12.02.2019

The exhaust system of a car regularly experiences heavy loads, as it operates in difficult conditions: at high temperatures, in rain, snow and frost, and comes into contact with aggressive environments and exhaust gases. Therefore, vehicle owners are faced with situations where they need to quickly repair the muffler on their own. A popular means of rapid resuscitation is bandage tape.

Why do you need thermal tape for a muffler?

Tuning the exhaust gas exhaust tract, which allows you to increase engine efficiency, includes replacing the manifold (a so-called “spider” is installed), eliminating the catalytic converter, and installing new resonators. However, the changes also bring with them several problems.

- Instead of the expected bass hum or sporty roar, the sound turns into an annoying metallic ringing;

- The temperature in the engine compartment increases, creating a danger for the battery housing, wire insulation, and other parts made of polymers;

- The gases in the “spider” cool quickly and their removal is difficult;

- The absence of a catalyst worsens the content of harmful substances in the exhaust.

Thermal tape for the muffler is designed to combat these problems. Initially (in construction, from where motorists borrowed the technology), asbestos thermal tape was used for thermal insulation. This function remains the main one when used in the exhaust system of a car.

How to wrap it with your own hands

To wrap the tape yourself, you must follow the sequence:

- Prepare the surface thoroughly: clean, degrease and apply heat-resistant paint against rust.

- Select application method: dry or wet.

- For the wet method, immerse the tape in water for a couple of hours. With this method, the material will lie more densely and acquire additional stretch.

- Wind with an overlap of 10 mm. It is wrapped in two covers, three are allowed.

When repairing, only whole strips are used, since winding from several parts will reduce the efficiency of the process.

- Metal clamps or thick wire are used to secure the winding.

- It is recommended to also apply a layer of thermal paint to the installed material.

Thermal tape is used one-time, reuse is unacceptable.

We recommend watching the video instructions:

Collector thermal tape.

The most common wrapping is the exhaust manifold. The thermal insulation properties of the winding solve the main problems.

The heat exchange between the manifold and the surrounding (under-hood) space deteriorates, therefore:

- The temperature of the exhaust gases remains high, they occupy a larger volume, which speeds up and facilitates the removal.

- The heated gases ensure afterburning of fuel particles, resulting in a reduction in the concentration of harmful compounds in the exhaust (the removal of the catalyst from the system is compensated);

- Even at high exhaust gas temperatures (for example, in turbocharged gasoline units the value reaches 1600 degrees), additional heating of the engine compartment is prevented.

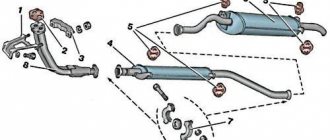

Methods for self-repairing a muffler (without welding)

The exhaust system of a car performs very important functions in reducing engine noise, reducing the temperature of gases escaping from the cylinders, as well as partially eliminating the smoke and toxicity of exhaust gases.

The malfunction of the elements of such a system cannot go unnoticed. The breakdown of the muffler is especially obvious. When depressurized, this element immediately loses the function for which it received its name.

Considering this feature of the breakdown, it is necessary to restore the functionality of this part as quickly as possible, otherwise increased attention on the road cannot be avoided not only from motorists moving in traffic, but also from traffic police officers.

The easiest way to correct the situation is to install a new part, but due to various circumstances, replacing a faulty muffler may be impossible. Fortunately, it is possible to repair the muffler yourself without welding or replacement.

This article will discuss simple and effective ways to restore the functionality of this element of a car’s exhaust system, but first it should be recalled under what circumstances such a breakdown can occur.

Causes of muffler failure and preventive measures

It is easier to prevent a disease than to treat it later. This statement is also true for car breakdowns.

Of course, it is impossible to avoid all the nuances on the road. But knowing about the dangers that threaten the elements of a car’s exhaust system, you can try to use preventive measures to delay the occurrence of a particular malfunction.

If the car is used constantly, then sooner or later problems with the muffler will arise, regardless of the quality of the material from which this part is made. Located in the lower part of the car, this part is constantly exposed to the abrasive effects of sand and stones falling on its surface. And if, when the car is moving, a fairly large solid object ends up between the wheels, then the muffler can be completely destroyed from a strong impact.

