Why does the VAZ 2114 not start?

If the VAZ 2114 does not start, then you should not be too upset. This car is quite simple, most faults can be easily fixed within an hour. The article discusses the main diseases, breakdowns, as well as solutions.

VAZ 2114 does not start in different ways. Can be divided into several groups. The main group is the absence of a spark. Group 2 is the absence of fuel. The third group is the absence of both.

The timing marks on the VAZ are not set correctly

Another reason why the VAZ 2114 does not start may be a mismatch of the timing marks. The reason for the mismatch of the marks may be weak timing belt tension, cut teeth, or the crooked hands of a mechanic at a service station.

A discrepancy of more than two teeth will noticeably affect the operation of the engine of the fourteenth. With a slight deviation, the engine starts up a little worse, does not hold idle, and stalls when switching to neutral gear. If the deviation exceeds 4-5 teeth, the sound of the engine changes, air escaping under pressure through the valves that are not opened in time becomes audible, thrust noticeably disappears, and starting the engine is extremely problematic.

- To check, we need a “10” key; use it to unscrew the three bolts securing the timing case.

- Next, put the car in 5th gear and push it until the mark on the camshaft pulley and the rear cover match, you can also turn the pulley with the key to “17”

- We remove the protective plug from the clutch housing and see if the mark on the flywheel matches the mark; if not, then you need to loosen the tension roller and align the belt according to the marks.

Checking the crankshaft sensor VAZ 2114

Perhaps this is the only sensor without which a VAZ car will not be able to start at all. If, when the engine is cranked with the starter and the ignition and fuel supply are working properly, there is no seizure or ignition of the fuel, then the problem is in the DPKV. The cost of the sensor does not exceed 300 rubles; it is better to replace it. However, there is a way to check: checking the crankshaft sensor video

If after the performed operations it was not possible to determine the breakdown, please write your problem in the comments, I will be happy to answer your question!

If you find an error, please select a piece of text and press Ctrl+Enter.

VAZ 2114 does not start - no spark

The VAZ 2114 operating system is a typical injection engine. Using the crankshaft position sensor, the control unit determines the position of the pistons in the cylinders, after which it supplies them with a spark or gasoline. So, the conventional eight-valve engine 21124 has a typical malfunction. The fact is that the crankshaft position sensor chip tends to rot. A new chip in the store costs 15 rubles, replacing it takes 15 minutes. In most cases, this solves all problems.

Now let's look at more complex cases when the VAZ 2114 does not start. First, you need to make sure that power is supplied to the ignition module. To do this, remove the chip from it, and then measure the voltage at the central terminal and the ground of the car. There should be 12 volts here when the ignition is on. If there is no 12 volts here, we dig towards the faulty control unit. This is the most difficult diagnostic case, so we will not consider it.

We made sure that 12 volts are supplied to the ignition module via the positive line; we need to know for sure that the ignition module itself is working. It must be said right away that diagnosing the ignition module is usually relative. It allows you to check the integrity of the coil and resistance. However, it does not allow measuring the inductance, as well as the breakdown voltage at the moment of ignition. In addition, this position does not allow you to check the energy accumulation time of the coil. Therefore, we take a regular cartoon and check the resistance between the second and third terminals of the coil.

The resistance here should be about 1.2 kOhm; if it is less than 1 kOhm, the coil should be replaced. This indicates that the primary ignition circuit is short-circuited. After this, we check the secondary coils of the ignition module. To do this, we measure the resistance between the first and fourth, second and third terminals for high-voltage wires. Here, the coil resistance may vary from manufacturer to manufacturer, so it is best to look at the relative resistance, that is, it should be approximately the same.

If there are no other reasons, we check the high-voltage wires for resistance. The wire resistance for cylinder 4 should be no more than 5 Kom. The resistance for the armored wire of the first cylinder should not exceed 10 kOhm. The last item to check is the candles. In general, in this case it is easier to screw in new ones, since not every city has a stand for checking spark plugs.

The timing marks on the VAZ are not set correctly

Another reason why the VAZ 2114 does not start may be a mismatch of the timing marks. The reason for the mismatch of the marks may be weak timing belt tension, cut teeth, or the crooked hands of a mechanic at a service station.

A discrepancy of more than two teeth will noticeably affect the operation of the engine of the fourteenth. With a slight deviation, the engine starts up a little worse, does not hold idle, and stalls when switching to neutral gear. If the deviation exceeds 4-5 teeth, the sound of the engine changes, air escaping under pressure through the valves that are not opened in time becomes audible, thrust noticeably disappears, and starting the engine is extremely problematic.

- To check, we need a “10” key; use it to unscrew the three bolts securing the timing case.

- Next, put the car in 5th gear and push it until the mark on the camshaft pulley and the rear cover match, you can also turn the pulley with the key to “17”

- We remove the protective plug from the clutch housing and see if the mark on the flywheel matches the mark; if not, then you need to loosen the tension roller and align the belt according to the marks.

Checking the crankshaft sensor VAZ 2114

Perhaps this is the only sensor without which a VAZ car will not be able to start at all. If, when the engine is cranked with the starter and the ignition and fuel supply are working properly, there is no seizure or ignition of the fuel, then the problem is in the DPKV. The cost of the sensor does not exceed 300 rubles; it is better to replace it. However, there is a way to check: checking the crankshaft sensor video

If after the performed operations it was not possible to determine the breakdown, please write your problem in the comments, I will be happy to answer your question!

If you find an error, please select a piece of text and press Ctrl+Enter.

VAZ 2114 does not start, spark plugs are dry

To begin with, turn on the ignition and listen to whether the fuel pump is working. If the fuel pump does not work, then first of all we check its fuse. In addition, it is worth paying attention to whether the fuel pump relay clicks after turning on the ignition. If this is not the case, then the problem is most likely in the ignition switch, or the relay itself is faulty. If the relay clicks, this indicates that the fuel pump activation circuit is closed. Then you need to check the voltage at the relay, after which we remove the back seat, remove the chip from the fuel pump, turn on the ignition and measure the voltage at the chip. In general, the fuel pump chain runs through the cabin, so rarely anything happens to it. From this we conclude that the fuel pump most likely simply burned out. After the replacement everything will return to normal.

If the VAZ 2114 does not start, the fuel pump is running, the starter is turning, then you need to pay attention to whether there is fuel in the fuel rail. For this purpose there is a special spool, which is closed with a black cap. After turning on the ignition, you need to press on this spool; fuel should flow out of the ramp. If this does not happen, then we check either the fuel pressure regulator by squeezing the return line to the fuel tank, or change the fuel filter. Ideally, you need to screw a pressure gauge onto this spool, which will show the pressure in the fuel rail. It should be 3.2 atmospheres after turning on the ignition. If you clamp the return line, the pressure should be at least 6 atmospheres.

When we are sure that there is pressure in the fuel rail, we need to make sure that the injectors open. To do this, remove the chip from any injector, and then add voltage to the red-pink wire with the ignition on. This is a general plus. It is constant on the injectors. If 12 volts is not observed on this line, then we go look in the control unit.

