Flushing hydraulic compensators without removing the motor

In some cases, troubleshooting a car with your own hands allows you to not only achieve significant savings, but also prevent serious breakdowns in a timely manner. In this article we will talk about the problem of hydraulic compensators, how you can wash the hydraulic compensators yourself and save yourself from even bigger problems in time.

What are hydraulic compensators and where are they located?

The hydraulic compensator (HC) is an important part of the gas distribution mechanism. This part is found in the engine of every modern car.

This element is located above each valve, directly below the camshaft cams. The main valve itself is a cylinder, inside of which there is a check valve, a plunger pair and a plunger spring. There are also channels for oil in the cylinder walls.

Why are hydraulic compensators needed?

While the engine is running, all its parts heat up. Including valves. As you know, when heated, bodies expand. Consequently, there is an inevitable reduction in the gaps between the valves and rocker arms, through which the camshaft cams act on them.

On older car models, the clearances were adjusted manually (valve adjustment). This is a delicate job that requires certain skills and tools. If the gaps were set incorrectly, problems appeared. For example, the characteristic knocking of valves, familiar to every owner of an old car, indicates that the gaps are too large.

Reduced clearances also entailed loose valve closure with all the ensuing consequences. For these reasons, it was necessary to check the size and adjust these gaps quite often, since during engine operation the settings and adjustments were constantly changing.

Thanks to the introduction of hydraulic compensators, the need to adjust the thermal clearance of the valves has disappeared. Having a Civil Code allows you to do this automatically. In other words, hydraulic compensators simplify the overall process of servicing the internal combustion engine, increase the life of the valve mechanism, and allow the engine to operate more elastically and steadily.

What are the signs of hydraulic compensator failure?

The main sign of a malfunctioning hydraulic lifters is a characteristic metallic knocking sound when the engine is running. It manifests itself especially clearly when the speed increases. The knocking sounds like a clattering sound and can be heard clearly. It appears due to the fact that the compensator becomes dirty from the inside and, as a result, does not have time to select a gap.

In this case, you can wash the hydraulic compensators without removing them. However, before you start dealing with this particular part, it is worth checking the oil pressure. If it is too low, the compensator will not be filled with lubricant in the required quantity.

Also, knocking is possible not only due to contamination, but also as a result of wear of the plunger pair or ball valve. In this case, it will not be necessary to flush, but to completely replace the hydraulic compensator with a new one.

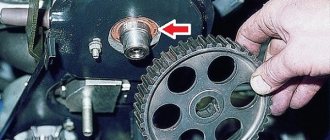

You can determine a non-working part as follows. Having previously removed the valve cover and gained access to the compensators, you should put on each of them. If the compensator is recessed without any effort, then it is most likely out of order. Such an element can not be washed, but immediately replaced with a new one. In other cases, HA can be purified.

How does the washing process work?

This procedure, although it will take time, will not cause any particular difficulties if you follow a clear procedure. It must be carried out indoors (can be in a garage) without drafts and dust in the air. It’s worth noting right away that it won’t be possible to clean the hydraulic compensators without completely disassembling the engine. However, there is also no need to unscrew the power unit to the last screw.

Before starting work, it is necessary to prepare three containers, the depth of which will allow the expansion joints to be completely immersed in the flushing liquid. As such, you can use high-quality 92 gasoline or kerosene. In addition, it is recommended to leave the car in the garage for 24 hours before the procedure, so that as much oil as possible can drain into the pan.

So, the procedure will be like this:

- You need to turn off the power to the car by disconnecting the battery. This is a safety precaution and should not be neglected.

- Disconnect the air filter.

- Remove the cylinder head cover. To do this, you need to unscrew the bolts with the appropriate key.

- Remove the rocker arm axles and remove the hydraulic compensators from their sockets.

- Clean the outside of the parts using a synthetic bristle brush.

Upon completion of cleaning, the hydraulic compensators should be rinsed in the first container. At this stage, each of them must be immersed in the flushing liquid and pressed on the ball valve several times using a wire through the hole in the plunger. Press carefully so as not to break the spring. After this, you need to press the plunger.

When its movement becomes easy, the same procedure must be repeated in a second container with gasoline or kerosene. But before this, you should thoroughly drain the liquid from the compensator by squeezing out the valve ball. Additionally, you can rinse the channels in the compensator body using a syringe.

