| Euro 1 | 1992.07 | 2.72 (3.16) | — | 0.97 (1.13) | — | — | — |

| Euro 2 | 1996.01 | 2.2 | — | 0.5 | — | — | — |

| Euro 3 | 2000.01 | 2.30 | 0.20 | — | 0.15 | — | — |

| Euro 4 | 2005.01 | 1.0 | 0.10 | — | 0.08 | — | — |

| Euro 5 | 2009.09 | 1.0 | 0.10 | — | 0.06 | 0.005 (DI) | — |

| Euro 6 | 2014.09 | 1.0 | 0.10 | — | 0.06 | 0.005 (DI) | — |

| IDI - diesel engines with separated combustion chambers; DI - diesel engines with direct fuel injection; | |||||||

To ensure that the amount of harmful emissions does not exceed permissible standards, car manufacturers usually use ceramic catalysts. But there are also alternative options:

- Chemical catalysts.

- Magnetic-strictive catalysts.

All these modifications have different operating principles, providing fairly effective exhaust gas cleaning. At the same time, the catalyst does not have a significant negative effect on engine power and other technical characteristics of the car.

Pros and cons of catalyst removal

For car owners, there are several advantages to removing the catalytic converter:

- no need to buy and regularly replace a short-lived, expensive part;

- engine power increases;

- fuel consumption is reduced;

- sensitivity to fuel quality decreases;

- the engine does not “suffocate” due to deterioration of exhaust gas removal.

But despite all the advantages of removing the catalyst, this procedure also has a number of disadvantages. First of all, the composition of the exhaust deteriorates, and as a result - a more destructive effect of the car on the environment. And if for some reason exhaust gases enter the cabin, an unpleasant odor may be felt there. If you do not open the windows for ventilation, your head begins to hurt - the driver and passengers receive a weak release of CO and nitric oxide.

If the catalytic converter is not removed correctly or the flame arrester is not installed correctly, engine fault messages may constantly appear on the dashboard. In addition, difficulties arise with technical inspection, and an unpleasant rattling sound may appear while driving.

How does a catalyst work?

The operating principle of this unit is quite simple:

- exhaust gases leave the cylinders and enter the “cleaning honeycomb”,

- the filter heats up red hot,

- the exhaust burns out,

- oxidized substances settle in the cells of the neutralizer,

- the exhaust gas leaves the exhaust pipe.

In order to start the cleaning process, the temperature inside the catalyst must be at least 750°C. Combustible substances leave the cylinders with insufficient heat - 500-550°C. Chemical reactions that occur when gases enter the filter space heat the cells and lead to the burnout of harmful substances.

Where to remove the catalyst

You can remove the air purification device yourself - to do this, you need to remove the exhaust manifold, disassemble the required unit, or cut it out with a grinder. However, to do this you need to know where exactly the catalyst is located. If you had to cut it out with a grinder, you will additionally need welding. If you intervene independently, there is a high risk that an odor will appear in the cabin or an unpleasant sound when driving.

It is best to entrust this work to professionals from a car repair shop. Specialists are guaranteed to do everything quickly and correctly, and will also help you choose the best alternative to the catalytic converter: flashing, “fake” or flame arrester.

Chemical catalysts

Chemical catalysts or anamegators are a large group of catalysts that can be classified as additives. These catalysts are added to fuel and allow it to change its structure and properties. This reduces the toxicity of exhaust gases, ensures a higher degree of combustion, and minimizes the possibility of unwanted detonation processes.

The principle of operation of the catalyst is based on changing the orientation of the hydrocarbon molecule, which improves the conditions for the oxidation reaction with oxygen. Thanks to this, it becomes possible to ensure more complete combustion. As a result of small changes in the chemical composition of the fuel, engine power increases, and the concentration of toxic substances in the exhaust gases decreases.

Manufacturers offer various anamegators. When choosing, keep in mind that the efficiency of application will depend on the correct concentration of the catalyst in the fuel, so follow the requirements and recommendations of the manufacturers.

The use of chemical catalysts can also increase fuel consumption by about 10%, which is considered its main disadvantage.

Stereospecific polymerization

The discovery of olefin polymerization with the subsequent production of stereoregular polymer substances has an important historical significance in the history of the study of catalysis. The discovery of catalysts characterized by stereospecific polymerization belongs to K. Ziegler. The work on the production of polymers carried out by Ziegler interested J. Nutt, who put forward the assumption that polymer uniqueness should be determined by its stereoregularity. A large number of experiments involving X-ray diffraction have proven that the polymer obtained from propylene under the influence of the Ziegler catalyst is highly crystalline. The action effect is stereoregular in nature.

