I changed the timing belt, set the marks - it stopped starting. When I changed it, the belt slipped about 6 crankshaft teeth. I set everything according to the marks, checked the TDC, everything is normal, but it stopped starting.

- What accessory belts should I install on the Priora and do I need to change the pump? – 5 answers

- Do the valves on the 2011 Priora 16v bend? – 5 answers

- Bent valve on Priora 2011? – 3 answers

- Won’t start after replacing the VAZ Priora timing belt – 2 answers

- Do the valves on the Priora (2170) bend? – 1 answer

And when it slipped 6 teeth, did you turn the crankshaft? If so, and the engine is 126 - the valves are bent - check the compression!

Align the belt, unscrew the spark plugs, manually turn the engine, and then measure the compression with a compression gauge.

Six teeth is a lot. An unambiguous meeting of pistons and valves. Sorry.

I’m not sure, but it seems to me that the pistons are machined there to avoid meeting with the valves. I dare to suggest that: Don’t forget that the crankshaft makes two revolutions, while the camshaft(s) only make one revolution, so the marks could coincide, but the crankshaft should be turned one more full revolution. I personally “flew” with this when I changed the timing belt. Most likely, it turns out that the spark on the spark plug appears at the moment of purging the cylinder, and not at the moment of compression.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

It sometimes happens that after changing the timing belt, the car does not start. The problem can occur on different cars. This may appear on different models. The prerequisites under any circumstances will be approximately the same. It is better to eliminate them immediately after identification. For this purpose, it is worth knowing that our client has options for defects that prevent the engine from starting. By and large, there are not that many of them. It is also important to change the timing drive (gas distribution mechanism).

No matter what mistake leads to the following dilemmas. Before checking the timing drive, be sure to check the condition of the ignition system and battery. The reason you will like this question.

After changing the timing belt, the car does not start. If this problem appears after the timing belt breaks, then the cause must be found. If the drive breaks, the valve timing is lost. In most cases, a collision between pistons and valves occurs. This most likely ends in bending of the valves, or worse, damage to the pistons.

Some domestic manufacturers once made pistons taking into account such a threat. They have special recesses for valves on the upper surface of the pistons. Such engines can be found on VAZ-2108, 2109. Also, some cars of the tenth family were equipped with similar engines. Among foreign cars, we find such pistons on some Mitsubishi, Renault and some other brands. But only on fairly old cars.

It turned out that such grooves noticeably reduce engine power.

Read

Identify the problem with the valves, of course, using 2 methods:

- Remove the valve cover and carefully turn the engine. Here, pay close attention to the operation of the valves. If one does not work, then it is mainly bent. This method is not reliable; in some cases the valves will not work properly;

- A more reliable method is to examine the condition of the valves specifically on the removed head. What can our client do? Bent valves are visible to the naked eye.

After replacing the timing belt, the car does not start? Several reasons why

Sometimes it happens that after replacing the timing belt, the car does not start.

The problem can occur on different cars. Moreover, it can appear on a variety of models. The reasons will be approximately the same in any case. It is advisable to eliminate them immediately after identification. To do this, you should know all the possible faults that prevent the engine from starting. In principle, there are not so many of them. It is also important to change the timing drive (gas distribution mechanism) correctly. Any mistake can lead to subsequent problems. Before checking the timing drive, be sure to check the condition of the ignition system and battery. This may be the reason.

Tips and tricks

When replacing the timing belt, the rollers should also be replaced. Otherwise, the old rollers may jam, which will lead to a timing belt break.

When replacing, you should select either original parts for this model, or their high-quality analogues, but only those recommended by the manufacturer itself. You need to be wary of numerous fakes.

The service life of the belt is significantly reduced by severe vehicle operating conditions. For example, driving in the cold season on a cold engine increases wear on parts.

Problems in the cliff

After replacing the timing belt, the car does not start. If this problem occurs after the timing belt breaks, then the cause must be sought in this. If the drive breaks, the valve timing is lost. Most often, a collision between pistons and valves occurs. This ends, at best, with bending of the valves, and at worst, with damage to the pistons.