Another important step is verification. To do this, after dipping the part into the third container, you should draw liquid into the fluid, then release the valve and remove the part from the container with the plunger up. When you press the plunger with your finger, it should remain motionless. If everything is in order, then you can return the expansion joints to their place, install the rocker arms, the cylinder head cover (the bolts should be tightened from the middle to the edges), and so on.

After assembly, all that remains is to start the engine and let it idle for a few minutes. After washing, hydraulic compensators should not knock at idle speed; also, after cleaning them, knocking should not occur after the internal combustion engine is heated and the unit reaches operating temperatures.

What's the result?

So, as you can see from the article, there is nothing difficult about washing hydraulic compensators yourself. It will just take time. In order to increase the service life of these parts, you should keep the lubrication system clean, use only suitable high-quality motor oils and replace them on time, as well as change the oil filter in a timely manner.

krutimotor.ru

Flushing agents

- Gasoline 92, diesel fuel. Helps wash away stubborn dirt deposits.

- Flushing oil, “five-minute” flushes. are considered mild means that are used if the engine was running on oil from one manufacturer.

- Metal conditioner TURBO. A synthetic product used to protect engine friction units and flush hydraulic compensators.

- Complex Oil Treatment. Increases the viscosity of engine oil and seals the gaps between the camshaft and valves when flushing mechanisms.

- VitaFlush is an oil system cleaner. A universal product that is used when changing oil as a preventive measure for flushing and protecting parts from wear. Effectively removes the effect of “sticking” of expansion joints.

Return to contents

Flushing hydraulic compensators: procedure. Knock of hydraulic compensators when cold

Repairing a car yourself in most cases allows you not only to save a lot of money, but also to prevent serious malfunctions in a timely manner. In cars equipped with 16-valve cylinder heads, hydraulic compensators may knock. The situation can be corrected. Flushing the hydraulic compensators will help. Let's figure out how this is done.

Hydraulic compensators: what are they and where are they located?

These elements are an important part of the gas distribution mechanism. These hydraulic compensators can be found directly above the valve. To be more precise, under the camshaft cam.

This part looks like a cylinder. Inside it there is a special check valve, a plunger pair, and a spring. Special channels are made in the walls of the hydraulic compensator. They serve to circulate oil.

Function of hydraulic compensators in the engine

During operation of a car engine, every part of it heats up to high temperatures. The valves are also subject to heat. If you remember the physics course, then at the moment of heating the body expands. This means that the gaps between the valves and rocker arms in the valve mechanism will inevitably decrease.

On older car models with simpler engine designs, valve clearances were adjusted manually. This is not a difficult job, but it requires certain skills, knowledge and a set of tools to complete it. If the gaps are adjusted incorrectly or at the wrong time, certain problems will arise. One of them is a knock, which is familiar to every owner of such a car. This noise indicates that the gaps are too large.

Small gaps also led to certain problems. Because of this, the valve did not close tightly. It was necessary to adjust the mechanisms quite often, since during the operation of the motor the settings were constantly lost.

Thanks to the introduction of hydraulic compensators, the car owner no longer needs to adjust valve clearances. Now this is done automatically. In other words, the presence of hydraulic compensators in the engine design significantly simplifies the engine maintenance process, increases the life of the valve mechanism, and provides the engine with more elastic and stable operation.

Signs of a hydraulic compensator malfunction

One of the characteristic symptoms is a metallic knocking sound during engine operation. These noises can be heard especially clearly when revving up. A clicking sound will be heard. The most common cause is contamination of the hydraulic compensator from the inside. Therefore, it cannot select thermal clearances in a timely manner.

Sound on a cold engine

You can also hear the knocking sound of the hydraulic compensator when cold. After the engine warms up, the sound disappears. But it may persist. If these sounds occur only when the engine is cold, then it’s not so bad. There are several reasons that can be easily eliminated with your own hands.

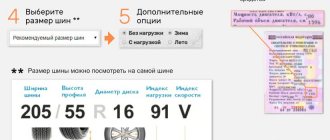

Wrong choice of oil

Noises on a cold engine can occur for trivial reasons - the engine is filled with oil of higher viscosity. Sometimes it does not meet the manufacturer’s requirements or has expired.

