Welding a cast iron engine block

Massive cylinder housings are made from cast iron. This durable material has one significant drawback - it is very fragile.

When struck, cracks form on it or the wall is completely destroyed. Due to small defects, service stations often suggest replacing the engine, although cracks can be effectively eliminated by welding ICE (internal combustion engine) blocks. Is it possible to repair a cast-iron engine block yourself, and how to do it correctly, professionals tell us. They have proven in practice that in a garage, having a welding machine and working skills, it is possible to restore the tightness of the metal and its operating parameters. This engine has been in use for many years.

Methods for welding a cast iron cylinder block

To reliably eliminate small defects in the form of cracks, there are several effective methods. Difficulties arise when repairing aluminum alloys. This is due to a change in the properties of the metal when heated, the formation of a refractory oxide film. The aluminum engine block requires some gas welding skills. If cracks appear in cast iron, welding of the cast iron block is carried out in three ways:

- when heating everything;

- fragmentary heating of the repaired area, used when it is impossible to completely heat the overall body;

- electric welding on a cold surface, this method is most popular due to the ease of execution and the quality of sealing cracks.

Hot welding

According to the technology, the part to be welded must be heated to +600-700°C, this is done in special furnaces and furnaces. Craftsmen carry out the process in casings with an asbestos layer. Gas burners are used for this. When heated, the metal retains its plasticity and viscosity. It is better welded by the electric arc liquid bath method using electrodes of the MNCh-2, OMCh-1, OMCh-2, OZCh-2, OZZHN-1, TsCh-4 brands.

The method is used to seal cracks in hard-to-reach places. Special holes are made in the casing to seal defects. Heating is carried out slowly, since a sharp temperature change deteriorates the quality of cast iron.

Cold welding without preheating the block

The process of eliminating cracks is carried out using three methods:

- electric arc using flux, cast iron filler rods, graphite or carbon electrodes;

- manually using a protective atmosphere (argon), the electrode must contain graphitizers that reduce the fragility of the weld;

- semi-automatic with flux-cored filler wire in a carbon dioxide atmosphere. The cold method of metal repair is more economical; it involves heating the area in the weld area to a temperature of + 80°C.

How to seal holes in a cast iron cylinder block?

#26 Albertik

Helmsman 1st class

- Main crew

- 948 messages

- From: Tolyatti

- Vessel:

Comfortina 32 - Title:

Antila

#27 Sasha240255

- From: Moscow region

- Vessel:

Process in progress. - Title:

“Mikhail Svetlov”

Then I’ll try to cut off the welding seam protruding beyond the plane of the wall with a grinder and put a cover on top with bolts with a gasket made of rubber or paronite with ordinary sealant. Are there any special features for drilling cast iron with an electric drill and cutting threads in cast iron?

#28 felt boots

- From: Rechnovsk

Welding on cast iron is a complete mess, it’s the same as welding on clay. In addition, strong stresses appear. They tried to weld in vain, now drilling in these places will be very problematic. Yes, I am repairing cast iron blocks. There are almost no hopeless cases. The best way, but the most painstaking process is drilling along a crack, cutting threads and screwing in screws. First (using the example of a 10 thread) you drill holes through 16 mm (between the drilling centers), cut the thread and screw the pins onto the red thread lock, use a grinder to cut them off at the root. Then between You drill them again, screw them into the ceiling and cut them off. It turns out great. But in your case, after a failed welding, this method is no longer realistic - the cast iron will be as good as the winner - the drill won’t hurt. Bend the plate along the profile, drill around the perimeter and onto the bolts. A good quality one for the plate sealant, just not borscht. Apply it (sealant), wait until it cools, press the plate with bolts so that the sealant is two millimeters thick, and the next day stretch evenly.

Post edited by felt boots: April 12, 2010 – 20:42

#29 Albertik

Helmsman 1st class

- From: Tolyatti

- Vessel:

Comfortina 32 - Title:

Antila

#30 chainik

- From: Russia

- Vessel:

motorboat 11x3.1 m

There is no need to cook anything. Now there is a sealant for blocks, 2-component, I can name the brand tomorrow, I have it in the trunk. You make a patch from aluminum, adjust it to something not on the block with a hammer, periodically lean it against the block, the cracks also need to be covered, they will split when heated, that is, fit it dry, lean it against the block, drill a hole for M5, no more, suddenly the wall is thin, coat the patch with sealant, put it on the screws, and forget that there was once a hole in the block. I glued a hole in the head in the Saab 2 months ago, no problem . Sincerely.

Post edited by chainik: April 13, 2010 – 06:32

#31 chainik

- From: Russia

- Vessel:

motorboat 11x3.1 m

judging by the sketch, the channel is not affected. But I froze the piece that fell out using the same “thin” method, it turned out wonderful

the channel is not affected, just do not tighten the bolts along the lower horizontal part of the patch, they will fall into the channel. Do you recommend installing a gasket, just a layer of sealant?

2All: they welded with special electrodes for cast iron, bought individually, and I went to two construction markets and bought one electrode for cast iron of different brands there, after which I brought them to the welders and they tried to weld a piece of cast iron broken out of a block with each, and then I bought several electrodes of the brand that has proven to perform best. Naturally, the inverter was cooking with direct current and the polarity was set correctly.

