The principle of operation of a car air conditioner

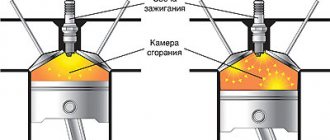

Climate control in a car works on approximately the same principle as a home air conditioner or refrigerator, only the devices in it are much more compact. In particular, the compressor and external radiator are located under the hood, and without understanding the design of the air conditioning system, finding these devices will be problematic. A heat exchanger is installed in the cabin, which produces cold air, cooling the interior of your car during the warm season.

The operating principles of the device are based on a simple cycle:

- When the air conditioning compressor starts operating, it builds up pressure and forces freon to move through the system from the external radiator to the internal heat exchanger;

- when entering the radiator, the device releases heat and reduces the temperature, turning into a gaseous state, at which point cold accumulates in the working environment;

- in this form, freon passes further through the system and enters the cabin; in the heat exchanger it again comes into a liquid state, releasing cold through the heat exchanger into the cabin;

- then, under pressure, the liquid is sent back to the air conditioner, the process is repeated again;

- The air flow from the air conditioning fan is directed to the internal heat exchanger, which contributes to the transfer of cold into the cabin.

If a leak develops in any device in the system, there is a high risk that the installation will stop working and require repair. You should also regularly monitor the operation of the compressor. Any extraneous sounds or a decrease in cooling efficiency is a reason to contact a specialist or independently measure the pressure in the system. You can read the instructions on how to make such measurements, and also watch thematic videos to understand the issue.

Instructions for use of the composition

The sealant for eliminating freon leaks in a car air conditioner is used according to the following instructions:

- To activate the air conditioning or cooling unit in a car, you must set the system to the lowest possible temperature.

- Then remove the protective part from the bottle and connect the adapter.

- If a flexible transducer is used, the transparent tube must be freed from air.

- The adapter connects to the filling valve to cool the car or air conditioning unit.

- After this, the sealant is introduced.

- If the sealant is purchased in aerosol form, pressing the trigger 6-8 times is sufficient to set the optimal flow.

- Apply the substance by spraying it and holding the valve pressed for 1 minute.

- After this, the adapter is disconnected from the device and the effectiveness of the actions performed is checked by stopping the operating device for half an hour.

Related article: Tire sealant: how to choose and use the product

On video: Sealing a car air conditioner.

How do you know when you need to recharge your car's air conditioner?

Refilling the air conditioner in general is necessary if the device begins to cool poorly. This means that the volume of freon in the system has decreased, pressure is not built up, and the remaining working fluid cannot provide the required efficiency of the climate system. But in this case, you also need to make sure that there are no leaks or other problems. This can be a real challenge in terms of DIY diagnostics. At the service, leak testing is performed using special equipment quite quickly and accurately.

Refilling the air conditioner in a car is also necessary if it has not been turned on at all for more than 3-4 months. Before turning on the device, you should check the pressure in the system. Long-term operation of the equipment in the absence of the normal amount of technical fluids will cause compressor failure. Therefore, the issue of regular air conditioner maintenance should be treated with the utmost care.

Pay attention to the cooling intensity, as well as the operating features of the climate control, if one is installed on your car. If, when you turn on the “Auto” mode, fuel consumption increases significantly, and the air conditioner constantly tries to turn on the maximum speed of the cabin fan, the problem may be due to the fact that the pressure is low. The automatic climate control system in this case tries to compensate for the low pressure by increasing the circulation speed. The compressor operates at its maximum capacity.

Advantages of sealants

Any sealant for a car air conditioner will work on this principle: the substance detects a freon leak and seals it permanently without chemical reactions with oxygen or moisture. Most sealing products are capable of working with damage in the system of no more than 0.05 mm.

The list of main advantages of compounds for car air conditioners includes:

- The composition permanently seals the air conditioning system in the car.

- The sealant is compatible with any freons, including CFC, HFC and HCFC.

- Noticeable when using a lamp with ultraviolet light.

- Significantly reduces the noise level of the compressor during its operation.

- The composition does not include polymers.

- Ideal for preventive use and does not cause damage to the system compressor.

- Suitable and equally safe for every part of the air conditioning system or refrigeration system.

Article on the topic: Sealant for concrete - classification, purpose, methods of application

How to choose a refrigerant?

Cars produced before 1992 used R12 freon. Then, for environmental reasons, R134a freon began to be used. The thing is that R12 freon vapors destroy the ozone layer. Therefore, the entire industry, as well as the automotive sector, has long been moving away from it. But the freon class is not the only feature that needs to be taken into account when selecting a refrigerant.

