Creating a fuel reserve is not a necessary and regular procedure, but sometimes it helps out in difficult and dead-end situations. Gasoline is necessary for the movement of vehicles and its absence when traveling on a long journey or to an area where there are no gas stations will create certain difficulties for the driver and passengers.

The various photos of gasoline cans presented in this article will help you visually evaluate the wealth of choice of such car accessories.

There are a number of mandatory rules and recommendations; they must be taken into account when choosing a spacious and inexpensive container that may be useful to the car owner.

How to choose the right canister for your car

When choosing the best solution for where to buy a gasoline canister, you need to decide on a set of factors that will help you choose the right accessory.

Depending on your own preferences and the future intended use of the container, it is important to take into account a whole set of technical and operational features:

- material of manufacture and shape of the gasoline canister;

- volume or capacity, capacity of a car accessory;

- the presence of additional structural elements;

- functional manism and the method of closing the neck;

- the size and width of the neck for filling and draining liquid.

Experienced car owners know that it is often necessary to have several cans in the garage at once, differing in type, volume and purpose.

If gasoline for a car, a motor boat engine or other equipment, a chainsaw or a lawn mower is stored in one container, then a separate canister contains gasoline already mixed with oil.

Gasoline cans: separation by material

A standard 10-liter gasoline can can be made from a variety of materials; most often, manufacturers use metal or plastic.

Metal and alloy containers are designed for long-term storage of gasoline, and it is important to remember that according to current legislation, gas stations do not dispense fuel in plastic containers.

Photo: igraite-vmeste.livejournal.com

In everyday life, we rarely think about the structure of the things we use every day. So, for example, when choosing batteries in a store, a rare buyer will find out the energy intensity, the vector of the discharge curve and the temperature range of use of the “power element”, limiting himself to determining the required size. For the buyer, it practically does not matter that next to the battery he chose there was a similar one that cost 10% more, but in the end would have served him 50% longer. But if at the everyday level selection errors pass almost without a trace, then on the scale of an industrial enterprise the risks increase thousands, or even millions of times.

Purchasing employees often take into account only the obvious characteristics of a product, giving preference to companies that offer the lowest prices and favorable delivery conditions. However, in order to really save money, you need to approach the issue of choice more carefully. Thus, when purchasing plastic containers, buyers pay attention only to the appearance, capacity and price, missing the most important physical and chemical characteristics of the products. This article will help you not make a mistake when choosing a supplier of plastic containers, indicating the key points that you need to pay special attention to, and will also demonstrate, using examples of plastic canisters, how to recognize really good containers.

The production of rigid polyethylene containers is a complex, high-tech process, and in many ways it contains the nuances that you need to understand in order to choose high-quality containers that are optimal for your company.

The quality of the final product is influenced by three key factors: raw materials, production technology and equipment used.

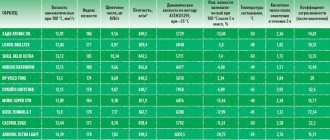

If we talk about raw materials, the following types of polyethylene are mainly used for the production of canisters: HDPE 276-73 (and its analogues), HDPE 273-83, and HDPE PE 3 OT 49. In order not to rely solely on words, we present the main technical characteristics of these types of raw materials.

The table is clickable.

As can be seen from the table, polyethylene under the brand name HDPE 273-83 has incomparably greater chemical resistance, and also significantly exceeds HDPE 276-73 in strength characteristics. PE 3 OT 49 also has a low cracking resistance, which indicates the low chemical resistance of products made from this brand of HDPE. And although you will not always be able to distinguish by appearance what raw materials this or that canister is made from, you should pay attention to the texture of the surface and the elasticity of the walls of the canister when pressed. Containers made from HDPE 273-83 polyethylene have a matte surface and more elastic walls. In any case, you need to ask the manager of the selling company a question about the raw materials used.

Now let’s describe the production process itself in more detail. Canisters, like many other types of polyethylene containers, are made using extrusion blow molding. Schematically, this process can be divided into the following stages:

1. homogenization of the melt; 2. molding of a sleeve blank; 3. closing the mold, inflating the workpiece in the mold and molding the product; 4. cooling the product and removing it from the mold; 5. final processing of the finished product.

Let's start with the first point. Homogenization of the melt, that is, the process of obtaining a homogeneous material for subsequent molding of a tubular blank, occurs in an extruder operating on the principle of a “meat grinder”, along the perimeter of which heating elements are located that melt polyethylene granules to a viscous-flowing state.