Post edited by chainik: April 13, 2010 – 06:36

#32 Byi

Helmsman 3rd class

- From: Pongoma village

- Vessel:

Karbas (self-built) - Name:

karbas

#33 volatile

- From: N. Novgorod

- Vessel:

Kostromich 1606 - Title:

Selfless

It happened that I missed the moment of draining the water and for a couple of days it was -15 and my cast iron block cracked. in the area of the 1st cylinder liner, a cast iron plate was squeezed out from the inside along a crack in the shape of the letter “P”. I broke the plate because... It was also cracked lengthwise, so I cut out a patch from the old stove lid and tried to weld it. first with a semi-automatic device with a carbon dioxide cylinder, but due to the length of the power cable there was not enough power for the device (it was not possible to drive the boat to the place where there is power near the water and it was not possible to drive the car with the cylinder there due to the lack of such a place), then they welded inverter with electrodes on cast iron. It was welded, but due to local overheating at the welding site, many cracks formed around the seam. I’m planning to seal them with some kind of material such as sealant or glue that is resistant to temperature changes - please suggest such a material. engine 4H 10.5/13.

#34 Albertik

Helmsman 1st class

- From: Tolyatti

- Vessel:

Comfortina 32 - Title:

Antila

the channel is not affected, just do not tighten the bolts along the lower horizontal part of the patch, they will fall into the channel. Do you recommend installing a gasket, just a layer of sealant?

#35 Ya&R

It will be useful: Which H8 lamps are better for fog lights?

- From: Our Palestines

- Vessel:

Colander with handle - Title:

Oh, of course!

Post edited by Ya&R: April 13, 2010 – 13:41

Welding technology

Now let's talk in detail about how to weld a crack with your own hands. Parts are pressed out at the site of damage. The defect is discovered after hydrotesting; for convenience, the crack is marked with a thick chalk solution. 5 mm holes are drilled at the ends.

To weld a cast iron block you will need:

- welding machine with current regulator or inverter;

- 2–3 electrodes, it is better to purchase universal Zeller 855;

- chamfering tool;

- brush and hammer for cleaning the seam and removing scale.

The crack must be welded using the following technology:

- The seam area is cleaned to a shine and degreased.

- Flux is applied to both sides of the edges, protecting the cast iron from heating.

- The repair area is heated by a gas burner evenly and gradually, the direction of movement is along the crack.

- The seam is formed in small sections, up to 15 cm long per pass.

- The resulting seam is heated for about five minutes so that the metal cools slowly. When subjected to sudden cooling, it will become brittle and will not withstand the workload.

- The scale is carefully knocked off, and after a visual inspection the joint is well cleaned, especially if the chip is in contact with other parts.

By forging each roller separately, you can immediately eliminate possible defects.

When a defect is found on the engine block, do not rush to replace it. It is better to consult with specialists whether it makes sense to undertake repairs. It is possible to weld a block crack with cold metal in a garage. You need at least basic welding skills to get the job done accurately. Some service stations provide welding services for internal combustion engine blocks; this is much more expedient and cheaper than completely replacing the engine.

How to avoid engine damage in the event of a sump failure

Let's start with the fact that the damage listed above threatens not only passenger cars, but also vehicles with increased ground clearance (city crossovers and SUVs).

At the same time, one of the most serious problems, along with dented sills or various problems with the chassis, can be considered a situation when, for one reason or another, the engine sump was broken.

First of all, you need to take into account that it is strictly prohibited to continue driving a car with a broken pan. The fact is that the pan itself on most cars is a kind of reservoir for engine oil (an exception is a dry sump system).

From the sump, the oil pump of the lubrication system constantly takes in lubricant, after which it supplies engine oil under pressure to the loaded rubbing elements and components inside the power unit.

It is quite obvious that the engine oil will simply leak out even through a minor crack in the sump, and without the proper amount of lubrication, the oil pressure will drop, oil starvation will begin, as a result of which the engine will be subject to severe wear. If the leak is strong, then the power unit can completely jam in just a few minutes.

In view of the above, the following recommendations must be adhered to:

- If, while driving, there was a collision with any obstacle or the driver felt an impact in the area of the front axle of the car, then the load should be removed from the internal combustion engine as quickly as possible (release the gas, reduce the speed, lower the engine speed to the minimum, stop car and turn off the engine).

- Then you should open the hood and carefully inspect the car engine from above and below. When inspecting the upper part, you should check the integrity of the engine mounts and their fastenings, inspect the internal combustion engine for fresh leaks at the gasket locations, etc. As for the lower part, it is highly advisable to find the place where the blow directly fell.

Then (only if there are no strong and extensive dents on the pan) the engine can be started, after which you need to evaluate the operation of the power unit for extraneous noise, knocking, etc. You also need to make sure that the emergency oil pressure light on the dashboard does not light up. If everything is in order, you can continue driving on your own.

How engines are restored using welding

Welding of various engine elements was in great demand in an era of shortage of spare parts and restrictions on the free replacement of units. However, even today this operation has not lost its significance and is capable of bringing the engine back to life from the other world when, for one reason or another, it needs to be saved.

Serious damage to the cylinder block or its head is not a death sentence for the engine. Yes, on the one hand, it is easier to change the damaged element. Now it’s not a problem to buy, for example, a new short block (cylinder block assembly). But in some cases, the price of such a purchase may be equal to half the current cost of the car itself. Therefore, repairing engine components using welding may be a more profitable option.

Theory and practice

With the help of welding, it is possible to successfully treat cracks, restore the walls between the cylinders, and even seal a hole in the block punched by a connecting rod. In each specific case, only the master himself determines the feasibility of such complex repairs and its cost. The limitation is the location and nature of the damage. In some cases, successful repair is impossible in principle, and in others the cost of the issue is very high.

It will be useful: How to determine the remaining tread of a tire?

The specifics of welding depend on the material used to make the parts. It is easiest to work with aluminum alloys - their melting point is low, and the metal flows well. Things are much more complicated with cast iron. To work with it you need higher temperatures and more expensive equipment.