Pay attention to these factors:

- the manufacturer - a very cheap Chinese product often hides low quality, and this becomes a real problem in operation;

- composition - be sure to read the composition, as sometimes manufacturers indicate that freon should not be mixed with other mixtures;

- price - even a good-brand product with a low price tag should raise some doubts; it could be a fake with cheap ingredients;

- compatibility - some manufacturers fill the system with other types of environmentally friendly refrigerant, and this must be taken into account;

- replacement volume - you can buy a 500-600 gram cylinder, but it may not be enough, and if you buy a large cylinder, you will simply have to throw away most of it.

Do not forget that for self-replacement it is best to find a cylinder in which the liquid is filled under pressure. Correct use of such a cylinder will allow you to refill the air conditioner yourself without additional equipment. If you buy a standard freon cylinder, you will also have to look for a unit that can pump the freon into the system at the required pressure.

How to replace freon in an air conditioner

If there is a need to replace the refrigerant in the air conditioning system, you will need to perform similar actions in several stages.

- First you need to determine what type of freon you have in your air conditioner. Unsuitable refrigerant will not guarantee correct operation of the device. To do this, see the instructions that come with the air conditioner. If this is not possible, then you can find its electronic version on the Internet.

- The next stage is preparatory work. It should be remembered that working with freon requires mandatory compliance with safety precautions. For example, you need to wear a mask and safety glasses, and don’t forget to wear gloves.

- Before replacing freon in an air conditioner, you should determine the location of the compressor in the device. And again, the instructions for the air conditioning system will help us, which in most cases contains a diagram of its structure. This element is made in the form of a cylinder.

- Further actions involve inspecting the freon kit. It usually consists of a freon tank and two valves. Each valve must be installed on the compressor pipes. As for the installation process, it is described within the instructions.

- After this, you should adjust the air conditioner. But first you need to be sure that the system is capable of pumping refrigerant. For this purpose, it is necessary to start the device and set the highest power mode. This is how freon will have to get into the equipment.

- The final stage involves the direct addition of freon. This operation is carried out after checking the system’s ability to receive freon. In order to add refrigerant, you need to get a container with it, which must be mounted between two valves that are installed in advance. The process in question must be carried out in accordance with the attached instructions. Since the system is running, refrigerant will immediately begin flowing into the system. The air conditioner is turned off when all the freon is pumped out of the container. Next you can remove the valves.

In fact, performing all the above steps will not be difficult. A freon pressure sensor can make the job easier. It is important to comply with all safety requirements, do not forget about it. Provided that all of the above work is carried out competently and correctly, stable operation of the air conditioning system can be guaranteed, which will not cause any problems.

What do you need to buy to refill your car air conditioner?

If you are already tired of going to the service center with problems with your air conditioner, you can try to service it yourself. To do this, you will need not only certain skills, but also a small set of equipment. As mentioned above, it is better to buy a small freon cylinder in which the material is charged under high pressure. This will immediately save you from the need to purchase expensive pumps and other equipment.

To refill or check the pressure in the car air conditioning system, you will need the following tools:

- a metrological station is inexpensive equipment, but you should not save on it, otherwise saving can lead to problems with the quality of the device;

- hoses - you will need several meters of hose, which can be connected to the metrological station, as well as to the filling hole in the car;

- an adapter with a tap, with which you can connect the equipment to the freon circulation system in your car;

- a pressure gauge, if you don’t have other more accurate equipment for measuring, but a pressure gauge will not always help you take the necessary measurements accurately and correctly.

Please note that all products must be of high quality. A bad hose can rupture when the pressure increases. A bad fitting or poor-quality coupling will lead to freon leakage and inaccuracies in the pressure gauge readings. Sometimes equipment can be rented or built from scrap materials. But you shouldn’t save much on this process. In general, excessive savings on car maintenance and repairs are unlikely to lead to anything good.

Popular types of automotive sealant for eliminating freon leaks

Autech aerosol composition for sealing car cooling devices can eliminate small leaks. In this case, the master will spend a small amount of time and effort on repairs using the composition.

The principle of operation of the product is very simple - it literally cements leaks without harming the air conditioning system. At the same time, the car owner will not experience any restrictions during further operation of the air conditioning systems. Aerosol sealants contain special components that do not pose a danger to freon and the car’s cooling system as a whole. Autech varieties can protect air conditioning systems from loss of coolants of any variety and brand; it is not necessary to select suitable components by composition or type. With equal effectiveness, the composition can be used both to eliminate leaks and for preventive purposes, in order to maximally protect the car from possible losses of freon, which is very important in the spring-summer period.

Extreme refrigeration system sealant will eliminate leaks in both rubber and metal components of the air conditioning system in a car, as well as any refrigeration units. You can work with this substance on leaks no larger than 0.05 mm in size.

