In modern cars, whether foreign or domestic cars, electric window lifting mechanisms are installed, which facilitate the operation of the car and allow you to spend a minimum of effort on closing or opening the window. Such devices may differ in design and are designed for doors depending on their location (front/rear, left/right). The main element is the drive, which provides the transmission of torque for the movement of the glass, and lifting is carried out using a special device that transforms the rotation of the roller into a translational movement.

Such a device may differ in design, and rack and pinion windows are a popular type of mechanism that is distinguished by its reliability and improved quality. Not all cars have them installed initially, but if you wish, you can select electric windows of this type for any model and modification of the car.

The power window device - what's the highlight?

Every year, car manufacturers are trying to make the driver feel as comfortable as possible while behind the wheel. Thanks to this desire, many different devices appeared in cars. One of them was an electric window lift. Let's look at the issues related to this device.

The history of the appearance of electric windows

For the first time, power windows appeared in cars that were produced by the German automaker Brose in 1928. The device was mechanical, and the patent for it had been issued two years earlier. Automatic windows did not appear until 1940 in America in the Packard 180 model from the now defunct manufacturer Packard. The operation of these devices was based on the use of an electro-hydraulic system, and the device itself was significantly larger than the modern one. Then the Ford concern began to use automatic window lifts in its cars.

Since 1941, seven-seat sedans and limousines of the Lincoln brand have already been equipped with such a system. Cadillac brand cars also have this mechanism at their disposal. Further, automatic windows developed along with systems for convertible convertibles. The windows worked in conjunction with systems that automatically folded the roof. First, a vacuum drive was used, and then a drive with a hydraulic pump. In parallel, engineers worked on developing different types of lifts. Electric lifts first appeared in the 1956 Continental Mark II, a collaboration between Brose and Ford Motor Co.

Purpose of the power window

Window lifters were originally created so that the driver and passengers could independently lower and raise the windows in the car. In the case of an electric window regulator, everything is much easier to do, since such a device has an electric drive. This window lifter is a comfort system, that is, it creates additional convenience for the driver and passengers. Today, models are equipped mainly with electric windows; devices with mechanical drives have almost been forced out of use.

The design and principle of operation of the electric window lifter

The electric window lifter is mounted in the cabin, and more specifically, inside the door frame, on it itself or on a separately installed subframe. A power window regulator includes a drive mechanism, a lift mechanism and a control system.

The drive mechanism (or motor-gearbox) in its operation combines an electric motor, gear and worm gears, which are made in the form of a single unit. This mechanism is necessary to create the force that will raise and lower the glass. Due to the use of a worm gear, the window cannot be opened accidentally. The worm gearbox is designed so that rotation will be transmitted in only one direction - from the worm to the wheel. If an attempt is made to rotate in the opposite direction, the transmission will be blocked.

The lifting mechanism directly raises and lowers the glass. The design of the mechanism can be very different, hence the gradation of window lifters. They come in rack and pinion, cable and lever types. The most popular among manufacturers are cable and lever lifting mechanisms.

A cable window lifter is a flexible element (chain, cable, toothed belt) that is stretched inside the door between several rollers. The flexible element is driven through an impulse coming from the drive drum. When the drum rotates, one branch of the flexible element is wound up, and the second branch is wound up. The element itself begins to move forward. The flexible element is connected to the glass using a plate.

A lever window lift uses a lever, a slider mounted at the end of the window, and a glass mounting plate. The lifting mechanism may have one or a pair of levers (due to the fact that there are two of them, the movement will be uniform). The impulse to movement is transmitted from the drive mechanism to the wheel with the sector. The wheel itself engages with the lever and also provides the lever with movement. Some double-arm designs have two wheels rather than one.

The rack and pinion lifting mechanism includes a fixed rack and a guide plate that is connected to the glass. The drive mechanism is located on the plate, and its gear engages with a rack, causing the glass to move. The glass moves in a given direction thanks to guides: gutters are located within the doors, and special rails are located in the body.

The control of electric windows can be direct or electronic. With direct control, the electric lift is controlled by a three-position switch, which is connected to the power circuit of the electric motor. When the switch is moved to the first position, the motor rotates in one direction, and when the switch is in the second position, the motor changes polarity, that is, the direction in which the motor rotates changes. Since such a window lifter is quite a dangerous thing, it is used in fairly limited quantities.