Answers@Mail.Ru: VAZ - 2114, 1.5 injector, hard to start when cold

well then the oxygen sensor

Well, clean the injector, and don’t forget this is a “VAZ” and not a “MAZDA”

Same problem, I'll try to change the RDT, maybe it will help

From the very beginning it was necessary to wash the throttle and measure the pressure in the ramp.

what does the scanner say? what errors are there? what are the idle values of the IAC and TPS sensors?

cool... they change everything, at least just to ventilate it with a tester, maybe you don’t need to change it. Well, all that remains is to check the lambda and the forces. And just for fun, change the filters.

Change the controller, forces, DD, change the piston, clutch, gearbox. If it doesn’t help, come to me for diagnostics, for 300 rubles I’ll tell you what’s wrong. and how to fix it!!! ! Honestly, I love such clients! You tell them that for half an hour’s work it’s 500 rubles, they leave a thousand in tips, they bow at your feet, and they look at you like a wizard!!!!

Fuck everyone is so smart, but in fact, scratch your turnips, I have a similar problem and the diagnostics show everything is fine, no deviations from the norm, but no one can determine the problem, and don’t even think about cleaning the injector, it is advisable to clean only the injectors

touch.otvet.mail.ru

VAZ 2114 does not start, the starter does not turn

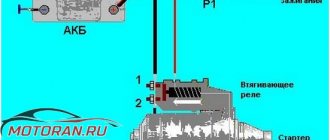

The VAZ 2114 does not start, the starter does not turn, then the first thing you need to pay attention to is that the solenoid relay clicks. If it clicks, remove the starter, disassemble the solenoid relay, and then protect the contact patches. If the starter does not turn, no clicks are observed, then you need to listen to whether the starter relay clicks. If it doesn’t click, then we just change it, the problem goes away. If the relay clicks, but the starter does not click, then the solenoid relay needs to be replaced.

Starter for VAZ 2114 - frequent malfunctions, replacement and repair

The VAZ 2114 model range is considered the most reliable type of vehicle. But sometimes unexpected cases may arise when it simply stops starting. And what to do in such a situation when the car engine does not start and the starter itself does not move. Unfortunately, not many people know the solution to this problem, but there is a way out. You just need to find out and analyze in detail all the possible causes of the breakdown.

The first problem is that the starter turns, but does not engage

Let's consider the following situation when the VAZ-2114 does not start, but the starter continues to turn. You should also take into account the nuance that the starter still does not engage. The mechanism of the problem is as follows:

- the key is inserted into the ignition;

- the fuel pump pumped up the fuel mixture;

- during the ignition startup process, the starter turns in idle mode (experts call this process “the starter does not catch”).

Experienced motorists note that a similar situation occurs in VAZs with high mileage, so we can talk about wear of either the starter itself or its parts. So, most often the overrunning clutch or “Bendix” suffers; the main element here is the gear. It is this overrunning clutch gear that causes a lot of trouble, because its teeth are often subject to wear. The mechanism of the malfunction appears as follows:

- the driver turns the key;

- the starter starts to spin;

- The overrunning clutch gear cannot engage the engine due to tooth wear.

In this case, there is only one way out - replacing the bendix. You can actually carry out this procedure yourself at home, or you can seek help from qualified specialists at a service center.

Even in the starter, its gearbox may fail. This problem is less common than the previous one. This gearbox includes several types of gears, which are also subject to wear due to the long life of the vehicle. There are five gears in total:

- one small;

- three satellite gears;

- one large one, attached directly to the gearbox housing and engaged with the satellites.

Even an experienced specialist will not immediately say in which of the named parts the gear teeth have worn out. To do this, you will have to remove the starter and disassemble it to inspect all the components.

Other malfunctions

There are other types of breakdowns that can occur with the starting system of the VAZ-2114 power plant, and each of them has its own symptoms:

- If the starter turns even after it has been switched off, the most common culprit is that the relay armature is stuck in the retracted position. In this case, you can stop the starter only by disconnecting the battery from the on-board network (by removing one of the terminals). Everything can be eliminated by rebuilding the relay or replacing it;

- If the starter turns on without permission, it is likely that the relay cover is damaged. As a result, the armature spring, which holds it in the depressed position, loses its support and the armature itself can move without permission inside the relay, periodically closing the contacts. By replacing the retractor, this malfunction can be eliminated;

- The starter starts working, but the flywheel does not spin, and a cracking sound is heard. There are two reasons for this malfunction. The first is that the starter mounting bolts have become loose, so the starter has come loose and is warped. As a result, the gear cannot engage, but at the same time it rotates and contacts the flywheel (hence the crackling noise). The second is that the gear teeth have crumbled or worn out, resulting in no engagement. To eliminate this, you should first check the tightness of the bolts; if it is normal, then you need to remove the assembly and inspect the condition of the gear;

- The starter turns on, but the flywheel does not turn, and there are no external sounds. This indicates that the gear is not reaching the flywheel. To understand why this happened, you will also have to remove the starter and carry out an inspection.

As you can see, most often problems arise not with the electric motor itself, but with its additional elements - the relay and bendix.

We diagnose the starter

To remove the starter and inspect it for faults at home, you can use a step-by-step algorithm:

Step 1: put the VAZ-2114 in a repair pit.

Step 2: remove the car engine protection.

Step 3: Open the hood.

Step 4: Remove the battery "-" terminal.

Step 5: Disconnect the wiring harness.

Step 6: Remove the crankcase protection.

Step 7: Unscrew the fastening nut to remove the wires from the traction relay.

Step 8: You should also unscrew the two starter mountings from the bottom of the car.

Step 9: Remove the last top fastener.

Step 10: remove the starter (this is done from the bottom of the car).

After removing this VAZ-2114 part, it is visually inspected for the presence of external damage and malfunctions. If everything is in perfect order, then the removed part should be disassembled element by element and a thorough inspection of each element should be carried out:

- unscrew the retaining nut;

- release the solenoid relay from the wire;

- unscrew the bolts securing this relay from the back cover;

- remove the retaining ring, which is located on the back of the rotor;

- Unscrew the nuts from the studs and the bolts securing the wires from the windings to the brush holder;

- remove the brush assembly;

- remove the pin that secures the Bendix fork;

- remove the rotor and stator separately;

- Remove the retaining ring from the rotor.

After all the described operations, you can begin to inspect the overrunning clutch and gearbox, namely the gears that are part of them. It’s worth immediately inspecting other elements of the starter that affect the functioning of the vehicle as a whole. Experts include irreparable breakdowns of the main elements of this part:

- rotor failure;

- stator failure;

- destruction of the rotor and/or stator windings;

- broken bushing.

In these cases, it is better to replace the old starter with a new one than to repair it.

Removing and installing the starter on a VAZ 2114

Repairing the starter with your own hands is certainly within the capabilities of every motorist.

Important: But before starting such work, you first need to turn off the power to the on-board network. What is meant is removing the terminals from the car battery.