The SealUp variety can be used to seal threaded connections, joints and couplings of vehicle air conditioning systems.

Related article: Sealant-gasket: varieties, manufacturers and instructions for use

Thanks to the sealant, a durable film is formed on the threads, resistant to chemicals. At the same time, the sealant composition remains elastic, ideally fills all microcracks and adheres well to internal surfaces. Can be used to seal metal and plastic elements that are subject to the greatest possible vibrations. The sealant can function at operating temperatures from -90 to +200 °C. Can be used both under vacuum and at pressures up to 500 bar.

Technology of using sealant for car air conditioning (2 videos)

Sealant for air conditioning: types and applications (15 photos)

The process of refilling a car air conditioner - what needs to be done?

First of all, find the fitting under the hood to which you need to connect. The air conditioning system of most cars has two lines. The thicker tube represents the low pressure line, the thinner tube represents the high pressure line. We need to connect the filling hose to the fitting on the low pressure line, that is, find the fitting on a thicker tube. Typically, filling holes are not difficult to find, manufacturers do not make life difficult for service stations, but this rule can be violated.

Next, you need to organize your work in accordance with the following stages:

1. Find the cap on the low pressure line. We clean this cap from dust and dirt so as not to fill the car with a dirty working environment.

2. Next, you need to open the cap and immediately connect the hose of the pre-assembled filling complex to the system. Having a good pressure gauge or metrology station in this facility will be a key aspect of success.

3. Next, you need to start the engine, increase the speed to 1500 rpm by pressing the gas pedal. Then you need to turn on the air conditioning to maximum and activate the air recirculation mode in the cabin.

4. Next, raise the freon cylinder above the connection point to the low pressure line. On the main line itself we unscrew the tap. Filling with freon begins and pressure in the system builds.

5. At this stage, the device begins to pump freon through the lines, and you can already see certain indicators of the pressure gauge. If the indicators remain at complete zero, you can stop the procedure and go looking for problems in the circulation system.

6. It is important not to exceed 285 kPa in the low pressure line. If this threshold is exceeded, the air conditioning compressor has a good chance of failing and forcing you to invest in repairs.

7. Through the window of the filter-drier, you can see if there are any bubbles or other inclusions in the liquid. If the freon is clean, then there are no problems, you can continue refilling.

8. When the air in the cabin is very cold, and the hose right next to the fitting on the low pressure line becomes icy, you can stop the air conditioning charging procedure. At this stage, the device should work efficiently and without problems.

If during the process you notice that the pressure begins to jump or exceed the permissible level, you need to close the tap on the line. You need to open it as carefully and slowly as possible. You should also inspect all freon circulation systems to identify any problems or leaks. If you do everything correctly, you should not have any difficulties operating your car air conditioner.

Air conditioning compressor device

Based on their internal structure, there are several types of compressors:

- piston The most common are axial piston superchargers with a rotating inclined disc. A swinging washer on the compressor axis moves the pistons, forcing gaseous refrigerant from the low-pressure zone into the high-pressure line;

- vortex (spiral) blowers. They are used to advantage in systems where it is necessary to cool the interior of a large volume (for example, buses);

- rotary-vane.

The difference between compressors in the way they regulate the load is also important. Until now, most cars have compressors with an electromagnetic clutch, which, when activated, closes the pulley and the compressor axis. In such a system, the engine service belt constantly rotates a pulley mounted on the compressor shaft through a bearing. In this case, the clutch is rigidly connected to the shaft and when voltage is applied to the clutch winding, the phenomenon of electromagnetic induction occurs, forcing the spring-loaded disk with the hub to press against the pulley. The force of friction causes them to rotate together.

On more modern systems, a combined load control method is used. In addition to the electromagnetic clutch, the compressor design includes a valve that regulates the amount of refrigerant sucked in by the supercharger.

How much does it cost to service an air conditioner?

In general, the cost of car services can range from 500-700 rubles for this procedure. But if you contact an official station, the cost may be much higher. For example, the official Skoda service will charge you at least 2500-3000 for the procedure of checking the pressure in the freon circulation system. If something needs to be refilled or repaired, the price tag will increase.

At ordinary stations the cost ranges from 500 to 1500 rubles, and at large service stations they will not always undertake this procedure. They already have a lot of work to do, and refilling your air conditioner does not promise them much profit. If you simply carry out maintenance work once a year, it is better to find a good specialist. But if the air conditioner is old and you have to refill or service it often, you can learn how to do it yourself.

We invite you to watch a short video about the process of refilling a car air conditioner:

A crooked flaring of the pipe for the fitting connection is the most common reason that freon leaves the air conditioner. The bottom picture shows what a properly flared tube should look like. The top one shows an example of what service technicians find at the leak site.

