Temperature sensor VAZ 2110

The most important condition for the normal operation of a modern car is constant monitoring of the temperature conditions of its systems.

In Ladas of the tenth family, temperature sensors are used in the engine cooling system, air conditioning system, and also to measure the ambient air temperature outside the car.

The sensor is designed to control the heating of antifreeze that circulates in the car's cooling system. The measurement results are transmitted to the electronic control unit to automatically adjust the composition of the fuel mixture, adjust engine speed and activate the radiator cooling fan.

If the sensor is faulty, the injector does not work correctly, and when critical temperatures are reached, the fan does not turn on and the antifreeze boils.

The sensor is a resistor in a metal case, the electrical resistance of which varies depending on the temperature of the antifreeze.

For VAZ 2110 early releases, the temperature sensor was located in the upper part of the cylinder block, on the left side of the engine. The injection “Tens” are equipped with two temperature sensors:

- Coolant temperature sensor, the readings of which are read by the vehicle's ECU (this sensor is located on the front side of the thermostat housing);

- Antifreeze temperature gauge sensor on the dashboard (located in the engine block under the upper radiator pipe).

The indicated sensors are the same for VAZ 2110 with 8-valve and 16-valve engines.

Tip: When purchasing a temperature sensor, make sure that the kit includes a metal sealing ring.

Sensor functions

This device performs a lot of tasks. Based on its readings, the fuel mixture is prepared and the ignition timing is changed. The element also gives commands to turn on the fan in case of overheating.

Enrichment of the mixture is always associated with increased temperatures in the power plant. The lower the engine temperature, the richer the mixture needs to be fed into it. Any electronic control unit works on this principle. And the domestic top ten is no exception.

Replacing coolant temperature sensors

Replacing a faulty temperature sensor is carried out as follows:

- The car is installed on a flat surface, the terminal is removed from the battery.

- The coolant is partially drained so that the antifreeze level in the engine block is below the sensor installation location.

- For free access to the place where the sensor is located, it is recommended to dismantle the air filter housing.

- The electrical wiring block is disconnected from the temperature sensor, and the sensor is turned out of the mounting hole using a spanner wrench “19”.

- A sealing washer is installed on the new temperature sensor; for additional sealing, the last couple of thread turns can be treated with a high-temperature sealant (for example, red “Abro”).

- Then the sensor is screwed into the hole, the connector is connected, the air filter housing is installed in place, and refrigerant is added to the cooling system.

After completing assembly, you need to start the engine and warm up the car until the fan turns on to make sure the system is working. You should also check the tightness of the installation of the new sensor visually.

The instrument panel indicator temperature sensor changes in the same way.

Replacement process

To check and replace the temperature device, you will need the following tools and materials:

- Socket wrench set to “19”;

- Sealant;

- Coolant;

- Copper washer.

Note. The temperature sensor is located in the VAZ 2110, often in the intake manifold near the thermostat housing, rarely in the cylinder head. It is installed so that the tip comes into contact with the coolant. Only in such cases is his signal correct. If the coolant level is low, the sensor readings may be incorrect.

When is replacement needed?

If the resistance of the sensor is high on a cold engine and no electric current passes through the indicator, its needle is located at a low value. In cases where the temperature gauge does not indicate the engine temperature, then, first of all, you need to check the electrical circuits of the sensor. You should also check the current supply to the electrical circuit. If the indicator arrow jerks erratically, inaccurate voltage supply or unstabilized voltage may be received. This requires replacement of the stabilizer. If you still suspect that the temperature indicator is faulty, then before replacing it you should check its functionality:

- if the arrow indicates low motor temperature, then you need to disconnect the electrical connector from the temperature sensor and connect it to ground;

- if the arrow deviates when the ignition is on, then the VAZ temperature sensor is faulty and needs to be replaced;

- if the needle does not move, it is necessary to remove the instrument cluster and check the electrical circuit between the indicator and the sensor and the voltage supply (if the electrical circuit is in good condition, it means that the temperature indicator is faulty and needs to be replaced).

Note. It should be borne in mind that quite often problems with the device arise due to poor wiring or loose, rusty connectors.