The electronic window regulator has a more complex design, which includes input devices, an actuator and an ECU. The input devices are the operating mode switch and glass location sensors. The ECU design includes three-position switches. On the driver's side of the door there is a switch block through which you can control the window regulator on each door. In the same place there may be a switch for blocking the glass lifts on the doors. Glass position sensors can be Hall sensors. They are mounted on a worm wheel. When the worm wheel rotates, the magnetic flux changes, and this change is converted by the sensors into voltage pulses coming out of the sensor.

The electronic control unit takes into account:

1) The number of pulses when the amount of lowering (raising) the glass is determined;

2) After turning on the glass movement blocking, the duration of these pulses is calculated;

3) When the direction of movement is established, the pulse shift from a pair of sensors is taken into account.

Each window regulator often has its own ECU. In this control unit, signals from incoming devices are converted into control pulses for the actuator - a DC electric motor. There is communication between all blocks through the central control unit. Thanks to electronic control, the functionality of electric windows is significantly expanded. In addition to performing their standard functions of raising and lowering glass, lifts can implement the following functions:

— automatic closing and opening of windows;

— blocking switches on;

— ensuring operability after the engine has stopped working;

— control of power windows from outside;

— reversing movement in case of obstacles while closing the windows;

- the glass can automatically lower when the frameless door opens.

Ensuring automatic closing and opening of the window depends on how long the switch is pressed. If the press is short, the window will be raised or lowered, and if the press is long, the window will close or open automatically.

To ensure that the transportation of children in such a car is as safe as possible, the system is equipped with a power window lock for the rear seat windows from the driver’s seat. The electric window program means the system operates even after the engine has stopped running and the ignition is turned off. Thanks to this, the windows can be closed without restarting the engine. When the engine is turned off, the window regulators are in working order from a couple of seconds to several minutes. This depends on the design features of the mechanism.

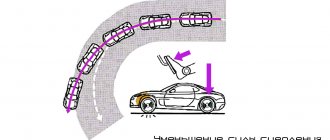

In terms of safety, the function of reversing the movement of glass if it encounters an obstacle on its “path” will be very important. This function is implemented through control of the rotation speed of the drive mechanism. At the moment when the speed decreases, that is, a sufficiently long signal comes from the Hall sensor, a signal is sent from the ECU that changes the direction of rotation of the electric motor to the opposite. This will cause the glass to begin to roll down.

It's rare to find a window regulator that can be controlled externally. This is done by turning the ignition key, which must be inserted into the door lock. Some car models provide for closing the windows using a remote-controlled central locking.

Window regulators perform a very important function - they make your life easier and do not distract you from driving.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

Was this article helpful?

auto.today

Ordering qualified assistance for installation of mechanisms on Yuda

To ensure that the installation of any electric window regulator is quick and efficient, contact the specialists registered on the Yudu website. You are guaranteed high speed of work and exceptional quality of installation of the universal mechanism for raising and lowering the glass. The cost of installing power windows depends on their type.

The advantages of contacting YouDo performers are as follows:

- extensive experience and knowledge of the structural features of automobiles

- installation of ESP using equipment from trusted manufacturers

- favorable prices for all services provided

Contact the YouDo specialists, you will receive a car with perfectly working electric windows. Place an order for the installation of any electric window lift using a special form on the Yudu website or mobile application. Prices for installation of window lifters offered by Yudu craftsmen are affordable.

Design and types of window lifters, manual, electric, pulse, rack and pinion, cable

The window regulator is used to lower and raise the glass in the car door. Initially, mechanical devices, popularly called “oars” and “meat grinders,” were used for this purpose. Today, they are being replaced by power windows with an electric drive, and manual ones are used, as a rule, on the cheapest cars in minimal configurations.

In addition to the fact that electric windows are convenient to use in themselves, the car owner has the opportunity to improve them in order to insure against his own forgetfulness. We are talking about installing power window closers that automatically close all windows when the car is set to alarm.

Electric window regulator

Electric windows are installed inside the doors either in special subframes or attached directly to the body. In general terms, the window regulator device looks like this. They consist of the following main parts:

- drive;

- lifting mechanism;

- control unit.