Any welding work involves strong local heating of the part, as a result of which it can “lead” (violation of its geometric dimensions). Therefore, it is very dangerous to carry out such activities on a motor installed on a car, and without final quality checks. The banal welding of some torn bracket with this approach can lead to the fact that the nearest cylinder will move, and the piston in it will generally jam. Professionals very often encounter negative consequences of such welding to varying degrees of severity. Repeated repairs are much more difficult for the master himself and more expensive for the client.

High-quality welding technology involves preheating both aluminum and cast iron parts. Elements made of light alloys are heated to approximately 250ºC, and elements of heavy metal - up to 350–400ºC. More is possible if the equipment and the welder’s patience allow working with a hot part. In this case, the consequences of strong local heating are minimized. After welding, the parts are slowly cooled.

After any type of welding, it is necessary to check the geometry of the parts, for example, the diameters of the cylinder along the entire height and the plane of the mating surfaces of the block or its head, as well as their crimping in a hot water bath. If some elements still fail, then their geometry is restored to factory parameters.

Light alloys

Although aluminum alloys are quite convenient for welding, they also have their own unpleasant features associated with the quality of casting. When working with the same part, there are areas in which the metal melts very well, while in others it foams and a lot of slag and dirt float up. Experts note that this is often not related to a specific automaker.

Welding on alloys is carried out using special aluminum wire. The cracks are excavated to the base and new metal is deposited on top. Large holes are sealed using high-quality aluminum patches.

The cost of work depends on the specific case, because the complexity of their implementation is always different. It is very difficult to determine the average price tag, but rough calculations can be made. Welding a hole in the wall between the cylinders today can cost from 5 thousand rubles, and repair by installing a patch can cost from 7–8 thousand. Welding the entire mating surface to restore its plane for an inline four-cylinder block and its head costs approximately 9 thousand rubles. for every detail.

Heavy metal

Welding cast iron requires even greater skills from the master. Its high melting point greatly complicates the work and threatens that the metal may crack. Also, this type of welding requires a special, expensive filler wire.

Some cracks in cast iron elements are welded, but sometimes you have to cut out the affected area and apply a patch. The final decision regarding the repair method is determined by the master himself, depending on a host of factors. The patch is cut from a thick sheet of steel. The fact is that when it is welded into a plane, internal stresses arise, which threaten the appearance of cracks. Slight deformation of the patch helps remove them. Naturally, it is impossible to bend a cast iron part a little without sacrifice, but steel is more ductile.

If a breakdown of the walls between the cylinders in a cast iron block is welded, it is very rare, since the welding site is subsequently processed with great difficulty with a cutter. Patches are not applied to such damage. Further development of cracks is stopped by drilling holes at the beginning and end. Next, such a block is sleeved using a special technology using sealant.

Welding of the mating surfaces of cast iron blocks and heads is done by analogy with aluminum elements. The price of the work is the same. But installing a patch will cost more, since an expensive additive is used during welding.

There is an opinion that welding is an extremely dubious method of repairing engine parts with an unpredictable result in terms of the further service life and overall reliability of the unit. But if the craftsman is properly qualified, the restored structure will last no less than its factory version, and you don’t have to look far for evidence. Today, many representatives of motorsports, as well as owners of vintage cars or entire museums, resort to this service. In the first case, the reliability of welding work has been proven in harsh racing conditions, and in the second case, it has been proven by the high and unique requirements imposed by a specific customer.

We thank INOMOTOR LLC for assistance in preparing the material.

Photo: from the archive and magazine “Behind the wheel”

Glue instead of welding part 6

(published in abbreviation)

ALEXANDER KHRULEV, Candidate of Technical Sciences

“I missed the oil” - this is how one of the drivers described his case. If you missed it, it means you didn’t check it in time. And the engine was left without oil. The consequences are clear: the connecting rod bearing “knocked”. It ended up that the connecting rod broke off and, falling between the crankshaft and the block wall, punched a good hole in the cylinder block.

This block, of course, needs to be changed. But it costs money, and a lot of it. So, although there are options, they do not always provide a real way out of the situation.

But what if you don’t change the block? Should I try to repair it? Well, it’s a good thing, but it’s not easy, requiring knowledge and some experience.

To cook or not to cook?

In principle, it is possible to repair a cylinder block with any damage. The whole question is how economically justified it is.

Of course, before starting to correct such complex damage as holes, it is necessary to outline a repair technology. The most important question is how to seal the hole. The complexity of the work, the need for special equipment and tools, and ultimately the reliability of the engine after repair depend on this.

The traditional method of repairing holes in the cylinder block is welding. However, it is difficult to simply take and weld a hole. Local heating in the weld zone always leads to the occurrence of large stresses when the block cools. And this is dangerous - cracks may form. But even if there are no cracks, the strong heating will still not go in vain, and after cooling the block may turn out to be deformed.

Of course, the result greatly depends on the qualifications of the welder and the equipment used. For example, if the block is heated before welding and then slowly cooled, the stresses will be noticeably reduced. This means that deformations will decrease and cracks will most likely not appear. True, such a process requires a special oven, and this is not so cheap. By the way, good welding equipment is also not cheap. Welding has other disadvantages related to the materials from which the engine blocks are made. Thus, alloying elements present in the metal often interfere with obtaining a high-quality weld.

When the hole is welded, the strength and rigidity of the block, damaged as a result of the breakage, will be restored. But this does not mean at all that the repaired block will regain its former tightness. It must be checked - and, if necessary, the seam must be additionally sealed, for example, using various adhesive compositions.

So it turns out that in many cases welding is a rather complicated and not the most successful method of repair. Which one is better? There is no definite answer, but there is still an alternative to welding.