Many manufacturers at one time made pistons with this danger in mind. They have special recesses for valves on the upper surface of the pistons. Such engines can be seen on VAZ - 2108, 2109. Also, some cars of the tenth family were equipped with similar engines. Among foreign cars, such pistons can be found on some Mitsubishi, Renault and some other brands. But only on fairly old cars.

It turned out that such grooves significantly reduce engine power.

There are two ways to identify a problem with the valves:

- Remove the valve cover and carefully crank the engine. At the same time, carefully monitor the operation of the valves. If one does not work, then most likely it is bent. This method is not reliable; in many cases the valves will work as they should;

- A more reliable way is to study the condition of the valves directly on the removed head. All bent valves are visible to the naked eye.

An article on the topic “Which VAZ engines do not bend the valves.”

If you determine that the valves are damaged, you will have to replace them. This must be done as a complete set. Don't forget to grind the new parts properly.

Incorrect replacement

Often a problem with engine starting occurs during a scheduled belt replacement. This is mainly due to incorrect assembly. In this case, the phases do not match. In practice, it turns out that the compression stroke ends in one cylinder, and the spark hits the other. Therefore, it is important to make the replacement carefully and carefully.

Mismatch of marks on the pulleys is a fairly common mistake among novice mechanics. Many people forget to turn the engine on them. As a result, the spark cannot meet the piston. Be sure to check the position of the marks. Remember that the rotation speed of the crankshaft is different from that of the camshaft. To accurately determine the position of the fourth cylinder at top dead center, you should unscrew all the spark plugs.

A rubber plug is inserted into the fourth cylinder; instead, you can take a disposable plastic bag; they also clog the hole for the spark plug. When the engine “shoots” the plug, the cylinder will be right near the dead center of the compression stroke.

All that remains is to move it up a little, checking the position with a screwdriver. After this, the position of the marks is checked. The bottom one will naturally match. Well, unless of course you touched the crankshaft. So pay attention to the top one. If it doesn't match, then that's the reason. Remove the belt and align the camshaft pulley according to the marks. Then install the belt and try to start the engine. Most likely it will start.

Also on some models there is a mark on the flywheel. Few people know about her. But it must also match. Often the reason for the engine not starting after replacing the timing belt is precisely this. Keep in mind that the flywheel is often dirty, and it can be quite difficult to see the mark there. Therefore, be careful.

On carburetor engines, when replacing the belt, the ignition may be disrupted. More precisely, the compression stroke moves from the fourth cylinder to the first. This is a sign of unskilled assembly. You should adjust everything according to the marks again. If you need to drive right now, this happens, then you can swap the high-voltage wires of the fourth and first cylinders. This will help you start the car without problems.

Details

. Some drivers, trying to save money, do not buy new rollers. In this case, the installed belt simply slips and the car does not start. The same problem can happen if the components are selected incorrectly. Always purchase belts and pulleys recommended by the manufacturer. Also, the entire timing drive must be replaced; partial replacement can lead to breakdowns.

Conclusion

. Replacing the gas distribution mechanism drive is a rather complex and responsible procedure. Even with experienced mechanics, it may happen that after replacing the timing belt, the car does not start. If newbies get down to business, then this is generally a common occurrence. In this regard, carefully study the rules for replacing the drive, as well as all possible causes of further malfunctions.

Why does the alternator belt whistle?

What are the causes of a whistling alternator belt? Typically, the whistling starts when the engine is cold or in wet weather - when the engine has just been started and other energy consumers have also turned on. It also starts whistling when you press the gas pedal - and after a while the unpleasant sound disappears.

In the cold

The main reason is moisture ingress. Fortunately, this problem is easy to fix. The belt drive is not protected by casings - in the absence of protection for the engine crankcase, water from puddles gets on it. The whistle may appear even after the power unit has warmed up, but in this case it will soon disappear.

The appearance of a whistle can be explained by insufficient tension of the belt drive or a violation of its structure. In addition, working fluid may get on the consumable, and this can lead to more serious consequences - it may simply fly off. Contact with synthetic ATF oil is especially dangerous. The ingress of conventional motor oil leads to stretching of the consumable and, as a result, to the appearance of unpleasant sounds.

Check the tension rollers, as over time they begin to jam. The belt may not move parallel to the pulley, resulting in friction with the rollers. The unpleasant sound will be heard constantly. This will lead to severe wear on the belt drive and may cause it to break. Urgently take the car to the service station!

