Benefit or harm: is gas harmful for a conventional gasoline engine from various positions?

A lot has been said about the positive and negative aspects of owning a gas equipment. Mostly related aspects are emphasized, and the direct influence of blue fuel on the internal combustion engine has not been studied within the framework of theory. There is only practical evidence that with proper configuration of a gas cylinder installation, the service life of the motor is certainly not reduced. Power units confidently maintain up to 300,000 km without major intervention.

The common belief that gas dries out the engine is unfounded. The argument is that gasoline is more of a solvent than a lubricant. This is also the general trend. There is not a single justified reason that gas is harmful to an ordinary gasoline engine. However, there is little practical evidence of a decrease in the cyclic durability of internal combustion engine parts. Let's look into them.

One of the common complaints is burnt out exhaust valves. Gas burns worse and can burn out at the outlet - this is how mechanics explained the reduction in cylinder head life on cars with initial generations of gas engines. The reason is manual adjustment of the gas supply due to the lack of calibrating electronics. On modern installations, such a disadvantage can only appear when driving in the “accelerator to the floor” mode, which is undesirable.

On a note. After installing gas equipment, it is necessary to adjust the valves. The combustion temperature of blue fuel is 40°C higher than gasoline, so the gap should be increased by an average of 0.05 mm.

Opponents of gasification should take into account the fact that gas:

- Extends the life of spark plugs.

- Does not wash off the oil film from the cylinder walls, even if diesel oil is poured into the gasoline engine of the car.

- Does not form carbon deposits in the combustion chamber.

Installing equipment on a car

Often, motorists who are considering the possibility of switching to gas fuel are worried about problems associated with it, such as interference with the car’s life support systems. But there is no need to worry about this, since this process does not require structural modification of the engine. It can be compared to installing additional equipment, for example, an alarm system.

In other words, installers do not tamper with the engine. The equipment is not implemented, but only complements the existing mechanism. After installing LPG, the car can drive on both gas and gasoline. If you run out of gas fuel, you can easily drive to the gas station using gasoline. The main thing is to make sure that both tanks do not empty at the same time.

How is gas harmful to a car engine?

Gas equipment has long been a source of fierce controversy among motorists. Some consider propane-butane to be harmful to the engine, while others do not see any harmful effects in it. How are things really going?

What people don’t say about HBO, which allows you to significantly increase your range and save on fuel. As a rule, rumor speaks of burnt-out valves, although in practice everything is not so clear and obvious. Let's figure it out.

A number of experts believe that propane-butane itself is completely harmless to the engine. Moreover, in a certain sense it is even useful! Gas has a higher octane number than gasoline (about 110 versus 92-98), which means it reduces the risk of detonation. In an engine running on propane-butane, less soot and deposits accumulate. Finally, gas fuel does not enter the engine crankcase - it does not change the properties of lubricants and does not dilute them.

Then what is the root of evil? It is not the fuel that has the negative consequences, but the operation of the equipment. If the equipment is not configured properly, then, for example, the same valve burnout that people hear about in horror stories can occur. And this happens - we personally know of a number of cases when owners of a second-generation Chevrolet Tahoe with gas equipment “ended up” with cylinder heads repaired. Correct tuning means the correct fuel-air mixture ratio. For gasoline, the stoichiometric ratio of air and fuel by mass is 14.7, while for propane-butane it is 15.6. If the unit receives a richer or leaner mixture, it will face problems.

Shutterstock/VOSTOCK Photo

The second scenario promises quite serious consequences, when there is not enough fuel in the stoichiometric combustible mixture. In this case, it burns longer, and the temperature in the combustion chamber rises. This is where valve burnout occurs. Spark plugs have a hard time too. An enriched mixture threatens to burn out the exhaust system and cause catalytic converters to fail, which in itself is also not cheap.