- in cases where the temperature gauge constantly shows a high temperature, you need to disconnect the electrical connector from the device (if the gauge needle moves on the cold temperature scale when the ignition is on, this indicates a malfunction of the temperature sensor and it needs to be replaced).

The breakdown of this device is sometimes noticeable visually - this is a liquid leak, severe corrosion of the clamps or cracks on it.

Note. You should also check the condition of the coolant. If it has been used for more than 3 years (for a regular one) and more than 5 years (for a durable one), then it needs to be replaced. It is replaced if there are clear signs of contamination.

Replacement directly

Replacement of DTOZH is carried out in the following order:

- First, the ignition is turned off and the wire is disconnected from the battery terminal;

- The coolant is drained from the radiator;

Note. It is not necessary to drain the coolant completely; you can open the drain valve and drain such a volume of liquid so that its level is below the sensor.

- To make it more convenient to work, you can remove the air filter;

- The block with wires is disconnected from the temperature sensor by squeezing the plastic clip;

- The DTOZH is unscrewed from the cooling system pipe using a key set to “19” (in this case, the sensor is removed along with the copper sealing washer).

Note. Care must be taken when working with the sensor. Damage to the device may interfere with the normal operation of the engine control system. You need to know that it cannot be removed until the engine has cooled down.

If replacement is necessary, install the new sensor in the reverse order of removal.

- Before screwing in the temperature sensor, apply a thin layer of sealant to its threads;

- The sensor is then screwed into place and the electrical connector is connected to it;

- Coolant is poured or added to the cooling system;

- After this, the engine is started and the operation of the temperature indicator sensor is checked.

Finally, the cooling system is checked for leaks. If necessary, the sensor is wrapped tighter into the thermostat housing. It is also necessary to check the cooling system for the presence of air in it, which, when entering the thermostat, can cause engine overheating, thereby changing the readings of the temperature sensor.

Note. In cases where the leak cannot be eliminated, the sensor must be reinstalled. This will require applying more heat-resistant sealant to the threaded part or replacing the copper washer.

It is recommended to watch this video before carrying out work.

Cabin temperature sensor

To control the heating system of the VAZ 2110, a cabin temperature sensor - DTVS is used. Based on its readings, the controller adjusts the position of the heater valve and the fan rotation speed, supplying cold or hot air to the machine. The sensor is located in the middle of the ceiling panel, behind the central lamp. The sensor consists of a thermoelement and a microfan installed in a rectangular plastic housing.

Replacing the temperature sensor with your own hands is quite simple: you need to carefully pry off the retaining latches with a screwdriver, lower the sensor and disconnect the wire block. The new device is installed in the reverse order. Catalog number of the original part: 2110-8128050-02, its average cost is about 800 rubles.

If, after installing a new sensor, inconsistencies arise between the mode selected on the climate control unit and the actual temperature in the cabin, then adjustments should be made. To do this, you need to remove the heater control unit from the panel and turn the adjusting screw on the left side of the case (to increase the temperature - clockwise, to decrease - in the opposite direction).

How to check DTOZH

First of all, you need to remember that in order to correctly indicate the temperature of the coolant, the sensor must be immersed in this very liquid. Therefore, regularly check the presence of refrigerant and its level in the system. This is perhaps the very first thing that should be done if there is a suspicion of inadequate operation of this meter.

If the level of antifreeze in the cooling system is in perfect order, then the contacts may be oxidized or there are other irregularities in the connection of the coolant temperature sensor. You can check its connection yourself. Typically, but not always, this sensor is installed next to the thermostat. In some engines, there is more than one DTOZH. Therefore, check the number of sensors and their location, which are correct for your car. When you have found the coolant temperature sensor and determined that everything is in order with its connection, you need to check the device itself. To do this, the DTOZH must be dismantled, since it must be checked by immersion in a glass of boiling water.

And so, take your sensor, lower it into a glass of boiling water and measure the resistance at the output. In general, there are no uniform indicators of changes in resistance. Sensors for different machines, from different manufacturers, will show different resistance differences. The correct values at certain temperatures, specifically for your sensor, need to be found on the Internet.

Accordingly, if the sensor resistance readings and the reference values coincide or have a minimal error, then the coolant temperature sensor is in good working order. Well, if the resistance values differ, the sensor needs to be replaced. Actually, its design itself, as well as the principle of operation, do not provide for any repairs. Therefore, there are simply no other alternatives.