The freewheel may become stuck. It is usually attached to the generator armature; its purpose is to reduce the load on the belt. The power unit functions unevenly - there are moments of “splash” when the fuel burns out in the cylinders, and moments of attenuation when gas begins to be removed. This negatively affects the belt if the crankshaft and the generator armature are in a rigid connection. So the alternator belt whistles on cars with clutches - this happens almost all the time.

The pulleys of the pumps, crankshaft and generator gradually wear out. For example, if a small pulley on a generator wears out and a large pulley on the crankshaft wears out, this will put excessive stress on the small element. Typically, pulleys are made of aluminum, which is by no means a hard material. The teeth wear out quickly and it starts to whistle. The track on the pulley itself can also be damaged - for example, crumpled after an impact. Pebbles or dirt get into the pulleys. This can easily be avoided by simply cleaning them from below with a brush. The whistle may disappear, or it may remain if the pebbles have managed to damage the surface of the teeth.

People, help, it won’t start after replacing the timing belt!

Good evening everyone!

I decided to change the timing belt, when disassembling I saw that the front oil seal was leaking = changed it, then I decided to go through and wash and clean the VCG system, I was disarmed that the ejection pump was not working = installed a new one, the valve on the DZ pipe (with a stone, blows in all directions) didn’t bother, left it as it was Yes, one pipe was replaced with a simple oil-resistant one. I took it apart and removed the manifold and immediately replaced the gasket under the intake manifold. The TDC marks coincide, the engine is turning, there is a spark, the injectors are spitting gasoline, the compression is 11 in all. The car is assembled but without headlights, radiator grille, bumper because... I want to go to the car wash to wash the air conditioner radiator.

Is there anyone from Berezniki (Perm region) who could come and do a diagnosis. Let's agree.

PS Maybe she should get headlights so she can start

pavel1 said: 03/21/2011 21:17

sysanin

, Did you mix up the wires for 1.2 spark plugs?

After replacing the timing belt, the car does not start? Several reasons why"

After replacing the timing belt, the car does not start? Several reasons why

Any mistake can lead to subsequent problems. Before checking the timing drive, be sure to check the condition of the ignition system and battery. This may be the reason.

Car won't start after timing belt replacement

. If this problem occurs, then the reason must be sought in this. If the drive breaks, the valve timing is lost. Most often, a collision between pistons and valves occurs. This ends, at best, with bending of the valves, and at worst, with damage to the pistons.

Many manufacturers at one time made pistons with this danger in mind. They have special recesses for valves on the upper surface of the pistons. Such engines can be seen on VAZ - 2108, 2109. Also, some cars of the tenth family were equipped with similar engines. Among foreign cars, such pistons can be found on some Mitsubishi, Renault and some other brands. But only on fairly old cars.

It turned out that such grooves significantly reduce engine power.

There are two ways to identify a problem with the valves:

- Remove the valve cover and carefully crank the engine. At the same time, carefully monitor the operation of the valves. If one does not work, then most likely it is bent. This method is not reliable; in many cases the valves will work as they should;

- A more reliable way is to study the condition of the valves directly on the removed head. All bent valves are visible to the naked eye.

Possible reasons

First of all, you need to understand what actions were carried out with the motor that could have caused its malfunction. If the problem appeared immediately after replacing the belt, then perhaps the marks were set incorrectly or the belt was not tensioned enough. The car's fuel filter or injection nozzles may be clogged.

The timing belt is set incorrectly

In situations where the belt was replaced by an unqualified person, the motor may not work due to the belt being misaligned. This leads to a phase mismatch. There is a failure in the interaction between the ignition system and the gas distribution mechanism, so the gas mixture enters one cylinder, and the spark ignites in the other.

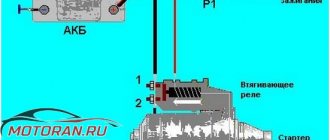

The engine is aligned taking into account the position of the marks on the pulleys - they must coincide with the marks located on the belt protective cover. This is the end position of the compression stroke of the first cylinder.