The drive combines an electric motor, worm and gear drives. All components are combined into a common block. The task of the drive is to transmit force to the lifting mechanism to raise or lower the glass. Thanks to the worm gear, the possibility of unauthorized lowering of the window glass is eliminated. Rotation in a worm mechanism can only be transmitted from the worm to the wheel; if force is applied in the opposite direction, the mechanism will be blocked.

Types of lifts

The lifting mechanism is an actuator, its task is to raise and lower the glass. Structurally, lifts differ from each other; there are the following types:

- cable;

- rack and pinion;

- lever

Each of them has its own advantages and disadvantages.

Cable

The main advantage that sets a cable window lift apart is its high maintainability. Spare parts can be found in almost any store, and repairs can be done yourself. This advantage offsets the disadvantages of the mechanism, namely wear of the cable, its pulling, low strength of the plastic guide heads and the susceptibility of the electric motor to overheating.

Rack and pinion

Rack and pinion windows are more durable. The principle of their operation is that the rotational motion transmitted from the electric motor to the gears turns into linear motion of the racks. Such window lifters, in addition to being reliable, have a higher speed than cable lifters, and produce less noise.

However, rack and pinion windows are not without their drawbacks. The main one is that the gears need lubrication, otherwise they quickly wear out and stop working normally. The second drawback is inherent in those devices whose manufacturers saved on metal and made the gears plastic. This material is much inferior in strength to aluminum, which has a very significant effect on service life. Finally, rack and pinion windows require more space inside the car door.

Lever

The lever mechanism combines high reliability and small size. The electric motor in such a mechanism rotates a gear, which transmits rotation to one or two levers. The levers move the plate that holds the glass. The operating principle gives rise to the main disadvantage of such a device, which is the uneven speed of glass movement: the higher it is, the lower the speed.

The glass itself, regardless of what types of window lifters are used on cars, moves along guides. Within the doors, this role is played by gutters, and inside there are special rails.

What are impulse windows?

There are two types of power windows: impulse and non-impulse. Pulse window lifters can operate in both pulse and normal modes. Normal mode means that the power window operates only when the control button is pressed. In pulse mode, one short press is enough to completely lower or raise the window.

As a rule, impulse windows are equipped with five-position control keys, which from the neutral position have two positions up and two down. When the key is moved to the first position, the window regulator operates as usual, and the window will go down or up exactly as much as the driver wants. In the second position, a control pulse is sent to completely open or close the window.

The second name popularly given to automatic window lifters is sequential. This term is used incorrectly, since “sequential” means “sequential” (from the English sequence). Everyone knows sequential gearboxes, in which shifting occurs sequentially. What a sequential window regulator is supposed to be remains a mystery. Most likely, someone just really liked the word.

Do-it-yourself electric window installation

The question of self-installation is usually asked by owners of domestic cars. There are many tutorials on the Internet on how to install electric windows on a VAZ-2107, VAZ-2110, VAZ-2114 and other models.

Stores sell window lifters for specific cars, for example, VAZ-2110 or VAZ-2114, or universal ones that can be installed in almost any car (for example, VAZ-2107). The difference between them is that in order to install a specialized mechanism, it is necessary to completely dismantle the old mechanical one, while the universal one is combined with the existing one.

Since there are no special power windows for the VAZ-2107, the only way to automate the process of opening and closing windows is to install universal power windows. To do this, the “oar” handles are dismantled, an electric motor is installed inside each door, which, through gears, drives the original mechanical window lifter.

ZnanieAvto.ru

Repair

Repairing this mechanism, as mentioned above, is not difficult if you know the design and operating principle. In particular, let's consider the ESPD mechanism itself, which is not a gear reducer, like mechanical varieties. In electric front door lifting mechanisms, only a drum is used. It is into the hole of this drum that the gear motor shaft is inserted. The gearmotor itself consists of a worm-type gearbox, as well as an electric motor that runs on current from permanent magnets. The design of this gearmotor is similar to the design of the windshield wiper device. As for the direction of the current in the armature winding of this gearmotor, it is reversible. And the built-in thermobimetallic fuse perfectly protects it from overloads.