Outdoor temperature sensor

On “Dozens” of later releases with a VDO dashboard with two displays and a trip computer, an outside air temperature sensor was installed. When the engine was turned on, the temperature readings outside the VAZ 2110 were displayed on the instrument panel screen.

The sensor is located inside the front bumper, next to the front fog lamp. The installation side of the device in each specific case may be different (on the driver’s side or on the passenger side). If the temperature sensor was installed by the owner himself, then most often it was taped with electrical tape to the base of the towing eye.

Catalog number of the original temperature sensor: 2115-3828210-03, its approximate price is about 250 rubles.

If the outside air temperature sensor does not work, remove the plastic protection of the left or right front wheel arch (depending on the location of the sensor), disconnect the wiring connector and remove the sensor from the holder in the front bumper. Installing a new part is performed in the reverse order.

Crankshaft regulator

As you understand, the location of all sensors on the 8-valve injection VAZ 2110 is different, but they are all combined into a single system. The crankshaft sensor is no exception.

Regulator

Through the operation of this device, the system determines when to supply fuel and a spark to ignite the mixture. In fact, the design of the unit is presented in the form of a magnet and a coil of thin wire.

Its strengths include:

- Works for a long time and efficiently even under high loads;

- Functions in conjunction with the crankshaft pulley;

- If the sensor breaks down, the engine stops working or limits the speed to no more than 3500 revolutions.

The device is located on the oil pump, literally at the very top of the pulley teeth. To be more precise, 1 millimeter from them.

Operating temperature of VAZ 2110: diagnostics and replacement of the coolant temperature sensor

Drivers who regularly drive on country roads often see the following picture: a car is standing on the side of the road with the hood raised, and steam is coming from the engine compartment. The cause of this situation is most often the temperature sensor. In one case, the motorist himself is to blame for the breakdown; he did not notice the temperature increase, and in the other, the electronic element was worn out. The coolant sensor (DTS) rarely breaks, but if this happens, then urgent replacement is required. After studying this material, the reader will learn what the operating temperature of the engine is, why the VAZ 2110 engine gets hot, how to check the DTOZH and how to replace/install a new element in a car where the injector is located.

Speed sensor

It provides the electronic system with data about the current speed of the vehicle. It is relatively reliable, but in reality, developers have a lot to think about.

Location

It has two characteristic malfunctions:

- At idle speed the engine turns off;

- A broken sensor can partially affect the speed characteristics of the car.

Operating temperature and causes of engine overheating

Under normal conditions, coolant circulation ensures a temperature of 86-90 °C. During hot periods, the indicator may lag, then after turning on the fan, the temperature stops at 94-108 °C. A frequent question from car enthusiasts: what is the temperature in winter when it’s cold? The first 10-15 kilometers the indicator may be below 80 °C, but after this point it should rise to 85-90 °C. These data are suitable for VAZ 2110 injector.

Also, the operating temperature depends on the type of firmware, fan speed and other features, so the normal value is 90-105 °C.

Now you know what the normal operating temperature of the VAZ 2110 is, so it’s time to study the reasons for its excess. If the “culprit” of the overestimated indicator is not the DTOZH, then the following actions should be taken:

- Check the outer part of the radiator for contamination.

- Replace the thermostat in the VAZ 2110 injector.

- Check the coolant level in the expansion tank; if it becomes low, add it to the required level.

- Adjust the ignition timing.

- Check that the fan is turned on.

Improved start-up and operation of the VAZ 2110 radiator fan

- The presence of a “thermal pumping” effect (the temperature during a hot period of time constantly fluctuates from the point at which the radiator fan (Carlson) is turned on to the point at which it turns off).

- Shock electrical (current) loads on the on-board network.

Smooth start of the coolant fan. Photo report.

- Fan performance is excessive. The radiator temperature drops quickly, causing the fan motor to start and stop frequently.

- The coolant sensor response temperature is too high. The indicator needle is approaching the red zone, the engine is running unstable and may “boil”.