How to seal a hole

So, the technology used should be accessible and inexpensive, that is, it should not require expensive equipment, tools and materials; it must be performed by semi-skilled personnel and ensure high engine reliability after repair. All of the above requirements are fully satisfied by the repair method using adhesive compositions.

Are you surprised? In vain. The technology of gluing blocks has long been tested and successfully used by a number of specialized workshops.

Any adhesive composition, like welding, cannot be applied simply, as they say, directly. It is imperative to comply with the requirements, which have already been worked out quite well. Let us briefly formulate the task: it is necessary to repair the hole in the block, ensuring high strength and tightness of the wall after repair. Its solution is available to any workshop or service station.

As always, we need to start with preparation. It is necessary to thoroughly clean the surface around the hole (both inside and outside the block) to a width of 25 mm. Next, you should cut and fit the linings from sheet steel with a thickness of 0.0.8 mm. In order to close the hole with an overlap of 20 mm on both sides - inside and outside. Since the shape of the overlays will most likely be complex, repeating the “relief” of the block’s surface, it is better to first make cardboard templates, and only then cut out the overlays using them.

The linings are adjusted into place by tapping them with a hammer to ensure their precise fit to the block. Where there is a complete fit, holes are marked and drilled. To do this, the overlay is pressed against the block, and with a 5,5,2 mm drill, through drillings are made through the overlay in the wall of the block. The holes should be located evenly along the contour of the hole with a pitch of 50 mm. The holes in the plates are drilled to 6.5 mm, and M6 threads are cut into the holes of the block. Where the walls of the block are quite thin (less than 10 mm), you can drill holes in the block up to 6.5 mm, and then use one bolt to tighten both linings - both outside and inside.

It would be useful to pre-assemble the structure - install and tighten all the bolts in order to check how the linings fit on the block and how the bolts are tightened. All that remains is to thoroughly clean the surfaces of the linings, degrease everything with acetone and proceed to the final stage of repair - applying the adhesive composition. What should I apply?

Indeed, the epoxy resin that was widely used in the past is no longer suitable today. For example, without filler it will leak out of the gaps between the pads and the block. Without a plasticizer, nothing will work either - the hardened resin will crack, since the cylinder block constantly experiences heating-cooling cycles, leading to stresses that are dangerous for the resin.

Compositions such as “cold welding” are more successful. Their base, as a rule, is the same, epoxy, but the properties due to additives are better - strength, ductility, and adhesion. Some of these materials can withstand high temperatures - up to 3000C, which will not be superfluous for the engine.

But from the available options, we chose the composition of the American company Belzona.

For the repair of cast iron parts, the company's program includes compositions with fine cast iron chips, ideal for cylinder blocks. And, of course, many years of experience in using these compositions to repair blocks is also worth a lot. In our opinion, the only drawback of Belzona materials is the relatively high price (more than $100 per kilogram).

It will be useful: What is the best adhesive for auto glass?

Having mixed the components in the required proportion (1:3 by volume), apply them to the block wall along the contour of the hole and press one of the pads. After this, the hole is filled with the composition and a second overlay is installed. There should be enough composition between the linings that when the bolts are tightened, some of it is squeezed out along the entire contour of the linings.

When the composition has hardened, all that remains is to cut off the protruding part of the bolts (for aesthetic reasons or if they interfere with something) and paint the block.

Motor Technologies – St. Petersburg © 2002-2020 tel. +7 (812) 388-08-55

We draw your attention to the fact that this website is for informational purposes only and under no circumstances constitutes a public offer as defined by the provisions of Article 437 of the Civil Code of the Russian Federation. For detailed information, please contact 812-3880855 or other methods indicated on VKontakte.

Technology and methods of welding cast iron cylinder block

The need to weld the cylinder block arises when cracks appear on it. A large number of blocks are made by casting cast iron. Cast iron is a fairly strong and hard material, lends itself well to casting and has a low melting point compared to steel. The negative side of the material is fragility and low viscosity. In this regard, the most common malfunction of blocks is the appearance of cracks.

It will be useful: What is better, studded or non-studded tires?

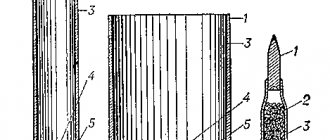

Rice. 1. Cylinder block

Examples of restoration of parts made of aluminum alloys

Author: admin on October 28, 2016

a crack in the outer wall of the cooling jacket at the corner of the block, with one end extending to the threaded hole for the head mounting stud. Technical requirements: the strength and tightness of the connection must be ensured.

The most appropriate way to repair damage is by argon-arc welding. A groove is cut along the crack and the surface is cleaned until the oxide film is removed, i.e. until clean metal appears. Before welding, the area around the crack is heated to a temperature of 250-280°C. This operation is carried out with the flame of a gas burner, on which tip No. 4 or 5 is installed. The metal is heated to the required temperature within 1.5-2 minutes. To prevent possible warping of the block flanges, a technological sleeve is inserted into the hole under the cylinder liner.

For welding, torch No. 2 is used, in which a tungsten electrode with a diameter of 5-6 mm is installed. The welding process is carried out at a welding current of 240-280 A. The crack can be welded from either end, but it is better to start from the threaded hole, then move to the side surface of the block.

The appearance of pores in the weld metal is a consequence of the ingress of scale into the weld pool, sucked from the internal cavity of the block. A weld that has pores must be remelted without adding filler metal. In this case, the burner is given crescent-shaped movements across the seam or loop-shaped movements perpendicular to the plane.

After welding is completed, the cylinder block at the welding site is covered with sheet asbestos to slowly cool the metal. In order to ensure the tightness of the welded joint, the cylinder block is pressurized on a hydraulic stand under a pressure of 0.3-0.4 MPa.