- To remove the starter, at the very beginning you need to take a thirteen key and use it to tighten the 2 bolts that secure this device to the clutch housing. Previously, VAZ 2114 cars were mainly equipped with three screws, but if suddenly an additional bolt is discovered, in order to unscrew it you will need to jack up the car and climb under it and then twist it. By following these simple steps, you can eventually disconnect one wire on the relay. And move the mechanism forward (but the most important thing here is not to overdo it).

- Still using the wrench number thirteen and twist the nut, which directly fixes the wires connecting the relay output from the car battery to the positive terminal. Next, you should carefully inspect the flywheel teeth. And if after such an examination defects are revealed, then they must be completely replaced with new spare parts.

- Then you should resort to using a Phillips screwdriver and unscrew the two screws that secure the top cover of the device itself. Next, you need to tighten the nut; it performs the function of fixing the output of the winding of the unit directly to the solenoid relay. And then the so-called washer is pulled out - a bracket.

- Next, you should pick up a ten-size wrench and use it to unscrew the two elongated tightening screws and pull them out. After such work has been done, it will be easy to visually inspect the condition of the bushing at the moment.

- In order to make it much easier to separate the mechanism body, it is necessary to hit it an indefinite number of times, but not very hard on the lower part. When performing this procedure, it is best to have a wooden block and a mallet (rubber hammer) on hand. After you have managed to remove the cover, you need to immediately inspect the brushes and make an objective assessment of their condition. If the decision has been made to replace, do so.

- Using a suitable screwdriver, remove the bendix from the fork. Then, using a hammer, knock out the retaining ring. After dismantling the bendix, if necessary, replace it. Ultimately, the reassembly procedure is performed in reverse order.

The second problem is that the VAZ-2114 does not start, the starter and engine are spinning

Experts describe the mechanism of this problem as follows:

- the driver inserted the key into the ignition;

- the fuel pump pumped the fuel mixture;

- the starter began to spin;

- the engine also turns over, but does not start;

- at the same time the pistons are set in motion.

Experts can explain this situation by saying that:

- The belts have slipped off by one tooth from the camshaft gear (the reason for this could be wear of this gear).

- The belts on the flywheel, which is located under the thermostat, have come off.

- Air is supplied incorrectly to form the air-fuel mixture (this may be the result of a failure of the mass air flow sensor, which indirectly affects the starting of the vehicle).

- The problem is with the spark plugs:

- the candles were flooded;

- there is no spark either on one cylinder or on two adjacent cylinders.

- Malfunction in the ignition coil.

- Failure in the engine electronic control unit program.

- The optimal pressure when supplying fuel is violated.

- The injectors are faulty.

Experts advise looking at the errors that the on-board computer gives and be sure to conduct computer diagnostics of the car.

Why might the engine be difficult to start?

You can look for the culprit in such a situation in several directions. Among them, the most important problems are:

- Malfunctions in the electrical equipment of the machine;

- Problems with fuel supply;

- Poor performance of the engine control unit.

You immediately need to configure the readers, which does not start at all and does not start well, they have several different causes of malfunctions. Today the emphasis will be placed on poor engine starting. Let's talk about this in more detail.

Failures in the fuel system

It’s worth noting right away that there is no point in considering major engine breakdowns, since the average driver will neither be able to diagnose nor repair them, so you should pay attention not to those faults that can be eliminated with your own hands or in a short time.

For example, if a VAZ-2114 does not start, it is worth checking its fuel system, and first of all, you need to take care of the following aspects:

- presence of fuel in the gas tank (the sensor may be wrong);

- the integrity of the gas pipelines running along the bottom of the car from the tank to the engine;

- serviceability of the coarse filter in the fuel tank;

- the serviceability of the fine filter in the tank below, near the spare wheel.

Of course, both the fuel pump itself and its relay can fail, which can partly be attributed to the car’s electrical network. You can determine the breakdown yourself by listening after turning the key in the ignition to the characteristic sound of fuel pumping - if there is none, the pump, relay or wiring is faulty.

Additionally, according to the instructions, you can connect a pressure gauge to the fuel network, measuring the fuel pressure in it: a reading below two and a half atmospheres will indicate an unlikely leak. In such a case, you will need to look for leaks in the tank and gas lines - for this it is better to drive the car into a pit.

Unlike the coarse filter, the mesh in the tank under the bottom of the VAZ-2114 may well become clogged and littered, so it is worth checking it first if other faults are excluded.

Engine starting

There are several fairly simple rules, following which you can relatively easily start your car engine in cold weather.

Before starting, you should, as they say, wake up the battery. To do this, just turn on the headlights on high beam for just a few minutes. Then, turning on the ignition, you need to wait 10-15 seconds. During this time, the fuel pump will have time to pump fuel into the injection engine. After this, they press the clutch - the starter turns a certain number of parts, and this action will reduce their number and reduce energy consumption.

Only after the described steps can you try to start the power plant. The starter is turned on for a few seconds (up to 8), otherwise there is a risk of draining the battery charge to a critical level.

In a situation where it does not start the first time or the engine stalls, you should make 2 more attempts, but no more. Failure clearly indicates the presence of some more serious problem. It needs to be found and eliminated.

Most often, the spark plugs are filled with fuel. There are different ways to deal with this situation:

- remove old ones and install known good ones;

- warm them up on a gas burner;

- just wipe with a clean cloth.

Frequently burning candles greatly reduces their service life - this should not be forgotten.

In some cases, the starter turns, and in general the engine shows signs of life, but the vehicle does not move. Here you will need:

- open the throttle valve;

- After starting, keep the clutch pressed for a short time so that the engine picks up speed;

- then it is slowly released (the car may start moving with the gear out).

No ignition when turning the key

The second broad area of searching for the problem is the electrical system of the car, due to a malfunction in one of the components of which the VAZ-2114 does not start and does not respond at all to turning the key in the ignition switch. To begin with, just in case, it’s worth checking the functionality of the battery under the hood: many drivers, when starting a deep search for a breakdown, forget about such a banal reason for the lack of current.

You must carefully and calmly make sure that the ignition switch itself turns smoothly, without encountering obstacles or jamming, which in theory could lead to an unsuccessful engine start

Next, you should turn your attention to more specific components and assemblies, checking their serviceability one by one:

- Check the instructions for two relays - the starter and the ignition switch, which are located above the clutch pedal. You can evaluate their performance using the car manual, but usually they are simply replaced with ones that are known to be good for diagnostic purposes.

- A faulty starter, or more precisely, a solenoid relay: if it breaks down on the road, you can try tapping it lightly if it just jams. Having reached the overpass, you need to turn it manually - connect the body to zero on the battery, and the other contact to positive.

- If the starter actively begins to turn, the problem is not with it; if there is a current supply, but it does not turn, the brushes are broken. Lack of response will indicate a malfunction of the retractor relay, and a sharp and unpleasant sound will indicate a breakdown of the overrunning clutch in the starter.

The connection of the contacts itself also requires study, since it is likely that they have broken or oxidized due to moisture - they will need to be cleaned or re-twisted, and then insulated.

Causes of malfunctions and their repair

As a rule, if the unit is in working condition, it must quickly spin the engine flywheel after turning the key in the ignition switch. The starter may not turn, or it still works and does not start moving, then the car engine does not start, and the indicator lights up on the dashboard - this phenomenon will precisely prove that the device is not working.

