Drivers constantly discuss which struts are better: gas or oil? However, the problem of assessing these components is complex, and it does depend heavily on the specific situation. Sometimes classic oil shock absorbers are the best choice, while in other cases you can't resist gas shock absorbers. They differ in design, parameters and influence on driving comfort. It's worth getting a little closer to these differences and explaining how to make the right choice.

The use of shock absorbers in a car

Their main task is to maintain the operation of the elastic suspension, that is, to reduce vibrations resulting from unevenness as much as possible. If it were not for the shock absorber, the car would be installed only on springs, which did not dampen vibration.

Driving such a car would be like cruising on a boat. Thanks to damping elements such as shock absorbers, the car will deviate from its natural position due to uneven roads, but will automatically return to its previous position. Without shock absorbers, the recovery time would be obviously longer.

However, comfort is not the only goal of the entire suspension system. Moreover, this is just a derivative of his actions, and not a priority. The main task is to ensure contact of the wheel with the surface, and therefore safety. If the system did not have an element responsible for damping, the car’s wheels could bounce off bumps. You don't need to explain that this is a very undesirable and dangerous effect.

This causes not only a temporary loss of control over the car, but also incorrect operation of electronic systems such as ABS. This system "releases" braking force when the wheel loses contact with the surface. The result may be that ABS will not brake the vehicle on rough roads. In this situation, it is better not to have any brake support system, because this system requires constant contact of the wheels with the ground to perform its functions.

What's more, faulty shock absorbers mean that suspension and braking components wear out faster and your braking distance increases. They also cause the headlights to be in the wrong position.

Oil shock absorber

What can I tell you about him, everything that I described above fits him 100%. That is, there is a cylinder, there is oil in it, a piston with a rod, and there are several check valves on the piston. It is only worth noting that it contains only oil and nothing else, that is, there is no gas or anything else.

The device is very durable, but not as productive. The thing is that if you frequently drive on poor roads, the oil inside can boil, that is, a cavitation effect will appear, bubbles will begin to form (if you want, it will almost boil). Cavities form inside; they very quickly pass through the piston valves, thereby impairing its operation. That is, the car will hold worse. Due to frequent overheating, the viscosity of the oil also suffers, the liquid loses its properties and again passes through the piston valves faster. Another feature of the oil version only works in one direction, that is, only for compression. For example, the car compressed it, but the rod does not come back out, that is, the car (through the spring) needs to be pulled back out. It is worth noting that these options are quite comfortable and soft, if you want, energy-intensive, they often swallow holes and bumps perfectly. BUT they don’t like heavy overloads and frequent rolls, the rod doesn’t come out on its own, it needs to be pulled, but what if the car is turning? That’s why for the city, for low speeds, they are really ideal (they provide simply excellent comfort), but for racing, or sudden acceleration and braking, they are not designed, if only because of roll. Thus, it is possible to identify the following positive and negative aspects Pros : Widespread on the market, 50% of cars are equipped with just such options Simple design Cheap enough Durable enough, can travel from 60,000 km and above The ride is most comfortable with it. It absorbs bumps perfectly Cons : It is more prone to rolls, the rod does not go back on its own, it needs to be pulled out with the help of a spring, if at low speeds this is practically not noticeable, then during sharp braking or starting, either the front or the rear sags. It overheats quite quickly, especially in summer and if you often drive on uneven roads. When heated, the characteristics deteriorate, a cavitation effect appears inside. From overheating, the oil can lose its properties and characteristics deteriorate. If air gets inside, the performance drops significantly; it needs to be replaced urgently. Oil options are durable and on uneven roads this is an ideal solution, be it a city or a dirt road; at high speeds and racing they quickly overheat and often cannot hold rolls.

The principle of operation of shock absorbers

The damping system is subject to compression and expansion during operation. In professional language, these processes are called compression and reflection.

The simplest examples are oil shock absorbers, in which the phenomenon of reducing vibrations by reducing friction occurs during their movement. This is why oil is used in shock absorbers. Its movement, caused by the displacement of the piston, dissipates energy, providing apparent resistance, reducing vibrations.

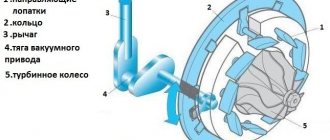

This principle is applied using two types of shock absorbers - monotube and twin-tube. Both types differ from each other in the location of the compensation chamber. The design of a monotube shock absorber is much simpler and consists of the following elements: a piston rod with a permanently attached piston in which there are two valves, a piston that separates the working chamber from the compensation chamber, and, of course, the housing.

