Removing the catalyst in our country is very popular among car enthusiasts. Some of them believe that the catalyst may fail at the wrong time. According to others, the efficiency of the catalyst is seriously impaired due to the poor quality of our fuel, which leads to a drop in engine power. No less common is the opinion that removing a clogged catalyst helps reduce fuel consumption. How to check if the catalyst is clogged?

In most cases, experts recommend checking the catalyst first and only then deciding whether to remove it. Often, dismantling this element of the exhaust system can lead to an error, since the electronic engine control unit treats this as a breakdown. The problem can be solved by simply reflashing the ECU. But first of all, you need to understand how to find out if the catalyst is clogged. It is very important to check it carefully. In our article we will also look at the main signs of a clogged catalyst.

Read more about what a catalyst is and how it works here.

Self-test methods

- The most affordable option is to remove the catalyst and carry out a visual inspection. In order to understand whether the honeycombs are clogged, it is necessary to use a light source. As a rule, removing the catalyst can be very difficult, since the fasteners stick quite strongly. The fact that all work is carried out under the car also adds extra hassle.

- You can also check the catalyst by determining the amount of harmful substances in the exhaust gases (one of the signs of a clogged catalyst is an increased content of harmful substances).

- Measuring the exhaust back pressure (if the catalyst is really clogged, the resistance will be very high, which also affects the pressure).

Autopub advises using all the above methods. Only in this case can you find out for sure whether the catalyst is clogged.

About the catalyst, its malfunction and replacement options

What kind of detail is this - a car catalyst, because of which the car can lose dynamics, simply stall and not even start afterwards??? Because of which fuel consumption may increase, trembling and vibration may appear, an extraneous unpleasant rattling sound under the bottom or in the engine compartment, an unpleasant smell of hydrogen sulfide??? And in the end, the turbine may fail, the engine gaskets can be squeezed out, and an unexpected engine overhaul may occur.

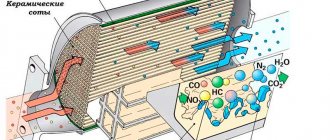

A catalyst, or more precisely a catalytic converter for exhaust gas purification, is a part of the exhaust system, which is most often located after the exhaust manifold or turbine and in front of the middle part of the muffler (resonator, corrugation or main muffler). The catalyst (in the exhaust system can be like one, two, three and even four) are responsible for the function of afterburning exhaust gases to environmental standards EURO-2, EURO-3, EURO-4, EURO-5. Since after burning fuel in a car engine, a number of pollutants are released into the atmosphere , the catalytic converter was developed to reduce their levels and neutralize

A) carbon monoxide (CO) - a poisonous, colorless, odorless gas B) hydrocarbons - which are one of the main components of the so-called “SMOGA” C) nitrogen oxides (NO)

Catalysts are divided into several types

A) according to the structure - ceramic and metal B) according to environmental standards - EURO-2,3,4,5

Until 2000, cars were equipped with catalysts of the EURO-2 environmental standard; after 2000, EURO-3 and EURO-4, respectively. And in recent years, some car brands have already reached EURO-5.

CATALYST RESOURCE. SIGNS OF PROBLEM. CONSEQUENCES OF MALFUNCTION. REPAIR AND REPLACEMENT WAYS.

In theory, the service life of catalysts is designed for 100-120 thousand kilometers. But in practice, it often happens that they fail at an earlier date, as it is not trite to say, most often due to poor, low-quality fuel. It can also fail due to malfunctions of the ignition system (when either the ignition coil or the spark plug fails and incorrect mixture formation occurs and the fuel burns completely not in the combustion chamber but in the body of the catalyst itself) It can also become clogged when it gets into oil gets in from the internal combustion engine or turbine. It happens that it fails due to mechanical damage and sudden temperature changes (when a heated catalyst falls into a puddle or snowdrift).

Here are some signs that can help identify a faulty catalytic converter:

1) Most often, on cars after 2000, the CHECK ENGIRE error lights up on the instrument panel and subsequent diagnosis of error codes reveals malfunction P0420-P0430 (Efficiency below the threshold or ineffective operation) 2) Loss of vehicle power (and it manifests itself more noticeably on a warm engine, in traffic jams, when going uphill) 3) Increase in fuel consumption by 1.5-2 liters 4) Extraneous, rattling sounds in the engine compartment or under the bottom of the car (depending on the location of the catalyst) 5) The appearance of a pungent odor of hydrogen sulfide

These signs can be detected individually or together. It may be that the CHECK ENGIRE light is not on and there are no errors, but the car does not run and consumption has increased. But sometimes, on the contrary, the CHECK light is on and the car feels good.

But in any case, if any of the symptoms are present, it is necessary to conduct a diagnosis and identify the cause. And if a malfunction of the catalyst is detected, then repair or replace it, since a faulty catalyst can lead to more serious damage, such as

1) When the catalyst is clogged, due to the back pressure, there is a large load on the piston group of the engine, on the turbine and automatic transmission, which accordingly reduces their service life several times. 2) The CHECK ENGIRE light itself indicates ENGINE MALFUNCTION and is responsible for the operation of almost all engine sensors. And if your light is already on due to a faulty catalyst and another critical fault appears, you won’t know about it because CHECK is already on. 3) The worst thing is that when the catalyst fails, its ceramic base begins to crumble and, due to back pressure, can get into the piston group and, accordingly, the engine will soon need to be repaired...