Reactions of this type take place on the plane of a solid catalyst containing transition metals, for example Ti, Cr, V, Zr. They must be incompletely oxidized. The equation for the catalytic reaction between interacting TiCl4 and Al(C2H5)3, during which a precipitate is formed, serves as a clear example of this. Here the titanium is reduced to 3-grade state. This type of active system makes it possible to polymerize propylene under normal conditions of temperature and pressure.

Oxidation in catalytic reaction

Catalytic oxidation reactions are widely used by humans, due to the ability of certain substances to regulate the rate of the reaction itself. Some applications require complete oxidation, such as neutralization of CO and hydrocarbon-containing contaminants. However, the vast majority of reactions require incomplete oxidation. This is necessary to obtain in industry valuable but intermediate products that may contain a certain and important intermediate group: COOH, CN, CHO, C-CO. In this case, a person uses both heterogeneous and monogenic types of catalysts.

Among all the substances that can accelerate chemical reactions, oxides occupy an important place. Mostly in solid state. The course of oxidation is divided into 2 stages. In the first stage, oxygen oxide is captured by the hydrocarbon molecule of the adsorbed oxide. As a result, the oxide is reduced and the hydrocarbon is oxidized. The renewed oxide interacts with O2 and returns to its original state.

Meaning of the word catalysis

(from the Greek katálysis ≈ destruction), a change in the rate of chemical reactions in the presence of substances (catalysts) that enter into intermediate chemical interactions with the reacting substances, but restore their chemical composition after each cycle of intermediate interactions. Reactions involving catalysts are called catalytic. The amount of reactant that can undergo transformation in the presence of a certain amount of catalyst is not limited to any stoichiometric ratios and can be very large. This distinguishes catalytic reactions from induced or conjugate reactions, when one reaction is caused or accelerated (induced) by another and an irreversible transformation of the inductor substance occurs. Possible changes in the catalyst during catalytic reactions are the result of side processes that in no way determine the catalytic effect.

Exposure to a catalyst opens a new reaction pathway, usually with a large number of steps, in which the catalyst is part of the active complex (activated complex) of at least one of the steps. If in this case the reaction rate becomes greater than in the absence of a catalyst, then the reaction is called positive (it is often identified with the general concept of reaction). The opposite case is also possible, when negative reaction occurs: in the presence of a catalyst, one of the possible reaction paths is excluded and only slower ones remain, as a result of which the reaction slows down or is even almost completely suppressed (see Antioxidants, Chemical inhibitors). A special case of catalysis is the acceleration of a reaction under the influence of a reaction product or one of the intermediate substances formed during the reaction (see Autocatalysis).

K. is not associated with a change in the free energy of the catalyst, and the effect of the catalyst cannot therefore shift the equilibrium position of the chemical reaction. Near equilibrium, catalysts accelerate both forward and reverse reactions equally.

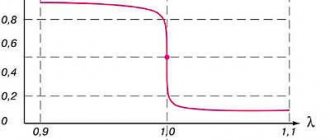

The main factor determining the rate of chemical transformation is the activation energy (E) ≈ the difference between the energies of the active complex and the initial reacting molecules. If we assume that the reaction does not violate the equilibrium distribution of energy between the molecules, then the probability of the formation of an active complex, and therefore the reaction rate, in a first approximation, is proportional to exp (≈E/RT), where R ≈ gas constant, T ≈ absolute temperature. It follows that the reaction rate is higher, the lower E is, and due to the exponential dependence, it increases significantly even with a slight decrease in E. In Fig. shows the change in energy during a reaction without a catalyst (curve 1) and with the participation of a catalyst (curves 2 and 3). Curve 2 with two maxima corresponds to the formation of one intermediate product. The number of stages and intermediate products is often significantly large. The interaction of reactants with the catalyst may not lead to the formation of a stable form of the intermediate compound (curve 3). But even in this case, the catalyst is part of the active complex and the interaction of the reactants with the catalyst determines the reaction path. If the energies of the active complexes of all stages of the reaction path with the participation of a catalyst are lower than the energy of the active complex of the reaction without a catalyst (i.e., and E3 is lower than E1), then the participation of the catalyst will lead to an increase in the rate (positive K). In many cases, reaction acceleration is achieved due to the appearance of energy-rich particles during the reaction itself, and their concentration can exceed the equilibrium one (see Chain reactions). For example, the catalytic effect of water on the oxidation of carbon monoxide is associated with the development of reaction pathways involving hydroxyl groups and hydrogen atoms. Negative K. is often associated with the cessation of a chain reaction due to chain breakage during the interaction of a negative catalyst with active particles. An example is the retarding effect of oxygen on the combination of hydrogen and chlorine.