This design does not have an expansion tank, because the working part of the chamber has a variable volume. The lower part of a monotube shock absorber is a gas-filled compensation chamber. The volume in both chambers is always constant, while during operation the working part “occupies” some volume from the compensation part. Without this maneuver, the movement of the piston would be impossible.

The twin-tube shock absorber is already more complex, but its operation is also based on the idea described above. Its design still contains a piston rod with an attached piston with valves, an inner housing, and a working and compensation chamber. However, instead of a movable piston separating the two baffles, there is a permanently attached lower baffle, which, like the piston, contains valves.

In a single-pipe design, the compensation chamber is located under the working chamber, but here one part is inside the other. The compensation chamber surrounds the working chamber and contains oil instead of compressed gas. Since one part is located in another, it is not difficult to find a disadvantage of this solution. This is of course the cooling of the working chamber, it is worse here.

Differences and features of oil or gas shock absorbers

Oil and gas shock absorbers differ mainly in their design. If you are not sure what type of item your vehicle has, remove it from the vehicle and hold it in the position it is in the vehicle. Now simply compress the shock absorber and release it, and then watch how the piston rod behaves.

In the case of a gas shock absorber, we are dealing with a monotube design in which there is no compensation tank. At the bottom of the shock absorber there is compressed gas, which is separated from the oil by a piston. When the gas shock absorber is compressed, the pressure increases, which is manifested in the downward movement of the piston. The piston rod slides into the working chamber.

After releasing the shock absorber, a so-called rebound occurs, in which the piston moves upward. As a result, the oil pressure above the piston increases, and the fluid again passes through the valves and channels.

In the case of an oil shock absorber we are dealing with a two-tube design. When the shock absorber compresses, oil flows into the space above the piston, which means there is a limited amount of space in the cylinder available for fluid. Therefore, it is pressed into the expansion tank.

During rebound, the piston rod is pulled out of the cylinder and the oil pressure above the piston increases. The fluid accumulated in the expansion tank flows to balance the volume of the piston rod, which slides out of the working cylinder.

Therefore, the main difference between oil shock absorbers and oil and gas (gas) shock absorbers is the compensation chamber. In the first case, it is open, and in the second type, the muffler system is closed.

However, if we still do not know how to recognize gas and oil shock absorbers, we must go to a car workshop where a specialist can easily indicate which model of the element is in our car. This way, you will definitely avoid mishaps with the wrong shock absorber selection.

The best Japanese and Chinese shock absorbers

The best shock absorbers for cars presented in the list work reliably. Among a fairly large number of manufacturers, it is their models that have become the most popular all over the world. Japanese and Chinese dampers were especially loved by European automobile concerns. They are installed on many budget brands of cars. Japanese automakers prefer this reliable filling to more expensive analogues.

Tokiko

Less common than Kayaba, but softer in perception, Tokico shock absorbers cannot be called very popular. The company has only two manufacturing plants: one of them is located directly in Japan, and the other is based in Thailand. But the quality of production in both cases is excellent, which is not typical for most American and European factories. Only a fifth of exported Japanese cars have this wonderful suspension - this is the trend of the year: Toyota Camry, the heavier Toyota RAV-4 and almost all Lexus cars, which rely on both speed and comfort.

In addition, shock absorbers are found on some American cars (usually Ford models) and products of the Chinese automobile industry - Gili, Cherry and (dubious information) Lifan. The rest of the market is given over to the more popular Kayaba. However, Tokico has one very important advantage over its eternal competitor - the dampers of this company are much less counterfeited.

Kayaba

A young but potentially very strong company, supplying about 80% of the Chinese market with shock absorbers, as well as supplying goods to European and American cars. In their country, they are widely used in Mazda, Honda and almost all Toyota cars (with the exception of Camry and RAV-4).

Since its founding, the company’s bosses wanted to grab a larger piece of the market, so they launched several conveyor lines for the production of road and sports shock absorbers. In general, the series nomenclature is as follows:

- Exel-G – gas-oil shock absorbers for city roads, characterized by increased controllability and minimalist comfort (for those who like to “powder” within the city);

- Premium – a series of oil shock absorbers with increased comfort;

- Gas-a-Just - reinforced monotube rear shock absorbers, suitable for the popular Japanese drift;

- Ultra SR – a lightweight series of sports dampers to ensure better vehicle stability;

- AGX – adjustable sports-type gas shock absorbers that can be adjusted to your driving style;

- MonoMax is a gas-oil series operating under high internal pressure. Minimum comfort and maximum controllability at the cut-off point.

Sensen

Sensen shock absorbers are an affordable alternative to Kayaba. The company's high-tech enterprises are fully robotic and are considered the most advanced in China. Officially, the country of origin for Sensen is China, but factories are also located in Taiwan, Thailand, and Malaysia.