The starter does not start, does not turn the relay, does not click VAZ 2114

- Such problems can be caused by oxidation of the contacts on the car battery or assembly.

- There is only one way to eliminate it - it is absolutely necessary to clean them.

- A completely discharged car battery can cause the unit to prematurely fail to function properly. In this case, you need to check with your own hands how charged the battery is.

- If the dashboard signals and you see an exclamation mark, it may be that there is a short circuit between the turns of the retractor winding. In this case, the correct solution would be to completely replace the entire mechanism.

- VAZ 2114 car owners are increasingly faced with a serious problem of broken wires in the unit itself. For an accurate determination, first of all you need to inspect the contact between the two plugs (ignition switch and electric motor).

There is no short circuit between the two plugs in the elements of the contact part

Problems with the performance of the armature - this part may become stuck. Checking it is as easy as shelling pears; all you need to do is check its rotation with your own hands.

Starter brush assembly

If the solenoid relay does not perform its function correctly, then the unit rotates well or does not move at all, then the reasons for this are as follows:

- A car battery that is not fully charged or its terminals have become oxidized. In this case, a warning light may light up on the dashboard indicating that there is not enough charging energy in the battery, which enters the unit and is unable to spin the armature. Any motorist should definitely take note of monitoring the terminals and if oxidation forms on them, remove it immediately.

- Poor connection of electrical contacts on the car battery mechanism and on the solenoid relay.

- If the contacts themselves have not oxidized, they still need to be diagnosed. How well they are tightened (contact screws), a weak connection makes poor contact. Poorly tightened contacts can undoubtedly cause a short circuit and subsequently melt the wires.

- Worn brushes and burnt commutator. If, as a result, their inoperability is revealed, it is these parts that must be completely replaced with new ones in the future.

Armature closure if we mean winding

When the battery is fully charged, the vehicle will not start; the final reason for this can only be the relay winding. There may have been a short circuit or break in it; the only way to fix it is to completely replace the relay.

The engine flywheel does not spin, what are the reasons?

The starter slips. This problem can only be detected through diagnostics.

- Broken gears of the gear mechanism. It is also possible to eliminate it by completely replacing it with a new part.

- The engine started to work, but as a result the unit continues to spin, while grinding and vibration comes out.

- If vibration is felt in the car, it is necessary to diagnose the fixed mechanism.

- The device is not installed correctly.

- A broken lid means it definitely needs to be replaced urgently.

- The gears of one of the elements have worn out due to this (drive, flywheel and gearbox rims).

- An unfamiliar sound may still appear as a result of wear of the bearing tabs.

- And ultimately the bendix failed.

- If for some reason you cannot start the internal combustion engine, you can try to start it by closing the starter itself directly.

No spark at the spark plug

Just among all the reasons that the VAZ-2114 turns over but does not start, most often motorists are faced with the absence of a spark at the spark plug. You can check this this way: by unscrewing one spark plug, connect it to a high-voltage wire and carefully, touching only the insulated parts, apply it to the cylinder head cover. At the same time, a second person must turn the starter from the passenger compartment, and if there is no spark, we need to look for the problem.

If the VAZ-2114 injector does not start, you need to pay attention, firstly, to the ignition module and the chip that is connected to it - these components not only often break, but also often come from the factory defective.

The condition of the crankshaft position sensor should be assessed: by monitoring the phases of movement of the cylinders in the block, it is an important component of the entire ignition system.

Although this sensor does not break down very often, it is necessary to check it, although in the absence of service it is practically impossible to do this - a professional oscilloscope is required.

Finally, a unit such as the electronic control unit of the injector could fail: electronic brains tend to fail on more expensive cars, so it is necessary to organize basic diagnostics for them:

- apply a spark to the first and third or second and fourth cylinders;

- recognize injection phase irregularities;

- As a preventative measure, clean the contacts on the electronic control unit from oxidation.

Lack of warm-up speeds at V.

- Thank you

- I do not like

Sedoff 12 Dec 2012

- Thank you

- I do not like

Valeriy Pus 12 Dec 2012

- Thank you

- I do not like

Denis26 12 Dec 2012

- Thank you

- I do not like

Sedoff Dec 13, 2012

Is there no need for an on-board computer?

It's worth it, I wrote it. It doesn't reveal anything that criminal.

If there is confidence in the correct operation of the IAC, then I would wash the injectors.

I was thinking about this. Here’s a question: remove it and rinse it, clean it on the device, or pour an additive to clean the system into the tank.

- Thank you

- I do not like

Sedoff 13 Dec 2012

- Thank you

- I do not like

guruman Dec 13, 2012

It’s worth it, I wrote. It doesn't reveal anything that criminal.

I was thinking about this. Here’s a question: remove it and rinse it, clean it on the device, or pour an additive to clean the system into the tank.

If you have never washed it, it is better to replace it with new ones. In terms of money, it’s almost the same as cleaning, but new ones give you more confidence.

- Thank you

- I do not like

romych79 Dec 13, 2012

If you have confidence in the correct operation of the IAC, then I would wash the injectors.

I'll add! I had a similar thing - I got tired of cleaning the throttle body (all black), I changed the TPS, it helped, but then I still cleaned the injectors. which I regret now, for some reason they installed one new one and now there is a suspicion that they are not working correctly. It would be better to buy new ones. By the way, I’ve already changed 3 DPDs, now I installed Arzamas (if I’m not mistaken) it seems to work

- Thank you

- I do not like

Valeriy Pus 13 Dec 2012

- Thank you

- I do not like

romych79 13 Dec 2012

Wash the injectors with or without removal, fill in additives or not, or even install new ones - that’s up to you to decide. I had in mind the fact that perhaps the injectors are spraying poorly, so when it’s cold the required speed is not reached.

No, it's unlikely. Of course, anything is possible, but it looks more like some kind of electronic glitch or valve. My injectors were dead to death - the car pulled barely, it accelerated to 100 km for about a minute and a half, but the revs did not jump. I’m sitting here and I just can’t remember, not so long ago the revs were also jumping, but I don’t remember what I did specifically with this problem. but if the diagnostics reveal nothing, then the problem remains in the mechanics

- Thank you

- I do not like

Denis26 Dec 13, 2012

- Thank you

- I do not like

Sedoff 13 Dec 2012

How does the car behave while driving? Poor acceleration, failures? Does your BC show the duration of the injection pulse and the ignition angle? And the IAC during warm-up and after

Everything shows normal. When hot it drives perfectly. Sometimes only when you sharply press the gas pedal there is a failure, but it’s so rare that I can’t say for sure whether I’m eating or not. All parameters are normal (I wrote) and the oxygen sensor and flow meter and RXX and others. This computer is: https://www.multitron. k_vaz_inj/x115/ Today I removed the catalyst and installed a forward flow (this is the standard pipe instead). So it started up as expected and the speed is normal. The catalytic converter looks intact, not melted or clogged, hmm, some kind of dilemma and strangeness. I’ll keep track of what and how. I still haven’t washed the injectors, I didn’t succeed.

