Reasons for clicking when switching on the ignition

Let's look at the main reasons leading to complete or partial inoperability of the starter:

- problems with the power supply to the starter unit - most often the ground contact is disrupted due to a weakening of the bolted connection or its oxidation. In addition to the starter, the relay, solenoid and main relays are powered to ground, so these components are also subject to checking for quality contact;

- Solenoid relay is faulty. The most likely cause is a winding break/short circuit, and occasionally mechanical failure occurs;

- Short circuit in the starter winding. A typical breakdown for older cars, practically never encountered on cars with mileage up to 100-150 thousand km;

- problems in the contact group - most often it is a blown fuse, but there are conductivity problems in the ignition switch or wiring contacts;

- starter clutch slipping. Since the coupling cannot be repaired, it will need to be replaced;

- The starter drive is clogged, causing it to move along the threads tightly and with difficulty. It can be solved by cleaning and lubricating the thread after disassembling it.

Let's look at typical problems and problematic issues in which the crankshaft of a car practically does not turn or barely turns when the ignition is turned on:

- in winter, such a problem can arise due to the mismatch of the engine oil with the region of use - it thickens and prevents the crankshaft from turning;

- dead battery. It is also more common in winter, since at low temperatures the battery loses its charge much faster;

- The clicking of the starter indicates wear of its brushes, although on some VAZ models there will not even be a clicking sound with this problem.

Occasionally, there are other reasons that lead to the impossibility of starting the engine, regardless of whether it is cold or warm. So, it may turn out that the return spring located in the retractor relay has failed. It is also possible to unstick the stator magnets - this can be cured by disassembling and gluing them together manually.

Let's take a closer look at the main reasons for the starter's inoperability.

The reasons that the starter does not turn may be a malfunction of the retractor relay, a weak battery charge, bad electrical contacts in the circuit, mechanical failure of the starter, and so on. It will be useful for every car owner to know what to do if the starter does not turn the engine. Indeed, in most cases, repairs can be done yourself. Moreover, a breakdown usually occurs at the most unforeseen moment, when it is not possible to use the help of a car repairman. Next, we will consider in detail the causes of the malfunction and methods for eliminating them.

Signs of a faulty starter

There are actually many reasons why a car won't start. However, a starter malfunction can be determined by the appearance of one or more of the following symptoms: - the starter does not turn on; — the starter clicks, but does not turn the engine crankshaft; — when the starter is turned on, the crankshaft rotates very slowly, which is why the engine does not start; - you can hear the metallic grinding of the Bendix gear, which does not engage with the crankshaft. Next, let's move on to discussing the possible causes of a possible breakdown. In particular, we will analyze situations when the starter either does not rotate at all or does not rotate the engine crankshaft.