- “Softer” temperature regime of the engine without strong temperature fluctuations;

- Reducing the load on the system by starting currents of the electric motor by reducing their number and magnitude;

- Noise reduction.

xn--2111-43da1a8c.xn--p1ai

The purpose of the DTOZH and its location

The engine temperature sensor is an electronic device that does the job of a resistor. Its resistance varies depending on the environment. To work you will need a standard set of tools. In the “ten”, the electronic device is installed on the cylinder head.

In all cars, a temperature sensor monitors the temperature of the power plant. This element is also responsible for the emergency start of the fan. If the driver has basic skills in handling electrical appliances, then there is no need to go to a car service center; you can replace them yourself.

How to replace DTOZH

Before purchasing a new device to replace the old one, it is worth checking the markings on the old sensor. It is better to purchase exactly the same device.

Other, although similar elements, may give the wrong readings, the ECU will misunderstand them, and the driver will see false readings on the instrument panel. A copper washer must be included with the new element. If it is missing, it is purchased separately.

Dismantling and installation of a new element

Before changing the fan switch sensor, it is necessary to remove all working fluid from the car radiator. After this, you can proceed to replacing and installing a new VAZ 2110 injector element to turn on the fan:

- It is necessary to disconnect the negative terminal from the battery - this will protect against a short circuit that may occur during dismantling of the electronic element;

- Next, you should disconnect the wire block, as shown in the photo:

Important point! There is a sealing gasket on the DTOZH body. When removing the DTOZh, you need to make sure that it does not fall into the hood. A gasket may be needed when installing a new sensor, since the gasket may not be included in the DTOZH kit.

All VAZ-2112 sensors 16 valves and their location: diagram and description

The efficient operation of the injection engine is ensured by a set of sensors. They all connect to the ECU. Lada hatchbacks of the 2112 family were produced only with injection engines, and two varieties of these internal combustion engines are 16-valve. We will talk about them further. All VAZ-2112 sensors, their location and appearance will be shown in the photo.

The excess oil pressure sensor, which is not connected to the ECU, is shown in the video.

Where are the valve and temperature sensors on the VAZ 2110?

The owner of a modern car, stuffed with various electronics, inevitably has to figure out where the VAZ-2110-2112 valve sensors are located. After all, the car enthusiast himself can change any of them; for this, he does not always need to go to a service station, waste time and pay money. Most drivers only know the coolant temperature gauge sensor and the device that monitors oil pressure. But there are much more of these devices in modern VAZ cars.

Possible malfunctions and ways to eliminate them

The following symptoms may inform the car owner about the failure of the DVT:

- The quality of the exhaust gases is too low, which is associated with a violation of the combustible mixture in the cylinders.

- Fuel consumption has increased, and noticeably.

- Problems have arisen in the operation of the power unit. The dynamics of the vehicle may decrease, and the engine power as a whole will also deteriorate.

- Combinations of errors may appear on the dashboard, and the ECU may also send a signal to the dashboard about the need to check the performance of the motor.

- The power unit has become more difficult to start.

When they detect the first signs of problems, many motorists immediately drive their car into a garage or service station to change the controller. In practice, symptoms of DTOZ malfunctions are often associated with damage to the electrical circuit and poor contact of the device with the vehicle’s on-board network. Therefore, if you encounter a similar problem, we first recommend checking the condition of the wiring.

Photo gallery “Diagnostics of DTOZH”

1. DTOZH connected to a multimeter in a container with antifreeze

2. Dependence of temperature (left), resistance (right)

Powertrain heating meter

A device for measuring the coolant temperature of the VAZ-2110 is built into the pipe located on the right side of the engine. The sensor body, which is a thermistor, is in direct contact with the antifreeze. The more the engine and coolant warm up, the more the resistance of this device drops. The controller, which supplies an electrical signal to it, calculates the engine temperature depending on the magnitude of the voltage drop and takes the following actions:

As many as 3 important functions depend on how correctly the VAZ coolant temperature sensor of the tenth family works. The device is considered quite reliable, but sometimes fails due to chafing of the wiring insulation by the accelerator cable, or a break in the circuit inside the element, which happens less frequently. Damaged wires must be replaced, as well as the faulty device itself.

Several recommendations on how to check the temperature sensor. The following signs indicate a malfunction:

- a noticeable increase in fuel consumption because the processor does not prepare the mixture correctly due to a non-functioning meter;

- an engine warmed up to operating temperature does not start well;

- the fan turns on spontaneously at different temperatures;

- a non-working coolant sensor causes incorrect readings on the panel.