Sometimes there are recommendations to select the appropriate oil for a gas engine. The main argument for those giving such advice is as follows: since the temperature in the combustion chamber will be noticeably higher, it is not a fact that the oil poured into your engine will cope with work under more extreme conditions. Firstly, the protection of the internal parts of the unit will deteriorate. Secondly, the engine will begin to coke and form deposits and soot. And thirdly, there is a risk of increased oil consumption. Perhaps sometimes this is the case, but we can judge from our own experience of long-term operation of a car with LPG, into which the most common synthetic oil is poured, and the horrors described above are never observed. Note that we are talking about an older car, whose naturally aspirated engine is initially reliable and not too picky about the quality of the lubricant.

So is everything as scary as the folk horror stories say? Not at all! By the way, previously things were worse with the reliability of gas equipment than they are now. Suffice it to recall the first three generations of the ejector type, which were characterized by backfire in the intake manifold caused by an incorrect combustion process or, more simply, spontaneous combustion in the intake manifold. Excessive pressure created at the moment of popping in the intake can damage the air flow sensor, not to mention damage the intake tract. Injection-type gas equipment, whose history began with the fourth generation of systems, does not have this.

Signs of engine parts rejection

Cylinder block

Do not forget that the block has ceased to be a numbered documented part. In other words, it can be changed without any problems.

Be that as it may, we must remember that cracks anywhere in the cylinder block are unacceptable. There should be no deep nicks, scratches, scuffs or burns on the cylinder surface - only small rubs that cannot be felt to the touch are allowed.

Next, the flatness of the mating surface under the block head is checked.

By comparing measurements of the diameters of the cylinders and piston skirts installed in these cylinders, it is possible to determine the gap between the piston and the cylinder, which should not exceed 0.15 mm on almost all passenger car engines. If the gap exceeds this value, then the cylinders will need to be bored and honed to accommodate oversized repair pistons. In this case, the piston rings must be replaced with new ones of repair size.

All of the above applied to a cylinder block made of cast iron. If your engine has an aluminum cylinder block, then a special coating is sprayed onto the surface of the cylinders or thin-walled cast iron bushings are installed, which motorists call liners. So, the coating, if it is torn off, cannot be restored in any way. You have to bore holes for installing repair sleeves, whose internal diameter will be nominal. The same thing has to be done with blocks from the factory equipped with thin-walled cast iron liners, because the thickness of their walls will not withstand boring to the repair size, and pistons for a given engine are not always produced with a repair (increased) diameter.

Crankshaft

Cracks anywhere on the shaft are unacceptable. On the main and connecting rod journals of the shaft, as well as on the surfaces mating with the working edges of the shaft seals, scuffs, scratches, nicks and risks are not allowed.

To assess shaft wear, use a micrometer to measure the diameters of all main and connecting rod journals of the crankshaft in two diametrically perpendicular planes.

Cylinder head

The technician must check the condition of the hydraulic pushers. When repairing the cylinder head, the oil seals should always be replaced. Check valves and guide bushings for wear.

The surface of the head adjacent to the cylinder block must be flat to ensure the tightness of the gas joint, as well as the channels for the passage of oil and coolant.

After carrying out engine restoration work, the craftsmen should not lose sight of the main oil supply element of the engine - the oil pump. If its worn parts do not provide proper oil pressure, then - “hello, new capital”.

How HBO and gas affect the engine

It is not surprising that against the backdrop of a global rise in the price of petroleum products, a huge number of motorists are trying to reduce fuel consumption in any way possible. Let us immediately note that in developed countries the problem has been solved, but not in a “budgetary” way.

In simple words, the more economical modern diesel engine in Europe is confidently replacing its gasoline counterparts. For this, conditions have been created in the form of affordable lending, reduced taxation on vehicles with a diesel engine, etc.

However, in the CIS, for obvious reasons, not everyone can afford a new or “fresh” two or three year old used diesel car for cash or even on credit. It turns out that the main available alternative is to convert an existing gasoline car to gas, that is, install LPG.

At the same time, responsible drivers often wonder whether gas is harmful to the car engine. In this article we will talk about how gas affects the engine, and also consider the main features of the operation of a gasoline internal combustion engine using a gas-air mixture.

Recommendations

Comments 71

What's crazy? Or are you delusional yourself? You should have said something to the point. And everyone knows how to fuck.

By the way, write without mistakes. Otherwise, it’s even more offensive to have such an interlocutor.

