Home / Car reviews 260 ..

Lifan X60 / Lifan, 5-door crossover, 128 hp, 5-speed manual transmission, 2012 - 2020 - the starter turns, but the engine does not start

The starter turns, but the engine does not start

Causes

There can be quite a few reasons for this behavior of a car. The main ones are listed below. We have divided them into two categories. First, let's look at those that any beginner can handle:

Human factor

: You forgot to turn off the anti-theft, which blocks, for example, only the fuel pump. The exhaust pipe is clogged. Kind people put a rag or a potato in it, or maybe you just drove into a snowdrift - there are many options. The exhaust pipe must be freed.

All of the above, in general, is not a breakdown, and can be solved in no time. Now let’s look at the reasons associated with a technical malfunction: If the starter turns very slowly, then the cause may be the oil in the engine that has thickened in the cold. Or maybe it’s a discharged battery after a long stay or its terminals are heavily oxidized. In this case, the voltage of the on-board network may drop so much that the engine control unit refuses to work. Well, everything is clear here: the oil should be filled according to the season, the battery should be charged or replaced. Something has frozen - water in the gas line, diesel fuel in the tank or filter. Look for a warm box! The fuel pump is faulty. This is easy to verify, unless you are trying to start the car near a busy and noisy highway. If the environment is quiet, then a sensitive ear can detect the absence of the characteristic buzzing of the fuel pump during starter operation. In the best case, poor contact in the circuit is to blame; in the worst case, you will have to replace the pump. The flywheel crown rotates. This sometimes happened on cars of previous years, up to the VAZ-2109. You can hear that the Bendix is engaged with the ring, and the ring rotates on the flywheel with a squeal. The flywheel is about to be replaced.

The starter does not engage with the ring

. Reason: wear of parts, chipped teeth, etc. When you try to start, you hear grinding teeth. Get ready to replace the ring gear or flywheel.

Bendix stuck

. Whether its drive failed, or the Bendix itself, it doesn’t matter. You can hear the starter motor spinning at high speeds, but there is no further attempt to crank the engine. Get ready to repair or replace the starter itself.

Failure of the ignition system in gasoline cars

. We check everything - spark plugs, coils, wiring, etc. The glow plugs of a diesel car do not work. The problem may be in the control unit, as well as in the power relay. The candles themselves should also be checked - you will have to tinker with this.

Timing belt shattered

. It’s easy to feel: it’s easy for the starter to turn. If you're lucky (the pistons don't meet the valves), it's enough to replace the belt; if not, then half the engine.

The timing belt jumped several teeth, disrupting the correct valve timing. Again, in the best case, you will need to return the belt to its place, but in the worst case, you will face expensive repairs. Increased resistance to rotation of the crankshaft: scuffing on shafts, bearing shells, parts of the cylinder-piston group, deformation of shafts. Check if the engine can be cranked when pushing the vehicle with the manual transmission in top gear. With an automatic transmission, you will have to try to turn the engine using the bolt securing the auxiliary drive pulley. If the engine can be turned over relatively easily, then the search for the cause will need to be continued.

Seized alternator, power steering pump, air conditioning compressor

. A faulty unit prevents the engine from turning. To check, you can first see if the belt is straining excessively when trying to crank the engine. If your suspicions are confirmed, you can remove the auxiliary drive belt and try to drive to the service station under your own power. Of course, this will only work on cars where the coolant pump rotates the timing belt. With a non-working pump and no coolant circulation, even a cold engine will quickly boil. They tried to steal your car at night, but something went wrong. As a result, the attackers dug around, broke something and disappeared in disgrace. Here, without diagnostics at a service station, the problem cannot be solved.

What to do

If the starter turns, but the engine does not start, first of all you should check the power supply and ignition systems. Please note that all these checks should only be performed when the starter turns smoothly without jerking. Otherwise (jerks when the starter operates or clicks instead of the usual buzzing), the problem should be looked for, first of all, in the starter itself.