This stage is of great importance for the quality of the final product. Disadvantages of the extruder, which lead to the production of a material that is non-uniform in temperature or density, affect the operation of the entire blow molding machine as a whole and manifest themselves in the form of shrinkage (seals and irregularities) on the surface of the canisters, which negatively affects their strength characteristics.

At the moment, in terms of technology, German companies are recognized leaders in the production of extruders, whose products ensure consistently high quality of material preparation. Many Russian manufacturers of polyethylene containers use cheap equipment made in Asian countries, but in this case there is no talk of quality stability.

At the next stage, special attention should be paid to the process of forming the tubular blank, since it is here that the use of innovative technologies has a positive effect on the quality of the finished product.

The distribution of raw materials according to the shape of the tubular blank determines the strength characteristics of the finished product. The most vulnerable places of canisters are the ribs and corners (because when they fall, they receive the main impact force), as well as, due to technological features, the mold closure zones.

However, if you extrude a tubular blank with the same wall thickness along the entire perimeter and length, then it is in these areas that the canister wall thickness will be minimal. This is due to the fact that when blown, the workpiece in these places will stretch much more than on the walls, since these points in the mold are farthest from the surface of the tube workpiece.

Manufacturers of polyethylene containers are trying to combat this phenomenon using various methods. World experience has shown that the most effective way is to use a 3-level wall thickness control system:

1. WDS – system for dynamic distribution of raw materials along the height of the workpiece. This system allows for optimal distribution of raw materials over the entire height of the product, preventing a decrease in the wall thickness at the corners of the canister due to changes in the distribution of raw materials along the length of the workpiece.

2. SFDR – static radial distribution system of raw materials. Thanks to the use of the SFDR system, it is possible to flexibly adjust the wall thickness around the circumference of the workpiece, which allows you to evenly distribute the raw material along the entire perimeter of the canister, including in the weakest places - the ribs of the product.

3. PWDS – dynamic radial distribution system of raw materials. The PWDS system dynamically optimizes the distribution of raw materials across the workpiece shape to direct it to problem areas through the use of computerized hydraulic systems that allow the shape of the stock to be changed during the preparation of the workpiece. The use of this system solves the problem of violating the integrity of the bottom and near-neck parts of the canister in the area where the mold closes when dropped.

It is the use of all three control systems in combination that makes it possible to achieve the best strength characteristics of canisters.

The main disadvantage of the 3-level wall thickness control system is its cost. In Russia, only a few companies producing polymer containers can afford to install such systems. The vast majority are limited to purchasing equipment equipped only with the WDS system, and as a substitute for SFDR they use a profiled mandrel, which also allows strengthening the ribs of the product. However, in this case, the tuner does not have the ability to quickly fine-tune the parameters, and therefore has to put up with some flaws that appear during the production process, such as various deviations of the wall thickness from the specified value.

“Indeed, the introduction of these systems into the production process requires significant investments,” says Hamlet Maratovich Oganesyan, General Director of the Container Products Plant CJSC, “however, global trends in the development of the polymer packaging market tell us about the need to integrate these innovative developments into production, since customers are all They attach greater importance to the quality of purchased packaging, realizing that packaging not only preserves the product, but also carries an image component. Our plant was one of the first in Russia to acquire equipment equipped with these systems. Both we and our clients appreciated the effectiveness of this equipment from our own experience. In addition, following the latest trends, our production has installed Delta Engineering and Steffes automated quality control systems for canisters, which allow us to check the tightness, weight and presence of defects of each product coming off the conveyor. This gives our customers confidence in the quality of purchased containers produced at the Container Products Plant.”

After the hose blank is formed, the mold closes and air begins to flow through a special hole. At this stage, the clamping force of the mold (which affects the quality of the canister in the seam area), the temperature of the workpiece, and the air pressure are important. With increasing pressure, the surface quality of the canisters improves and warping decreases, which ultimately affects both the presentation and their performance properties. Incorrect setting of parameters or the use of low-quality equipment is easily determined by the appearance of the finished product: the presence of sink marks, non-uniform surface of the canisters, various deformations.

The cooling stage begins from the moment the workpiece comes into contact with the surface of the cooled mold and ends after the thickest parts of the canisters adjacent to the neck have cooled. Premature removal of products is accompanied by softening of the areas adjacent to the neck and their irreversible deformation. And since the cooling process takes from 50% to 75% of the molding cycle time, many manufacturers neglect minor deformations, increasing the productivity of their equipment, but this negatively affects the quality of the canisters.