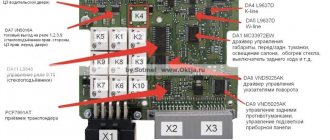

Door ESPD connection diagram

To be precise, the ESPD circuit consists of:

- block;

- front door ESPD switch;

- ESPD gearmotor;

- ignition switch;

- relay;

- external lighting switch.

So, let's begin the repair process:

- disassemble the upholstery, remove the window regulator (how to do this was written above);

- You now need to remove the cable part from the motor mechanism;

- completely remove the cable from the reel;

- unwind it.

Note. You will need to carefully inspect the splines, which are often worn out. In addition, if the splines remain like this for a long time, they deform the landing cylinder, which creates a huge load on the gearmotor motor.

- grind the protruding parts of the cylinder on a milling machine;

- we restore the roundness of the cylinder.

Note. In this case, you will need to ensure that the bulges on the back side of the cylinder, which appeared due to the rotation of the drive shaft, are ground off.

We take a two-millimeter steel plate, from which we cut out a circle of a suitable size;

Cut a circle from a metal strip

- after this you need to mark the stiffening ribs on the circle;

- We put the plate in place.

Note. It is desirable that the plate fits tightly and with some effort.

Assemble the coil in reverse order.

There is no need to attach the plate itself additionally to the coil, because it already sits securely. And the design of the ESPD body itself is made in such a way that it does not allow the plate, even a homemade one, to become loose and fall out. As for turning the plate, everything is reliable here because of the stiffening ribs. Let's continue:

- wind the cable onto a reel;

- install the cover.

Note. Do not forget to thoroughly lubricate the cable with some kind of lubricant, for example, lithol or grease.

- put the cable in place, tightening it a little using a special bolt;

- Now all that remains is to install the ESPD in the door.

Usually this is enough for the glass to go down and up normally again. The speed of glass lifting may even increase compared to what it was before the repair. After all, restoring the roundness of a cylinder, especially an ESPD that has been in operation for a long time, will only be beneficial. Its friction and resistance to the engine are reduced, and this, in turn, has a positive result. It is recommended to watch this video before starting work.

Power window motor - how does it work?

Many drivers remember mechanical window lifters, which they jokingly called “meat grinder” among themselves. Today, many cars are equipped with a special motor that can quickly and silently raise or lower the window. But time shows that progress is not stuck and the world provides us with more and more innovations and bold solutions that can not only simplify our lives, but also protect us from dangerous situations. So, one would think, and so modern ESPs have improved even more. They developed mechanisms that could quickly insure an inattentive driver who, leaving his car unattended, forgot to raise all the windows. Called power window closers, such mechanisms automatically raise all the windows after the car is set to alarm or when all the doors are locked, that is, when the central locking is turned on.

It is known that automatic window lifts are driven by an electric motor that is built into the car door. Along with the electric motor, there is also such a thing as a motor servo drive. We will talk about these two phenomena and the principle of operation of the electric motor, as well as its installation and removal in our article.

Window lift motor servo drive

Before you understand what a window lift motor servo drive is, it’s probably worth first delving into the meaning of the servo drive itself. It is a drive with guidance through negative feedback, which allows precise control of the movement parameters.

Under this name there can be any type of mechanical drive (device, working element) that has a sensor (position, speed, force, etc.) and a power traction control unit (electronic circuit or mechanical traction system) that maintains the necessary parameters on the sensor in automatic mode (and, as a rule, on the device) based on a given value from the outside (the position of the control knob or a numerical value from other systems). In simple words, a servo drive is a kind of “automatically precise performer”.

The electric window lift motor with servo drive operates on the same control principle through negative feedback, which controls the movement parameters.

It is equipped with a connector and gear. The connector contains a pair of contactless selectors on a Hall sensor. The proximity switch on the above sensor uses a set of magnets on a spindle that rotates to extract information about the RPM of the power window motor and pushes a synchronous pulse to the advanced power window switch. Thus, with each rotation of the axis of the electric window motor, the contactless switch fires one pulse. Accordingly, the power window master switch sets the angular speed and direction of rotation of the electric motor.

2. Removing and installing the window lift motor

A person who has nothing to do with the service station employees can also remove and install the electric motor. By following a simple diagram and making all the settings correctly and delicately, you can do it quickly and easily. Well, let's figure out how to remove the front door window lifter motor. First, you must make sure that you have disconnected the ground wire from the battery. Next, we move directly to the door itself. First, you need to remove the trim using the lever U30800. Then we disconnect the decorative grille of the speaker using the lever U30800. Using lever T20043, disconnect the upholstery panel.