Checking the fuel system should be performed sequentially - from the fuel pump to the injector (carburetor):

1. If you have an injector, then when you turn on the ignition, you should hear the buzzing of an electric fuel pump in the cabin. If there is no buzzing, it means either the fuel pump motor is burnt out or there is no voltage to it. Therefore, it is necessary to check the fuel pump itself, as well as its fuse.

2. With carburetor cars, everything is a little more complicated: the fuel pump is driven by the camshaft, so to check you will have to remove the end of the hose from the carburetor inlet fitting or the fuel pump outlet fitting. If you pump the manual pump lever several times, gasoline should come out of the fitting or hose.

3. To check the presence of gasoline in the injector rail, press the valve of the fitting for connecting the pump: gasoline should flow from there.

4. Be sure to check if the fuel filter is clogged. Perhaps the engine simply does not have enough fuel, so it does not start.

5. Another reason why the starter turns but the car does not start is a clogged throttle valve.

After completing all the steps described above, you can try to start the car again. If the starter still turns, but the car does not start, then you need to move on to checking the ignition system.

1. First, you should unscrew the spark plug and check for a spark. To do this, you need to put a high-voltage wire on the switched-off spark plug, touch the spark plug skirt to the metal part of the engine and turn the engine using the starter (you will need an assistant for this). If there is a spark, then the spark plug is working.

2. If there is no spark in a fuel-injected car, then the problem is in the ignition module.

3. If there is no spark in the carburetor engine, then you should check the ignition coil. Pull out the central wire from the distributor cover, place its end 5 mm from the metal part of the engine (without touching) and ask an assistant to crank the engine with the starter. If there is no spark, the coil is faulty.

4. If there is a spark and the ignition coil is working properly, you should remove the distributor cover and look for any defects under it (carbon deposits, cracks, etc.).

There are times when all these checks are not enough, and the car owner has to carry out deeper checks to identify the reason that the starter turns but the engine does not start. Reasons why this could be include:

1. Burnt fuse. This doesn’t happen often, but it’s still worth checking the integrity of the fuses in the blocks.

2. Corrosion on any of the electrical parts.

3. Condensation under the hood. There have been cases when the car did not start precisely because of excessive moisture under the hood.

Specifications

Technical characteristics of Lifan X60 / Lifan in a body of 5 doors. crossover with a 128 hp engine, 5 manual transmission, produced from 2012 to 2015.

Lifan is a popular brand of budget cars from China. The most common problem with these cars is a breakdown of the ignition system, but this is not the only reason why the Lifan X 60 does not start. To solve the problem, you need to check the functionality of all systems.

Lifan cars (x 60, x 50, lifan smily)

In Russia, the number of Lifan cars increases every year. Despite prejudices against Chinese cars, they remain popular among consumers. The reason for this is the affordable cost and acceptable quality.

The model range is represented by crossovers and business sedans. Technical description of the most popular crossover Lifan X60:

- petrol 16-valve engine;

- 128 horsepower;

- fuel consumption - 8 liters per 100 km;

- acceleration to 100 km/h in 11.2 s.

In terms of performance, the model competes with Toyota RAV4, Chery Tiggo, Nissan Qashqai.

Despite all the positive qualities of the brand, these cars are also prone to breakdowns. When the car does not start, you first need to check a trivial thing - the level of gasoline in the tank. If everything is fine with it, you can use traditional methods: try to start it from a hill or light a cigarette from a neighbor. But in case of breakdowns, the root cause needs to be looked deeper.

Reasons why Lifan won't start

The reasons why Lifan X 50 and X 60 do not start are common to all models of the brand:

- problems with wire contacts;

- insufficient level of technical fluids;

- starter failure.

To start the engine you need a spark, which is supplied through an electrical circuit from the battery. Therefore, first of all, you need to check that the battery is charged. To do this, it is important to install another battery. If the car starts, the problem is a discharged battery.