After cooling, the mold opens and the finished product is sent for final processing (removal of excess material, deburring, etc.). But even such a seemingly simple operation does not go smoothly for all manufacturers of industrial packaging. Often on sale you can find products packaged in canisters that have pronounced sharp edges and burrs in the seam area. There is a good chance that a customer will cut their hand on such a sharp edge, and this will almost certainly mean that they have purchased your product for the last time.

So, to summarize all of the above, we will describe what needs to be done to avoid making a mistake when choosing a supplier of plastic containers.

At the preliminary preparation stage, check with the manager on what equipment and from what raw materials the canisters and their components are made. Although this information is difficult to verify, the answers to these questions will go a long way in demonstrating the manager's competence.

When the preliminary selection is completed and product samples have been delivered to you, you can begin express analysis of the quality of the canisters. At first glance, they all look about the same, but it’s worth taking a closer look at them and examining them for flaws.

Disadvantages : Presence of tension marks on the body of the canisters. Possible reasons : Uneven heating of the material during the formation of the tubular blank; use of low-quality raw materials; incorrect equipment settings. Consequences for your company : Increased risk of canister cracking; damage and deformation of canisters during stacking; difficulties in the process of gluing labels to canisters, as well as the subsequent preservation of the presentation of the label.

Disadvantages : Presence of tension marks on the body of the canisters. Possible reasons : Unreasonably shortened cooling cycle; incorrect equipment settings; crooked neck or oval neck. Consequences for your company : Difficulties when using an automated line for packaging products; leaks caused by the lid not fitting tightly to the edge of the canister neck; increased risk of cracks in the throat area when falling; deterioration of presentation.

Disadvantages : Strong unpleasant chemical smell from the neck. Possible reasons : Use of low-quality raw materials. Consequences for your company : Impossibility of storing food products, as well as highly pure substances due to the appearance of foreign impurities.

Disadvantages : When examining the inner surface of the canister through the neck or cutting the canister, significant changes in wall thickness (variation in thickness) are visible. Possible reasons : Asian equipment; poor homogenization of the material; incorrect setting or lack of wall thickness control systems. Consequences for your company : Deterioration of the physical and chemical properties of the container; increased risk of depressurization due to impacts and falls; the occurrence of deformations and cracks during stacking; deterioration of presentation.

Disadvantages : Sharp edges and burrs around the seam and filler neck. Possible reasons : Reducing the final processing stage of the finished product to the detriment of quality; manual flash removal; poor-quality equipment or its untimely maintenance. Consequences for your company : Loss of presentation; increasing the likelihood of minor injuries both during manual packaging and transportation by enterprise employees and customers when operating canisters with your products.

Disadvantages : Uneven surface of the canisters. Possible reasons : Poor homogenization of the material; use of recycled materials; improper cooling. Consequences for your company : Deterioration of the physical and chemical properties of the container; increased risk of depressurization due to impacts and falls; deterioration of presentation; complete or partial peeling off of the label.

Disadvantages : When completely tightening and then unscrewing the lid, the control ring did not come off the lid. Possible reasons : Poor design; incorrect temperature conditions; use of unsuitable raw materials. Consequences for your company : Possibility of unauthorized access to products.

Disadvantages : Presence of sagging and seals on the cover. Possible reasons : Poor design; incorrect temperature conditions; use of unsuitable raw materials. Consequences for your company : Difficulties in the automatic capping process; increased risk of container depressurization when dropped; deterioration of the presentation of the container.

Using these quality control methods will allow you to avoid obvious mistakes when choosing a supplier. Naturally, an inspection cannot replace full-fledged tests in a serious laboratory, but such tests are not always advisable.

Choosing quality packaging will allow you to:

- be confident in the safety of your product, packaged in containers whose quality is stable from delivery to delivery;

- ensure speed and convenience of loading and unloading operations, as well as reduce logistics costs;

- reduce warehouse costs for storing packaged products by stacking canisters in several tiers;

- ensure high-quality automated capping process;

- expand the sales market, ensuring high reliability and presentation of packaging during transportation over long distances, characteristic of the vast territory of Russia, and leveling significant temperature changes, regardless of the season of the year;

- emphasize the image of your company due to the good presentation of the packaging;

- minimize the number of canisters accidentally opened or cracked as a result of a fall;

- maintain or increase customer loyalty to your brand by relieving them of problems associated with the operation of canisters.