Clutch housing of ZMZ-53 engine

broken flange securing the crankcase to the cylinder block. Technical requirements: the strength of the connection must be ensured.

Damage can be repaired in several ways, including manual arc welding. In this case, the quality of the welded joint will be slightly lower than when welding by any other method, but the productivity will be higher.

First of all, you need to fit it in place and secure the broken part. If it is not preserved, then it is cut out from a sheet of aluminum alloy AMg 8 mm thick, or from a rejected clutch housing. At the junction of the broken part and the crankcase, bevel the edges on both sides. After this, the broken part is pressed against the crankcase, grabbed at two points, and then welded on all sides. Welding is carried out with an OZA-2 electrode with a diameter of 5 mm at a welding current of 180-200 A. The seam is then cleaned to the level with the main surface.

Cylinder head of the GAZ-51 engine

thread failure in the spark plug hole. Technical requirements: the restoration method must ensure that a thread of the nominal size is obtained.

A block head with the indicated defect can be restored in several ways: by installing a threaded spiral insert, by installing a threaded insert with a nominal thread, by welding the hole using argon-arc welding and gas welding. The most labor-intensive of these methods is gas welding. An example of restoring a block head using gas welding is given only because not all enterprises have yet implemented argon-arc welding and the process of restoring parts using spiral inserts. At the same time, gas welding, as one of the oldest methods of joining metals, is available at almost every repair enterprise.

Before welding, the defective hole must be prepared accordingly: drill out until the old thread is completely removed and countersink the socket for the spark plug washer. These operations can be performed in one step using a countersink drill. The cutting part of this hole drilling tool has a diameter of 19 mm, and the countersink part is 28 mm.

Then the cylinder head is heated in an electric furnace to a temperature of 280-300°C and, after removing it from the furnace, it is placed on a workbench on a special stand with the connector facing down. The stand has protruding plugs that cover the bottom of the spark plug hole in the head.

Welding of the defective hole is carried out with a torch with tip No. 5. The flame is adjusted to an acetylene flow rate of approximately 750 l/h; it should be “soft”, with a slight excess of acetylene. The metal is heated by the reduction zone of the flame using circular movements of the burner around the perimeter of the hole. As soon as small wrinkles begin to appear on the metal, the filler rod is brought to the flame and its end is heated. Then the rod is dipped into a jar with diluted LF-4A flux and delivered to the welding site. The end of the rod destroys the oxide film on the metal surface and immediately melts several drops from the rod, mixing them with the base metal freed from the film. Periodically, flux is delivered to the welding site and floating oxides and non-metallic inclusions are removed with a scraper.

After the hole is completely filled, the welded metal is leveled using circular movements of the torch, then the cylinder head is turned over with the parting plane up, the reverse side of the weld is heated, oxides and contaminants are removed with a scraper, a few drops of filler metal are added and the welded surface is trimmed, giving it the shape of the surface of the combustion chamber in this place.

Immediately after welding, the surfaces of the deposited metal are moistened on both sides with warm water and the flux residues are cleaned off with a steel brush. After this, the surface should be clean and free of yellowness (signs of the presence of residues of reacted flux).

The part is then slowly cooled by placing it in a box of sand or covering it with sheet asbestos. Then a hole with a diameter of 16.3 mm is drilled along the conductor, a countersink is used to make a platform for the spark plug washer and a thread of the nominal size is cut with M 18*1.5 taps.

Cylinder block of the ZMZ-24 engine

crack in the bridge between the cylinders. Technical requirements: the strength, tightness and high corrosion resistance of the welded joint must be ensured.

It is most advisable to weld the crack using argon-arc welding, since this method provides local heating of the defect location and higher quality of the welded joint.

The groove along the crack is selected with a slotted grinding wheel. Before welding, the crack zone and the zones for seating the sleeves are heated with a gas burner flame to approximately 250-280°C. Then the crack is welded on both sides, paying particular attention to ensuring that there are no undercuts in the seam. After welding, the block is covered with asbestos to cool slowly, then machined on a boring machine.

Cylinder block of the ZMZ-24 engine

corrosion of the lower seating belt under the cylinder liner. Technical requirements: the accuracy of the mating of the sleeve and the block must be ensured.

It is advisable to carry out repairs by dimensional calibration with an epoxy composition. First, the upper and lower seating belts under the liner are cleaned of scale in the cylinder block. This is best done with a special mandrel in which cutters are mounted, adjusted to the diameter of the upper and lower flanges of the block. The belts, cleaned to a shine, are then wiped with a solvent and after it evaporates, a thin layer (up to 1 mm) of an epoxy composition is applied to the surface of the lower belt. Then the calibrating mandrel is lubricated with a thin layer of liquid mineral oil, inserted into the place of the sleeve and pressed so that the upper thrust shoulder of the mandrel is tightly pressed against the upper flange of the block under the sleeve. After the epoxy composition has cured (after about a day), the calibration mandrel is removed from the block and cleaned of excess extruded composition.

To eliminate this damage, an epoxy composition filled with aluminum powder is used. Instead of polyethylene polyamine, you can use the AF-2 hardener. In this case, calibration is recommended to be carried out approximately 1-2 hours after introducing the hardener into the composition and applying it to the surface. Curing of the epoxy composition into which the AF-2 hardener is introduced is carried out at a temperature of 20°C for 8 hours or 2 hours at 80°C.

autocarta.ru

Preparing the cylinder block for welding

Before carrying out welding work to repair the unit, it is necessary to thoroughly clean it of dirt, oil and other contaminants. Cracks and discontinuities identified on the block must be marked with chalk or other convenient means.