Reasons why the starter does not turn

Often the reason that the car does not start and the starter does not turn the flywheel is a discharged battery. This reason is not directly related to the breakdown of the starter, however, before diagnosing this unit, it is necessary to check the charge of the battery and, if necessary, recharge it. Most modern car alarms block the starter circuit if the voltage level from the battery is 10 V or lower. Therefore, you will not be able to start the engine under this condition. To prevent this from happening, monitor the battery charge level and recharge it periodically if necessary. Also be aware of the density of the electrolyte. However, we will assume that everything is in order with the battery charge level. Let's consider one particular case... Owners of a 2007-2008 Ford Focus 2 car may encounter a problem when the starter does not turn due to an error in the original immobilizer. Diagnosing this breakdown is very simple - to do this, just turn on the battery power directly to the starter. However, it works without problems. As a rule, official dealers replace the immobilizer under warranty. The reasons that the starter does not turn and “shows no signs of life” may be the following situations: Deterioration or disappearance of contact in the starter circuit. This may occur due to corrosion or deterioration of the bolted wires. We are talking about the main “ground” contact attached to the machine body. It is also necessary to check the ground of the main and starter solenoid relays. According to statistics, in 80% of cases, problems with a non-working starter come down to malfunctions in the car’s electrical circuit. Therefore, in order to eliminate the problem, it is necessary to inspect the wiring, that is, inspect the starter power circuit, tighten the bolted connections on the blocks and terminals. Using a multimeter, check for voltage on the control wire going to the starter; it may be damaged. To check it, you can close the starter “directly”. How to do this is described below. The starter solenoid relay is faulty. This could be a break in its windings, a short circuit in them, mechanical damage to internal components, and so on. It is necessary to diagnose the relay, find and eliminate the fault. You will find additional information on how to do this in the corresponding material. Short circuit in the starter winding. This is a fairly rare, but critical problem. It occurs most often in starters that have been used for a long time. Over time, the insulation on their windings is destroyed, as a result of which an interturn short circuit may occur. This can also happen due to mechanical damage to the starter or when it is exposed to aggressive chemicals. In any case, it is necessary to check for a short circuit, and if it occurs, then the solution would not be repair, but a complete replacement of the starter. Problems with the ignition switch contact group, which may be the reason why the starter does not turn. If the contacts in the ignition switch are damaged, then no current passes through them to the electric motor, and accordingly, it will not spin. The test can be done using a multimeter. Check whether voltage is supplied to the ignition switch and whether it leaves it when you turn the key. It is also necessary to check the fuses of the contact group (usually located in the passenger compartment, under the “dashboard” on the left or right side). Slipping of the freewheel of the starter drive. In this case, repair is impossible; the mechanical drive of the starter must be replaced. The drive moves tightly along the shaft thread. To fix it, you need to disassemble the starter, clean the threads of debris and lubricate them with machine oil. Next, we will analyze the problems of which this fact is a symptom. that the starter cranks the crankshaft very slowly, which is why the engine does not start. The viscosity of the engine oil does not match the temperature conditions. This situation can arise when the engine oil becomes very thick in extreme cold and prevents the crankshaft from rotating normally. The solution to the problem is to replace the oil with an analogue with the appropriate viscosity. You will find tips on how best to do this in this article. Low battery. If it is not charged enough, then there is not enough energy to turn the crankshaft at normal speed using the starter. The solution is to charge the battery or replace it if it does not hold a charge well. This situation is especially relevant for winter. Poor contact of brushes and/or poor tightening of wire tips going to the starter. To eliminate this breakdown, it is necessary to inspect the brush assembly, change the brushes if necessary, clean the commutator, adjust the tension of the springs in the brushes or change the springs. In some modern cars, the electrical circuit is designed in such a way that if the starter brushes are significantly worn, no voltage is supplied to the solenoid relay at all. Therefore, when you turn on the ignition, it will not click. Let's list a few more atypical situations due to which the starter does not turn both cold and hot. So: The problem is with the control wire that goes to the starter. If its insulation or contact is damaged, it will be impossible to start the engine using the key. We recommend that you review it. To do this you will need the help of another person. One of you should try to start the engine using the ignition key, while the other one pulls the wire, trying to “catch” the position in which the necessary contact will occur. Another option is to apply a direct “+” from the battery to the mentioned control wire. If the engine starts, you need to look for the cause in the ignition switch; if not, in the insulation or integrity of the wire. If the problem is a damaged wire, then the best option is to replace it. Sometimes the permanent magnets in the starter stator become detached from the housing. To eliminate the damage, you need to disassemble the starter and re-glue them to their designated places. Fuse failure. This is not a common, but probable reason that the starter does not work and does not turn the engine. First of all, we are talking about fuses for the contact group of the ignition system. The return spring on the starter retractor relay flies off. To eliminate the malfunction, it is enough to remove the specified relay and install the spring in place.