The nature of the intermediate chemical interaction during K. is very diverse. Typically, two groups of catalytic processes are distinguished: acid-base (heterolytic) and redox (homolytic). In the processes of the first group, an intermediate acid-base interaction of the reactants with the catalyst occurs, for example, the transfer of a proton from the catalyst to the reactants or vice versa. In subsequent stages, the proton moves in the opposite direction, and the catalyst restores its composition. When reacting with aprotic acids, the interaction occurs through a free pair of electrons of the reacting substance. Examples of acid-base acid are the hydrolysis of esters accelerated by acids; hydration of olefins in the presence of phosphoric acid catalysts; isomerization and cracking of hydrocarbons on aluminosilicate catalysts; alkylation; polymerization and many other reactions. In redox reactions, intermediate interactions are associated with electronic transitions between the catalyst and the reacting substances. This group includes the oxidation of sulfur dioxide to trioxide in the production of sulfuric acid; oxidation of ammonia to nitric oxide to produce nitric acid; numerous processes of partial oxidation of organic compounds, for example, ethylene into ethylene oxide, naphthalene into phthalic anhydride; hydrogenation; dehydrogenation; cyclization and aromatization of hydrocarbons; decomposition of hydrogen peroxide and many others. Metals of the 4th, 5th and 6th periods of the D.I. Mendeleev system, which have an unfinished d-shell of electrons, their compounds and, to a lesser extent, compounds of elements, have catalytic activity in relation to redox reactions with an expanding f-shell (lanthanides and actinides).

The groups considered do not cover the entire variety of catalytic reactions. The nature of the intermediate interaction during reaction is much more complex and depends on all the details of the electronic structure of both the reacting substances and the catalyst. The specific mechanisms of catalytic reactions are diverse and have so far been firmly established only in a few cases.

Depending on the phase state of the reactants and the catalyst, homogeneous and heterogeneous catalysts are distinguished. An intermediate position is occupied by microheterogeneous catalysts in colloidal systems (for example, catalysts with enzymes). In homogeneous reactions, the catalyst and reactants form one homogeneous system; there are no interfaces between the catalyst and the reactants. In heterogeneous reactions, the catalyst and reactants are in different phases and are separated from each other by an interface. The most important cases are when the catalyst is a solid and the reaction system forms a liquid or gaseous phase. In this case, the intermediate interaction occurs mainly on the surface of the solid catalyst.

The choice of catalyst composition for a particular reaction is a very complex problem, so far solved mainly empirically. In the USSR, a number of theoretical approaches based on the correlation of individual particular properties of catalysts with their activity were proposed and developed. Thus, the multiplet theory of catalysis (first published in 1929) assumes the intermediate interaction of reactants with several atoms on the surface of solid catalysts and attaches decisive importance to the correspondence of the distances between atoms in the molecules of the reactants and the parameters of the crystal structure of the catalyst. Subsequently, the theory was supplemented by the idea of the need for a certain correspondence between the energies of the bonds broken and formed as a result of the reaction, and the energies of the bonds of the reactants with the catalyst during intermediate interactions. Significant spread in the 50s. gained an understanding of the dependence of the catalytic activity of solid catalysts with semiconductor properties on their electrical characteristics, the so-called electronic theory of K. According to this theory, it is assumed that the intermediate interaction of reactants with the catalyst is carried out with the participation of conduction electrons of the solid catalyst and therefore depends on its collective electronic properties ≈ the location of energy bands and local levels of electrons, the electron work function, the concentration of current carriers, etc. In heterogeneous catalysts, the assumption (put forward in 1939) of the existence on the surface of solid catalysts of special active centers, which are edges, corners, or various structural disruptions (dislocations) of the normal crystal structure. It was also assumed that when a catalytically active substance is applied to an inert support, special catalytic properties are exhibited by individually located atoms or combinations of a small number of atoms ≈ ensembles.

The emergence of precise methods for determining the surface of catalysts has made it possible to establish that the activity per unit surface (specific catalytic activity) is determined by the chemical composition and depends very little on structural dislocations. The specific catalytic activity of different crystal faces sometimes differs several times. Violations of the chemical composition (deviation from stoichiometry, introduction of impurities, local chemical formations, etc.) have a great influence on activity.