- Thank you

- I do not like

Sedoff 21 Dec 2012

- Thank you

- I do not like

Abodne May 24, 2014

the whole problem is in the liquid cooling sensor (the one with a connector for two wires is located near the thermostat).

There is a spark, but the engine does not start

If the starter turns, there is fuel in the tank, the pump delivers it, and the spark plug gives a spark - but the engine still does not start - you will have to turn to more specific units, since this situation is uncommon in the practice of owning a VAZ-2114.

First, you will need to check the injectors: this cannot be done in a garage; you will need to tow the car to a repair shop and clean them with ultrasound. If there is a breakdown on the road, you can easily diagnose faulty injectors - if the spark plugs are dry and not filled with gasoline, it means the injectors are not supplying fuel.

Another thing is that something incredible must happen for them to break in all four cylinders at the same time, and before that they did not force the engine to triple for some time.

Even less common are problems with insufficient pressure in the fuel system, caused by failures in various electronic sensors of injection VAZs. In addition to the pump, for some reason the throttle position sensor or mass air flow sensor may fail. The electronic injector control unit will simply not allow the engine to start if at least one of the sensors gives it an error when accessed.

The most common reasons: what is the problem?

It is worth noting that a malfunction can be determined by indirect signs without even opening the hood of the car. For example, if the starter turns, but the engine does not catch on or immediately stalls, the problem lies in the fuel system. Without exception, all the reasons for the inability to start the engine can be divided into two main groups:

- malfunction of one of the fuel system components;

- lack of contact of the electronic ignition system.

It is also necessary to include the following in a separate category of faults: the engine “knocked”, the timing belt broke. In this case, expensive repairs will be required. In other cases, you can get by with a little bloodshed.

Useful tips

Additionally, experts advise turning your attention, when all other options have already been excluded, to the timing belt - when replacing it, the technicians could have set the phases incorrectly.

In addition, a banal belt break or excessive rotation is likely.

Very exceptional situations include a skewed cylinder head (for example, due to overheating), impaired compression in the cylinders and misaligned rings.

One should not discount such a banal reason as low-quality fuel: in places far from cities, where there is nothing to choose from, cunning entrepreneurs can pour in a completely indecent mixture.

The engine will not start immediately from such gasoline, which will serve as an additional diagnostic sign, and there can only be one solution - drain the low-quality fuel and fill it with normal gasoline. In such situations, however, there is nowhere to take it from, so you will have to rely on a tow truck or compassionate motorists who will stop to help.

Useful video

You can glean additional interesting information from the video below:

- Repair, design, malfunctions of the VAZ 2114 cooling system

- The VAZ 2114 engine gets hot: causes and their consequences

- Which starter is better to install on a VAZ 2114

Hello! Problem on VAZ 2114 2004 8kl. injector example: in the cold at -5-10 in the evening the engine started as in the summer before, the car sat overnight the temperature dropped to -15-20 and did not start, the battery is 2 years old, I changed the spark plugs weeks ago and at -20 it does not start at all, it’s worth it change the temperature, it will start in the summer. Thank you.

VAZ 2114 won't start

> This article will discuss the sequence of what needs to be done if the VAZ 2114 does not start. Modern VAZ models are equipped with a fuel injection system, the diagnostics of which differs from the approach to classic models with a carburetor. The presence of many, a control microprocessor, an electric fuel pump - this scares many. But if you act in a clear logical sequence, checking each element one after another, then even a motorist with little experience can easily find a fault.

VAZ 2114 won't start

VAZ 2114 will not start, sequence of actions: 1) From the very beginning, you don’t need to climb anywhere, you need to sit in the driver’s seat and look at the instrument panel. When you turn on the ignition, do the indicators come on? If more than one indicator does not light, then either the battery is completely drained, or the fuse in the instrument panel power circuit has blown. 2) When the ignition is turned on, three indicators should light up on the panel: emergency oil pressure, battery charge, “check engine” - from the control microprocessor. If the check engine light is not on, you need to check the fuse and relay for power to the microprocessor.

Controller VAZ 2114

“check engine” indicates that the microprocessor is energized and ready for use. It must be said right away that the control microprocessor has many names: ECU, controller, microcontroller, brains. The microprocessor is located to the left of the passenger seat under the glove compartment. There is also a strip with three relays and fuses. The first relay is for the microprocessor, the second is for turning on the cooling system fan, the third is for turning on the fuel pump. For now we are interested in the first fuse, through which the injector microprocessor is powered. When you turn on the ignition, the first and third relays should click: power is supplied to the microprocessor and the fuel pump.

Controller and fuel pump relay VAZ 2114

Until you get the check engine light to come on, you don’t need to look any further. If the indicator is not lit, the VAZ 2114 engine will not start. 3) If everything is in order with the indication on the instrument panel, check the following: when you turn on the ignition, you should hear the operation of the fuel pump in the rear seat area. If there are no sounds, check the fuse and relay for the fuel pump as described in point 2. If the fuse and relay are OK, you need to remove the rear seat and check for voltage at the fuel pump connector. 4) Next, we try to crank the engine with the starter; if the starter cannot crank the engine crankshaft, we check the following: — All connectors are put on the starter and clamped. — Listen to whether the solenoid relay clicks when you try to crank the engine. If the retractor does not click, it means either there is no voltage supplied to it when the ignition key is turned, or it has failed. It is extremely rare that the starter is working properly, but it cannot crank the engine because the piston has hit the valves due to a torn timing belt, but this is all checked further. 5) If the necessary indicators are lit on the panel, the fuel pump is pumping, the starter is turning the engine, then we proceed to the most basic and active steps to troubleshoot: first, we check the spark. To do this, unscrew the spark plug, put a high-voltage wire on it, lean it against the ground and turn the starter. This operation should be carried out gently by two people. Check for spark on all four cylinders. The following options are possible: 5a) There is a spark on all cylinders. Everything is fine, go to point 6. 5b) There is a spark on cylinders 1 and 4, but not on cylinders 2 and 3. Or, on the contrary, there is a spark on cylinders 2 and 3, but not on cylinders 1 and 4. In this case, the ignition module most likely needs to be replaced, since one of the coils in it has failed. The ignition module of the VAZ 2114 has two ignition coils. One works on cylinders 1 and 4, the second on cylinders 2 and 3. In rare cases, replacing the ignition module does not help, in which case it is necessary to resolder the transistor switches in the microprocessor. 5c) There is no spark on any cylinder: - The most common reason for this is failure of the VAZ 2114 DPKV (crankshaft position sensor). The sensor does not necessarily fail. Wires may come loose in its connector. — The gear wheel on which the DPKV works. It is connected by a pin to the generator wheel. If the pin pops out, the gear wheel will not spin, and accordingly the DPKV will not work. Check that the gear wheel is securely attached to the generator wheel. Visually check that it turns when the starter rotates. 6) Unscrew the spark plug from any cylinder; it should be wet with gasoline. If it is dry, then you need to check the fuel system. We check the fuel system by measuring the pressure in the fuel rail of the car. If there is no pressure gauge, then you can simply unscrew the plug from the hole for the pressure gauge and turn on the ignition - the pump will start working and a good stream of gasoline should spray out of the hole. Naturally, you don’t need to smoke or illuminate yourself with an incandescent lamp. If there is no fuel pressure in the fuel rail, change the fuel filter and check that the fuel line from the gas tank to the rail is not clogged and is intact. 7) If there is a spark and the spark plugs are wet from gasoline, then it is necessary to remove the timing belt protective cover and check the timing marks. Engines with 16 valves have two camshafts, each with a mark. We also check the mark on the oil pump gear.