The starter clicks but doesn't turn over

Very often, when the starter malfunctions, it is not the mechanism itself that is to blame, but its retractor relay. It is important to understand that when you turn on the ignition, it is not the starter that clicks, but the mentioned relay. Malfunctions consist of one of the following reasons: Failure of the power wire that connects the starter windings and the traction relay. To solve the problem it is necessary to replace it. Significant wear on starter bushings and/or brushes. In this case, they need to be replaced. Short circuit on the armature winding. You can check this using a multimeter. As a rule, the winding is not repaired, but another starter is purchased and installed. Short circuit or break in one of the starter windings. The situation is similar to the previous one. The device needs to be replaced. The fork in the bendix is broken or deformed. This is a mechanical failure that is difficult to fix. The optimal solution in this situation would be to replace the bendix or the fork separately (if possible). The starter does not turn hot. Sometimes car owners have problems when the starter does not turn “hot”. That is, with a cold engine, after a long period of parking, the car starts without problems, but when it heats up significantly, problems arise. In this case, the most common problem is incorrectly selected starter bushings, that is, having a smaller diameter than required. When heated, a natural process of increasing the size of the parts occurs, which is why the starter shaft jams and does not rotate. Therefore, choose bushings and bearings in accordance with the manual for your car. Also, in extreme heat, contacts in the vehicle's electrical system may deteriorate. Moreover, this applies to all contacts - on the battery terminals, the solenoid and main starter relay, on ground, and so on. Therefore, we recommend that you inspect them, clean and degrease them. The starter is a simple but extremely important mechanism in a car. Therefore, its failure is critical, as it does not allow the engine to start. In most cases, problems are related to the car's electrical wiring, poor contacts, broken wires, and so on. Therefore, if the starter does not turn over and does not start the engine, the first thing we recommend is that you inspect the contacts (main ground, relay contacts, ignition switch, etc.).

Battery is very low

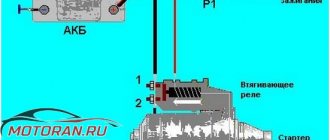

We have already mentioned that this is the most common and common case. And to understand why this happens, let's figure out how a car starter functions. As soon as we turn the key in the closed circuit, by closing the contacts, the supply voltage is supplied to the contact group of the solenoid relay, and the electromagnetic component of the current sets the starter armature in motion. It, in turn, closes the circuit between the starter motor and the battery and at the same time moves the Bendix gear, establishing the engagement of the starter shaft with the crankshaft flywheel.

When the battery is severely discharged, its charge may be sufficient to move the armature core, but there is no talk of cranking the crankshaft. If the starter clicks but does not turn, this means that the Bendix gear is mating with the crankshaft with a characteristic sound, but there is not enough battery charge for more. But there is one nuance here: since the voltage supplied by the battery is too low, the electromagnet cannot hold the core, and it returns to its original position (the action of the spring is stronger than the electromagnetic one). Over a short period of time, the charge is slightly restored and sets the core in motion again - this cycle can be repeated several times.

What should you do when the starter does not turn when you turn on the starter, but just clicks? First of all, make sure that it is the battery that is to blame: with the ignition on, try turning on several consumers at the same time and pressing the horn. If the battery is dead, you will not hear a signal or it will be far from normal (wheezing, fading, distorted sound).

Starter relay failure

If the car does not start, the starter clicks, the motor does not turn, and the car owner is sure that the battery is charged - it is very likely that the problem element is the starter relay. The clicking sound is precisely a consequence of the triggering of the switch.

In such cases, you can start the engine using a regular screwdriver. The operation algorithm is simple. For cars with manual transmission it is as follows:

- tighten the parking brake;

- move the gearbox lever to neutral;

- turn on the ignition;

- take a flat-tip screwdriver and move to the engine compartment;

- securely close the contacts of the retractor relay with a screwdriver;

- As soon as the engine starts, carefully remove the screwdriver.

If you have never done this and doubt your abilities, it is better to abandon this idea. A mistake made can have serious consequences (short circuit with a fire in the engine compartment, spontaneous starting of the car, etc.).

For modifications with an automatic transmission (robot, variator), the procedure will be slightly modified:

- tighten the parking brake (if the transmission is robotic or variable);

- We switch the automatic transmission selector to parking mode (P), press the brake, turn on the ignition;

- Then we close the relay contacts in the same way (there can be three of them), after starting the engine, remove the screwdriver.