If the mark is shifted by several teeth, then you need to remove the belt and align the pulley with the mark. Some vehicles also have a mark on the flywheel. It must match too. Read more about setting marks when replacing a belt in this article.

The main problem in this situation is dirt and scratches on the flywheel. They can be similar to marks in their size and appearance. There are cases when car owners post a part according to them. As a result, the engine refuses to start.

Insufficient tension or belt is too tight

After replacing the belt, you should immediately check its tension. This can be done by eye. You should press your hand on the tensioned belt between the timing sprockets. You should hold the roller with your other hand so that it does not scroll. The permissible level of deflection is approximately 5–8 millimeters. And also the belt should not rotate along its axis more than 90 degrees .

When installing the belt, it is extremely important to ensure that the direction of the arrows on it coincides with the direction of rotation.

If the belt is not tensioned enough, it will constantly slip. The operation of the entire gas distribution system will be disrupted, which will lead to a phase shift at the camshaft. Because of this, the power of the internal combustion engine decreases, fuel consumption increases, and the engine heats up more. If you tighten it too much, the timing belt will break. In this case, the bearings will fly off the camshaft and crankshaft.

Engine compression failure

Engine malfunctions may occur due to low pressure in one of the engine cylinders. To find out, you should check it with a special device - a compression meter . Before starting the test, you should perform a number of actions:

- The engine must be warm.

- There should be no fuel supply, so you need to turn off the fuel pump and injectors.

- Remove the air filter and spark plugs.

- The battery must be charged.

There are two types of compression tests - with the throttle valve closed and with the throttle valve open. If the damper is open, you can detect deformation of the valves, scuffing of the cylinders, and burnout of the piston. If the damper is closed, you can see cracks in the combustion chamber and detect valve depressurization.

The pressure in the cylinders is checked one by one - first in the first cylinder, then in the second, etc. The compression gauge is connected to the spark plug holes. The crankshaft is turned by the starter until the pressure level stops increasing. After the compression gauge readings have been recorded, it is reset and I begin measuring the next cylinder.

The indicators are compared and the broken cylinder is determined from them. Typically, engines have an average of 10 atmospheres. The difference between the cylinders should not exceed one atmosphere.

Most often, the cause of low pressure is burnout of the piston rings. When the pressure in the engine decreases, you need to start repairing it.

Bent valve

When the belt breaks, the camshaft stops rotating, the valve timing is disrupted, and the valves no longer open or close. But the pistons continue to move. The pistons and valves collide, causing the valves to bend.

Previously, engine manufacturers took measures to ensure that the valves did not become deformed when they broke, by cutting recesses into them to suit the size of the pistons. But this idea was quickly abandoned when it turned out that due to these notches the overall engine power was reduced.

There are two ways to check valves:

- You need to remove the cover from them and manually turn the motor. If one of the valves does not move, it is most likely deformed. The method is very unreliable, because often even bent valves can create the appearance of normal operation.

- The entire cylinder head is removed. Damaged valves become clearly visible. It is recommended to replace not only defective valves, but also the entire set.

AVTOTRUE.RU

- Home

- Auto garage

- After replacing the timing belt, the car does not start

After changing the timing belt, the car

does not start? Several reasons why

It sometimes happens that after replacing the timing belt, the car does not start. The problem can occur on different cars. This may appear on different models. The prerequisites will always be approximately the same. It is better to eliminate them immediately after identification. For this purpose, it is worth knowing what remains to be done for our client regarding defects that prevent the engine from starting. By and large, there are not that many of them at all. It is also important to change the timing drive (gas distribution mechanism).

No matter what mistake leads to the following dilemmas. Before checking the timing drive, be sure to check the condition of the ignition accounting program complex and the battery. Cause you'll like it better here.

Car won't start after timing belt replacement

.

If this problem occurs after the belt

, then the cause must be sought in this. If the drive breaks, the valve timing is lost. Most often, a collision between pistons and valves occurs. This ends, at best, with bending of the valves, and at worst, with damage to the pistons.

Many manufacturers at one time made pistons with this danger in mind. They have special recesses for valves on the upper surface of the pistons. Such engines can be seen on VAZ - 2108, 2109. Also, some cars of the tenth family were equipped with similar engines. Among foreign cars, such pistons can be found on some Mitsubishi, Renault and some other brands. But only on fairly old cars.