When buying a car secondhand, it is recommended to immediately change the oil to a new one. Also, before replacing, you need to flush the inside of the engine. This can be done simply with your own hands in a garage. Experts recommend using semi-synthetic fluids. If the oil has been changed, but the knocking of the hydraulic compensator when cold is still heard, it is worth considering other reasons.

Valves

Sometimes hydraulic compensator valves can fail. In this case, oil will leak out when the engine is not running due to loose connections. Air will enter the system, which then disappears when the oil displaces oxygen.

Inlet

It happens that the inlet hole on the hydraulic compensator becomes clogged. The hole is responsible for supplying oil to the part. When the engine heats up, the temperature of the oil also increases. The gaps widen and the oil begins to flow as expected. However, various viscous elements then clog the inlet again. You can replace the oil with one whose viscosity is lower. Cleaning the engine will also help. Along with these measures, flushing the hydraulic compensator is also effective.

Oil filter

If this element has not been changed for a long time, then this is also one of the reasons why the hydraulic compensator will knock on a cold engine. Together with the heating of the engine and oil, it will begin to flow normally through the filter. But more often than not this does not happen. The elements knock even on a warm engine. Changing the oil along with the filter will help solve the problem.

How to check the performance of hydraulic compensators

How to check hydraulic compensators on a VAZ? By removing the valve cover, you can gain access to these elements. Next, press on each of them with a finger. If a part fails, it will be recessed without effort.

In this situation, it will no longer be possible to restore the element. Only replacement will help. How much it costs to replace hydraulic lifters depends on the car model and engine. So, for most VAZ models this operation will cost five thousand rubles. If imported spare parts are selected, then the price will be 7-10 thousand. Naturally, this is not an exact cost - specific figures depend on the region and make of the car. If the mechanism is recessed only from serious force, then flushing the hydraulic compensators will help restore functionality and eliminate the knocking.

Preparing for washing

So, if there is a knocking sound, but the hydraulic fluids are in good working order, then you should wash them. To do this, remove the air filter and cylinder block cover. The rocker arm axles, where the hydraulic compensators are located, are also dismantled. They are carefully removed from their seats. Before washing, prepare three containers, which together have a volume of about five liters.

Before washing, you should let the car sit in the garage for a day. During this time, the oil will drain from the hydraulic fluid into the pan. Flushing hydraulic compensators will be successful and effective if done indoors, where there is no dust and wind. Kerosene or A-92 gasoline can be used as a flushing liquid. But you can also use specialized products.

Instructions, procedure

After dismantling the expansion joints, they are cleaned from the outside with brushes with artificial bristles. Then the parts are washed in the first container, which has previously been filled with liquid for washing hydraulic compensators. Each element is lowered into the container and the check ball valve is pressed several times with a wire. Then press on the plunger.

If the stroke of the plunger becomes easy, then the compensator is washed in a second container. However, before this, all liquid is drained from the compensator. To do this, just squeeze the ball. The oil circulation channels are washed using a syringe.

An important point in performing this operation is checking the mechanisms. So, by lowering the compensator into the third container with a cleaning agent, liquid is drawn into the part.

Then the part is lowered and pulled out so that the plunger faces up. If you press your finger on it, it will not move. When everything is exactly like this, the parts are returned to their place and the engine is assembled.

Using this simple procedure, you can restore the hydraulic compensators to their functionality. Even an expensive Liqui Moly hydraulic compensator flushing additive will be no more expensive than replacing these elements with new ones.

How to wash hydraulic compensators without removing them

For those who are too lazy to remove the main body, you can wash it without dismantling it. So, to do this, the intake manifold is dismantled. Then take any decoking liquid and pour it into each of the cylinders. Next, the engine is turned with the starter. Then remove the cover and douse the compensators with carburetor cleaning agent. It is better to choose a good and expensive liquid. Then they leave the car untouched for a couple of hours.

Then everything is assembled in reverse order. When starting the engine, it is recommended to press the gas to the floor. Smoke will come out of the exhaust pipe and various debris will fly out. They gain high speed and hold it until smoke stops coming out of the exhaust pipe. It is recommended to drive at high speeds for some time. This type of washing of hydraulic compensators without disassembly is very widely used by car owners. However, it is not as effective as with removal.

Additives and liquids for washing HA

According to most experienced car enthusiasts, only A92 gasoline should be used as the best cleaning agent. Kerosene will also work. Along with these folk remedies, famous manufacturers of auto chemicals offer branded liquids and additives. It must be said that most of these products are ineffective. But many people use them because they know well how much it costs to replace hydraulic compensators. There is a lot of information about a product from Liqui Moly to reduce the knock of hydraulic lifters.