Therefore, the main rule for extending the life of the unit is to drive the car carefully.

The muffler is connected to the exhaust system via threaded connections, so if the nuts are not tightened well enough, this part can be lost while the vehicle is moving. To prevent this from happening, the condition of the threaded connections of this element of the exhaust system should be checked from time to time.

The muffler often becomes unusable due to metal burning, but this process cannot be completely stopped. The failure of this part as a result of thermal and corrosive effects can be slightly slowed down only by treating the inner surface of this part using graphite impregnation.

If, despite all the preventive measures taken, the muffler burns out or its body is damaged as a result of mechanical stress, then many owners immediately become interested in the question of how to connect the muffler pipes without welding.

Such repairs can be carried out at home using a special sealing compound.

Muffler repair by cold welding

Cold welding is a two-part adhesive that can be used to glue metal products. Is it possible to cold weld a muffler, because this part is exposed to a very high temperature of the exhaust gases.

The cold welding adhesive composition tolerates high loads and temperatures well, so if a burnout appears in the muffler or a crack from mechanical stress, it is necessary to remove the part from the car and perform the following steps:

- Thoroughly clean the damaged area. Cleaning is carried out with coarse sandpaper or using attachments on a drill or grinder.

- The metal, cleaned of rust and carbon deposits, is thoroughly degreased using a solvent.

- Cold welding is applied to the damaged area. To apply the plastic type of glue, you should use gloves.

- After applying the composition, you need to wait about an hour and then polish the layer of hardened glue.

- After a day, the part can be installed on the car and operated without any restrictions.

Muffler repairs by cold welding must be carried out in a warm room. Only at temperatures above +5 degrees will the two-component adhesive composition react with the metal surface.

:

Ceramic Repair Tape

Ceramic tape is a popular and effective muffler repair tool.

A small hole in the muffler is sealed in the following sequence:

- The metal is cleaned of rust and carbon deposits.

- The ceramic tape is wetted with water.

- The hole is sealed by repeatedly wrapping the muffler with ceramic tape.

This method is temporary, but during the entire service life of the “bandaged” muffler, its function will not be impaired, and in case of repeated burnout, you can easily wind a new layer of ceramic tape.

Muffler repair with sealant

In the retail chain you can find special high-temperature sealants for the exhaust system of a car.

Such products contain special cement or ceramic additives. Which, when exposed to high temperatures, harden and form a layer that prevents exhaust gases from escaping from the damaged area of the vehicle exhaust system.

The process of repairing a muffler using sealant is usually carried out in the following sequence:

- The damaged area is thoroughly cleaned using sandpaper.

- The cleaned surface is slightly moistened.

- The sealant is applied in a thin layer to the damaged area of the muffler and the part is left for 30 minutes.

- The muffler is installed in place.

- Start the car engine for 10 - 15 minutes to dry the crack sealed with sealant.

- After 10 - 12 hours, the car with the repaired unit can be used.

Using sealant for repairs allows you to delay the purchase of a new part for a long time.

Reviews

Reviews of various muffler repair tools can be found on the Internet, but choosing a tool that can be guaranteed to restore the functionality of the part can be very difficult.

Car mechanics who repair the exhaust system, if it is not possible to purchase a new muffler or repair the damage by welding. It is recommended to purchase expensive ceramic sealant and use it to seal the hole.

To increase the reliability of the coating with a high-temperature sealant, experts advise winding several layers of tin over the applied composition, which then must be securely secured with a wide clamp.

If such repairs are carried out correctly, the muffler will last a significant amount of time. And when new burnout points form, it will be possible to repeat the above steps in a new place.

Conclusion

How to repair a muffler without welding is described in detail in this article. All of the listed methods for eliminating damage to this part are actually working, so the choice of method depends entirely on the car owner.

If you have free time and a desire to try out all the methods for eliminating such a breakdown, you can begin repairing the suppression using cold welding. Which is inexpensive and you can buy such glue in any specialized online store.

Other uses.

In principle, thermal tape for muffler winding can be used in many cases, helping to solve a lot of problems with the exhaust system:

- Protect elements from minor mechanical damage;

- Act as a sealant at joints;

- Ensure operation in case of minor defects - fistulas, burnouts, cracks.