If this is not the problem, you need to check all the wires and terminals. Often, due to oxidation, the current does not reach its destination and the electrical circuit does not close. Also, Chinese cars are characterized by wire breaks and rotting, so you need to visually check their integrity.

It is worth checking the fuses that are located under the steering column and under the hood. Due to excessive load on the network, they could burn out, as a result of which the machine would no longer start.

To start the car, several conditions must match. Manufacturers put them in the mechanisms, and everything works automatically; the driver only has to follow the operating rules and monitor the level of technical fluids. What can affect the engine starting:

- lack of oil;

- problems with gasoline supply;

- lack of coolant.

To ensure that oil and gasoline are supplied in the required volume, you need to monitor the cleanliness of the filters, as well as the condition of the gasoline pump. In addition to gasoline, air is needed to start the engine. It may not flow at all or in insufficient quantities due to a clogged fuel filter. The technical description of Lifan Smiley and other cars contains information on how often you need to change filters and update the oil.

If there is not enough antifreeze, the engine may overheat and boil. It can only be started after it has cooled down. To do this, it is recommended to open the hood and turn on the heater so that the engine releases excess heat.

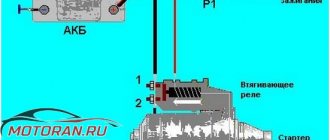

A malfunction of the starter can be judged by the following signs: when you turn the ignition key, there are no sounds, you can’t hear the engine trying to start. In this case, you need to check the voltage at the starter and coil. If it is missing, the part will have to be replaced.

In addition to the starter, the relay may burn out. In this case, you can connect the starter directly to the battery. If it helps, then you will have to change the relay. If the starter does not click, the problem may be either the starter or the relay.

In some situations, the starter can be repaired. As a result of long-term use, the armature brushes may wear out or the rotor or stator may burn out. But repairing a starter is a difficult and expensive task. Therefore, most car owners buy a new part.

When the entire electrical circuit from the battery to the spark plugs has been checked, but the engine still does not start or stalls immediately, experts recommend checking the compression in the cylinders. Due to insufficient pressure in the combustion chamber, the fuel-air mixture does not explode, so the engine does not spin up. To check you will need a compression gauge.

Low compression values mean that the engine requires major overhaul. The service life of engines on Chinese cars is 150,000 km without repairs and without problems. But reviews from motorists report that after 100,000 km, major repairs may be required. Manufacturers explain this by low-quality oil.

In order for the car to serve for a long time and not fail at the most inopportune moment, you need to follow the operating rules, fill in high-quality oil, and change filters regularly.

The Lifan X60 is a fairly popular car that has established itself among Russian drivers as a budget alternative to comfortable sedans. Thanks to the optimization of production from the Middle Kingdom, the cost of this car reaches the price tag of a modern Lada, which gives drivers the right to choose even in the budget segment of the auto market.

However, like any equipment, the Lifan X60 may experience technical problems, and regardless of the intensity or conscientiousness of the service, in particular, it may not start. There are few reasons why ignition is not supplied to the Lifan X60 engine:

- Loss of electrical circuit contact;

- No supply of technical fluids;

- The starter does not work;

- The power unit began to boil.

Each of the above problems can equally interfere with starting a vehicle, however, in most cases, any malfunction is easily diagnosed and quickly eliminated.

GAZ Gazelle 1999, 100 l. With. - breakdown

Cars for sale

GAZ 2217, 1997

GAZ 21 Volga, 1968

GAZ 3110 Volga, 1999

GAZ 2217, 2010

Comments 26

what to do the ignition does not work the snout clicks but the starter does not crank

I bought a power fuse block a long time ago, but it turned out to be a new model with 6 mm studs. And I have smaller terminals!

I need to work hard on the wiring, but it’s still cold!))

Today! I use the indicator to touch the chip of the “+” wire leading from the fuse block to the PC, it doesn’t light up, I touched the insulated terminal “it’s on”, I jumped into the cabin, I turn the key, the starter doesn’t work.