It is not difficult to replace an element; access to it is open. But when unscrewing, antifreeze will flow from the pipe, so you must first wait until the power unit cools down. Then take a plastic container and partially empty the cooling system by draining the antifreeze from the cylinder block. After this, you can unscrew the old one and install a new VAZ-2110 temperature sensor.

Diagnostics of DTOZH

All car owners should know how to check the temperature sensor on a VAZ-2110. By checking, you can save on the cost of a new device, although its price is not entirely high.

You can test the element by heating it. You need a suitable container. It could be a glass or a teapot. Hot water is poured into it. The water should be heated to approximately 100 degrees - the heating should be monitored with a thermometer. Next, the working part of the device is lowered into water. However, it is precisely the part of the temperature sensor that is located in the motor that needs to be lowered. Contacts must not be in water. Then a multimeter is connected to the contacts and the resistance is measured.

A working sensor at a liquid temperature of 100 degrees has a resistance of 177 ohms. At +50 degrees the resistance is 973 Ohms. If the values do not correspond to the norm, then the faulty element should be replaced. If the indicators are within these norms, then everything is in perfect order.

Air flow control

The location of the mass air flow sensor (MAF) is on the air duct running from the filter to the throttle valve. The device consists of 3 elements located inside the air flow. The first one measures the temperature of the incoming stream, and the other 2 heat up to a certain degree. The stronger the flow passing through the air sensors of the VAZ-2110, the more intensely they are cooled. The controller that supplies the voltage determines the air flow by the energy spent on heating the 2 elements in relation to the temperature of the first meter.

There is another design of the MAF device with a silicon mesh and two elements; it operates on the same principle. The marking of the first type is 2112-1130010, the second - 21083-1130010. Receiving signals from these devices, the processor makes a calculation and changes the duration of fuel injection for the VAZ-2110. The following signs indicate a sensor failure:

- the engine stalls when switching from high speed to idle;

- unstable operation at idle;

- difficulties arise when starting the engine;

- increased fuel consumption.

Replacing the mass air flow sensor control device is not difficult; you need to disconnect the wires, remove the old sensor from the air duct and install a new one.

Air regulator

Having determined the amount of air, the system determines the required volume of gasoline. The air sensor is responsible for the suction volumes. The disadvantages of this device include:

- Due to exposure to moisture, performance is impaired;

- At low speeds, the sensor produces increased readings;

- The device cannot operate normally when idling;

- Problems may arise when starting the engine;

- After increased power mode, the engine may stop abruptly;

- Fuel consumption increases.

How does this sensor work? Let's try to figure it out.

- The regulator design includes three sensitive components that are installed in the air flow. One of the elements determines the temperature of the intake air, and the other two heat up to the required levels.

- Air flow is determined by measuring the power of electricity to maintain the required temperature.

- The regulator has a mesh that is mounted in the air flow.

- All this allows you to transfer information to controllers, which, in turn, enable certain modes to change or maintain loads.

Determining the position of the crankshaft

The task of this element is to determine the location of the pistons, along which the controller produces a spark in one or another cylinder. On VAZ-2110 cars, the 8-valve injector and subsequent models, the sensor is located near the crankshaft toothed pulley. In earlier dozens with a carburetor, the devices could be located inside a mechanical ignition distributor. Then they were called Hall sensors and controlled the position of the pistons by rotating the camshaft.

The device is a magnet with a small coil that generates electrical impulses when a metal mass approaches, the role of which is played by the teeth of a pulley.

The magnetic Hall meter of the VAZ-2110 is the most important element in engine operation, and if the sensor fails, the engine will not even start.

Fortunately, the device is very reliable and operates for a long time. Replacement is simple and does not require a description.

Sensors are invaluable helpers

VAZ 2110 injector crankshaft sensor

As mentioned above, the electronic system would not cope with all the assigned tasks if it were not for the sensors. They are the ones who transmit to the main unit the information necessary for the entire injector system.