Don't misunderstand, but you have problems with physics.

I accept such things in conjunction with evidence)

What am I doing wrong? Is it that the propane-butane mixture has higher volatility? Or is it that this mixture burns longer and adjustments are required because, otherwise, the high valves are already passing flame through themselves, and not exhaust gases? Is it because the mixture is “dry” and has no lubricating properties? When they say the engine is drying out, they mostly mean gaskets and rubber elements.

It takes too long to explain and this is far from school level. And yet you can see the level of “one woman said” or “that’s what they say in a car service”, which is essentially the same thing, that woman, that 99% of car mechanics, physics and chemistry textbooks were distorted during breaks, and all their verbal diarrhea is nothing more than idle nonsense not supported by anything.

May be. You did the same at the moment) so while there are no better explanations, I, like a grandmother, will rely on theory, my experience and observations. Thanks for your opinion

Because of such opinions, many people have the opinion that gas is evil, valves burn, cylinders explode, the car stinks, etc. It's all about setup and quality of equipment. I see no point in proving otherwise. There are tons of articles about this.

This is not why the valves burn. Look for the reason. The hands are burning.

Valves burn 1. On a car without a gas mixture 2. On a lean mixture (analogous to gas cutting - we increase the temperature by adding oxygen, only in our case we increase the temperature due to depletion, actually cutting the valves due to the outflow of exhaust gases) On a normal mixture, even without a gas engine you won’t lose seats

This is what you need. Carbonated. The car is on gas!

Well, good luck to you... use it!

I use. After the steam room I went well...

No, there you have to supply water through a special censer. And everything else is from the evil one!

I shrank from 2l to 1.8. But consumption has dropped. I'll wait until it dries down to 1.6 liters. And the engine gets wet with gasoline!

People like you can dry out up to 0.8... you there... be careful)

So sometimes I run on gasoline on the highway so that it gets wet again. And once a year I wash it with holy water

Well, you're doing the right thing here. Nothing to add. Try soaking it in gasoline overnight. There might even be 2.5!

I won't feed her then. What if he swells up to J-Z. Tama 2.5l and 6 pots. The guys will burn and I won’t pass

The influence of gas on the engine and its service life

It is well known that given the great popularity and demand for gas equipment, this solution has both supporters and opponents. Let us immediately note that in this article we will not consider in detail all the pros and cons of gas equipment, as well as the features of operation, installation of equipment, etc. Let's focus our attention exclusively on the power unit.

- First of all, for normal operation of the engine on gas, both the gas system and the engine itself must be correctly configured. In other words, installation and configuration should only be carried out by a qualified specialist. As for the car owner, he is also required to fully adhere to all regulations and recommendations regarding the operation and maintenance of gas equipment.

Ignoring these rules has led to the widespread belief that gas spoils the engine. One of the arguments is the fact that gas has a higher octane number compared to gasoline (92-98 for gasoline, while gas has about 110 or more). Many drivers claim that a higher octane number causes the engine to operate in abnormal modes, the gas “dries out” the engine, valves burn out, etc.

Indeed, gas has a difference in octane number and is somewhat different from gasoline in terms of combustion characteristics, but with proper settings it cannot have a significant impact on the condition of the internal combustion engine, CPG, valves and other elements. Once again, for this to happen, the setup must be done correctly.

A rich mixture damages the catalysts, burnout may occur in the exhaust system, the engine will run intermittently, errors may appear and the check mark may light up. As for a lean mixture, when the mass fraction of fuel (gasoline or gas) in the composition is less than air, then the consequences of driving for the engine will be much more serious.

Leaning causes the mixture to burn longer in the combustion chamber, and the combustion temperature also increases. As a result, valves and valve seats burn out, the service life of spark plugs is significantly reduced, and local overheating occurs.

Further, the problems progress, as improper operation of the spark plugs and other factors cause backfire. In short, there is a serious disruption of the combustion process in the cylinders. We also need to add to this the incompetence of many craftsmen in various handicraft services for installing gas equipment, as well as the desire of car owners themselves to save as much as possible. It is clear that the causes of many problems with the engine after installing gas equipment are obvious.