I threw a parallel wire “+” from the block and secured it to the PC, everything works!

Thank you all so much for your advice!

Does the relay click from the key? if yes, the control circuit is working.

Assuming that the starter itself is working, since it directly comes to life when shorted, a power circuit remains: a wire from the main fuse box to the relay and from the relay to the starter. Well, and, to the heap, the largest and thickest wire with + battery.

check for snot and oxidation of compounds. and that's all.

does it spin straight, but the retractor does not work, or does it click straight?

I have a small wire (which I temporarily ran in parallel) leading from the PC (in parallel) to the lilac wire, I put it on the “+” terminal on the starter and the starter turns!

Well, the retractor itself works or clicks. The nickels may just burn out, or the holding winding may burn out.

Yes, the retractor works!

And does the engine turn normally in a straight line? then the lock, the starter relay, and if there is a relay in the gap from the signaling system, then look at that too

In short, when I bought the car, I started to wash everything and discovered that a wire was laid from the starter relay (it was just dangling), I threw it away, four months later a friend came up and said there is a SHABASHKA), give the car, I say, take it of course. I left for work, he calls 2 hours later, he says the starter isn’t working, he came, he says let’s change it, and there’s a snowstorm outside, we call another friend and say melt the potbelly stove in the garage, we’re on our way, we got stuck, we transferred snow with a volume of GAZ -53)), they changed it the starter but it doesn’t work, I bought a new starter relay, again “0”, that’s where I remembered about this wire. In the end they set the starter to “RETAKES ITSELF”, the battery is new and it barely turns!

I came home tired, my father said, “You don’t have mass,” and this wire is “MASS,” and in the end I didn’t understand what the wire was. I installed the old starter and everything works!

This happened about two months ago! And today it refused again!

The ground on the retractor relay is short, it is screwed to the cabin, + goes from the fuse block through the relay to the retractor plug, control comes from the lock.

The engine should turn straight if you connect the plug on the retractor with a wire from the battery positive

if the engine does not turn, or poorly, then it is a thick mass on the body. if it is normal, then + nuts. If it clicks, it's the retaining winding. if it clicks and doesn’t turn, then nickels

To be honest! I didn’t understand! + on PC comes from the lock? The ground is short on the body! (on a PC) How to check the ignition switch?

control + ground from the lock to the body and to the engine somewhere, it looks either like a healthy pigtail or like a thick black wire, check from the lock, there is either a pink or red thin one, you can easily find it by holding the key in the starter position

There is no contact in the electrical circuit - we start looking for problems correctly

In almost any structural unit of a modern vehicle, troubleshooting should begin with the vertebrae of the electrical circuit. A simple contact break or blown protective fuse can cause the engine to not respond to the starter - before dismantling and disassembling components, it is first necessary to:

- Inspect the battery terminals for oxidation, and also check the battery charge level;

- Check the integrity of the wiring leading from the battery to the starter and from the starter to the engine;

- Inspect the fuses in the car block. Depending on the year of manufacture of the car, the fuse box may be located in the passenger compartment under the steering area or under the hood on the right side of the engine.

Analysis of the state of the electrical circuit will allow you to timely identify problem areas and, if necessary, replace damaged areas. Most engine ignition problems involve a broken contact in the electrical circuit, which occurs due to blown fuses, broken or rotted wiring, which is especially important for the Chinese automobile industry.

Remember, if there are damaged areas in the electrical circuit, it is recommended to eliminate the problem areas - otherwise, the situation in the future may cause a short circuit in the wiring, which can lead to expensive electronic repairs.

No supply of technical fluids: briefly about the main thing

To form the optimal air-fuel mixture ratio and successfully ignite the power unit, it is necessary to create almost ideal conditions for the engine. Problems with starting the power unit may arise due to:

- Insufficient amount of antifreeze or coolant;

- Low volume or low quality technical oil;

- The presence of blockages in the air supply channels;

- Insufficient fuel supply to the combustion chambers.