The manufacturer promises that with the help of this additive you can clean not only the expansion joints themselves on any car, but also the valve openings. The additive also improves the lubricating qualities of motor oils. If necessary, the liquid can also be used as a cleaner for the entire lubrication system.

If, for example, the hydraulic compensator of a Niva-Chevrolet knocks due to contamination, then this product copes well with this problem. Reviews from motorists note that there is no need to even drain the oil. It is enough to pour one bottle of this product into the filler neck. In other cases, additives will not help - this is not a cure for all diseases. But the manufacturer still recommends adding the additive at every oil change.

After washing, the same hydraulic compensator of the Niva-Chevrolet stops knocking after 50 kilometers of the vehicle. If you consider how much a new element costs, then the washing price of 400 rubles is a significant saving. But reviews note that this is not always effective. In advanced cases, it is necessary to replace the entire hydraulic compensators.

fb.ru

When are hydraulic compensators washed?

Elements of the car system need to be washed as they become dirty, or preventive measures should be taken regularly, such as wiping them of dirt without removing the engine. There is another problem in which mechanisms need to be cleaned - tapping. However, with this option, it is difficult to do a thorough cleaning with your own hands; with a full wash at the service, experienced specialists will help you professionally get rid of plaque and dirt. Also, expansion joints should be cleaned every 50 thousand kilometers.

How to wash the hydraulic compensator yourself: procedure

In order to eliminate gaps in the drive, hydraulic compensators were invented at one time. If water, air or any other contaminants get into them, a knocking sound appears in the valves while the car engine is running.

This very unpleasant effect can be eliminated by cleaning following a certain procedure. First of all, you need to make sure that the hydraulic compensators are the source of the unpleasant noise and interruptions. You just have to listen when you start the engine. Immediately after starting, a noise should be heard, which intensifies if you change the crankshaft speed. In the absence of these signs, you should definitely look for the cause of the knocking not in the engine. If everything is confirmed, open the hood, fixing it, and disconnect the air filter with the cylinder block cover. In addition, it will be necessary to remove the rocker arm axles, where the failed hydraulic compensators are located. They should be carefully removed from the nests in which they are located. Before you wash the hydraulic compensator yourself, prepare three containers with the same volume, with a capacity of about five liters.

How to wash the hydraulic compensator yourself

Care must be taken to ensure that the container is deep enough to completely immerse the hydraulic compensator in it. Then we fill the canisters with diesel fuel and label them, which will make it possible not to get confused, but to use each container directly for its intended purpose.

Regarding the purpose of the containers: the first is needed for preliminary rinsing, the second is used for final rinsing, and the third is needed for refilling. After immersing the hydraulic compensator in the first container, thoroughly clean its outer side. Then we immerse it only halfway and squeeze the valve ball through the hole in the plunger. In this case, you need to simultaneously move the plunger until you feel it move freely. Next, we lower the hydraulic compensator into container number two, where we repeat the entire procedure of washing it. Now you can immerse the hydraulic compensator into the last third container, where, while holding the valve ball pressed, we fill it with diesel fuel. Having done this, we take out our hydraulic compensator and check the plunger for immobility. All that remains is to install the washed hydraulic compensators with all other parts in reverse order and start the engine, leaving it to idle for a few minutes.

It is in this order that self-flushing of the hydraulic compensator is carried out.

autoremka.ru

Why are hydraulic compensators knocking?

A hydraulic compensator is a device responsible for automatically adjusting the thermal gap in a separate valve. Thanks to their use, engine operation becomes easier. The reason is that you don’t have to adjust the valves manually. They also increase the service life of the gas distribution mechanism. It functions more evenly because the thermal gap is always within the manufacturer's tolerances.

But it happens that the hydraulic compensator starts knocking. Over time, the knocking becomes stronger and becomes impossible to ignore. Often there are three reasons.

- Severe natural wear and tear or manufacturing defects in design.

- The engine lubrication system operates intermittently.

- The engine oil is not compatible with the engine, or it has been used for too long, as a result of which it has lost its original properties.

The driver must remember that the compensator is capable of knocking not only constantly, but also in a certain engine operating mode.