Of course, if the exhaust manifold burns out, it will not be possible to restore the unit’s functionality. For thin-walled elements - resonators or pipes, wrapping with thermal tape will be a good option for a quick repair, allowing you, if you do not restore functionality completely and permanently, to get to a garage or service center without problems.

Thermal tape for a motorcycle muffler has become a tuning classic. The exhaust system of a car is hidden from prying eyes; for bikers, taking care of the exterior of a motorcycle is one of their priorities. The owners highly appreciated the quality of the tape, its ability to both combat minor defects and give the muffler a stylish appearance. Thermal insulation characteristics are also important, thanks to which they provide reliable protection of the legs from burns.

How to repair a muffler using bandage tape

Let's move on to how to properly use tape to repair a muffler.

- Step 1 . Prepare the muffler for use. It must be at room temperature - it is unacceptable to work with hot parts! Using a wire brush or other abrasive device, remove dirt, paint residues and burns. Degrease the surface.

- Step 2 . Prepare the bandage tape for use. If it is made on a silicate basis, open the package and pour water inside. Wait a few minutes, shaking the contents occasionally.

- Step 3 . Apply the bandage to the problem area . Wrap it tightly, as if you were looking at a regular elastic bandage. Additionally, secure with the wire that comes with the kit or another wire that you have on hand. Apply the tape overlapping, layer by layer. Start winding not from the damaged area, but with a margin of 1-2 cm. For high-quality repairs, eight to ten layers of tape are enough.

- Step 4 . Wait for the adhesive layer to harden - this will take a maximum of 45 minutes. Constantly level the tape all this time - this way the result will be much better. It takes one day for complete polymerization.

If you are using a sodium silicate bandage and only one part needs to be repaired, use the package at a time - it does not last long. Work in a warm (temperature 14–22 °C) well-ventilated area, use gloves as personal protective equipment.

Some manufacturers sell the tape complete with pastes and resins. They help speed up the hardening of the adhesive layer and improve sealing performance.

Follow the listed steps and our recommendations exactly - this will help you end up with a repaired muffler or other product that needs urgent restoration. But remember that this type of “reanimation” does not eliminate the need to replace the muffler in the future.

Muffler repair

The best way to avoid problems with restoring exhaust system parts is to seek help from specialists. The service center will advise you, make an appointment for diagnostics and carry out repairs of any complexity. Make an appointment with us by phone listed on the website, and we will serve you daily from 10:00 to 23:00. We provide services in St. Petersburg and the region. We guarantee prompt and high-quality execution of work. We have affordable prices and our own database of car parts from trusted suppliers.

Properties and selection.

Thermal tape is a strip of textile made from fibers with high thermal resistance.

Initially, the main material was asbestos. After its use was banned (asbestos fibers released into the air pose a serious threat to health), the tape began to be produced on the basis of other heat-resistant substances. Today, products are made using silica threads and graphite-based compounds. The former have higher operating temperatures.

New technologies make it possible to produce threads based on ceramics, carbon, expanded clay, and basalt. Methods are used to deposit particles of molten mineral components on the fibers (LR technology), resulting in a durable fabric that is resistant to extremely high temperatures and does not contain substances harmful to the environment and human health.

When choosing, several characteristics are taken into account:

- Limit temperature. The vast majority of materials are designed to withstand temperatures of 800-1100 degrees without loss of properties. Such tapes are suitable for thermal insulation of manifolds of non-turbocharged engines, windings of car mufflers, and tuning of motorcycle exhaust systems. Turbo units require limits of 1500 degrees and above, which are also provided by some products in the manufacturers' range.

- The width of the line. The material is supplied in rolls with a width of 25 mm and a length of 2 m or more. The choice is determined by the convenience of winding. The exhaust manifold is wrapped with a 25mm wide tape; for tuning motorcycle mufflers, a 50mm strip is more convenient.

- Color. Recently, the nomenclature consisted of white, black and bronze ribbons. Now the range of manufacturers has been significantly expanded, which allows motorcycle owners to choose a solution that exactly matches the color scheme of the bike.