Air regulator

VAZ 2110 injector temperature sensor

In order to find out how much fuel needs to be supplied to the ECM engine, you need to know how much air enters it, because these two elements are interconnected. The amount of gasoline is determined from the amount of air. And the air sensor is usually responsible for determining the amount of air, which measures the amount of air sucked in by the engine in kg/h. The main disadvantages of the mass flow sensor:

- Moisture that comes with the air (it interferes with normal functioning);

- Overestimation of readings, which occurs in most cases at low speeds (as a rule, overestimation does not cross the line of 10-20 percent);

VAZ 2110 injector fuel sensor

- Uneven operation of the vehicle unit at idle;

- Problems starting the engine;

- Unexpected engine stop after power mode;

- Increased fuel consumption, etc.

Operating principle of the air regulator:

- This type of regulator has 3 sensitive elements in its design. They are installed in the intake air flow and one of the elements determines the air temperature, and the other 2 are heated to the set temperatures.

- Air flow is determined by measuring the power of electricity that maintains set temperatures.

- The air regulator is also equipped with a special mesh, which is also installed in the intake air flow.

VAZ 2110 injector idle speed sensor

Thus, the data from the regulator is sent to the controller, which already uses its own data and tables corresponding to the mass fuel consumption signal.

Fan switch sensor

VAZ 2110 fuel level sensor injector

This sensor is designed to turn on the fan that cools the engine of the VAZ 2110 car. It has its advantages:

- Ultra-reliability, which is ensured by a solid filler that expands when the temperature rises;

- The fan activation sensor is equipped with a spring-loaded lever, which completely eliminates various defects;

- The regulator eliminates the formation of sparks that can occur as a result of instantaneous connection of contacts;

- The reliable design of the sensor (if you buy a high-quality one) allows you to increase the service life for many years).

VAZ 2110 injector fault sensors

The principle of operation of this sensor is not only that it allows the fan to turn on faster. This control allows the fan to operate even when driving at speed.

Crankshaft sensor

This sensor is the main one and its readings determine the timing of spark and fuel supply. The part is a piece of magnet with a coil of thin wire. Advantages:

- Hardy;

- Works in tandem with the crankshaft pulley;

- When it fails, the engine stops or limits the speed to 3500 rpm.

The regulator is installed on the oil pump housing and is located at a distance of 1 mm from the top of the pulley teeth.

Coolant temperature sensor

VAZ 2110 injector temperature sensors

- Loss of electrical contact inside the regulator itself;

- Violation of the insulation of wires located near the accelerator cable;

- The sensor may fail if the fan turns on when the engine is cold;

- It may be difficult to start a hot engine;

- Increased fuel consumption is possible if the sensor fails.

Speed sensor

Provides information to the controller regarding vehicle speed. Reliable, although not as reliable as other regulators. Main faults:

- If this sensor fails, driving characteristics may deteriorate, although only slightly;

- The engine may stall at idle.

Phase sensor

This sensor is installed only on VAZ 2110 engines with 16 valves. The information provided by this sensor is used to organize fuel injection into a specific cylinder. A malfunction of the sensor can lead to only one problem: fuel output switches to pairwise-parallel mode, and this leads to a sharp enrichment of the fuel mixture. The information above does not apply to all sensors. In addition, if the sensors fail, you will need step-by-step instructions for replacing them. When installing the desired sensor with your own hands, it is recommended to use photo and video materials. The price of sensors in stores is not high and anyone can buy them.

Other control devices

The remaining sensors are also connected to the controller and perform important functions. Failure of any of them leads to an increase in fuel consumption, loss of acceleration dynamics or unstable operation of the power unit. Here is their list:

- throttle position detector;

- knock sensor;

- speed meter;

- oxygen sensor;

- phase detector.

The element that determines the angle of rotation of the throttle valve is installed on its body and is directly connected to the axis. The task is to facilitate the supply of excess fuel to the cylinders when the accelerator pedal is pressed sharply. The principle of operation is similar to the accelerator pump in a carburetor, only of the electronic type. The device often fails, especially after washing the engine.

The knock sensor located on the front side of the cylinder block functions much more reliably. Unlike other devices, it generates a signal independently, acting on the principle of a piezoelectric element. The stronger the detonation flashes in the cylinders, the more voltage is supplied to the controller, and it regulates the ignition angle, trying to extinguish detonation. If necessary, change with a wrench.