Starter sticks

So I turn the key, and the starter starts to turn and immediately goes out. All the lights on the dash dim and the radio goes silent. I let go of the key and turn it again - the same canoe and the third time too. The fourth time the starter starts to turn normally, but before the engine starts it turns very it took 5-7 seconds. I disassembled the starter, everything seems to be fine, there is a small play on the outer bushing (about 1mm), I don’t know whether it’s a lot or not, but the bushing is intact. What’s interesting is that if you remove all the caps from the spark plugs, then everything comes back back to normal, it turns as it should. I draw your attention to the fact that the spark plugs remain in place, I only remove the caps. The option with early ignition is no longer necessary, because I installed it very late, but it didn’t get better. I drove it for about 2000 km. I’m really tired of driving with such trouble, I’m afraid that I’ll ruin the battery; it’s a new one, it’s a pity.

Burning of contacts in the solenoid relay

Signs indicating a malfunction in the solenoid relay of the starter unit:

- the power unit manages to start, but the starter also continues to work;

- after turning on the ignition switch in starter mode, a click is heard, but no cranking of the crankshaft is observed;

- After switching the ignition switch to starter mode, you can hear the starter trying to spin up (a strained buzz can be heard), but the crankshaft does not spin.

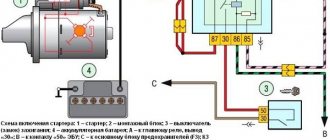

To find the reason why the starter solenoid relay clicks and the motor drive does not spin, it is necessary to diagnose the unit. Let's consider an approximate algorithm of actions for the VAZ-2110:

- the first thing to do is check the integrity of the electrical wiring going to the relay. If a break is detected, change the wiring;

- If the wiring is intact, check the functionality of the relay. Outside help will be required - one person turns the lock key, another in the engine compartment listens to the starter. If there is no click, we can talk about a faulty relay; If you hear a click, but the starter does not turn the shaft, you need to check whether the plates in the contact group are burnt. We need a simple tool - a flat screwdriver. We disconnect the contact group from the relay and use a screwdriver to close the terminals connecting the battery to the starter contact group. Thus, we apply voltage directly to the starter motor, bypassing the solenoid relay. If the starter starts, the obvious cause is a bad relay;

- in this case, we proceed to measure the voltage supplied to the relay. We will need a tester, one contact of which is connected to the positive terminal of the relay, and the other to ground. After turning on the ignition, the tester readings should be around 12 V. If you observe a lower value, the reason is a discharged battery.

Problems with the fuel system

Even the most “vigorous” battery and a new, working starter will not be able to start the car if problems arise with the supply of fuel to the cylinders. For this reason, the next thing to check is the engine power supply system.

1.Fuel pump

For carburetor and diesel engines, this unit is located directly next to the cylinder head or block. Injection power plants are equipped with an electric pump, which is installed in the fuel tank. Their operation is judged by a short buzzing sound that appears after the ignition is turned on. As for fuel pumps in carburetor engines, they are mechanically driven by a cam mounted on the camshaft.

It is easy to check the functionality of the fuel pump - to do this, remove the hose from the carburetor inlet fitting and lower it into a suitable container. After this, you should pump up the fuel using the manual pumping lever or by turning on the starter. If the result is negative, check the passage of gasoline through the fuel line and clean the mesh located in the top cover of the pump. If this does not help, then inspect the membrane and valves of the fuel pump. After replacing damaged and worn parts, the functionality of the device will be restored.

2.Fuel filters

Along the path of fuel passing from the tank to the engine there are several filter units - coarse meshes located on the fuel receiver, in the fuel pump and carburetor, and in addition, paper filters located in the section of the fuel line. The intensity and even the possibility of supplying fuel to the internal combustion engine depends on their purity. If you find a blockage, clean or replace the filter elements.

Throttle and injectors

Gasoline internal combustion engines operate on a fuel mixture, which is prepared in the carburetor or in the intake manifold (for fuel-injected cars). In the first case, the fuel passes through a whole system of channels, jets and nozzles that are located in the carburetor. In the second, it is supplied by injectors according to signals received from the electronic engine control unit (ECU).