In order to avoid the growth of cracks, its edges must be drilled. Small cracks up to 5 mm can be welded without cutting the edges. Deeper cracks must be made with cutting edges.

Rice. 2. Drilling cracks

The hole must not be made through, but only until a gap appears along the entire length of the crack. The crack prepared for welding should resemble a joint with a V-shaped bevel of the edges. This is done so that during welding all gases and impurities contained in the welding materials and base metal can escape to the surface of the weld.

Let's sum it up

As you can see, damage to the oil pan is a serious problem. Repairing such a breakdown also has certain difficulties and can be very expensive. For this reason, it is strongly recommended to immediately install additional engine crankcase protection.

At the same time, standard solutions that can be installed on a car are made of plastic and provide more protection from dirt and moisture than from impacts. This means that engine protection must be purchased separately, giving preference to the most durable metal products.

Let us also add that when choosing engine protection, you must also take into account that the engine compartment becomes more sealed and closed from outside air. This can cause problems with cooling the power unit, especially when the car sits for a long time in traffic jams with the engine running.

For this reason, it is advisable to buy only certified products that are specifically designed by the manufacturer for a specific car and its features (attachment points, oil drain hole, etc.), and not more affordable universal solutions.

In simple words, even a steel protection sheet can bend or break through from a serious blow (for example, from reinforcement). This means that if there is a collision with an obstacle, while protection is in place, the engine still needs to be immediately turned off and inspected. Only a timely detected problem allows you to avoid engine overheating, oil starvation or seizure as a result of oil leakage.

What should be understood by the definition of “engine knocked”. Why does the engine start knocking? In what cases does a knocking sound in the engine indicate a breakdown of the internal combustion engine.

Why the engine jams and the main symptoms of this malfunction. How to prevent the motor from jamming, what to pay attention to.

How to independently determine that the cylinder head gasket has burned out. Recommendations for pulling the cylinder head after replacement. Which gasket is better to choose?

Basic methods for repairing a cracked engine block. Crack detection, repair by welding, riveting or applying an epoxy layer.

The most common causes of engine knocking are: piston knock, connecting rod knock, crankshaft knock. What to do if the engine suddenly starts knocking while driving.

The appearance of knocking noises in different diesel operating modes. Fault diagnosis. The nature of the knocks of the crank mechanism, timing gear, and fuel equipment.

Cylinder block welding methods

Cylinder blocks made of cast iron must be welded in accordance with cast iron welding technology. The cylinder block can be welded in the following ways:

- welding with preheating of the entire cylinder block;

- welding with preliminary local heating in the welding zone;

- cold welding without preheating.

Hot welding with heating of the entire block

Hot welding of a cylinder block is performed with pre-heating of the block to a temperature of 600-700 °C. Heating is carried out in furnaces, furnaces or heating pits. For heating, special casings made of steel with a thin layer of asbestos are also used, in which the welding site is left open, and heating is carried out with gas burners. Preheating allows you to preserve the mechanical properties of the base metal.

Welding is performed with coated electrodes of the OMCh-1 brand or others for welding cast iron using the appropriate method. When arc welding, they try to keep the liquid metal in the weld pool until the edges are completely filled. After welding, the block must be cooled for a long time.

Welding with preheating at the welding site is used for volumetric structures, the heating of which is impossible completely due to their overall dimensions.

Cold welding without preheating the block

There are many methods for welding cast iron products without preheating:

- manual arc welding (a large number of welding electrodes have been developed);

- semi-automatic welding in carbon dioxide and flux-cored wire;

- argon arc welding;

- welding with carbon or graphite electrode submerged arc (cast iron rods are used).

How to detect cracks in the cylinder block

Not always, when we talk about a crack in the cylinder block, it means a serious defect noticeable to the eye. Quite often these are microcracks, which can be determined by one of the following methods:

- Pneumatic crimping;

- Use of ultrasound scanning;

- Application of specialized magnetically sensitive equipment;

- Hydrocontrol.

Article on the topic: The cooling radiator is leaking: what to do

Each of these methods allows you to determine whether there are microcracks in the cylinder block, and where exactly they are located. Most often, service centers, in the absence of specialized equipment for diagnosing a cylinder block, use the method of searching for cracks using water or air.

The essence of this method is simple - water is pumped into the cylinder block, and if it leaks out, it means there is a crack in that place. When using air, air is pumped inside, and the part itself is immersed under water, thereby, by the presence of bubbles on the surface of the water, it will be possible to understand whether there is a crack.

Please note: Magnets can be used to pinpoint the location of the crack. They are installed along the edges of the expected split in the cylinder block, after which the space between them is filled with conductive sawdust. If there is a crack, the magnetic field lines will break and sawdust will collect in the area where the microcrack is located.

Welding a cast iron engine block

For a welder, when repairing cast iron products, the main thing is to achieve the strongest possible seam, since it is the welded joint that is always the weakest point. When a cast iron engine block is welded, cracks, chips and other damage often occur. Basically, the thickness of such a block is from 4 to 8 mm, therefore, it is recommended to use electrodes with a diameter of 4 mm.

Electrodes for welding cast iron engine block

Cracks occur in the jackets of the cooling unit, since it can be subject to shock and is negatively affected by defrosting processes. Breaks may also occur in the block, which are caused by the destruction of the sleeve-piston group. At first you may get the impression that the damage can be repaired easily, but in reality this is not the case. The properties of cast iron put forward additional requirements for welding technology. There is also a great responsibility here, since incorrect movements can ruin the entire block. All this can take more time due to the need to interrupt the seam, simultaneously covering the slag and other things. All this is carried out in accordance with GOST 2246-70.

