Purpose

Knowledge of the operating features and purpose of a lambda probe is very useful for a car enthusiast.

Firstly, no one will be able to deceive the owner of the vehicle, and secondly, in the event of a breakdown, you can make a “diagnosis” yourself.

The task of the lambda probe is to create conditions for the catalytic converter to perform its functions, which filters the vehicle's exhaust.

Catalyst operation.

In essence, the catalyst reduces the harmfulness of the exhaust, and the lambda probe monitors the operation of this device.

The name of the probe comes from the well-known Greek letter “lambda”, which denotes the volume of oxygen in the prepared combustible mixture.

The lambda value is 14.7 units per unit of fuel. Proportionality is ensured thanks to electronic injection of the fuel mixture and the operation of a lambda probe.

The purpose of the device also depends on its position in the vehicle.

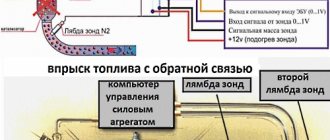

As a rule, an oxygen sensor is mounted in front of the catalyst, which makes it possible to accurately measure the oxygen level in the combustible mixture, and in case of imbalance, give a signal to the injection control unit.

To increase operating efficiency, new car models are equipped with not one, but two sensors, attached to one and the other side of the catalyst.

This design allows for more accurate analysis of the exhaust composition.

Regulator replacement

Replacing an oxygen sensor on domestic cars, as a rule, does not cause any particular difficulties. The only difficulty may be that the probe boils, after which it is practically unaffected by mechanical action. But even for such cases there are effective and step-by-step instructions. It is given below.

- The car climbs onto the overpass.

- The protection of the power unit is removed.

- The hood opens and work begins with the probe wires. The wiring from the oxygen sensor can be found on the CO hoses (cooling systems). They are secured with clamps.

- The plastic clamp holding the wiring is cut;

- The sensor is unscrewed with a key set to “22”.

If the device is not removed, the sensor is boiling. We proceed according to the following scheme. We spray the regulator with WD-40, wait a little and try to remove it again. If it doesn’t work again, start the engine and heat up the exhaust system a little, pour water on the regulator and try again. If that doesn’t help, you’ll have to heat the sensor directly with a soldering iron, tap it with a hammer (not too hard) and unscrew it.

The regulator is installed in the reverse order of removal. You must remember to connect the connector and secure the wiring to the hoses.

Knowing the signs of a malfunctioning lambda probe, you can react to it in time and replace it. A normally functioning sensor means high-quality and trouble-free engine operation. A motorist should never forget this.

Lambda probe is the traditional name for an oxygen sensor. It helps control the amount of oxygen in exhaust gases. Engine performance is directly related to how efficiently the fuel-air mixture burns. And oxygen is largely responsible for the combustion process. By adjusting its content in the mixture, you can control the combustion temperature: increasing or decreasing it accordingly. If there is a lot of oxygen in the mixture, then engineers usually denote this situation with the Greek letter lambda. Well, one cannot but agree that “lambda probe” in Russian sounds much more expressive than the everyday “oxygen sensor”.

The main tasks of the lambda probe

The oxygen sensor is installed where the exhaust gases pass, namely in the exhaust manifold. It is used in those cars that are equipped with an injector. To increase the accuracy of the assessment, two lambda probes are sometimes used. They carefully surround him, being on both sides of him.

The electronic control unit regulates the amount of fuel supplied to the engine. An oxygen sensor helps him with this. It transmits information about the oxygen content in the exhaust gases. Depending on the sensor readings, the amount of fuel injected increases or decreases. When there is too much oxygen in the mixture, its combustion temperature rises. This releases toxic substances that are dangerous to humans and the environment. The lambda probe indirectly controls the environmental friendliness of the exhaust system and strives to create conditions for the proper operation of the catalyst.

Evolution of development

Previously, oxygen sensors were resistive, which reduced the accuracy of measurements and the reliability of the devices themselves.

A modern lambda probe works as a threshold device. In this case, the signal received from the sensor allows you to accurately record the level of oxygen ratio in the exhaust and correct it.