By focusing on low cost, the company's developers and engineers were able to do the impossible. A mandatory stage is strict testing. That's why all Sensen shock absorbers come with a certified warranty.

The company's product range is not so large: shock absorbers are produced only for passenger cars and medium-sized cars. This specialization helps us focus on our core products while constantly working to improve their durability and quality.

Advantages:

- Chrome plated shock absorber rods are made from high carbon steel;

- The seals are supplied by the Japanese company Nok;

- Corrosion protection;

- Teflon coating of bushings;

- Robotic seam welding.

Flaws:

- After the warranty period they quickly fail.

Having bet on releasing an analogue at a more attractive price, Sensen was not mistaken. Consumers quickly appreciated products that met quality standards. The company's shock absorbers are installed by powerful automobile concerns Dongfen and Nissan.

Miles

Miles' head office is located in Belgium. This is where European participation in production ends; all shock absorbers are produced in Asian countries. However, Miles damper systems are becoming increasingly popular.

The young company has set a course for advanced technologies. All factories are equipped with the latest technology. Many operations are robotic. The result is good quality at a low price. And the ever-growing demand for products. In many respects, Miles shock absorbers are superior to their original counterparts.

Advantages:

- The working cylinder tube has a seamless design;

- Disc type valve system;

- Sealing gland NOK Corporation;

- Highly refined oil made in Korea;

- Precision machined chrome rod;

- Special additives eliminate foaming and aeration;

- Compliance with European quality standards.

Flaws:

- The front struts begin to leak after hard use.

The Miles company is establishing contacts with developers of automotive parts from Russia. This confirms the desire to take a strong position in the market and not disappoint consumers.

Patron

The company's shock absorbers are 20-40% cheaper than their analogues. Experienced drivers were initially alarmed by this fact. But as practice has shown, Patron dampers demonstrate high-quality operation at a low price. All brand products are included in the world's largest specialized auto parts catalog TecDoc, and the company itself is internationally registered.

The Patron brand is owned by the Shate-M Plus corporation and has 70 factories located in 11 countries. Including in Belgium, South Korea, Italy, Belarus, China. All models have a single control system. It consists of testing centers equipped with powerful test benches. Patron dampers work great in American, European, Asian cars class=”aligncenter” width=”701″ height=”276″[/img]

Advantages:

- Special additives in twin-tube shock absorbers prevent foaming;

- Adaptive models instantly change stiffness;

- Monotube dampers can be installed in any position;

- They have an improved cooling system;

- Quality similar to the originals.

This is interesting: Problems with the stove - diagnostics on your own: what to do if the fan does not work

Flaws:

- Short warranty period;

- At high temperatures, hardness increases.

In the Patron assortment, you can select shock absorbers by car brand or find a universal model that can be easily adjusted with your four-wheeled friend.

Which shock absorbers are better, oil or gas?

When choosing a gas shock absorber, you should pay attention, first of all, to its brand. Available on the market are original and therefore expensive spare parts, their cheaper substitutes, as well as low-quality fakes, which are characterized by low strength and resistance to damage and difficult driving conditions.

We don't have to buy the most expensive products to enjoy the quality we need. All we have to do is select those brands that have the greatest recognition among drivers and choose the most attractive option from them.

To answer the question of which strut is better, gas or oil, you need to know the advantages and disadvantages of these products.

Advantages

The advantage of oil shock absorbers, of course, is their trouble-free operation, which they owe to their simple design. It is extremely unlikely that the shock absorption will suddenly stop working due to some damage. Unfortunately, however, there is a risk that the oil damper will gradually lose effectiveness due to the oil foaming quite quickly. This may occur if the vehicle frequently travels at high speeds on uneven surfaces.

A gas-filled (usually nitrogen) shock absorber strengthens the chassis, increasing tire grip, which improves vehicle handling and allows higher speeds. It's no surprise that these shock absorbers are often used in sports cars. On the other hand, complex design increases the failure rate of shock absorbers. However, it should be remembered that due to the nitrogen separated from the oil, foaming does not occur, which increases the service life of the shock absorber.

Flaws

Oil shock absorber.

- Heavy weight;

- slow response to inequalities;

- less grip on the wheel;

- less damping force;

- risk of changes in oil parameters due to high ambient temperatures.

Gas shock absorber.

- Higher price;

- complex design;

- vulnerability;

- less comfortable ride;

It is difficult to unequivocally answer the question which struts are better: gas or oil or gas-oil.