In the cold

If the hydraulic lifters start knocking when cold, check which of the following is true.

- The oil is too thick. If the engine is not brought to the operating temperature range, the lubricant will begin to poorly penetrate into the cavities of the hydraulic compensator. To ensure that the cavity collects enough oil, you need to wait a little.

- The timing valve contains too much dirt. Solid particles appear if the engine oil has too many harmful impurities, or the owner delays the timing of lubricant changes. Also, the presence of debris indicates the release of wear products from some engine parts.

- Plunger jamming or severe mechanical wear. Most often, the cause is the penetration of abrasive particles into the oil structure.

How to wash hydraulic compensators yourself

Hydraulic compensators work to eliminate gaps that form in the drive. When air, water or other types of contaminants enter them, a knocking sound occurs in the valves during operation of the power unit. To eliminate this unpleasant effect, it is necessary to wash it. We will tell you how to do this procedure later in this article.

Initially, make sure that it is the hydraulic compensators that are causing the interruptions and unpleasant noises. To do this, start the engine and listen. A noise should appear, which will only intensify with a change in the crankshaft speed. Remember that if these signs are absent, the cause of the knocking is no longer in the engine.

Preparing for the process of washing hydraulic compensators

How to check and wash hydraulic compensators without turning to the help of qualified automotive service technicians? Especially if your car is quite old and the factory warranty has long expired, otherwise it will be considered an interference in the integral operation of the car’s power unit and then no compensation will be provided. Of course, you will have to tinker. But if you follow the step-by-step instructions and follow the advice, then this will become a completely doable task. So, let's begin?

This rather unpleasant effect can be completely eliminated by washing the hydraulic compensators in compliance with a clear procedure. Firstly, you need to make sure that the hydraulic compensators are the source of these unpleasant noises and frequent interruptions. You just need to start the engine and listen to it. Immediately after you start the power unit, you can hear an increasing noise that occurs when the crankshaft speed changes.

If these signs are absent, then the cause of the knocking should not be looked for in the engine. If everything is confirmed, then open the hood, secure it and disconnect the air filter and cylinder block cover. In addition to all this, it is also necessary to remove the rocker arm axles, on which the hydraulic compensators that have failed are located. Carefully remove them from the nests in which they are located. Before you start flushing the hydraulic compensator yourself, you need to prepare three containers of the same volume, approximately holding about five liters.

Before carrying out such procedures, the car should be left in the garage for at least a day to allow all the oil to drain as much as possible from the hydraulic compensators. It is better to carry out work indoors without wind and dust. And, of course, follow safety precautions! Open the hood and lock it. If the fastening is weak, which is typical for cars that have been in use for a long time, an additional spacer-clamp will be required so that the hood lid does not fall at the most inopportune moment. De-energize the vehicle by disconnecting the ground from the battery. Then get free access directly to the hydraulic compensators themselves. This is usually achieved in different ways on different brands and models, but you certainly won’t have to disassemble half the car.

The main thing is to remove the air filter and cylinder block cover. On some models, for example, you will need to remove the alternator belt and turn the alternator towards the radiator to gain access to the mounting bolt. You also need to dismantle and put aside everything that interferes with access: wires and supply hoses.

Before you start flushing hydraulic compensators, you need to make sure they are working. Otherwise, you will have to wash the non-functioning spare part, and then replace it with a new one. It just turns out to be extra double work. Checking hydraulic compensators is carried out quite simply, using the traditional method. Each hydraulic compensator should be pressed with a certain force. If it slides in easily with minimal effort, then it is most likely broken. This means that there is no need to wash it, but you should simply replace it with a new one. You can wash all the rest with a clear conscience.

The process of washing hydraulic compensators

1) Remove the rocker shafts.

2) Remove the hydraulic compensators from their sockets as carefully as possible.

3) Prepare containers for immersing compensators. They must be deep enough so that the expansion joints are completely immersed in the filler.

4) What should I use to wash them with? Many do this with regular 92 gasoline, diesel fuel or kerosene. The quality of the washing itself plays an important role here. Fill the prepared containers.

5) Dip each hydraulic compensator into the first container of gasoline and clean it.

6) Next, dip into the flushing liquid, but not completely, press the valve ball. Move the plunger until its movement is light enough.

7) Repeat the entire procedure described above in container number two, finally rinsing the hydraulic compensator in a more transparent washing liquid.