The optimal ratio is 14.7:1 (actual to required air volume). If the parameter ? meets this standard, then the mixture is ideal.

If the indicator is exceeded, the mixture is lean. If ?, on the contrary, is less, then there is a lot of mixture in the exhaust and the volume of oxygen is not enough for combustion.

The lambda probe was first manufactured in 1960 by Robert Bosch GmbH. The project manager was Günther Baumann.

The device entered mass production only 16 years later (in 1976). The first manufacturers to start production were Saab and Volvo.

Vehicle repair

Many car manufacturers insist that there is no point in repairing the lambda probe and you just need to replace it with a new one. But you should understand that the price from official dealers is very fantastic, especially if you are the owner of a modern vehicle. The simplest and most relevant way out of this situation is to purchase a universal sensor equipped with an adapter for a specific vehicle. Such devices can be purchased from Bosch. Taking advantage of its offers, you can buy used spare parts, which differ significantly in value and in the length of the warranty period. You can also get a previously used exhaust manifold, but in good and working condition. When you are completely convinced that the lambda probe is not functioning correctly and combustion products are accumulating on it, you can try to clean it. To do this, you should disassemble the device; the surface should have a temperature of 40 to 50 degrees. Next, the protective cap is removed and the contacts are lowered into phosphoric acid. Then the lambda probe is washed a couple of times with running water. The next thing to do is dry it well, apply sealing paste and reinstall it. In particular, the tightening torque is set by the manufacturers; it can vary, but generally 40 - 60 Nm. This process works very well in many cases.

Main device types

Today there are several types of oxygen sensors. All of them may differ according to several criteria:

- by number of wires - from 1 to 6;

- on the organization of the sensory element (there are two types - plate and finger);

- for fasteners in the exhaust pipe - flanged or threaded;

- according to the measurement range of the lambda parameter - broadband (measurement is made in the range from 0.7 to 1.6) or narrowband, controlling the lambda level at a level above unity.

Each type of device has its own characteristics.

One contact devices.

Equipped with one signal wire. It is through it that the signal generated by the device is transmitted.

2-pin sensors.

Equipped with two wires. One is a signal, and the second performs the function of grounding through the device body.

Using the grounding conductor, you can accurately determine the performance of the signal wire.

3-pin.

There is a signal wire, one ground wire and a third wire going to the heating device.

The peculiarity of such sensors is the rapid achievement of the desired temperature, an increased service life of the device, as well as lower requirements for the exhaust system.

The heating element, which is mounted in the system, has a power of 12 or 18 W.

4-pin devices.

They have four wires:

- signal conductor,

- the wire,

- feeding the heating device;

- the third wire is “ground”;

- fourth wire - can be used to solve any other problems (depending on the vehicle control system).

POPULAR WITH READERS: VAZ 2114 engine cooling system

This may be the position of the contacts.

For example, it can be used as grounding or to power a heating element.

The peculiarity of modern lambda probes is that they are interchangeable and have a similar design.

For example, you can replace heated sensors with non-heated ones. In this case, there may be problems with the connectors or the inability to power the device.

If there are not enough wires, you can lay them yourself and use the car contacts as a connector.

The markings may vary, but the signal wire is always painted black.

The "mass" may be yellow, gray or white.

The design of modern oxygen sensors

The oxygen sensor has two electrodes - internal and external.

The first is made of zirconium, and the second is made of platinum coating, which makes it more sensitive to oxygen.

The lambda probe is mounted in such a way that it passes the entire volume of exhaust gases of the vehicle.

As gases pass through, the external electrode evaluates the oxygen level in the exhaust gases, which leads to a change in the potential between the electrodes.

The greater the volume of oxygen, the higher the voltage level. The operating temperature of the zirconium with which the electrode is coated is 300-1000 degrees Celsius.

That is why oxygen sensors are structurally complemented by heaters, which are necessary at the time of start-up.

There are two types of sensors - point-to-point and wideband. They are similar in appearance, but differ in design and principle of operation.

Thus, a 2-point sensor consists of two electrodes. Its task is to fix the coefficient of increased air volume in the fuel mixture.