The oxygen sensor (otherwise known as a lambda probe) monitors the content of free oxygen in the exhaust gases, indicating that the fuel mixture is enriched or lean. Participates in the formation of this mixture and is very reliable in operation. It is afraid of leaded fuel and quickly breaks down when used. It is located in the first part of the exhaust tract, at the convergence of the exhaust manifolds.

The speed meter also works on the principle of a Hall sensor and takes readings from the speedometer drive shaft located near the gearbox. The task is to transmit information about the speed of the car to the processor.

Additional information about the operation of the timing belt is transmitted to the controller by a device that determines the phases. It is installed on VAZ-2112 cars with 16 valves in the upper part of the cylinder head. This device tells you when the fuel valves are opening by monitoring the position of the intake camshaft. This helps to synchronize the complex process of gas distribution and injection of the fuel mixture at the right time.

Phase sensor

As for this regulator, it is only present on a car with 16 valves. Its task is to provide information that will allow you to understand where and when to inject fuel into which cylinder.

Installation location

If the sensor fails, nothing particularly terrible will happen from the point of view of the integrity of the car. But fuel consumption will increase sharply.

We have not touched on all the signs, but we will try to talk about many of them in our special materials.

To understand how to repair your VAZ 2110, we recommend that you first study the operating manual in detail. It says about all the sensors, their tasks, location and, of course, replacement methods. Often, car owners ignore the manufacturer’s recommendations, although it is he who knows better than others how to perform this or that type of repair, preventive maintenance, and how to get to a certain unit, the same sensor, with minimal effort.

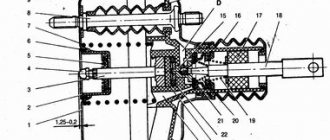

Connection schemes

In VAZ 2110 injection and carburetor engines, the TM-108 bimetallic temperature sensor is used in different ways to control turning the fan motor on and off.

For carburetor engines it is located on the radiator on the left in the direction of travel. When the threaded part located directly in the coolant is heated, the bimetallic plate bends and closes the contacts. The voltage from the battery is supplied through a fuse to one contact of the electric motor, the second, when the sensor is triggered, is connected to the housing, setting the impeller in motion.

For VAZ 2110 and TM-108 injectors, it is located near the thermostat, the signal is sent to the electronic control unit (ECU). The control signal from the ECU is sent to the cooling system fan relay, which, similar to the sensor of a carburetor engine, controls the electric motor.

Injection fan switch sensor

All engines have another device in the cylinder block, the signal of which is used to indicate the coolant temperature on the panel in the cabin.

Before independently repairing the fan switch sensor, it is recommended to understand in detail the design of the cooling system: https://vazweb.ru/desyatka/dvigatel/sistema-ohlazhdeniya-dvigatelya.html

Examination

An integral part of the process of installing/dismantling the coolant temperature sensor is checking its performance indicators. To achieve this goal, it is necessary to use some additional devices and tools:

- Ohmmeter device. Some drivers call it a multimeter.

- Temperature sensor with readings over 100 degrees Celsius (thermometer, thermometer, etc.).

- A container or container that is not subject to thermal activity with a volume of 0.6 liters.

Some drivers often confuse the coolant temperature sensor with the coolant temperature gauge sensor. You should be extremely careful here. The ohmmeter has two output wires with terminals. They should be installed on the sensor body and to the sensor output connector. The main indicators of device health are the following parameters:

- Temperature (measured in degrees Celsius).

- Sensor resistance (measured in Ohms).

Temperature readings must correspond to those of the ohmmeter. First, you should clarify the temperature indicators:

- 30 degrees Celsius.

- 50 degrees Celsius.

- 70 degrees Celsius.

- 90 degrees Celsius.

- 110 degrees Celsius.

This data must correspond to the following indicators of the multimeter device:

- 1350 – 1880 Ohm.

- 585 – 820 Ohm.

- 280 – 390 Ohm.

- 155 – 196 Ohm.

- 87 – 109 Ohm.