All of the above factors can become a problem that prevents the engine from starting and reaching the operating rpm. To diagnose and eliminate such situations, you must:

- Check the operation of the fuel pump and the volume of fuel in the tank;

- Inspect the condition of the engine coolant and oil and, if necessary, top up or completely replace consumables;

- Check the air filter.

In case of problem ignition of the engine, it would also be a good idea to check the condition of the spark plugs - perhaps further attempts are hampered by the banal filling of the electrodes with gasoline. If, after eliminating all possible causes, the engine refuses to start, it is worth inspecting the electric motor or starter of the power unit.

Compression reduction

In a diesel engine, the air-fuel mixture ignites under pressure. When compression drops, the air and fuel are not compressed to the required level in the cylinder. Because of this, the working mixture does not heat up to the nominal temperature. Self-ignition of atomized diesel does not occur and the engine does not start.

A similar situation occurs when the crankshaft speed is insufficient. During compression, part of the air manages to escape through the cracks and gaps into the sub-piston space. Because of this, the working mixture is not compressed to the nominal pressure and does not spontaneously ignite.

The reason for decreased compression is usually:

- wear or destruction of compression rings,

- the appearance of a gap between the contacting surfaces of the pistons and cylinders due to abrasion,

- presence of damage or wear in the valve mechanism.

To restore compression, the power unit must be overhauled and worn or damaged parts replaced. In some cases, rebuilding the engine is not practical, so in this case it is better to purchase a contract engine.

The starter does not work: what to do?

The starter is a complex structural mechanism in which a very extensive list of components can fail. However, in practice the most common situations are:

- Failure of the pull-out relay - identifying such a malfunction is quite simple: you just need to directly connect the starter to the battery. If the electric motor starts clicking, then the problem is in the relay; if not, the reason may lie in both the electric motor and the relay. Most often, such malfunctions are eliminated by simply replacing components;

- Starter short circuit - usually occurs due to a break in the insulating winding. A burnt starter cannot be repaired and requires a complete replacement of the product with a new one.

- Burnout of the rotor or stator - the cause of this problem is the habit of long torsion of the starter. Attempts to start the engine while holding the key for more than 10 seconds in the ignition position negatively affect the condition of all electrical systems of the engine, including the starter. If the stator or rotor fails, the electric motor becomes completely dead and does not respond to turning the key - the situation can only be corrected by replacing damaged components;

- Wear on the armature brushes occurs when the starter is used for a long time. The most pronounced sign that determines brush wear is problematic starting of the engine: when the engine starts after a few seconds, regardless of the operating temperature. The malfunction can be eliminated by dismantling the electric motor and replacing worn-out components.

Important to remember! Problems with the electrical part of the vehicle's power unit require certain qualifications - otherwise, independent repairs can only aggravate the problem. If you do not know the contraction units, it is better to entrust the repair to experienced mechanics - often calling a team is cheaper than the consequences of a makeshift repair.

How to Remove the Starter on a Gazelle

- Repair and overhaul of gazelle starter with Cummins ISF 2, 8 engine

- It so happened that there was only time to repair the Cummins gazelle starter in the evening, so all operations were carried out in the twilight and in the light of my bicycle headlight.

- In fact, in order:

- 1) Removed the protection from the battery;

2) I got to the starter, for a few seconds I was stupefied about how to unscrew the bolts for the sprockets, but the “10” head (which has 12 edges) came to the rescue and everything worked out! Although the upper starter mounting bolt (it’s not in the photo) slightly forced me to make some noise.

The power wire is unscrewed with a key set to “13”, the retractor control wire has a connector at the end, so it can be easily removed:

- What a bastard he is!

- Naturally, it is better to unscrew the top bolt first, so that the starter plays much less, although it will not fall out on its own, the tube with the dipstick going into the oil pan will not allow it to do this.

- 1) The back cover is held on by two long bolts with a “10” head:

- Start of analysis...