As for the broadband device, this is a more modern design. Its main feature is the use of injection current.

In this case, the design of the broadband sensor consists of two ceramic devices - a pumping device and a 2-point one.

How to identify the problem?

Let's look at possible signs of a malfunctioning oxygen sensor:

- Increased fuel consumption.

- Jerking when moving.

- Noticeable drop in power.

- Unstable engine operation at idle.

- Increased toxicity of exhaust gases.

Note that these symptoms do not always occur specifically because of the oxygen sensor.

Therefore, having identified one of the above symptoms, we proceed to a more detailed check of the device. We'll look at how to do this below.

Operating principle

Oxygen contains negatively charged ions. They are assembled on platinum electrodes and when the desired sensor temperature is reached (about 400 degrees Celsius), a potential difference (voltage) is created.

If the mixture is too lean, then the volume of oxygen in the gases will be high, and vice versa, if the mixture is rich, then there will be little oxygen.

In the first case, the voltage is 0.2-0.3 Volts, and in the second - 0.7-0.9 Volts.

The motor control system maintains a voltage level of about 0.4-0.6 Volts, that is, the lambda level is 1.0.

During movement, the operating modes of the motor change, which helps to adjust the voltage parameter in both directions. In this case, a narrowband sensor can only capture those parameters that are above zero.

The lambda probe, which is installed after the catalyst, has the same principle of operation.

After treating the gases with a catalyst, the oxygen level remains unchanged. This, in turn, allows you to maintain an optimal potential difference within 0.4-0.6 Volts.

Diagnostic and recovery methods

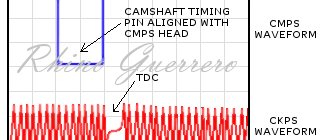

It is advisable to carry out diagnostics at a specialized service, using an oscilloscope, but such an opportunity is not always available, and it will not be free. You can try checking the sensor in a garage. For this, an accurate multimeter will be useful (analog will not work, only digital). It is also necessary to read the instructions for the car. There, among other things, the parameters of the lambda probe will be indicated. First you need to check the sensor visually. If various types of deposits are present on it, the test can be considered completed: the sensor is faulty. The next step is to disconnect the sensor from the block and connect it to a voltmeter. The pinout of the contacts is different for each manufacturer; you can clarify it using the Internet or the instructions for the sensor, if it was included in the kit. Next, the car starts, the vacuum tube is removed and the engine speed is brought to 2300-2500 rpm. The voltmeter should show a voltage of about 0.9 Volts, or 0.2 Volts with forced air intake. At intermediate speeds (1200-1500) the readings are considered normal within 0.5 Volts. All other values indicate incorrect operation or complete malfunction of the sensor.

Don't immediately run to the store. In some cases, washing the sensor gives results. To do this, it must be removed (while it’s hot, so as not to break the thread), and placed in phosphoric acid for 30-40 minutes, then dried and put back in its original place. There is a chance that the acid will dissolve any dirt that has gotten onto the sensor. If this does not help, the only thing left is to completely replace the device.

By the way, if there is no way to replace the sensor, but you need to make trips, you can do without it. In this case, the ECU takes average parameters and controls the fuel system based on the readings of other sensors. But this is not considered normal operation of the car and can only serve as a temporary solution. Remember that not only the ephemeral ecology is at stake, but also the good technical condition of your car.

The exhaust system of the car is gradually being modernized. And this applies not only to the installation of catalysts designed to clean gases from lead and other harmful substances. In addition, modern cars are equipped with an oxygen sensor. People call it a lambda probe. What is an oxygen sensor? Replacement, testing, malfunctions - further in our article.

Wideband lambda probe: main differences, operating principle

A broadband sensor for measuring oxygen levels is a lambda probe, which is installed in modern cars.

Its peculiarity is that it acts as a catalyst at the entrance to the device. The required parameters are measured using the input current.

The main difference between a broadband sensor is that it contains two working elements - a pumping element and a 2-point ceramic heater.

During the injection process, oxygen is passed through the corresponding element under the influence of current.

