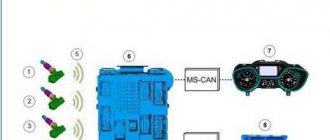

TPMS system using the example of an Emgrand car

The luxury version of the Emgrand has such a system; it includes a control unit and wheel sensors. There are two warning lights on the instrument panel: the TPMS fault light and the pressure reduction light.

In addition to pressure, the sensors also measure the temperature of the air in the tire, as well as acceleration. Data transmission to the system control unit occurs at a radio frequency of 433 MHz.

Pulse signals are used to transmit information, that is, sensors do not transmit data constantly, but at certain intervals and in short pulses. Thanks to this transmission scheme, the battery in the sensor can last for several years.

TPMS pressure monitoring systems can be of two types: direct and indirect control. The direct monitoring TPMS determines the actual tire pressure, while the indirect monitoring system calculates the possible pressure based on certain technical parameters.

The direct control system can accurately determine the pressure and temperature. the direct control scheme, in turn, has two varieties: high-class systems and low-class systems. A low-class system warns the driver when the tire pressure drops below a dangerous level, and a high-class system can not only warn, but also inform which wheel the pressure has dropped.

The Gili Emgrand is equipped with a low-grade direct control TPMS manufactured by Lier Company. The high-end system is found in the Haima 7 crossover with automatic transmission.

Classes, types and types of sensors

The catalog of available universal tire pressure checking systems is presented quite widely. They are divided according to two main characteristics. The first is the installation method.

- External TPMS, also known as Direct System. The controllers resemble ordinary “caps” that are screwed onto the nipple in 10 seconds. Their big advantage is ease of installation and low weight (9.6–10 g). The first makes it possible to use the system without beading/beading tires. Secondly, there is no need to balance the wheels.

- Embedded devices (Indirect). Such a device can only be mounted with flange and flange, since the controller is attached to the slope of the wheel rim using special clamps. They weigh more than external controllers, so after installation they will require an additional action - balancing.

Based on the completeness of the information displayed, systems are divided into high and low classes. In the second case, only an alarm signal is displayed on the monitor (or smartphone/tablet display), and the source of the problem is not indicated. High-end models, in addition to danger signals, can also show the level of air pressure and the damaged wheel, which greatly simplifies the driver’s actions.

Developers of these technologies separately offer TPMS for trucks, motorcycles, and cars. There are also universal options (which are suitable for all cars) and individual ones for a given car model.

This is interesting: Choosing a mirror DVR

Tire pressure monitoring system

The control control unit is activated when the ignition is turned on. The unit continuously checks the wireless signals from the TPMS sensors.

The TPMS receiver can store sensor ID codes (an identification code unique to each sensor). When receiving a signal, the TPMS receiver checks whether the received ID code matches the code stored in the control unit. If the codes match, the receiver transmits the information for processing using the TPMS alarm algorithm.

This algorithm evaluates changes in tire pressure and temperature changes over a given period of time and decides whether there is a potential danger caused by low tire pressure and then notifies the driver by turning on the tire pressure warning light.

In addition to processing sensor signals, the control unit can also conduct self-diagnosis of its circuits and operating status. If a malfunction is detected, the control unit turns on a warning light to warn the driver.

How to connect sensors

A branded TPMS system kit usually consists of:

- From controllers with signatures for each wheel (the number depends on the class of car, usually the set includes four caps for passenger vehicles and six if it is a tire pressure monitoring system for trucks). A signature of two Latin letters, where the first determines the horizontal position, the second vertical. Example: LF – left (left) front (front).

- Instructions.

- Transceiver with 1-5 buttons on the sides to indicate pressure standards. There is double-sided tape on the back of the receiver mount for easy installation. This device is held securely, you can safely mount it on glass or panels.

- A set of keys for disassembling controllers or receiver.

- Connection adapter (provided for wired devices).

- Spare parts (stickers, gaskets).

This is interesting: How to use the ELM327 auto scanner

The installation method depends on the type of device. External controllers can be installed independently by simply replacing the “original” air tube caps on the wheels. Here it is worth paying attention to the metal thread of the controller. It can be aluminum or brass. It is important that it coincides with the nipple’s own thread to avoid oxidation.

Internal TPMS is installed at tire service stations. The procedure is short and hassle-free, but it will protect the expensive tire pressure monitoring system from simple theft.

Types of tire pressure sensors, their design and operating principle

Air pressure sensors have different functionality and complexity depending on the method of their manufacture and installation.

Based on the principle of operation, there are 2 types of wheel pressure sensors - mechanical and electronic.

Mechanical sensor

It is a small transparent cap that screws directly onto the nipple. Inside this miniature device is a valve that measures the air density inside the chamber. Three light indicators (red, yellow and green) indicate the status of the air pressure in the wheel (the air in the tire squeezes the desired color strip into the transparent cap). A yellow indicator appears - the wheel needs to be checked, there is probably something wrong with the tire, a red indicator - urgently need to be pumped up.

This is interesting: How to test a car battery with a multimeter

The advantages of mechanical sensors include low cost, attractive appearance, clarity (no need to run around the car with a pressure gauge), convenience - the condition of the wheel can be assessed immediately, in any weather.

Disadvantages: relatively low accuracy of indicators and lack of protection against thieves. In addition, the condition of the wheel can only be assessed using this device while the vehicle is at rest. It will be absolutely useless while moving.

Another thing is more complex wireless electronic sensors.