Welding a cast iron engine block at home

How to repair a hole in a car body without welding: the best ways

It often happens that before painting a used car, we discover a through hole formed due to corrosion.

What can be done in this case, if we leave the topic of professional body repair and high costs. Is it possible to fix the hole yourself, and if so, how to do it? All this will be discussed below. If you decide to start painting your vehicle, it is likely that you will be faced with through holes in the body that have arisen as a result of exposure to rust. It is worth noting that body repairs are quite expensive, so not every car enthusiast wants to turn to professionals.

As a result, many are interested in how to repair holes in a car body without welding with their own hands. This is exactly what we will talk about now.

Apply putty

First of all, if you don’t know how to repair a hole in a car sill without welding, you should take a closer look at the putty method. This solution is distinguished by its simplicity, so you can resort to it even if you do not have special knowledge of body straightening.

Before repairing a hole in the car body, you should prepare:

- fiberglass and automotive putty;

- aluminum mesh;

- putty knife;

- sandpaper (if possible, it’s also worth looking for a sanding machine);

- primer, paint, varnish.

Fixing holes in a car body itself is distinguished by its simplicity. First of all, you should remove the rust using an angle grinder or any other suitable equipment. Next, we cut out the patch from aluminum, and then attach it to the body using masking tape. We apply a thin layer of fiberglass putty (here it is important not to touch the tape, because then you will have to remove it). When the putty sticks, peel off the tape and putty the remaining areas.

It is important that the layer is as thin as possible, without tubercles or other irregularities.

When everything is dry, sand everything using coarse sandpaper or a sander.

Having achieved a flat and smooth surface, apply a second ball of putty - automotive putty. We wait until it dries and level it again. Then the surface is primed (do not forget to cover the areas that do not require painting with film). When the primer is finished, you can paint the body.

It is worth noting that the patch will be more stable if you apply a couple of layers of putty on the back side. In addition, it is also possible to seal holes in the car body without welding using putty and without using a patch. In this case, it is necessary to apply a lining on the back side so that the composition is well fixed. On the other hand, this solution is only suitable for very small through holes.

There is another way to repair a hole in a car body without welding. A soldering iron is required here. First of all, we clean the area from rust. We make the patch from a sheet of metal (you don’t need to worry too much about this; an ordinary can of auto chemicals will do).

It is important that the patch is slightly larger than the holes and also completely covers them.

Additionally, you can coat the metal surface with anti-corrosion compounds - this will increase the quality of our repairs. Then we service the edges of the patch, after which, using a fairly powerful soldering iron, we solder it with a continuous seam.

In order for the putty to adhere well, it is important that abrasive marks (small scratches) appear on the patch.

The next step is primer. Here it is necessary to complete everything as quickly as possible to avoid the possibility of rust occurring in the future. It is best to first apply a thin layer of phosphate primer, and when it dries, another two or three layers of acrylic two-component composition (the interval between applications should be about 5-10 minutes). Everything dries in about 3-4 hours; if there is infrared heating, you can reduce the procedure to 20 minutes.

It is worth noting that this solution is more durable than in the case of aluminum mesh, and it can be used to eliminate holes of almost any size.

So, in the article we discussed how to repair holes in a car body without welding. It is worth noting that these options are not the most optimal. Naturally, it is better to turn to professional vehicle repair specialists. At the same time, self-repair will help give the body an aesthetically attractive appearance and also prevent further development of corrosion. Both options are distinguished by their simplicity, so repairs can be performed even without special knowledge and skills.

Recently, it has been possible to close the holes in other ways. One of them involves working with fiberglass.

Fiberglass patch

Instructions:

- The surface of the body is also cleaned and degreased, as in the two cases described above.

- Overlays are cut out of fiberglass, the size of which should be 2 cm larger than the hole size.

- The area is pre-primed and the composition is given time to harden.

- The pad is applied to a completely dry surface.

- Fiberglass linings are fixed using an adhesive-resin composition.

First, one overlay is glued, then the second, third, and so on. Again, it is recommended to put a lining on the reverse side.

After the glue has dried, the body surface is treated and painted.

Read more: What is tiptronic in a car, how tiptronic works in a car and how to use it

As you can see, holes on the car body caused by corrosion can be easily eliminated with your own hands. Visual examples can be seen in the video and photo.

Tired of paying fines? There is an exit!

Forget about fines from cameras! An absolutely legal new product - Traffic Police Camera Jammer, hides your license plates from the cameras that are installed in all cities. More details at the link.

- Absolutely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter connector;

- Does not cause interference to radios and cell phones.

Weldability of cast iron and other properties

Welding a cast iron engine block using a semi-automatic machine requires compliance with all the processing features of this material. Cast iron is highly saturated with carbon. But when exposed to temperature, it begins to evaporate and reacts with surrounding elements, which forms CO. When this compound gets into the metal, it leads to the appearance of cracks during welding.

Welding a cast iron block

It is also worth noting the property of rapid cooling of the metal. If we allow a sharp drop in temperature, which in this case can happen in a completely natural way, then pores and cracks may form in the metal, not to mention other deformations. During cooling, compounds of different crystal lattice structures are formed in cast iron. Accordingly, all these connections can have different volumes. This can cause internal pores to form.

It is also worth noting the low plastic properties, which leads to the appearance of overstresses in the metal, which also causes cracks to appear. This is especially true when welding thin metal with an electrode. The metal is highly brittle, which creates additional difficulties in processing and creates conditions under which cracks can form even with relatively small mechanical impacts.

It will be useful: How to properly wash a new car?