The air supply is metered using a throttle valve, which, depending on the engine design, can be mechanically or electrically driven. Clean the parts of this assembly and the throttle itself. Also check if fuel is being supplied to the cylinders. If you are dealing with an injection car, then press the fitting spool located at the bottom of the fuel rail - gasoline should flow out from there under pressure. If the stream is too weak, then check the filters, fuel line and pressure reducing valve of the fuel pump.

In carburetor engines, the fuel supply can be judged by sharply opening the throttle - in this case, a portion of fuel will be injected from the accelerator pump nozzle into the diffuser. In addition, for gasoline power units, inspect the spark plugs - they should not be dry. Otherwise, check for the presence of a control signal at the injectors. If everything is in order with this, then you should unscrew the ramp fastening and move it away from the manifold in order to inspect the spray nozzles when starting the engine. The absence of fuel streams or their weak intensity indicates the need to clean or replace the injectors.

This is interesting: How does a hand pump work?

As for diesel engines, fuel is supplied to them under high pressure, and a much more complex pump (fuel injection pump) and specially designed injectors are responsible for this. To repair these components, special equipment is required, so in this case it is better to contact specialists.

Something else useful for you:

- Why does the starter click after turning the ignition key, but the engine does not turn with the starter?

- Causes of alternator belt whistling and how to remove this whistling noise?

- How to check the starter when removed from the engine?

Video: The starter hums, but the engine does not turn over

Malfunctions of electronic systems

To check the ignition system, unscrew and remove the spark plug from one engine cylinder. Having installed the tip of the high-voltage wire on its contact nut, touch the spark plug skirt to the cylinder head and crank the engine with the starter. In this case, a powerful spark of a purple or blue hue should appear on the contacts. If the spark is too weak (or there is none at all), then we check the operation of the computer, ignition coils and distributor (for an old-style internal combustion engine).

Other reasons for difficulty starting when the starter is running

- The timing belt is torn, or is loose and has jumped several teeth - in this case, the valve timing turns out to be off, which is why the engine cannot start. It is enough to replace and mark the belt, unless such a nuisance ended with the pistons meeting the valves - in this case, a major engine overhaul will be required.

- The crankshaft rotates with noticeable force, which may be caused by various mechanical damage to the crank mechanism and the cylinder-piston group. Check whether the engine turns when you try to start it in top gear “from a tow” (for manual transmissions) or by turning the crankshaft pulley on cars with automatic gearboxes. Relatively easy rotation indicates that the cause of the malfunction is hidden elsewhere.

- One of the mounted units is jammed, which creates increased resistance to rotation of the engine shaft. To find the “weak link,” you need to loosen and remove the belt, and then try to manually turn the pump, generator, air conditioning compressor or power steering pump. If the breakdown occurred far from the service station, then you can only get to the nearest car service center in those cars in which the pump is driven by a timing belt. On other engines, you can try to connect the crankshaft and coolant pump pulleys with something suitable - a rope, a rubber strip cut from a car inner tube, etc.

- Failure of sensors connected to the ECU - crankshaft position (CPCV), Hall, etc. Due to their breakdown or incorrect operation, the engine control unit incorrectly regulates the fuel mixture or injects and ignites fuel at the wrong time when it is necessary .

- Sometimes the cause of a failure or incorrect interpretation of signals from a particular sensor is electromagnetic interference from the starter and other electrical units. In this case, it is difficult to identify the malfunction, so it is possible that you will have to turn to specialists for advice.

Worn starter brushes

Another common reason why the starter clicks, but the motor drive shaft does not rotate (and therefore does not rotate the crankshaft), may be wear on the starter brushes. Absolutely the same symptoms are characteristic of burnt relay contacts, but you won’t be able to start the car directly by closing the contacts with a screwdriver, as with a faulty relay.

But it remains possible to start the car from a tow if it is equipped with a manual transmission. In the case of an automatic transmission, you will only have to rely on the services of a tow truck or the help of another car as a towing vehicle.

Starter armature jammed

Among the rather rare causes of an emergency situation, when the starter makes clicking sounds, but the drive shaft does not rotate, is the armature jamming in the stator assembly. Typically, such a malfunction occurs on older cars, and without dismantling the starter it will not be possible to diagnose the problem - it has the same symptoms as when the brushes are worn out.