Timing marks VAZ 2114

If the marks do not match, then the engine valve timing will be disrupted and the VAZ 2114 will not start. First, you need to find out the reason why the marks are off, perhaps several teeth have been cut off on the timing belt, or perhaps the pump has jammed. In any case, after installing a new timing belt, you need to crank the engine in fourth gear by turning the camshaft nut with a wrench and controlling the rotation of all timing components. Filled candles must be dried over a fire and only then started the car. A spark does not form on flooded spark plugs. The following situation occurs: there is a spark, the spark plugs are wet, the marks match, but the car does not start. In this case, the injectors that pour fuel instead of spraying it are most likely dirty. In winter, this situation is aggravated as the microprocessor reads information from the engine temperature sensor and gives an even longer pulse to the injector for starting. In such cases, some do chip tuning, that is, they change the microprocessor settings in the engine starting routine. This will help, but dirty injectors will still ruin your life. 9) When the engine does not start, many people chaotically begin to check all the injector sensors. This is unnecessary fuss. The VAZ 2114 does not start due to one single DPKV sensor. If something else fails, the car should start. It may stall, detonate, start and stall, but it starts. The mass air flow sensor and the throttle position sensor are used to determine the duration of the pulse to the injectors. If one of them fails, the system starts working differently. The knock sensor adjusts the ignition timing. In general, you need to rummage through the remaining sensors with the car running and the engine not operating correctly. As you can see from the technique described above, it is not too complicated, it is important to act carefully and in order and you will definitely find the reason.

First, you need to find out the reason why the marks are off, perhaps several teeth have been cut off on the timing belt, or perhaps the pump has jammed. In any case, after installing a new timing belt, you need to crank the engine in fourth gear by turning the camshaft nut with a wrench and controlling the rotation of all timing components. Filled candles must be dried over a fire and only then started the car. A spark does not form on flooded spark plugs. The following situation occurs: there is a spark, the spark plugs are wet, the marks match, but the car does not start. In this case, the injectors that pour fuel instead of spraying it are most likely dirty. In winter, this situation is aggravated as the microprocessor reads information from the engine temperature sensor and gives an even longer pulse to the injector for starting. In such cases, some do chip tuning, that is, they change the microprocessor settings in the engine starting routine. This will help, but dirty injectors will still ruin your life. 9) When the engine does not start, many people chaotically begin to check all the injector sensors. This is unnecessary fuss. The VAZ 2114 does not start due to one single DPKV sensor. If something else fails, the car should start. It may stall, detonate, start and stall, but it starts. The mass air flow sensor and the throttle position sensor are used to determine the duration of the pulse to the injectors. If one of them fails, the system starts working differently. The knock sensor adjusts the ignition timing. In general, you need to rummage through the remaining sensors with the car running and the engine not operating correctly. As you can see from the technique described above, it is not too complicated, it is important to act carefully and in order and you will definitely find the reason.

Problems with the fuel supply system

The most common reasons that a car will not start when cold are:

- electrical problems;

- problems related to fuel supply;

- control unit malfunction.

ECU VAZ 2114

Below we will consider all these reasons in more detail.

If you notice that your VAZ 2114 is difficult to start, then first of all you should check the main electrical components and assemblies that affect its operation.

These include:

- starter;

- spark plug;

- throttle;

- electronic control unit.

In this case, the check should begin with the candles.

Plaque on the spark plug body

If the battery is in perfect order, then you should carefully examine the spark plugs. The presence of oil, carbon deposits, or colored spots on them may indicate that they are faulty. In this case, there are two options for solving the problem - either clean the existing spark plugs (for example, calcinate them or clean them with fine sandpaper and solvent) or replace them with new ones. The last option is the most preferable, since only it will help you find out for sure whether the spark plugs are to blame for the malfunction or not.

If upon inspection it turns out that everything is in order with the spark plugs, then you should check the high-voltage coil. This can be made easier by replacing it with a new, similar one. If the ignition coil (or rather the block) is working properly, then you should proceed to diagnosing the starter.

Starter for VAZ 2114

Checking the starter consists of carefully inspecting it and monitoring the condition of the main elements - the degree of wear of graphite brushes, brass bushings, etc. In addition, you should check the starter using a multimeter (tester), “ringing” it between one of the brushes and the armature. If the tester shows an open circuit, then there is a break in the winding and the part will have to be replaced.

Another reason why the VAZ 2114 does not start well with a cold injector may be a malfunction of the electronic control unit. Checking it at home is extremely problematic, since you will need special diagnostic equipment.

That is why you should either contact a service center to check the ECU or try replacing the unit with another one and try to start the car again. If the car starts right away, then the problem was in the block. In this case, you will have to either buy a new ECU or reflash the existing one (for this you will also need to contact a car service).

Very often the VAZ 2114 8-valve injector does not start well in cold weather due to a malfunction of the fuel system. To check it and identify possible malfunctions, you will have to carry out diagnostics:

- Electric pump.

- Fuel filter.

- Fuel line.

Gasoline pump VAZ 2114

Troubleshooting should begin by inspecting the fuel pump. Checking it is quite simple - when turned on, it should buzz, which will indicate its operation. If no sound is heard, then the pump is faulty and will have to be replaced with a new one of a similar model.

The next common cause is clogging or destruction of the filter. Everything here is also simple - you just need to remove and inspect the filter and, if it is worn out, replace it with a new one.

If the filter, like the fuel pump, turns out to be working, you will have to measure the pressure inside the fuel line (for this, there are both special devices and entire testers that allow you to diagnose the entire fuel system. The simplest version of such a device costs just over 1,000 rubles). If the pressure in the line turns out to be normal, then you should think about other possible reasons.

Fuel filter VAZ 2114

It would seem that the bulk of probable malfunctions have already been listed, as well as methods for eliminating them. But it should be remembered that, in addition to problems with the fuel system and electrical systems, other factors can be the reasons for poor “grasping” of the engine. And the most common ones are bad fuel and unsuitable oil.

So, if you notice that the car has difficulty starting when cold, then try to refuel at other gas stations (preferably not just at others, but at gas stations from other companies). In some situations, this alone may be enough to solve the problem. The same applies to butter.

If summer oil is used in cold weather, this can also lead to poor engine performance at start-up. It is worth remembering this and always change the oil according to the current season.

Poor fuel quality

Another source of trouble can be electronic sensors, and most often the crankshaft position sensor. It is he who transmits information to the controller, on the basis of which the ignition and fuel injection are controlled. It is very easy to find out about its malfunction - in this case, the check engine icon will light up on the dashboard. In order to check the condition of the sensor or replace it, you will have to contact the service department.