We hope that the tips given in this article will be useful to you and will help you choose a truly reliable supplier of quality packaging. Once again we thank the representatives of the Packaging Products Plant for the information provided and competent advice.

Plastic containers

For such products, elastic polyethylene and polypropylene are used, which are not capable of accumulating static stress, and products made from them differ in the following parameters:

- volume and capacity of liquid of any density;

- shape in the form of a cube or parallelepiped, barrel and cone;

- the presence of a handle at the top of the structure or on the side;

- color and density of the product, resistance to impact;

- screw cap and neck in different sizes.

An inexpensive and practical plastic canister for gasoline is in the arsenal of every car owner and differs in the material it is made from.

Aluminum canisters

Lightweight and fairly durable products are actively used by domestic car owners for storing and transporting fuel materials:

- different volumes and rectangular shape for storing the required amount of gasoline;

- maximum level of internal pressure while maintaining the tightness of the container;

- established indicator of pressure on the handle and neck size, method of transportation;

- the presence of an air bag or its absence in the internal cavity of the container and its body;

- outer coating made of enamel, using polishing or matte agents;

- The neck is closed using a threaded and lapping plug and a lever clamp.

Such accessories have a classic rectangular shape, are not subject to corrosion and must be completely recycled after use.

Stainless steel canisters

A reliable and wear-resistant metal canister for gasoline is characterized by increased oxidation resistance and other properties:

- have a horizontal or vertical design;

- withstand internal burst pressure up to 0.2 MPa;

- the design includes a tank with a neck, a handle and a threaded plug;

- are produced in different volumes and differ in fire resistance;

- look aesthetically pleasing due to the glossy surface of the canister;

- frost-resistant and not subject to physical impact.

Quite expensive and heavy containers are not very popular among car owners, but they guarantee maximum safety when transporting gasoline.

Additional accessories

Some types of canisters are offered with accessories that are designed to make them easier for the car owner to use. First of all, this concerns sand-truck type containers from manufacturers such as GKA or SamaraTara. The set of accessories includes various fasteners and clamps, as well as taps and caps for pouring the contents of canisters into the gas tank.

Fastenings and clamps allow the use of sand-truck type canisters on extreme trips. The containers are attached to the spare wheel, trunk, roof rails, cross members or to the rear side windows. The cost of such accessories is quite high and comparable to the price of the container itself. An alternative option would be to make fasteners or clamps from scrap materials, but the reliability of such options raises questions.

Clamps for transporting canisters of the classic vertical type are also produced. Such fastenings increase the stability of containers in the trunk of a car and prevent possible gasoline leakage as a result of the container tipping over.

In any case, external transportation of forwarding canisters on the body of a car will lead to them quickly breaking down. A few trips will be enough for the containers to lose their shape due to exposure to the sun and temperature factors. So the feasibility of such transportation of expedition canisters remains a debatable issue - a more reliable and durable option remains transporting the canister in the trunk of a car.

Design features of different containers

When choosing containers for personal use, it is recommended to take into account the following design features of the proposed containers, which will simplify the process of selecting a product:

- canisters with a watering can for easy transfer of flammable materials;

- canisters on wheels, which is convenient for loading and moving containers;

- wide and narrow neck, suitable for different filling methods.

Brush with scraper - how to choose the best models and what a brush with scraper should be like (85 photos + video)

Spare wheel cover - how to choose and make it yourself. 135 photos of the best models of 2020

Tie-downs for securing cargo: features of choice and tips on how to use a tie-down strap with a ratchet mechanism (110 photos)

A 20-liter gasoline canister with an average capacity can be made of a variety of materials.

Historical reference

Production of the current 20 liter metal canister began in Germany in 1936.

Let's first talk about the origin of the canister (it comes from a German word).

Production of the current 20-liter metal canister began in Germany in 1936, when the German army announced a competition for the latest model, and it was intended for storing and transporting fuel.

This canister replaced outdated models and equipped the army with universal canisters for transporting gasoline.

Over time, such containers have undergone many transformations, and today not only metal 20-liter canisters are produced in the world, but also modern analogues have been developed and are being created - plastic and PET canisters.

Plastic and PET canisters are modern, efficient and popular products.

Let us dwell separately on each type of canister and analyze their characteristics, properties and scope of application.