- 2) Remove the cover with light blows of a hammer:

This is the crap that goes on in the lid! Oxides, burnt areas on the 4 contact pads of the mass of the brushes!

- The contact plate of the brushes is also in a nasty state!

- Having pulled out the positive brushes, I remove the windings, the armature and the mounting plate with the brushes. I cleaned everything both on the plate and on the lid, treated it somehow with a liquid (an acquaintance brought me to use it), which soaks away oxides and rust and leaves an anti-corrosion film, it seems not on an acid base, so I used:

- I became better naturally!

- It’s also starting to make me have a little fun!)

- The starter is geared, so I added little lubricant to the gearbox. A roller bearing is anchored at the rear:

- Oh what!

- But the boot can’t do anything against water, because the mixture in the bearing is thick!(

- Accordingly, the generator bearing was also lubricated with the freshest fuel oil.

- In general, the condition of the mechanical parts of the starter (bearing, gearbox gears, pinion gear and bendix shaft, flywheel ring are also in good condition.

Accordingly, what can be said about the starter. The mechanical part is in good condition. Electronic in unsatisfactory! Rubber cuffs are inserted everywhere to prevent water from getting into the starter, there is even a drainage tube in the back cover, BUT it feels like all these rubber bands only help the water stay there! (I expected more from a manufacturer like Cummins!

The repair did not take much time and effort. The most difficult thing of all is to get the extension with the head onto the top bolt , unscrew it, and also carry out the reverse operation! The brushes themselves are virtually wear-free, as are the armature contacts.

Yesterday evening, no matter how sad, the situation repeated itself and it would be nice if it were somehow expected or simply solved, but at half past twelve in the evening, when the streets were not rich, and my friends had gone to bed or were going to bed, the car started and did not start...

Fortunately, my girl came to the rescue on her Getz and with a cable! 5 meters of towing did the trick, the car started up!) I myself find it difficult to imagine pushing the gazelle these 5, or even more meters!)

Now, of course, I took it off and dissected it:

The autopsy, like last time, showed that corrosion was to blame. In principle, the photos in the post on the link are similar. Corrosion. It’s corrosion in Africa too! In my opinion, a third-party manufacturer of the starter, which is equipped with my Cummins engine, is to blame for this situation.

Therefore, how to use such a crap design in an electronic contact that requires several hundred amperes is unacceptable.

The essence is that the brushes receive negative power from the metal plate on which they are installed, in turn, this plate is screwed to the back cover with 2 small bolts with sealing rubber bands, while the negative power reaches the iron plate due to pressing it against four ebbs inside the lid... absurd in one word. Over time, the aluminum back cover oxidizes on its own, and the fact that the starter manufacturer placed small stones in its internal cavity almost 2 cm above the bottom point of this cavity allows moisture to accumulate, accelerating the oxidation process. Cool?

The power unit is boiling: this problem can be solved

This situation arises in the case of intensive use of the vehicle in conditions not intended for this purpose. Engine boiling can occur as a result of the following reasons:

- Vehicle overload;

- Using low octane fuel;

- Long-term use of the engine at low speeds;

- Driving in a gear that does not match the engine speed;

- Breakage or violation of the main cooling circuit of the motor.

As a rule, you can prevent engine boiling by monitoring the operating temperature of the power unit. If the indicator on the temperature sensor increases, then you need to stop and check the cooling system and allow the engine to cool down - this is the price drivers pay for purchasing small cubic capacity engines.

If the engine does boil, you will have to wait until the operating temperature of the engine drops to the optimal level, after which you will need to add the missing amount of antifreeze. It is strictly not recommended to try to start an overheated engine that has not cooled down, as there is a risk of only aggravating the problem by adding a starter malfunction or valve failure.

After the boiling engine has cooled down and been successfully ignited, you need to take the car to the nearest service station - this will minimize the damage from the consequences of overheating. Also, a motor that has just cooled down should not be overloaded to avoid a relapse.