After replacing the timing belt, the car does not start.

It turned out that such grooves significantly reduce engine power.

There are two ways to identify a problem with the valves:

- Remove the valve cover and carefully crank the engine. At the same time, carefully monitor the operation of the valves. If one does not work, then most likely it is bent. This method is not reliable; in many cases the valves will work as they should;

- A more reliable way is to study the condition of the valves directly on the removed head. All bent valves are visible to the naked eye.

An article on the topic “Which VAZ engines do not bend the valves.”

The engine does not start after replacing the timing belt or chain

Replacing the drive elements of the gas distribution mechanism is a planned procedure that is performed at certain intervals or as necessary.

In the first case, we are talking about replacing the timing belt or chain, as well as rollers, chain tensioner and other drive parts after a strictly defined number of kilometers traveled (on average for a belt the figure is 50-60 thousand, for a chain – 150 thousand or more) . Also, the reason for an unscheduled replacement of a belt or chain may be accelerated wear, the appearance of extraneous sounds during operation, etc.

In some cases, a situation arises when, after replacing the timing belt or chain, the car engine does not start. This problem can occur on cars regardless of the make and model of the vehicle, the design features of the power unit, etc.

In this article, we intend to talk about why the engine does not start after replacing the timing belt, and also why, after replacing the timing belt, the power unit starts poorly, the internal combustion engine is unstable, or other problems arise with the engine.

Read in this article

Tips and tricks

On vehicles with a timing belt, it is strongly recommended not to limit yourself to replacing just one belt. At the same time, new rollers should be installed. Ignoring this rule may lead to subsequent jamming of the rollers and breakage of the new timing belt.

Also, after installation on old rollers, the new belt may slip and accelerate wear. Even if the engine starts normally, you may encounter noticeably increased noise during engine operation.

Let us also add that, structurally, the timing belt can also drive the pump (water pump of the cooling system). During replacement, you should separately check the condition of this element, and also change the pump strictly according to the regulations. If the water pump jams, then the belt may also break.

This suggests that during the work the contact chip for some sensor could have been damaged. To accurately determine the cause, the engine can be scanned for errors using a special OBD2 scanner.

When selecting belts and rollers, it is necessary to install high-quality analogues or original parts. You can purchase spare parts either as a ready-made installation kit or separately. Remember, low-grade counterfeits of ready-made timing belt installation kits from well-known companies Gates, Inna, etc. may be found on sale.

Finally, we note that replacing the timing mechanism is rightly considered a responsible procedure. Incorrect installation can lead to engine failure or unstable operation of the power unit. If you are not confident in your abilities, then it is better to entrust this procedure to experienced car service specialists.

After replacing the timing chain or belt, the engine does not start: main causes and troubleshooting

Before starting diagnostics of the timing drive, it is recommended to immediately check the proper operation of the ignition system, the condition of the battery, the correct connection of power system elements, electronic ECM sensors, etc. If no malfunctions are identified, then we move on to the gas distribution mechanism drive.

Similar malfunctions can occur on different car models. First of all, it is important to know that errors when replacing the timing drive can lead not only to failures, but also to subsequent breakdowns. It is also necessary to separately take into account the reason why the drive elements had to be changed.

The engine does not start: the valve is bent

For example, if the timing belt breaks, then the belt is changed and the car does not start, then bending of the valves after such a break should not be ruled out. The fact is that at the moment the belt breaks, the valve timing on many engines is disrupted, the camshaft does not rotate, and the timing belt stops working. This means that the valves no longer open and close in a timely manner.

Tips and tricks

On vehicles with a timing belt, it is strongly recommended not to limit yourself to replacing just one belt. At the same time, new rollers should be installed. Ignoring this rule may lead to subsequent jamming of the rollers and breakage of the new timing belt.

Also, after installation on old rollers, the new belt may slip and accelerate wear. Even if the engine starts normally, you may encounter noticeably increased noise during engine operation.

Let us also add that, structurally, the timing belt can also drive the pump (water pump of the cooling system). During replacement, you should separately check the condition of this element, and also change the pump strictly according to the regulations. If the water pump jams, then the belt may also break.