If you are faced with this problem and you need to repair and replace the catalyst, then you can contact a specialized center for the repair and tuning of exhaust systems, including repair and replacement of catalysts, “AUTOVICHLOP”, where they will explain everything to you at a professional level and suggest the most optimal ones and high-quality ways to solve this problem and will carry out the entire necessary range of work to repair and replace the catalyst with a guarantee and at reasonable prices in the shortest possible time.

How to find out if the catalyst is clogged - the best way

We decided to consider a method of checking the catalyst using the current back pressure.

Some experts advise welding special fittings in front of the catalyst, with the help of which a certain amount of exhaust gases will be collected. It is advisable to use threaded fittings into which, after checking, you can screw plugs (it is recommended to make them from brass).

In order to measure the back pressure, you need to screw the brake tube into the fitting to dissipate excess heat (the length of the tube should be about 40-50 cm). A hose should be put on the other end of the tube and a pressure gauge should be connected to it with a measurement interval of up to 1 kg/cm3. During the procedure, the hose should not come into contact with elements of the vehicle exhaust system.

To obtain an accurate result, it is necessary to measure the pressure while the car is accelerating, and the throttle valve must be fully open. All indicators when increasing engine speed must be recorded. If the back pressure with the throttle open is above 0.35 kg/cm3 within a certain rpm range, your exhaust system needs improvement.

Although this option really allows you to check the catalyst as accurately as possible, in real conditions not every motorist can devote the time and money to weld the fittings. Therefore, another method can be used.

How to check the catalyst for clogging? Method No. 2 - pressure gauge

The essence of this method is to check the exhaust system for back pressure. How to check the catalyst for clogging? For this we need a pressure gauge and an adapter. The latter should be of such a diameter that it fits tightly into the place of the oxygen sensor.

So, we unscrew the lambda probe and install a pressure gauge with an adapter there. How to check the catalyst? We start the engine, raise the speed to 2.5 thousand and look at the readings. Normal pressure should be at least 0.34 kgf per square centimeter. If the level is less, it means the element is clogged.

In this way you can check the catalyst of a VAZ 2170 or any foreign car. The only problem is the difficulty in removing the oxygen sensor. Often it “sticks” to the catalyst. It is also necessary to achieve maximum tightness of the connection. If the exhaust "cuts", the readings will be inaccurate.

Checking using available tools

- Unscrew the lambda probe installed in front of the catalyst and install a pressure gauge using the appropriate adapter. An ordinary hose can become an adapter, but complete tightness must be achieved.

- Start the engine and record the readings of the device (you will find out the back pressure at the outlet).

- Another person needs to rev the engine to 3000 rpm, and you need to record the pressure gauge readings. Then you need to raise the engine speed to 5000 rpm and record the received data again (4-7 seconds is enough).

There is another solution:

- Unscrew the lambda probe, which is located in front of the catalyst.

- Screw the fitting into its place.

- Connect the fitting to the brake pipe.

- Place a rubber hose on its end and insert it into the car interior.

- Do everything in the same sequence as in the first method, which we called optimal.

If the Check Engine light comes on on the instrument panel, do not panic, as this is a normal reaction of the ECU to the lambda being turned off. After installing this element in place, the light will go off.

I would also like to note that when checking the catalyst, a maximum of 0.35 kg/cm3 is more relevant for cars with a modified engine. Many experts believe that for conventional models a result of up to 0.5 kg/cm3 is quite acceptable.

After you have seen that the pressure gauge readings are seriously different from optimal, you need to try to clean the catalyst and rinse it. If this cannot be done, the part is replaced. Since in many cases you have to pay a lot of money for a catalyst, a decision is often made to dismantle it.

Signs of a clogged catalyst

You can find out that the catalyst will soon have to be changed or simply thrown away using some signs.

Signs of a catalytic converter malfunction:

- deterioration of vehicle speed performance;

- drop in maximum speed;

- problems with starting the engine;

- presence of a strong odor of hydrogen sulfide.

Recognizing the symptoms of a clogged catalyst is not very difficult. Often motorists simply do not pay enough attention to this issue. They simply press the accelerator pedal harder, while various chemical processes are already disrupted in the clogged catalyst.

There are only two main reasons for catalyst failure:

- destruction of the ceramic component or catalytic layer;

- contamination of honeycombs with soot or melting of the catalyst core made of ceramics.

If you notice even the minimal symptoms mentioned above, we advise you to check the catalyst, and it is better to do this as early as possible.

Often, car enthusiasts install a flame arrester instead of a catalyst. Are you also interested in this topic? Clicking on the link will help you understand all the intricacies of the process.

Why does the catalyst clog?

What does a working catalyst look like?

Article on the topic: Valve cover gasket - change without problems

The catalytic converter acts as a filter, and any filter element becomes unusable over time due to the accumulation of dirt. In the case of a catalyst, contamination can be accelerated by such malfunctions as:

- ingress of coolant or oil;

- low fuel quality;

- bad firmware of the control unit;

- gas equipment with an incorrectly configured control unit;

- mechanical damage;

All of the above reasons accelerate the clogging or melting of ceramic honeycombs.