Crankshaft position sensor VAZ 2114

A faulty intake air volume sensor can cause no less trouble. Its breakdown can lead to serious problems with the ignition, including complete inability to start the car.

It is very easy to check this sensor yourself - just turn it off and try to start the car. If it starts the first time, then the problem was in this sensor, and it will have to be replaced with a new one.

It is worth noting that a malfunction can be determined by indirect signs without even opening the hood of the car. For example, if the starter turns, but the engine does not catch on or immediately stalls, the problem lies in the fuel system. Without exception, all the reasons for the inability to start the engine can be divided into two main groups:

- malfunction of one of the fuel system components;

- lack of contact of the electronic ignition system.

It is also necessary to include the following in a separate category of faults: the engine “knocked”, the timing belt broke. In this case, expensive repairs will be required. In other cases, you can get by with a little bloodshed.

Engine starting is primarily affected by the following main components of the fuel system:

- gasoline level in the tank;

- the condition of the fuel line under the bottom of the car;

- cleanliness of filters.

It should be noted: even if there is gasoline in the tank, the car may not start. And the reason for this is the low fuel level. The pump may simply not be drawing in enough gasoline. Therefore, before starting to diagnose and inspect all the main components, it is advisable to fill the tank to at least a third. If problems with the electrical part are excluded, you need to pay attention to the fuel line. You need to check:

- no breakdowns or leaks in the fuel supply pipe under the bottom;

- the condition of the fine filter - often it simply becomes clogged, which leads to a decrease in the pressure level in the fuel system.

It is not possible to check the operation of the fuel pump manually on this car. This can only be done by ear. If, when you turn the key and turn on the ignition, the pump makes noise, then it is “alive”. Otherwise, you need to check whether power is supplied to it. If this is all right, you need to replace the pump. Its cost ranges from 1.5 to 3 thousand rubles, depending on the manufacturer.

You can check the pressure level yourself - just connect a special pressure gauge to the fuel system in accordance with the manual. This will allow you to diagnose the problem. According to the standard, the pressure should be at least 2-2.5 atm. If the indicator is less, then the engine will not start.

It sometimes happens that the engine does not start well when it is cold or frosty. The reason may lie in a faulty battery or simply in its discharge. You can check its status in the following ways:

- using a multimeter - the normal voltage between the terminals should be 12.6 V;

- using a hydrometer - normal density differs depending on the ambient temperature.

For example, if the engine does not start well at low temperatures even when it is hot, then the reason, obviously, lies precisely in the low battery charge level. Main electrical problems:

- the ignition switch is faulty;

- one of the two relays installed under the hood - ignition and starter - is damaged;

- the starter does not work;

- retractor device.

The ignition switch is one of the weak points of almost any car. Moreover, the VAZ 2114 is no exception. Checking its operation is quite simple. All you need to do is dismantle the device and then test all contacts using a multimeter. If it fails, the easiest way is to replace the ignition switch. There is no point in repairing it.

It is not possible to check the ignition and starter relays without opening them. Therefore, the best solution would be to simply replace both of them at once. Their cost in the store usually does not exceed 250 rubles per piece.

You can determine the functionality of the relay simply by sound. If after turning the key it clicks, it means that voltage is coming to it, it is being applied, it works as it should. When the ignition switch is working properly, the relay clicks - the next unit to check is the starter. Usually the problem lies in the retractor.

Sometimes just a light blow with a key helps solve the problem. If you have a heated, well-lit garage, the starter should be removed and carefully inspected. Brushes usually fail. If the car's mileage is significantly more than 150 thousand km, the bearing may fail. After removing the starter, you can try to start it directly from the battery. It's very easy to do this:

- the housing must be connected to the zero terminal;

- The positive terminal should be connected directly to the retractor using an alligator clip.

If the starter is working properly, it should turn over. If there is no reaction, the problem most likely lies in the retractor.

So, the starter spins, the engine spins, the pistons move, but the engine still won’t start. Here the problem is most likely in the fuel-air mixture, perhaps the marks have come off, etc.

Reasons why the injection VAZ 2114 does not start

The design of any modern car, the VAZ 2114 is no exception, is such that the successful production of a car depends on a number of positions. Previously, this was enough for the mechanical pump to supply fuel to the carburetor, and for the spark plugs to produce a spark. Today there are a lot of problems that prevent the engine from starting. An electronic injector requires the participation of several sensors, and the matter is not limited to them. In this article we will tell you why not and how to deal with it. In general, all causes of malfunction can be divided into two large categories:

- Fuel system problems. This group includes any breakdowns as a result of which fuel is not supplied to the engine at all, is supplied incorrectly, or mixture quality errors occur.

- Electrical problems. Ignition of the fuel mixture is ensured by sending an electrical signal to the spark plugs. If problems arise here (and there are a huge number of electrical elements), the car will not start.

The most terrible malfunctions can be included in a separate category - for example, a “knocking” VAZ 2114 engine, a broken timing belt and, as a result, bending of the valves. In these situations, expensive repairs cannot be avoided.

Other faults

The injector makes it quite easy to determine the cause of the malfunction. But repairs are much more difficult than on cars equipped with a carburetor engine. VAZ 2114 is equipped with engines of various powers. Easier maintenance with 8 valves. If the car takes a long time to start and the exclamation mark is on, then the reason may lie in the following:

- incorrect operation of injectors;

- poor quality fuel;

- low pressure in the ramp.

Often, over a long period of use, the injectors simply become clogged. As a result, they require cleaning. It is difficult to cope with such a task on your own. The solution may be to contact a specialized service. Cleaning is usually performed using ultrasound. Another option is low quality fuel mixture. If the car begins to stall or loses power immediately after refueling, then the problem lies precisely in gasoline.

Fuel system problems

Among the elements of the fuel system, the following factors influence engine starting:

- presence of gasoline in the tank;

- the integrity of the fuel lines under the “belly” of the car;

- cleanliness of the filters: coarse cleaning (located in the tank) and fine cleaning (located under the car, to the right of the spare wheel compartment).

Also included in this category are electrical components that are directly related to the fuel supply. This is an electric fuel pump and a fuel pump relay.

Before checking other methods, you must be completely sure that the VAZ 2114 with an injector is filled. “Yes, there are still five liters there” according to the indicator on the tidy or “I filled it up yesterday, I couldn’t spend that much” are not suitable. The gauge may be lying, and there may be leaks in the tank or fuel lines. Carefully check the car for fuel leaks; just in case, fill in 5-7 liters of gasoline from a canister.

The mesh in the tank rarely gets clogged, leave this option for last, but it’s worth trying to change the fine filter if electrical problems are ruled out.

The operation of the fuel pump is checked by ear (after turning the key, its operation should be heard; if not, the pump has “died”, or the pump relay, or a wiring break). According to the manual, you need to connect a pressure gauge to the fuel system. If the pressure does not stay within 2-2.5 atm, the VAZ 2114 will not catch due to insufficient fuel pressure.

What to do if the engine does not hold speed?