Next, we work directly with the glass itself: lift it and lower it down until access to the screws of the clamping blocks opens. Then we simply loosen the screws of these same pads and lower the glass to the middle. After the work has been done, we will have to lift the back of the glass and turn it to remove it.

After the glass is removed, you need to unscrew the screws that secure the door lock, after which you need to remove the lock cylinder body. Next, the only thing left to do is remove the lock from the door handle and remove the upholstery of the door supporting panel from the door frame. Unscrew the screws and remove the protective casing from the upholstery of the supporting panel. Having finally reached the electric motor, you should disconnect the connectors of the window lift motor, unscrew the screws and remove the electric motor. So you have mastered this, one would think, very intricate task.

The electric motor is installed in reverse mode, but during operation you need to pay attention to the adjustment of the door lock. Many people wonder how to check the proper operation of the window lift motor. In order to check the electric motor for the window regulator, you first need to transfer the voltage from the positively charged terminal of the battery and connect the terminals of the electric motor to ground.

Many people ask questions about what to do if problems with the window lift motor are still detected. In this case, you can, as a rule, contact the service station workers with this problem, or try to do the repair yourself following our simple instructions. So, if you have already taken up the matter yourself, the first thing you need to do is remove the electric motor according to the principle stated above.

Next, you should unscrew the gear motor cover and remove the cover. After we have done this, we dismantle the driven gear and turn the screws securing the electric motor to the gearbox housing. After you disconnect the electric motor wires from the block, you can safely begin pushing the seal along with the wires inside the electric motor housing. Then, you need to disconnect the motor from the gearbox housing. And now the most important thing begins.

With deft hands, you clamp the armature shaft of the electric motor in a vice, wrapping it with a fabric base so as not to expose the worm to any damage. Next, you knock out the anchor by hitting the motor body with a hammer through a soft metal stand. After the work is done, you can remove the plastic stop from the hole at the end of the shaft. Then, you rest the bushing against the support, and use a hammer to hit the end of the shaft through a punch. After disconnecting the rear bushing from the shaft, you can begin cleaning the engine. First, using sandpaper, you need to clean the inner surface of the electric motor housing and the armature shaft from rust. Then, you should thoroughly rinse all parts with gasoline. After cleaning, you can insert the rear shaft bushing into the motor housing and press it through the stand with hammer blows. Then it's a matter of little things.

We install the electric motor brushes and secure them with wiring, after which we install the armature in the gearbox housing. Finally, we release the brushes and evaluate their contact with the commutator. We check the electric motor for serviceability. Of course, self-repair requires sleight of hand and careful execution, as well as, one might say, a bit of patience and time. But its advantages are that, firstly, you will save on a visit to the service station and, secondly, you will prove to yourself that you are a master! Although, if you are not confident in your abilities, if the window lifter motor malfunctions, it is better to turn to professionals.

Operating principle of the window lift motor

I wonder, on what principle does the electric window lifter motor work? Based on impulse commands from the proximity switches on the Hall sensor in the power window motor, the power window control module in its main switch sets the desired position of the window and the direction in which it will move. Accordingly, the main switch controls the power window technology from the driver's position. When the primary position is set before handing over the vehicle, the window glass placement and operating direction are able to be imprinted on the control module in the power window master switch.

If the cable from the negative terminal of the battery is disconnected, as well as when the main switch connector or power window motor connector is disconnected, stabilizing the initial position is a must. With the help of an electric motor, the window lifter also moves. “One-touch” systems have become popular today, when, thanks to one press of the window lifter button, the glass gradually goes down or goes up to the extreme point.

Operating in one-command or one-touch lift mode, the window can move in the direction you select until the switch is reversed, causing the motor to stop, or until the ECU receives a signal from the door circuitry. The main problem with "one touch" is the fact that if a child, for example, becomes trapped in a window, he is exposed to serious injury. To prevent this from happening, you should use return technology. This system involves attaching an additional commutator to the motor armature, which, thanks to two brushes, transmits a signal corresponding to the rotation speed of the engine. If the system detects changes in engine speed when the window is closed below the expected threshold, the ECU will reverse the direction of the engine until the window is fully opened.