For example, in gas equipment that belongs to the initial generations (GBO-1 and GBO-2), the mixture quality adjustments are a simple screw that can only increase or decrease the gas supply. In other words, using a bolt you can enrich or lean the mixture. As a rule, many did this simply “by eye”, as long as the engine worked stably.

At the same time, not all drivers at that time knew that for correct adjustments, the service had to have a special and not the cheapest device (multicomponent gas analyzer). Moreover, in order to save gas, the owners themselves often made adjustments, tightening the adjusting screw and thereby greatly leaning the mixture.

The car worked normally, gas consumption dropped, and the power of the internal combustion engine also decreased slightly. But after a little time it all ended with, at a minimum, burnt-out valves. So, it becomes clear that the valves did not burn out because the engine was running on gas.

- Having dealt with the mixture, let's also talk about pops, which stand out on the list of common gas equipment problems. Backfire pops on cars with LPG are actually an uncontrolled spontaneous combustion of the gasoline-air or gas-air mixture in the intake manifold.

Engine operation and typical malfunctions

At the time of its creation, the legendary GAZ 53 car was equipped with two engine options with many modifications. The first of them was the 6-cylinder GAZ 11, which did not find its widespread note in this car model. In turn, the second version of the ZMZ 53 engine, with a volume of 4.25 liters, was installed much more times. Therefore, today the GAZ 53 engine is often exactly the ZMZ 53. This engine is a kind of standard for the reliability and durability of a car engine.

ZMZ 53 engine for a Gas 53 car

. However, in most cases, it has long since exhausted its safety margin and simply depreciated. This state of affairs often leads to failure of the unit and the need for its subsequent repair. Most often, engine failure is associated with the following faults:

- knocking of connecting rod bearings;

- burnout of exhaust valves;

- increased fuel and oil consumption;

- abrasion of piston rings;

- knocking of the upper bushings or pistons;

- burnout of cylinder block gaskets.

Engine oil for gas engines

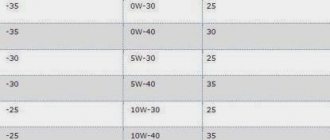

It should be noted that after switching to gas, experts recommend additionally selecting a suitable motor oil for cars with LPG. The fact is that when working on a mixture of gas and air, the temperature in the combustion chamber is higher.

For a lubricant, this difference is quite significant; some gasoline and universal oils simply cannot cope with such elevated temperatures. As a result, the protection of engine parts and components deteriorates. Also, regular oil when running on gas can cause increased coking of the engine, since the lubricant “burns” from heating, after which a lot of soot and deposits are created.

As a result, the engine cokes, oil consumption increases due to waste, etc. It turns out that after changing the type of fuel, you still need to separately approach the issue of selecting oil. It is optimal to use oils that meet the requirements and recommendations of the internal combustion engine manufacturer for tolerances, but it is also possible to use them in gas engines.

Today, the choice of such products is quite large, so there are no special problems with the selection of motor oil for a gas engine. Such lubricants are offered by leading brands Shell, Motul, domestic Lukoil and other well-known manufacturers.

Some good advice

- After integrating LPG into your car, in order to avoid problems with valves, regularly monitor the correctness of the gaps and the condition of the valves themselves, and, if necessary, adjust or replace faulty valves.

- Avoid long trips at extreme speeds (over 160 km/h). No, you can certainly "shoot" at this speed from time to time for overtaking or other needs. We are talking about driving at high speed, for several hours over several days or months. You must clearly understand that the engine of your car is still gasoline and is not entirely adapted, no matter what they say, for driving on gas at high speeds. And besides, it’s not logical to “pile up” when the main goal is fuel economy.

Something like this. That's all for me, thank you for your attention, I thank those who made it through the article to the end. Sorry, it’s not in a nutshell, brevity is the sister of talent, apparently my sister’s name is different (-; Good and Peace to all, see you again at HBO. For those who think that the article is not complete or the topic is not fully disclosed or simply want discuss, can do this using the comment form. I will be happy to hear your opinion on this matter. Bye!

Advice required. Replaced rings and bearings. What can you say about running in a gas engine? All the pros and cons.