In the 1960s, intermediate chemical interactions in heterogeneous catalysts were considered primarily as local, determined by the electronic structure of individual atoms or ions of the catalytically active component on the surface of the catalyst, taking into account the influence of the immediate environment. Significant assistance in the development of this approach was provided by the experimentally discovered analogy in the action of solid catalysts containing a certain metal in heterogeneous catalysts and soluble complexes of which the same metal is a component in homogeneous catalysts in solutions. In this case, the theories of the crystal field and the ligand field are used, which were previously successfully used in the chemistry of complex compounds. For a number of classes of catalysts and catalytic reactions, correlations have been established between the catalytic activity and the binding energies of the reactants with the catalyst during intermediate interactions, which facilitate the selection of catalysts in some cases.

The first scientific information about K. dates back to the beginning of the 19th century. In 1806, French chemists N. Clément and C. Desormes discovered the catalytic effect of nitrogen oxides on the oxidation of sulfur dioxide in the chamber process for producing sulfuric acid. In 1811, the Russian chemist K. S. Kirchhoff discovered that dilute acids can cause the conversion of starch into sugar (glucose) ; in 1814, he also discovered that this reaction could be catalyzed by diastase from barley malt, and this marked the beginning of the study of biological catalysts - enzymes. In 1818, the French chemist L. Tenard established that a large number of solids has an accelerating effect on the decomposition of hydrogen peroxide solutions, and the English chemist G. Davy discovered the ability of alcohol and ether vapor to be oxidized by oxygen on platinum. In 1822 German. The chemist I. Döbereiner established that hydrogen and oxygen combine on platinum at ordinary temperatures. This was followed by the discovery of a number of other examples of a sharp positive effect of substances on the speed or occurrence of chemical reactions. This led to the identification of a special group of phenomena called it. chemist E. Mitscherlich contact (1833) and Swede. chemist I. Berzelius catalytic (1835).

Subsequently, a large number of catalytic reactions were discovered, and over the past 50 years, catalysis has become the leading method for carrying out chemical reactions in industry. The use of catalysts makes it possible to carry out chemical transformations at high rates at low temperatures; most industrial catalytic processes could not be implemented at all without catalysts. By selecting catalysts, it is possible to direct chemical transformations towards the formation of a specific product from a number of possible ones. The use of stereospecific catalysts makes it possible to control the structure of final products, for example polymers. With the help of K. at the beginning of the 20th century. The problem of air nitrogen fixation was solved. Promoted iron and other catalysts made it possible to overcome the chemical inertness of elemental nitrogen and to carry out the synthesis of ammonia. At the same time, a catalytic method was developed for producing nitric acid by oxidizing ammonia on platinum grids. Modern methods for producing hydrogen from natural gas are based on catalytic reactions. Catalytic methods also occupy a dominant position in oil refining technology. Hundreds of millions of tons of high-quality motor fuel are produced using catalytic cracking, hydrocracking, reforming, cyclization and isomerization reactions of petroleum hydrocarbons. Catalytic methods play a particularly important role in the implementation of organic synthesis processes. In our country, for the first time in the world, the production of synthetic rubber was developed and implemented, based on the conversion of ethyl alcohol into divinyl using a multicomponent Lebedev oxide catalyst. Catalytic methods are used to obtain the vast majority of petrochemical synthesis products: solvents, aromatic hydrocarbons, monomers for the production of synthetic rubbers, synthetic fibers and other polymer materials. Catalysts are also widely used for polymerization.

K. plays a leading role in chemical transformations in living nature. The entire complex system for controlling life processes in organisms is based on catalytic reactions. Biological catalysts, called enzymes or enzymes, are protein substances with chemically active groups, often including atoms of transition elements. In some properties, enzymes are superior to industrial catalysts. In the USSR and abroad, research is being carried out widely on new types of complex synthetic catalysts - complex compounds, organic semiconductors, polymers, characterized by a simpler composition compared to enzymes, but simulating their action to a certain extent. The science of chemicals plays a significant role both in the progress of the chemical industry and in the discovery of the most important biological laws.

Lit.: Balandin A. A., Multiplet theory of catalysis, part, 1≈2, M., 1963≈64; Volkenshtein F.F., Electronic theory of catalysis on semiconductors, M., 1960: Catalysis, ed. P. N. Ernmett, v. 1≈7, NY, 1954≈60; Ashmore P., Catalysis and inhibition of chemical reactions, trans. from English, M., 1966; Thomas J., Thomas W., Heterogeneous catalysis, trans. from English. M., 1969; Kiperman S.L., Introduction to the kinetics of heterogeneous catalytic reactions, M., 1964; Boreskov G.K., Catalysis in the production of sulfuric acid, M. ≈ L., 1954; Krylov O.V., Catalysis by nonmetals, L., 1967; Fundamentals of predicting catalytic action. Proceedings of the IV International Congress on Catalysis, vol. 1≈2, M., 1970.

G. K. Boreskov.