After counting the number of received pulses, the ECU can also determine the position of the window. This is very important, since the window regulator should not reverse course when the window is braking when closed. In this case, initialization must be performed so that the ECU can remember the window position. As a rule, this is done simply by turning on the motor until the window is completely open, and then until it is completely closed. If you do not do this work, then the “close with one touch” function simply will not work.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

Was this article helpful?

auto.today

Why do you need the lock function?

Almost all power windows are equipped with a locking function. Its activation does not allow the window to be raised or lowered even when the control button is pressed. The option is designed specifically to ensure safety. It is difficult for the driver to keep track of children while driving, so it is safer to block the operation of the window regulator. The function is activated using an electronic control unit or a special button on the driver's door and its effect applies only to the rear electric windows.

To increase safety, the reverse movement function is also used. If there are obstacles, the lifting mechanism automatically lowers the glass. The system operates by controlling the rotation speed of the drive. If it decreases or lasts too long, the opposite control signal is received.

Electric windows do not affect driving safety, but they can increase the comfort and convenience of driving. You no longer need to use physical force or turn the mechanical drive for a long time - just press a button and automatically adjust the height of the glass position.

Window control unit - how to connect it yourself?

Installing electric windows on a car can significantly improve interior comfort. The window control unit allows you to control various actuators (most control units support connection to the central locking) from a single remote control. From the article you will learn how the power window control unit works and what malfunctions of this device occur. You will also learn how to install this unit in the car and connect it to the alarm and other electrical devices.

How does a power window work?

The basis of the window regulator is an electric motor, which through various mechanisms raises and lowers the glass. The window regulator has only two operating modes - raising and lowering the glass, which depend on the position of the control button. Some control units support a closer function, where a single press of the button will lead to full automatic opening or closing of the corresponding window. This function is provided by a time relay installed in the control unit. When the glass is completely closed or open, the limit switch is activated, cutting off the power to the electric motor. Therefore, the control unit, when you press the button, supplies voltage from the battery to the corresponding window regulator contacts.

How does the power window control unit work?

The control unit is a set of switches (switches) installed in a convenient housing that provide centralized control of the window lifters. Some models have backlighting for one or more buttons. It supplies power to the window motors depending on the position of the control buttons. There are also power window control units that automatically open or close the window to a certain level. Most of these blocks use the principle of pulse width modulation. Despite the complex electronic circuit, the operating principle of this unit is similar to simpler devices - pressing the button supplies power to the window lift motor.

It consists of:

- connector;

- printed circuit board;

- button mechanism;

- backlight LEDs.

How to connect the control unit to the on-board network and power windows + Video

If the control unit and window regulators are produced by the same manufacturer, then their connectors are fully compatible, so it is enough to follow the connection order specified in the installation instructions. This operation is performed after the wiring to the doors, cigarette lighter and alarm has been completely laid. If the manufacturers of the control unit and window regulators differ, a diagram of all devices will be required. It will allow you to determine which connector pins are connected to the corresponding buttons or electric motors.

If for some reason you were unable to obtain a diagram of the control unit or window regulators, contact any auto electrician. We have previously written about how to install electric windows on a VAZ with your own hands. He will open the housing of the control unit and, using the printed circuit board, will draw you a diagram of the device, and will also determine which window contacts are responsible for raising and lowering the glass. To connect, you will need to insert the corresponding wires into the mating part of the connector and crimp them. Don't forget to install a fuse in the power supply circuit of the control unit. This will avoid short circuits due to installation errors or other problems. If you are installing a new control unit, make sure that the operating current of its switches matches the operating current of the actuators. Otherwise, you will have to install additional relays to avoid overloading the buttons.

To connect to an alarm system (this is usually done to implement the functions of controlling the central locking and windshield closer), it is necessary to determine the contacts that send a signal to the central locking and windshield closer. Then connect them to the corresponding contacts of the control unit. Having completed the installation, you must first measure the current consumed by the entire system. It should not exceed the values specified in the instructions. In most cases, this is 0 Amps when there is no command and no more than 4 Amps when opening/closing one window. On lever window lifts it is possible to increase the current to 6-8 Amperes. If the current exceeds the specified values, it is necessary to find and eliminate the installation error. If there is no error, you need to check the operation of all window regulators. Perhaps one or more of them are sticking and require cleaning and lubrication.