Oil shock absorbers are inferior to the technological competition (they are simply older), but they have two main advantages: they are more convenient and cheaper at the same time. Thanks to oil shock absorbers, the suspension becomes softer and more comfortable. Because of this, drivers who prefer a quieter and more comfortable ride appreciate this type of shock absorber. Unfortunately, during heavy driving on uneven surfaces, the oil in the shock absorber can foam, which gradually reduces its effectiveness at damping vibrations.

Many users also have problems choosing a shock absorber manufacturer. As a rule, brands such as KYB (Kayaba), Monroe, Sachs, Bilstein, Delphi enjoy the greatest recognition among drivers and professionals. KYB aftermarket shock absorbers are manufactured in the same factories and use the same technology and quality control systems as factory-installed shock absorbers.

The shock absorbers feature high performance valve assemblies designed to compensate for wear of other chassis components once installed in the vehicle to restore driving comfort and safety. Cheaper choices when renovation budgets are limited may include Delphi, Kamoka, Denckermann and MaxGear.

The best European shock absorbers

The best shock absorber manufacturers were the Germans and the Dutch. Their experience is second to none and their quality and standards serve as a benchmark for everyone else in the world.

The founders of mechanical engineering lead the ranking in the production of components. And even high prices do not scare buyers. The durability guarantee is worth more.

Analysis of competitiveness, results of surveys of car owners and service station mechanics make it possible to present the TOP of the best European manufacturers.

Bilsteim

In 1954, Bilsteim was the first company in the world to install monotube shock absorbers on cars. This engineering discovery was immediately rated “excellent.” It turned out that the new type of damping devices improves handling without losing the level of comfort. And the debutant’s operating time turned out to be excellent.

The filling of modern Bilsteim products is innovative electronics. But the share of manual labor is also high. Therefore, each copy is of impeccable quality.

Advantages:

- One-, two- and four-way adjustment depending on the quality of the road;

- Improved directional stability;

- Compatible with any standard springs;

- DampTronic electronic suspension control;

- Pneumatic module;

- Helical suspension with individual settings.

Flaws:

- Correspondingly high price.

Installing Bilsteim shock absorbers in your favorite cars guarantees comfortable, safe driving even under heavy loads.

KONI

The manufacturer's products are in great demand among fans of a hard driving style. Its shock absorbers have a high damping capacity, stabilizing grip on the road surface, as well as good handling characteristics, especially in combination with low-profile tires. The design schemes of the products provide for a suspension system for any brand of car, as well as the possibility of their adjustment.

Other advantages of KONI shock absorbers include ideal ride softness, cornering stability, and the ability to withstand large static loads. High build quality is also considered the strength of the brand. This is confirmed by the fact that in Germany KONI shock absorbers are covered by a lifetime warranty.

BOGE

Owners in reviews note that BOGE shock absorbers do not have a negative impact on suspension characteristics. At the same time, they have an increased temperature range due to the unusual shape of the rod seal, a long mileage warranty and a special technology for hardening and micropolishing of the rod. The range includes shock absorbers for off-road (Turbo 24), smooth-riding gas (Pro-gas) and sport-driving (Turbo-Gas) options.

Despite the fact that the brand’s models are not inferior to market leaders in terms of durability when used in harsh conditions and ability to hold the road, they are much cheaper. This allows us to recommend them to everyone who does not know which shock absorbers are best to install on their car.

BOGE shock absorbers

SACHS

Our top list of the best original shock absorbers in terms of price-quality ratio, according to reviews, is headed by the manufacturer SACHS. He places an emphasis on versatility; the brand’s solutions can be installed on any car - cars, trucks, SUVs, Russian or foreign cars. It is worth noting the quality due to which the company’s shock absorbers are widely used in Formula 1 cars.

This is interesting: Adjusting the Lada Kalina headlights with your own hands, as well as how to remove them for replacement or repair

The brand’s assortment is constantly expanding, so drivers with any needs can choose a solution. SACHS shock absorbers have increased wear resistance, a noise reduction system, improved dynamic properties, as well as unique suspension dynamics. The main disadvantage is the increase in rebound spread at high temperatures. However, for anyone who wants to replace outdated shock absorbers, the brand's products are a good option.

HOLA

A new company that has already established itself as a supplier of good shock absorber models. In production, it focuses on the popular CFD series, designed for comfortable driving and G'Ride for those who drive on difficult roads and love extreme driving. When creating new products, they are subject to careful control and many tests using automated systems and personal analysis by the company’s engineers.

In reviews, users praise the Long Life Warranty system. Its essence is that when purchasing shock absorbers, the owner receives full technical and marketing support. The service life of HOLA solutions is high - up to 70 thousand kilometers. The downside is a little stiffness.

HOLA shock absorbers