Causes of crack formation

Welding a cast iron engine block with argon often works by sealing cracks. But they can also appear during the welding process. The main reason is a sharp drop in temperature, or a sharp increase. To avoid this, you should gradually heat up the cast iron before welding, and also do this after it, since otherwise it will cool down too quickly. Cracks may appear due to the active release of carbon from the composition when heated. To prevent this process, they use flux, which replaces the lost carbon, and also use protective gases, which will prevent the carbon from combining with oxygen.

Crack formation on a cast iron engine block

Voltage may also be generated due to hydrogen that has entered the seam from the atmosphere, or can get there in the electrode winding. Here you need to more carefully select the coating and protective environment to ensure reliable insulation for the metal. Insufficient carbon replenishment, which occurs with incorrectly selected flux, can also cause cracks. In this case, deformation occurs due to the unevenness of the internal structure of elements in which there is no carbon. They create deformation that leads to surface rupture or the creation of internal pores and cavities.

Modes and characteristics

There are different types and methods of metal welding. In order for the seam to be as reliable as possible, when creating it you need to be guided by proven parameters that can guarantee the successful completion of the work.

Symptoms of a crack in the cylinder block and cylinder head

There are several signs that, if detected, should sound the alarm and send the engine for diagnostics. They may indicate both the formation of cracks in the engine and other malfunctions. Most often, cracks in the cylinder block and cylinder head are indicated by:

- Regular engine overheating. If, due to a crack, the system is no longer sealed, this will lead to coolant leakage and constant overheating of the engine. This problem can also occur due to burnout or other defects in the cylinder block gasket;

- Problems with the operation of the temperature control device (thermocouple). This is fraught with severe overheating of the engine and its deformation;

- The expansion tank does not hold pressure and air pockets form;

- Incorrect temperature sensor readings. If the temperature sensor needle changes chaotically, either up or down, this may indicate sharp changes in the temperature of the engine itself during operation;

- Engine vibrations. One of the most obvious signs of cracks in the cylinder block. If the engine vibrates or shakes excessively, especially when driving uphill, this may indicate the presence of microcracks in the engine block.

How to cook cast iron using electric welding

Cast iron is a special alloy of iron and carbon, which has a melting point much lower than that of steel. With all this, molten cast iron hardens very quickly, forming large pores on the surface due to the release of gases. As a result, welding cast iron using electric welding is not easy, since you need to have not only cast iron electrodes specially designed for this, but also certain knowledge.

As for electrodes for welding cast iron, they contain special components in the coating that are not found in rutile electrodes. The electrode coating includes components such as thermite, ferrosilicon, aluminum, liquid glass, and some other components. An excellent alternative to electrodes for cast iron are graphite electrodes. They allow you to cook cast iron by electric welding, just like carbon and tungsten electrodes.

Unlike welding steel, welding cast iron requires special surface preparation. Preparing cast iron before welding will prevent many defects from occurring. How to cook cast iron using electric welding will be discussed in this article on the website mmasvarka.ru.

Oil pan repair: what you need to know

To begin with, many owners try to repair the hole themselves. Some also try to solve the problem on the spot so that they can get to the service station under their own power. For these purposes (depending on the degree of damage), sealants, liquid welding, conventional welding, metal rivets or even wooden plugs can be used.

In this case, you can try to use some suitable external sealant (do not pour “stop-leak” compounds directly into the engine oil), then you should add oil almost to the maximum on the dipstick and drive the car under your own power.

While driving, you should avoid even medium loads on the internal combustion engine and increasing the crankshaft speed by more than 25% of the total available number on the tachometer (the higher the speed, the greater the pressure in the lubrication system, which increases the likelihood of an existing leak becoming worse).

At the same time, during such a ride, you need to carefully monitor the oil pressure light, and also make stops at short intervals, check the oil level in the engine and re-inspect the damaged area of the sump. It should also be understood that this method of delivering a car to a service station under its own power involves traveling only over relatively short distances.

After the car has been delivered to the service, you can immediately replace the part, but you should prepare for certain financial expenses. Moreover, on some engines, the cost of the pan itself and the price of services for replacing it can be quite high, since replacing a part will require a fairly large amount of complex work.

It is for this reason that many take a different route and prefer to repair the oil pan using one of the available methods offered by specialists. Each method is selected individually, depending on the material from which the oil pan itself is made (steel or aluminum). The extent and nature of the damage, the risk of further enlargement of cracks, etc. are also taken into account.

It is quite obvious that one of the most reliable and proven methods is to weld the oil pan. In this case, the pan must be removed from the engine, since welding without removal directly on the internal combustion engine is strictly prohibited. The fact is that high temperatures can damage other elements and parts inside the unit.

Preparing cast iron for welding

To weld cast iron, it must be properly prepared. The surfaces to be welded must be cleaned with sandpaper or a grinder; you can also use a metal brush for this. To weld cracks in cast iron, defective areas are also subject to special preparation.

First of all, the cracks need to be slightly widened; this is most often done mechanically (by cutting out metal). The cutting of cracks must be carried out in such a way that the defect increases in size by at least 5 mm on both sides. The ends of the cracks after cutting must be drilled to stop their further spread.

Electrodes for welding cast iron

In order to cook cast iron using electric welding, you will need the following types of electrodes:

- For welding ductile cast iron - TsCh-4, OZCh-2 and OZCh-6 electrodes or MNCh-2 electrodes;

- For welding gray cast iron, electrodes OZCh-2, OZCH-4 and OZCH-6, OZZHN-1 and OZZHN-2, as well as MNCh-2 electrodes are used;

- For welding high-strength cast iron, you can use MNCh-2, OZCh-3 electrodes or OZZHN electrodes.

It is recommended to cook cast iron at low currents and continuously. Welding of cast iron products with carbon electrodes is carried out only with direct currents of direct polarity.