Crooked pipe flaring. Freon can leave the system for several reasons. These include manufacturing defects (very rare), material fatigue (essentially the same defect when soldering connections in the circuit, but manifesting itself over time as a result of constant increased vibration of the air conditioner), poor-quality seals in the valves or a worn (or even unplugged) service valve . But in the first place, of course, is the defect during the installation of the air conditioner. The same increased vibration may be a consequence of improper installation of the unit or lack of shock-absorbing pads. But most often, freon leaves due to incorrectly performed flaring of tubes at fitting connections or due to poor-quality soldering at the joints of pipeline sections.

Each split system has at least 4 points of fitting connections (2 each on the external and external units), and on multi-split systems there are even more. We can say that these are the most vulnerable points of the system, since their integrity depends entirely on the qualifications of the craftsman who manually performs these works. Without going into details, we note that it is very easy to flare a tube incorrectly. There are several rules, failure to comply with any of which leads to marriage. The ability to do flaring correctly is achieved by understanding the essence and ultimate goal of the operation, and, of course, by sufficient practice. So an incompetent, inexperienced worker is highly likely to allow a defect .

It has been noticed that a very large percentage of such “masters from the street” simply have no idea what exactly they are doing and why, mechanically repeating the actions, but not understanding the subtleties. The “skirt” of a flared tube must have a certain profile and characteristics, the existence of which numerous “nugget masters” are not even aware of. Any cracks, asymmetry, damage to the inner surface of the skirt are all causes of future leakage. Depending on the degree of defect, such a leak can be either immediate or quite long-lasting. That is, the “masters” will have time to hand over their work to you, receive money and leave... often forever. And only later will you discover that the freon has successfully disappeared from your new air conditioner.

The consequences of their “skill” have to be eliminated by other people, which, however, is for the best.

Let's sum it up

It is unacceptable to use a car equipped with air conditioning without using this wonderful device. It is necessary that the climate system works flawlessly and pleases the driver and passengers of the car with ease of control, excellent interior cooling parameters and other features. The comfort of traveling in a modern car, especially over long distances, is often determined by whether the car has air conditioning. If it doesn’t work, then the comfort will be conditional. You will have to open the windows, put your health at risk and listen to the rather strong howl of the wind.

Sometimes restoring or repairing an air conditioner is very simple, and you can do it yourself. You just need to study a little the theory of how the system works, and also buy inexpensive equipment that can be used in the future for regular maintenance. As a rule, such equipment will pay for itself after 2-3 uses, and you will be able to independently solve any problems associated with your car air conditioner at any time. But if you do not have experience and skills, you should entrust this procedure to specialists.

Car air conditioner malfunctions and their causes

If there are mechanical problems with one of the components of the car's air conditioning system, this can lead to the breakdown of another element, which will result in an expensive replacement of several components at once. To avoid this, it is necessary to take measures to repair the car air conditioner immediately after one of the following problems is noticed:

- Evaporator clogged. An unpleasant odor appears in the car interior when the air conditioner is turned on or water appears on the car mat;

Compressor malfunction. The air conditioning system makes a lot of noise during operation. To diagnose a compressor malfunction, you can inspect its housing. If there are traces of oil on it, it means it is jammed. In most cases, faulty car air conditioning system compressors are not repaired, but replaced with new ones;- Problems with blood pressure. If the operating air conditioner does not supply cooled air to the passenger compartment while idling, but operates normally while the car is moving, there is a high probability that high pressure will occur in the system. Most often, this problem occurs due to contamination of the capacitor;

- Poor power. If the air conditioner is charged, but does not work as it should, the reason for this is depressurization or a refrigerant leak;

- Spontaneous shutdown of the car air conditioner. This problem is most often associated with poor performance of the dehumidifier or thermostatic valve. The problem can be diagnosed by inspecting the pipelines that connect to these system components. The problem is with the one at the inlet of which the pipeline freezes.

Another problem that can occur with an air conditioner is the system malfunctioning due to electrical faults. In this situation, you may need to check the wiring.

Is it possible to do without pressure testing the system?

Nitrogen leak testing is an operation that requires specialized skills and equipment. Some masters shy away from doing it. But if an air conditioner is installed in the room with subsequent sewing of the freon line under the ceiling or embedding into the wall, it is better not to risk it. In the event of a leak, the scale of financial losses will be significant: it may be necessary to open the line, resulting in damage to the interior. To prevent this from happening, it is necessary to order the installation of an air conditioner with evacuation and pressure testing from specialized companies that are provided with special equipment, experienced specialists and provide a guarantee for their work.

Return to section