The operating principle of the broadband probe is based on maintaining the voltage within 450 mV.

The potential difference itself appears between the electrodes of the two-point element. Achieving the required voltage is guaranteed by changing the pumping current.

If the volume of oxygen in the exhaust decreases, the voltage between the electrodes increases, and the ECU receives the corresponding command.

POPULAR WITH READERS: Do-it-yourself injector flushing

After this, a signal of the required current strength is generated, which leads to voltage equalization.

The current strength is analyzed in the computer, after which the control unit acts on the injection system.

Normal operation of the oxygen sensor is possible at a temperature of 300 degrees Celsius, which is achieved using a heater.

Types of oxygen sensors, design features

The optimal mixture ratio is 14.7 parts air and 1 part fuel. This value is taken as one and is denoted by the Greek letter λ (lambda). Since it is the oxygen sensor that determines the quality of the mixture, over time it began to be called a lambda probe.

Three types of sensors have become widespread: two-band zirconium-based sensors, titanium dioxide sensors and broadband lambda probes.

The operating principle of the zirconium sensor is as follows:

One electrode receives exhaust gases, and the second - atmospheric air. At a temperature of 300-400 degrees, zirconium dioxide becomes conductive, and due to the difference in oxygen content in the atmosphere and the exhaust pipe, a voltage is formed on the electrodes, which varies in the range of ±0.1 Volt, depending on the concentration of gases. The control unit compares these values with the settings that are programmed in its memory and makes a decision to further reduce or increase fuel injection. With a lean mixture, the operating time of the injectors increases, and with a rich mixture, it decreases. The physical and chemical processes occurring at this moment in the sensor are a rather complex reaction, and are unlikely to be understandable to an uninitiated user.

Sensors based on titanium dioxide have a different operating principle. When the qualitative composition of the fuel-air mixture changes and the voltage is constantly supplied, the resistance of the device changes, and abruptly. Accordingly, the voltage also changes, which is recorded by the ECU. This sensor requires a constant temperature to operate. This is ensured by an incandescent filament, which is both a plus and a minus of the device. The plus is that the sensor comes into operation within 15-20 seconds after turning on the ignition, but the minus is that the heating element is fragile and subject to wear.

The most modern oxygen sensors are broadband. The design includes an injection element, which, as the name suggests, pumps oxygen from the exhaust gases. With a rich fuel mixture, the oxygen content drops, because of this, the voltage between the sensor electrodes increases, which is recorded by the control unit. Next, the current strength at the pumping unit increases. In fact, the generated current to maintain the required voltage is an indicator of the amount of oxygen. With a lean mixture, the process is similar, but goes in the opposite direction: air is pumped out, voltage and current drop, the ECU commands the injection system to increase the fuel supply time. A huge advantage of such sensors is the accurate transmission of signals, which means that the control unit controls the injector more correctly.

Modern cars are often equipped with several lambda probes. Their combined work makes it possible to achieve a minimum content of harmful substances in the exhaust.

What does a probe malfunction lead to?

The first trouble that results from the failure of the probe is an increase in the “gluttony” of the car and a deterioration in the overall dynamics.

The main reason is a distortion of the sensor readings, which leads to a deviation in the oxygen-to-fuel ratio.

If one sensor fails, the car remains on the move (much depends on the vehicle itself).

There are models in which failure of the mechanism leads to large amounts of fuel being consumed. As a result, urgent repairs may be required.

If the lambda probe breaks down, it should only be replaced with a similar mechanism.

If you install a device of a different type, the vehicle’s on-board computer may simply not perceive the signals from the new sensor.

If two sensors break down at once, the car becomes completely immobilized.

Read more here - signs of lambda probe malfunctions.

Frequent sensor breakdowns

Among the most common breakdowns are a non-working heating element, as well as loss of sensitivity. As a result, the performance of the device decreases. The most important thing is to try not to replace the lambda probe with any simulators. The electronic control unit will not be able to recognize someone else's signal. Consequently, the fuel mixture will not be adjusted using this simulator. Please note that if the oxygen sensor worked successfully in the conditions of our country (low-quality gasoline), and its service life is clearly more than three years, then you don’t even need to contact a diagnostician. The lambda probe must be replaced immediately. The Skoda clearly shows signs of malfunction with a mileage of over 70 thousand km. Some models of oxygen sensors may even have a service life of just over 30 thousand kilometers.