Control unit repair

All control unit malfunctions are related to mechanical or electrical problems. It is not difficult to determine whether the problem is in the control unit or other devices. If nothing happens when you press one or more buttons on the control unit, but pressing the buttons located on the doors turns on the actuator, the problem is in the control unit. For any other malfunctions, a comprehensive check of the entire system is necessary.

Repairing the control unit consists of three parts:

- Repair of the mechanical part of the buttons;

- Repair of printed circuit board and push-button contacts;

- Connector repair.

If you have a minimal understanding of electrical engineering, reading electronic circuits and know how to use a soldering iron, then repairing the control unit yourself will not pose any difficulties. Disconnect the control unit from the on-board network, alarm system and actuators, and then remove it from the vehicle. Check the operation of the buttons - they should turn on with minimal effort and a slightly perceptible click. If this is not the case, most likely the problem is that a spring or ball has popped out, which ensured that the buttons were turned on correctly.

Disassemble and reassemble the control unit over a clean table with a white tablecloth, this will avoid the loss of balls and springs. Prepare all the necessary tools in advance - a soldering iron, a tester, alcohol for cleaning contacts, long and thin screwdrivers (flat and Phillips), a jar for small parts.

Unscrew the screws or bolts that secure the control unit housing and carefully remove the lower part. Then unscrew the bolts or screws that secure the printed circuit board and remove it. On some control unit models, the circuit board is attached to the bottom, so remove the top first. On some Chinese models, microswitches are installed that are not designed for the current consumed by the window regulators in active mode. Therefore, burn marks are visible on the contacts of the switches/switches. If you find such traces on your switches, then you need to install two relays with normally open contacts on each button, the operating current of the contacts of which is at least 10 amperes. If you don't know which relays to use or how to connect them, contact any auto electrician.

Another reason for a malfunction of the control unit is poor contact at the soldering point. Carefully inspect the back of the printed circuit board. If the contact between the conductor and the printed circuit board is broken, then at the soldering site around the conductor there will be a small (several hundredths of a millimeter) detachment of the solder. You can detect it with a magnifying glass. Another way to detect such a problem is to wiggle all the conductors and parts on the printed circuit board. If you are sure that the problem is in the printed circuit board, but you cannot detect the defect, solder all the contacts yourself using rosin flux and tin or solder. After this, wash the tracks and contacts of the printed circuit board with alcohol and dry with compressed air.

Video - Repair of Priora electrical package

Carefully inspect the connector. There should be no traces of dirt or oxidation in its contacts. If there are such traces, it is advisable to replace the connector, because cleaning with special means will only give a short-term effect. Disconnect the battery and connect the corresponding contacts to all connectors of the control unit. If possible, try bending the contact plates in the connector to improve contact with the mating part. On Chinese control units, this sometimes helps restore the device's functionality. If the printed circuit board and switches are in order, but the control unit still does not work, and the connector contacts cannot be bent, the connector must be replaced. If you don't know how to do this, contact any auto electrician.

VipWash.ru

Important points

So, you can install an ESP on a VAZ 2109 yourself. In order to assemble a simple electrical circuit, no special electrical skills are required. Knowledge from a school physics course is quite enough. But at the stage of choosing window lifters you should be especially careful. It is strongly recommended to abandon both rack and pinion devices, even if their price seems incredibly attractive. Only lever window lifters should be installed, since they are the only guarantee that the glass will not freeze to the door on a frosty winter day.

The first car you bought for yourself only seems perfect for a while. Considering that for most drivers such a car becomes unpretentious, chances are high that you will not be the first owner of such a car. Well, if the previous owners took care of it properly, then such a car will not become a headache for you. If you are really lucky, you will get some “bells and whistles” as if by default.

However, they are not always needed. It is unlikely that anyone will seriously invest in old Lada models 2107, 2106 or 2109. The same applies to, for example, alloy wheels, leather interior and other excesses. However, some improvements are worth the effort. For example, it’s much more pleasant to insert a flash drive into the radio rather than fiddling with disks or cassettes. And certainly this category includes the installation of window regulators.