Electronic sensors

Can be installed on wheel caps or inside the air duct. They transmit the measurement results to a special display installed on the car’s dashboard or on the car owner’s key fob. Such a system, in addition to the amount of air pressure, additionally informs about the speed of the wheel, the heating temperature of the tire rubber, and especially gifted modern devices are able to transmit information directly to the screen of the owner’s mobile device.

By the way, this feature indirectly helps to monitor the condition of the wheel bearings and brake system. If problems arise with these components of the car (for example, a wheel gets stuck), the wheel rim heats up, which entails an increase in the temperature inside the tire. The sensor will “see” this and warn the owner in time, who can only think about the reasons for the sharp increase in temperature.

The electronic pressure monitoring system consists of 4 components - the sensor itself, the antenna, control and power units. If 4 individual antennas are installed, it will be immediately clear which wheel is damaged.

The undoubted advantages of electronic sensors are the ability to monitor the condition of all 4 wheels while driving, in real time and high accuracy (up to 0.1 atm). The main disadvantage is the cost. Not every car enthusiast is ready to fork out a fairly large sum.

It should be added that a system with external sensors is less vandal-resistant, but costs less. A system with external ones is the most expensive, but the most accurate and least likely to be stolen.

This is interesting: Toyota Corolla car review: technical specifications, configurations and prices for 2020

Modern automakers have introduced a system for monitoring intra-wheel pressure via ABS. If the wheel “goes flat”, the height of the tire profile changes, the rotation speed of the wheel increases, the system sees these changes and signals about them.

What is the optimal tire pressure to maintain?

Each brand of car has its own optimal value of air pressure inside the wheel, established by the manufacturer. Usually it is indicated either on a plate on the gas tank flap, or in the driver's door opening - on the side pillar.

But, unfortunately, these indicators are often calculated in accordance with the parameters of foreign roads, which differ significantly from ours. Sometimes it makes sense to compromise with the surrounding reality and, for example, “lower” the wheels by 5-10% - depending on the condition of the road surface on which you most often move.

The pressure recommended by manufacturers, depending on the height of the rubber profile, usually ranges from 1.8 to 2.2 bar, while it can differ by about 0.2 units for the front and rear wheels.

System

The safety of the driver and passengers greatly depends on the wheels and tires installed in the car. Therefore, incorrect pressure in these parts can lead to serious consequences. However, technological development is now capable of creating devices that monitor the air pressure inside the tires, and if it falls, they can warn the driver.

Appearance of a monitor displaying pressure information

Statistics show that reducing tire inflation pressure by even ten percent leads to an increase in fuel consumption by five percent. In addition, the service life of the wheels is reduced by almost 35 percent. This only applies to the economic component, since you will have to spend more money on maintaining the vehicle. There are many more factors that relate to safety. Normal handling, acceleration and braking depend on tire pressure.

Important!

According to the rating of automobile accidents, which is compiled by the American agency responsible for road safety, 40 percent of accidents per year are caused by faulty wheels.

Tire pressure monitoring systems throughout their existence have been based on two methods of data measurement:

- With direct metering;

- With indirect measurement of information.

The tire pressure control system appeared in the automotive industry in the nineties and immediately gained popularity.

The development of electronics has made it possible to produce sensors of relatively small sizes, which have a special transmitting device. The general name of such devices is direct measurement systems.

Initially, development was carried out to create and produce so-called indirect devices. They work due to the fact that when the pressure level changes, the shape and diameter of the tires change. In this regard, the change in pressure can be measured based on the number of revolutions of the disks and the speed of the machine. The special ABS and ESP systems operate in the described manner, which are respectively responsible for preventing wheel locking and slipping. These systems operate using indirect sensing.

You may be interested in Continental summer tires

But this method of calculation was found to be inaccurate, since it does not measure the temperature level inside the products and wheel slip. In this regard, most electronics manufacturers for the automotive industry have switched to producing devices with a direct measurement method.

Appearance of the device for measuring tire pressure

Features of work

A device with a similar operating principle is called TPMS - tire pressure monitoring system or tire pressure monitoring system. Special sensors mounted in the wheel rim are used as a meter. They are used to measure temperature and pressure levels right at the place of work. Subsequently, these measurements are sent via a transmitter to the head unit and displayed on the display. A special transmission frequency is used, which does not affect the operation of the vehicle's electronic devices.

All devices are powered using standard batteries, so data is transmitted only when the vehicle is moving and only if the pressure in the wheels changes.

They exist as the most primitive devices, where information is transmitted using a sound signal and the lighting of a light bulb. Smarter systems are also common, where real-time data is displayed on a monitor and shows the pressure levels in each wheel.

The use of such systems in the automotive industry has given impetus to the development and production of more advanced devices by various global brands. and Goodyear collaborated to implement a system called Tire IQ. It is capable of not only measuring current data, but also indicating the distance that the vehicle can travel without changing a tire.

Note!

Many rubber manufacturers have begun to create and introduce special tires that can travel up to 150 kilometers even with a puncture or damage.

They are called Run Flat and can only be used in cars with a tire pressure monitoring system installed. This is due to the fact that the driver may not feel that the tire is punctured, so a device is needed that would notify him of the need to visit a tire service station.

The Nokian brand, which produces rubber, has developed a system called Road Snoop. In it, special sensors are built into the wheel rim, and the head unit with a monitor can be carried with you. The principle is that when the wheels are inflated to the required pressure level, this data is entered into the system memory and alerts the driver if the measurements change.

You may be interested in this About tires on Kia Optima