The fan does not turn on

There may be several reasons for this:

- Fuse. In the mounting block, fuse F7, rated 20 amperes, may be faulty - it is responsible for powering the electric fan and sound signal circuits;

- Thermostat. The liquid circulates only in a small circle, the radiator and sensor do not heat up, and accordingly, the fan does not turn on. You can check by simply probing the pipes; those connecting to the radiator should begin to warm up after opening the thermostat;

- Sensor. For a VAZ 2110 with a carburetor, the contacts are closed for testing; if the device malfunctions, the electric fan will turn on. The connector of the injection motor must be disconnected; with the remaining elements working, the ECU will detect a break in the circuit and issue a constant alarm signal to the relay, which will forcibly turn on the electric motor for cooling;

- Cooling system fan relay for VAZ 2110 injection engines. The sensor is turned off and the power contacts on the relay located in the additional fuse box are closed. If everything works, then we check the control winding: on one contact there is always a positive from the main relay, connecting the second to the body, we try to hear the operation click. But it’s better to simply replace the relay for testing, temporarily, with a known good one;

- Electric motor. During testing, the connector is disconnected; to force the impeller to turn on, voltage is supplied directly from the battery.

If all the elements are working properly, then you need to look for a break in the wires, “ringing” them one by one. Poor contact of the relay and sensor connection wire terminals with the car body is also possible. The worst case scenario would be an ECU failure, in which case the signal from “leg” 46 usually “floats” and does not reach the values of +12 volts (off) and 0 (on).

An article devoted to independent modification of the thermostat and its replacement is here: https://vazweb.ru/desyatka/ohlazhdenie/dorabotka-termostata.html

Some secrets you need to know

After completing these procedures, it is necessary to increase the coolant level to the maximum. This indicator should not be reduced or exceeded. The full and high-quality operation of the sensors and the entire vehicle depends on the exact fluid level. Knowledge of the main faults of the sensor can be very useful for its repair or replacement. If this device malfunctions, the vehicle may experience a so-called cold steering problem.

Note. If problems occur in this part of the car, fuel consumption may increase, which is extremely undesirable in normal operation of the vehicle.

Often, malfunction problems occur due to a breakdown of the sensor itself. The cause of its malfunction may be the electrical wiring of the car. One of the successful conditions for using the sensor is constant monitoring of the condition of the vehicle wiring. Sensors indicate engine operation, fuel emissions, and fuel economy. In case of problems with sensor fixation (thermostat failure), the sensor may produce too low a temperature. If the thermostat is removed or malfunctions, the sensor and motor will output the minimum temperature. A low temperature level will lead to deviations from the normal operation of the engine. This video instruction will help you do everything correctly.

During the work, it is also recommended to use photographic materials and other visual aids: maps, diagrams, etc. Replacing the sensor with your own hands is easy and simple, and the instructions presented above will help you avoid making mistakes. The price for replacing the sensor in car repair shops from specialists is high, and why should it if you can do everything yourself?

Controlling the coolant temperature is the most important condition for the normal operation of the vehicle’s power unit. This control is carried out by a coolant temperature sensor (CTS). And if such a sensor fails, malfunctions and malfunctions occur in the engine. In this article, we will look at the typical symptoms of a faulty coolant temperature sensor, and also tell you how to check and replace it.

DTOZH on VAZ-2114

First of all, it must be said that in addition to the coolant temperature sensor, there is a coolant temperature indicator sensor and these are two devices with different purposes. If the first one provides information to the electronic engine control unit, then the second one simply informs the driver about the temperature of the working fluid in the cooling system. Accordingly, the failure of the first sensor is a more serious problem.

According to its design, DTOZH is a thermistor. In other words, the sensor is designed in such a way that when the ambient temperature changes, its resistance to electric current changes. It is these changes that are recorded by the car’s electronics and based on them certain commands are issued. Accordingly, incorrect information received from the DTOZ or its absence at all disrupts the normal operating algorithms of the engine and the entire vehicle system.

Let's look at the main symptoms of a malfunctioning coolant temperature sensor:

- drop in speed or even spontaneous engine stop at idle;

- long-term warming up of the car;

- frequent engine exceeding the optimal temperature range;

- increased fuel consumption;

- reduction in overall vehicle controllability;

- dark smoke from the exhaust pipe;

- disturbances in the stable operation of the motor;

As you can see, the list of problems that arise from a failure of the coolant temperature sensor is quite extensive. Therefore, it is strictly not recommended to neglect this problem.