Causes of failure

It is worth noting that the oxygen sensor has increased sensitivity to breakdowns.

The cause of failure may be:

- Low quality fuel. With bad gasoline, certain parts of lead remain on the lambda probe. The appearance of such sputtering impairs the sensitivity of the electrode to the fuel mixture. Some time passes and the sensor can be thrown away.

- Mechanical failure. The oxygen sensor itself may fail. In this case, the main damages include a housing defect, a violation of the device winding, and so on.

The problem is solved by installing a new sensor. As for repairs, they are useless in case of such breakdowns.

3. Excessive volumes of fuel supplied to the engine cylinders simply do not have time to burn and fly out into the exhaust system in the form of soot.

Over time, black deposits accumulate on the components of the vehicle’s exhaust system, including the oxygen sensor. As a result, the lambda probe begins to work incorrectly.

As a “treatment” you can use special cleaners and rags to remove dirt. If the sensor clogs regularly, then it is better to change it.

Why does the oxygen sensor (Kalina) fail?

Signs of a malfunction may vary. First of all, this concerns the quality of the combustible mixture itself. Various deposits can worsen the performance of the oxygen sensor. The element also malfunctions due to depressurization of the housing.

This often happens due to obsolescence of the element. Less often, the housing is damaged mechanically, since it is located in a fairly safe place. Another reason is improper power supply. The sensor contacts may move away, as a result of which information is received incorrectly by the control unit. The composition of the fuel-air mixture is disturbed (too lean or rich). Another cause of malfunctions is an incorrectly set advance angle. This applies to cars with a distributor ignition system. Interruptions can also occur due to problems with high-voltage wires, or due to spark plugs. The engine begins to stall at idle and operate incorrectly at high speeds.

How to identify a breakdown?

A malfunctioning lambda probe can be recognized by the following symptoms:

- increasing the overall toxicity of exhaust vapors. Of course, it is impossible to determine this indicator by eye. Only a special device can help here. If the CO level has increased significantly, then we can confidently say that the oxygen sensor has failed;

- An increase in the car’s “gluttony” is a problem that can be seen almost immediately. The only thing is that an increase in flow rate does not necessarily indicate a sensor malfunction;

- The Check Engine light coming on is another signal that something is wrong with the system. As practice shows, the lighting of this light is associated with a breakdown of the lambda probe. To more accurately determine the error and identify the defect, you need to go to the service.

How to check the lambda probe for serviceability.

Stories of car owners.

Since the lambda probe is a rather “insidious” sensor, many problems can be associated with it. Often, with increased fuel consumption, car owners believe that the reason lies precisely in the pressure factor. Below are three stories from car owners that clearly demonstrate the problems and their solutions.

Alexey, a car forum user from Rostov, owns a Mazda 3 with a 2.0 liter engine. He had a problem with increased fuel consumption. Even in a quiet mode of movement, the car spent 15 liters per hundred kilometers. There was also an error “check” on the dashboard, indicating a malfunction of the lambda probe, as the driver believed. A new sensor for his car costs from 10 thousand rubles, and Alexey was not ready to spend that kind of money. There was an option to purchase an analogue part of the BOSCH brand costing 3 thousand rubles, but it might not fit the car due to resistance. Therefore, the car owner began to look for other methods to solve the problem. He remembered that a month and a half ago he started filling up his car at a Lukoil gas station, after which the check light came on. A friend advised me to add an additive to the tank that increases the octane number of gasoline. But the store dissuaded the car owner from doing this, because there is a high risk of burning the valves. But Alexey was advised to purchase a cleaning additive, which is also poured into the tank. He also checked the oil level and added it to the proper level. Alexey filled the gasoline at another gas station, after which he added the additive. Fuel consumption dropped to 9.5 liters, and the check went out. We can conclude that the error may also occur due to low-quality gasoline, and not only due to malfunctions of the exhaust system.