In the last container, fill the washed hydraulic compensator with gasoline or any other flushing liquid, holding the valve ball in the pressed position.

In the last container, fill the washed hydraulic compensator with gasoline or any other flushing liquid, holding the valve ball in the pressed position.

9) Remove the part and check the plunger.

10) Carry out this procedure with all hydraulic compensators, thoroughly washing and checking them, but the plungers must remain stationary. Then reassemble everything in reverse order. Tighten and connect power, hoses and wires.

11) Start the engine and let it idle for a while.

Tools for washing hydraulic compensators

To carry out the process of washing hydraulic compensators, you will need: a desiccant, tweezers, as well as three containers for flushing fuel with a capacity of approximately 5 liters each, a piece of hardened wire with a diameter of 0.5 mm and a length of approximately 10 cm.

At this point, our article on how to check and wash hydraulic compensators with your own hands can be considered complete. What should happen after you have performed this procedure? Firstly, this unpleasant knocking sound must go away when the power unit operates during a cold start. Secondly, washed and properly functioning hydraulic compensators, the valves themselves and the engine will be able to breathe in fresh air, and the car will operate more stably and evenly.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

Was this article helpful?

auto.today

Why the fuss

First, let's describe the possible reasons why hydraulic compensators usually knock. All of them come in two types: related to the design of the unit itself, or dependent on the supply of oil from the rest of the engine. So, let's list first the first, then the second. Malfunctions of the plunger mechanism:

- wear, defects in the surfaces of parts of the assembly;

- oil supply valve jamming;

- contamination or deposits on parts.

Also find out why valves are knocking and about replacing front shock absorbers. How to proceed

The main thing is not to panic when the hydraulic compensator knocks, and it’s unclear what to do. We need to look for the truth, analyze all options. For clarity, let’s look at a typical example: a car enthusiast complains that the hydraulic compensators on a VAZ 2112 with 16 valves are noisy. Initially, you should try changing the engine oil. If it doesn't help, we move on. Let's see what else can be done.

You can act in a similar way when, say, on another similar car - Priora - there is also a knocking sound from the hydraulic compensators. But suppose the described manipulations turned out to be useless. Why then do the hydraulic lifters on the same Priora knock in the car? What to do? It turns out that the problem is deeper - there are defects in the products themselves. They need to be replaced or thoroughly washed and each one removed. We will describe below how to do this using the Priora as an example.

- keys, heads;

- screwdrivers;

- automotive sealant;

- magnet.

- Disconnect the battery terminals, injector wires, and spark plugs.

- We dismantle the intake manifold, in addition, we remove the oil dipstick bracket along with the dipstick.

- We remove the timing belt covers, the belt itself, as well as the shaft gears.

- We dismantle the camshaft cover, and also remove the bearing housing.

- Having marked, we remove the camshafts.

- We have access to our products. It is precisely the faulty unit that is knocking, which, when lightly pressed with your fingers, will move easily.

- Using a magnet, we take out each compensating unit, if necessary, install a new one, or sort through and wash the old one.

- We do the assembly on the way back. When installing the cylinder head cover, we coat the joining surfaces with automotive sealant, and also be sure to fit a new gasket.

What's the result?

So, as you can see from the article, there is nothing difficult about washing hydraulic compensators yourself. It will just take time. In order to increase the service life of these parts, you should keep the lubrication system clean, use only suitable high-quality motor oils and replace them on time, as well as change the oil filter in a timely manner.

Will be useful: Diesel engine oil change interval

Knocking of hydraulic compensators: the main reasons for the appearance of extraneous sounds on a cold engine or a warm engine. How to find a knocking main engine without disassembling the internal combustion engine.

Engine flushing oil: in what cases and how it is used, what is included in the composition, advantages and disadvantages of this type of flushing of the lubrication system.

Features and types of flushing oils, how to use them. In what cases should you use flushing oil, what brand and type of flushing is best to choose.

Why oil leaks from under the gasket or valve cover housing: causes of lubricant leaks. How to fix an oil leak from under the valve cover yourself.

Do-it-yourself flushing of the engine cooling system radiator. How and what is the best way to flush the radiator from the inside without removing it from the car. Recommendations.

Why is it necessary to adjust the thermal clearance of the valves, manual and automatic adjustment. Features of operating an engine with hydraulic compensators.