Another problem that often occurs in the VAZ 2114 is that the engine starts, but stalls at speed. The cause is most likely to be found in the battery. Maybe the spark plug is faulty. To check this, you need to remove the spark plug and carefully examine it for damage. Even if there are no visible defects, but there is scale and carbon deposits, the spark plug still needs to be replaced with a new one. This is a part that cannot be repaired, it can only be replaced.

1. Oil pan drain plug. 2. Engine oil pan. 3. Crankshaft. 4. Oil filter. 5. Coolant pump. 6. Exhaust manifold. 7. Piston. 8. Intake pipeline fastening rod. 9. Laying the intake pipe and exhaust manifold. 10. Inlet pipe. 11. Nozzle. 12. Fuel rail. 13. Receiver. 14. Bracket. 15. Cylinder head cover. 16. Camshaft bearing housing. 17. Camshaft. 18. Crankcase ventilation system hose. 19. Valve pusher. 20. Cylinder head. 21. Bolt securing the head to the cylinder block. 22. Valve. 23. Spark plug. 24. Cylinder head gasket. 25. Upper compression ring. 26. Lower compression ring. 27. Oil scraper ring. 28. Piston pin. 29. Fitting for installing the oil dipstick. 30. Connecting rod. 31. Flywheel. 32. Cylinder block. 33. Oil pan gasket. 34. Oil dipstick. 35. Oil intake

It is inexpensive; for the fourteenth model, the price of a set of candles is about 500 rubles. But how do you know if the spark plug is working? A good candle always has a slight brick tint. It must be dry. If the spark plug darkens, it means it has burned out and must be replaced. If it's wet, it means it's flooded. There is no need for replacement, just dry and blow out the part.

Purge occurs when the engine is idling with the spark plugs removed. If the Lada has an injector, then you will have to work longer, also inspecting the fuel system, which is directly related to the operation of the power unit. The injectors are also subject to careful inspection. In winter, there are times when the candle just freezes.

This is not scary, it can be warmed up, cleaned and put back in place, then the engine will start working again. In this matter, such a point as normal fuel supply is also important. If the fuel mixture becomes depleted or, conversely, enriched, this, in turn, causes a serious malfunction, which ultimately affects the operation of the engine.

Pressure also plays an important role. A faulty pressure sensor is involved here too. If its readings are incorrect, it transmits erroneous information to the fuel system, which, in turn, does not supply the required amount of fuel. This creates the problem of a “lean” or “rich” mixture.

We have considered all the most significant issues related to engine problems. There are many reasons for its poor performance, but over time you will learn to identify them. This requires experience and patience.

Electrical faults

Most of the problems lie here, so we’ll look at each option in detail here:

Nothing happens when I turn the key

On a VAZ 2114, this usually indicates a violation in the ignition switch - starter line, but one of the reasons for the breakdown “for blondes” is a dead battery, do not forget about it (checked with a voltmeter: it should be at least 11.8 V - and with a hydrometer, if the battery is serviceable : at least 1.22 in each jar).

Let's move on. The cause of such a malfunction may be a breakdown of the ignition switch cylinder, and the injector has nothing to do with it. If, when turning the key, new sensations arise (something catches, turning has become easier or, conversely, more difficult), that’s the problem.

Under the panel, approximately above the clutch, there are two relays: ignition switch and starter release. The reason may be a malfunction of one of them. They are checked according to the manual by a good electrician or replaced with a known working one.

Starter. Often the cause may be a jammed “retractor”. If you are standing in a field, you should try hitting it with something heavy like a large key (without fanaticism) - it may help. If the car is parked in a garage, you should remove the starter and try to start it directly from the battery.

To do this, press the housing to the zero terminal of the battery, install the wire with the alligator clip on the positive terminal of the battery and bring it to the positive of the retractor. If the starter tries to jump out of your hands, everything is fine (be careful, it is not recommended to carry out this procedure without basic knowledge of safety precautions and an assistant!).

If there is no reaction, the problem is in the retractor. If the relay buzzes, but the starter does not turn, the problem is in the brushes. If the starter makes a terrible sound, but does not turn, the problem is in the bendix.

If the starter turns, replace the battery and check the power supply to the chips that are connected to the starter (with an assistant, one turns the key, the other measures it with a multimeter).

Also pay attention to the ground wire that goes to the battery. If there are breaks in the wiring at the point of contact with the body or at the terminal, it must be replaced. It is also worth disconnecting the wire from the body and thoroughly cleaning it with a metal brush. The reason for the failure to start may be simple oxidation.

The starter turns, but the car does not start

This is the most common situation in the case of the VAZ 2114. The procedure for solving it must begin with answering the question of whether there is a spark. To do this, take an assistant, unscrew one spark plug, put an armor wire on it and very carefully (avoid touching live parts, hold the insulated part of the wire) apply the spark plug to the cylinder head cover. While the assistant turns the engine, watch the behavior of the spark plug. If there is no spark, you need to look for it.

If there's no spark

The ignition module is one of the key problems of the VAZ 2114 on the injector. It breaks often and sometimes a new one comes with a defect. You can read more about checking the ignition module in other material on our website. Please note that the problem may also lie in the chip that is connected to the module. The presence of power on it must also be checked.

DPCV is another reason why there may be no spark. Since this sensor monitors the firing phases of the cylinders, it is one of the key elements of the ignition system. Note that the probability of its failure is lower than that of the ignition module. It is checked by an electrician using an oscilloscope; garage methods do not provide an accurate assessment of the condition of the sensor (only replacement with a guaranteed working one).

ECU. “January” is a relatively reliable injector, but the “brains” can also malfunction from time to time. Often the problem with them is identified by a violation of the injection phases: for example, a spark is supplied only to cylinders 2 and 4, or only to cylinders 1 and 3. Sometimes the issue can be resolved by simply cleaning the contacts on the ECU chip; it is also subject to oxidation, which causes signal loss.

For what reason does the power unit start poorly in cold weather?

Most often the problem is associated with freezing of oils:

This is especially true if the lubricant was not replaced with a frost-resistant one before the start of winter. If this is not necessary in warmer areas, then in northern latitudes this procedure is vital.

In addition, the problem is sometimes hidden in the quality of fuel, which is why you should try to at least refuel from reliable suppliers in cold weather. Of course, their prices are higher, but they can avoid problems.

It is also known that the battery always loses charge faster at abnormally low temperatures. Therefore, in the fall, you should definitely inspect the battery and, if necessary, add electrolyte, charge it, or even replace it with a new one. The battery is checked as follows:

- electrolyte level is measured;

- density is determined (when fully charged).

The standards here are as follows:

- the minimum density is 1.27 grams per cubic centimeter;

- in the northern regions – 1.29.

If the level is lower, then the electrolyte condition needs to be adjusted.

In addition, knowledgeable car owners also try to insulate the engine or the battery itself. For this purpose, for example, special so-called thermal cases are available for sale. It's not difficult to find the right ones. If you wish, you can build them yourself.

In general, much more electricity is consumed during the cold season than during the rest of the year. The generator alone cannot compensate for the lack of it. For this reason, the battery must be periodically recharged using a stationary device.

A problem with the battery can be suspected if:

- the fuel pump does not turn on;

- The ignition does not work.