The second story was told by Sergei, who bought a 1989 Opel Vectra A from his own hands. Fuel consumption was too high and reached 12 liters per 100 km. Since the Check engine light was on, it was decided to carry out diagnostics. It showed a faulty lambda probe. Sergei replaced the oxygen sensor, this helped, but only for two weeks. After this, the sensor became unusable again, and the “check” light came on. The car owner installed a used one so as not to spend a lot of money. This also solved the problem for a short time. Sergey began to look for more detailed information and found out that previously a different type of engine was installed on the Vectra A, and just starting in 1989, new engines were introduced. Structurally, they were no different, but in older engines a lambda probe was not provided, and different firmware was used. By reflashing the problem, the problem was eliminated, because the control unit now considered the CD non-existent.

Is it possible to turn off the lambda probe?

Disabling the oxygen sensor takes a few minutes for a specialist. But the benefits of such work raise serious doubts.

From the moment the lambda probe is turned off, the ECU switches to average fuel supply parameters to the engine, which affects reliability and fuel consumption (usually for the worse).

In addition, if the oxygen sensor is disconnected, it may be necessary to reflash the car’s ECU itself, because an error will constantly appear.

Therefore, if the lambda probe fails, it is advisable to replace it.

POPULAR WITH READERS: Is it worth installing silicone tint? Details about the pros and cons of static film

Diagnostics

Often, completely different failures are mistaken for a lambda probe failure. Therefore, before purchasing a new sensor (it costs a lot), you should definitely carry out diagnostics. The best option is to use a diagnostic scanner. The computer usually shows if there is a lambda probe error. In some cases, there is a complex of problems; in addition to the oxygen sensor, some other parts of the car also fail.

There is also a “collective farm” diagnostic method. It consists of turning off the sensor and checking how the car will work without it. It is believed that if the probe is in working order, its disconnection will lead to deterioration in engine performance or the inability to start it. If the sensor is faulty, there will be no changes. Unfortunately, this diagnostic method is not always reliable; it is better to carry out computer diagnostics.

We suggest disabling catalyst control at the software level. On most brands, I have the opportunity to reflash the computer to a full Euro2, with the ability to physically disable the rear oxygen sensors (DK 2).

The first option when you need to disable DK2 in the program:

After 100,000 miles, the heaters on the oxygen sensors begin to burn out. If DK 1 “dies,” you will have to replace it and in most cases only the original will do. If the oxygen tracking sensors (DK 2) fail, you have a choice, either replace it (them) or come to me and turn off the rear DKs in the program; cheating will not help here. The cost of disabling the second DC in the firmware is comparable to the cost of a new sensor, and in some cases cheaper. At the same time, unlike replacing sensors, disabling in the software is done once and forever, with a one hundred percent guarantee. In this option, the catalyst is not removed and continues to work for the benefit of the people.

The second scenario when you may need to disable DK2 control in the firmware:

The newer the car, the higher its ECO requirements. Accordingly, higher demands are placed on the quality of fuel and lubricants. For many, it will not be news when, after the introduction of the next EURO requirement in Russia, under warranty, complaints began about the check periodically lighting up. Almost everyone has the same error P0420 CATALYTIC NEUTRALIZATION SYSTEM EFFICIENCY BELOW THRESHOLD LEVEL.

Lambda probe decoy: what is it?

When replacing the catalyst with a flame arrester or dismantling the device, the signals from the two lambda probes will be identical. This, in turn, will inevitably lead to errors.

The problem is solved by installing a lambda probe blende.

It comes in two types:

1. Mechanical.

By design, it is a spacer made of bronze and having certain dimensions. Inside the unit there is a special crumb with catalytic spraying, which helps harmful substances burn out.

2. Electronic.

This decoy is a device based on a microprocessor that analyzes the entire process of exhaust gas passage and processes data from the first sensor.

The task is to ensure correct operation of the engine control system in conditions where the catalyst is broken or removed.