There is a wide selection of tape from several manufacturers on the market:

- Thermo-Tec. The company's products are the most widely known and include the widest possible range of offerings. The materials are produced using advanced technologies, are of high quality and wear resistance (service life is about 3 years). The price starts from 25-30 US dollars.

- Nova is a company that produces automotive equipment and materials. Products of acceptable quality have an attractive price (average cost is about $20).

- Aster. It produces films of good quality, but inferior in the main indicators to the products of the leaders. The main advantage is low cost, practically not exceeding 1000-1500 rubles.

Video with recommendations for choosing.

Advantages and disadvantages of processing

It must be understood that if this method provided only “advantages” without any risks, designers would have long ago put it on the assembly line for car production. Since this is not the case, it is necessary to directly note certain “disadvantages” of the innovation. The main thing is that it can cause some problems for the vehicle's exhaust system. Since after the winding the pressure will no longer be one-sided (only towards the muffler), the exhaust valves may come under a certain influence of gases, which increases the likelihood of them burning and premature failure. In addition, thermal tape can become a source of accumulation of moisture, salt, dirt and other foreign mixtures that are unsafe for the metal, and this is a reason for unwanted corrosion to begin on its surface. The third point is financial. We are talking about the considerable price of good quality thermal tape, which sometimes reaches several thousand rubles for 10 linear meters of tape.

Therefore, before you start wrapping, you need to carefully weigh all the pros and cons, and figure out whether there will be a tangible benefit from this or not. Experienced drivers understand perfectly well that an increase in power of 10 percent or more, as is sometimes heard, cannot be achieved based on their elementary physical laws. At best, it will be 3 - 4%.

Application technology.

The technology of winding exhaust system elements does not contain secrets. The main task is to ensure density and uniformity of laying.

Experts advise carrying out preparatory work before using the material on the collector. They include treating the “spider” with heat-resistant paint or special anti-corrosion compounds.

To obtain a layer of thermal insulation:

- Make several turns;

- Fix the initial section with a metal clamp (wire);

- Winding continued with overlapping turns of 1/3-1/2 the width of the tape;

- After a certain distance, the layer is additionally fixed with clamps (on the collector, due to its short length, installing 1-2 intermediate ones is sufficient).

- The end of the strip is carefully masked and also secured with a clamp.

Winding is carried out with force, which allows you to achieve the required packing density. Experts recommend moistening the material (place it in a container filled with water for 30-60 minutes) before use. After drying, the tape shrinks and adheres tightly to the surfaces.

Video with installation instructions.

The positive aspects of processing exhaust system elements with tape are determined by solving the underlying problems. Among the disadvantages of using the material are:

- Pressure created by a significant volume of hot exhaust gases. The result is increased load on the valve mechanism.

- Maintaining high temperatures inside system elements, leading to accelerated wear.

- Deposition of dirt, aggressive chemicals, and moisture absorption on the surface of the material. Treated parts lose their appearance over time, and constant contact with contamination provokes the accelerated development of corrosion processes.

Quite a high cost of the material.

What is bandage tape for?

Repairing a muffler with bandage tape is a temporary, therapeutic measure that does not replace a full repair or replacement. Using high-temperature tape (also called scotch tape) can help an exhaust system that has worn out over time. Often the muffler, resonator, and pipes—connecting and exhaust—fail. These parts are made of thin steel, which is susceptible to corrosion, which causes holes, cracks, and breaks to appear.

Many car owners are not ready to invest large sums in a full repair of the exhaust system, so they use bandage tape. This is an excellent alternative to welding.

Adding power

The main task when tuning is to increase power. Accordingly, the winding is also made for this purpose. In practice, a properly executed winding can give approximately 3-5% increase in engine power. And this despite the fact that you already have a modified and correctly configured exhaust system.

But, if you just installed upgraded pants and did not work with the rest of the muffler (in particular, you did not remove the extra resonators). You won’t notice any positive effect, or it will be very insignificant. In such a situation, you will at most make your car quieter.

conclusions

. Tuning the exhaust system is one of the most common techniques for increasing engine efficiency. At the same time, drivers have a question about why thermal tape is needed for the muffler. In fact, this is one of the options for additional exhaust modification. If used correctly, you can increase engine power, although only slightly. It is worth remembering that this option also has its drawbacks.