However, sometimes a difference appears: if you turn the key in the 3rd position to the start position, you will hear a fairly loud click, after which all the indicator lights go out for a while with the possible appearance of a specific smell - this is a sign of a jammed anchor. But it can also be mistaken for another fundamentally different malfunction - loss of ground contact.

Why does the starter turn normally, but the engine does not catch and does not start?

In half the cases when a car refuses to start, the starter is to blame. At the same time, the other half occurs in situations where the starter regularly rotates the crankshaft, but the engine starts only after repeated attempts or is completely silent. This could be due to a variety of reasons.

Driver inattention or negligence

The notorious human factor can manifest itself in the most unexpected ways. For example, a banal lack of fuel or an alarm that blocks the fuel pump. It also happens that some “well-wisher” clogged the exhaust pipe, or a careless driver, while backing up, got stuck in a pile of soil or a snowdrift. Such reasons do not fall into the category of technical malfunctions, but they can spoil a lot of nerves.

Technical problems - starter malfunctions

Every more or less experienced driver will distinguish the sound of a starter, which regularly rotates the engine, from the useless buzz of its electric motor when there is no engagement with the flywheel. When starting to troubleshoot, you should definitely make sure that the starter is functioning normally, and that no extraneous knocks, clicks or malfunctions are observed during its operation.

The starter is considered faulty in the following cases:

- The Bendix gear cannot engage with the flywheel ring gear. This manifests itself in a loud metallic grinding sound that appears when the starter is turned on. The reason for this phenomenon is wear of the mating surfaces, chipped teeth, etc. The solution to the problem is to install a new flywheel or ring. The latter can be rotated 180° and thus avoids the need to purchase a new part.

- The overrunning clutch or retractor relay mechanism is stuck. At the same time, the starter motor hums, but it makes no attempt to start the engine. In some cases, repeated attempts to turn on the starter help, but this only postpones the need for repair or replacement for some time.

- The crown is loose. A similar malfunction occurred on cars from the end of the last – beginning of this century, including the popular “nines”. In this case, the starter engages with the ring and begins to turn it, but it turns on the flywheel with a grinding noise. Only replacing the latter will help.

This is interesting: History of creation

Video: Watch for anyone who has problems turning on the starter. Useful advice from an auto electrician.

There is no voltage supplied to the starter from the battery

If a click is heard, but the starter motor does not spin when the starter motor is turned on, the reason may be a break in the electrical wiring in the area connecting the battery to the starter. But such symptoms are typical for most of the malfunctions described above, so for an accurate diagnosis you will need a tester and a control light. This is clearly visible in this figure:

If the power wire connecting the “plus” of the battery to contact “30” of the retractor relay breaks, the starter will be inactive, although the relay will click as before. In some cases, the problem can be diagnosed by a banal external inspection of the wiring, but most often you will need a tester, which few drivers carry with them. So road repairs are unlikely here.

Starter malfunction

Very often, when a motorist arrives at a service station, he hears the phrase “the starter takes on a lot of current,” but what does this really mean? To start the engine, it needs a certain amount of energy, the reserve of which is in the battery. A sign of obvious increased consumption is a decrease in the brightness of the dashboard lights and interior lighting. Here you need to look for a fault in the electrical wiring.

There is also a problem when the starter turns the engine poorly, turns slowly or does not turn at all. This symptom is characteristic of insufficient contact between contacts. This is often due to poor quality wiring.

Another common problem when the starter rotates but the engine does not start is a broken retractor relay. The serviceability is checked in the following way: the starter should be placed closer to the battery and two wires should be prepared (preferably with crocodiles), then the positive terminal should be connected to a similar one on the solenoid relay, with the negative terminal the action is performed in the same way. If during this a characteristic click occurs, then it is working properly. Otherwise, it will need to be replaced or repaired.

Some motorists are wondering: how to increase engine power using a starter? The answer is no, power can be increased, but not with the help of a starter; for this there are a number of other changes in the structure of the car.