Why does the timing belt break?

Causes of product damage:

- low quality belt;

- errors made during installation or replacement;

- failure of the tensioner rollers;

- wear of the belt teeth (the teeth wear out constantly during the operation of the car);

- pump jamming;

- foreign objects entering the gas distribution mechanism.

Late replacement

The service life of modern new products for distribution mechanisms depends on the make of the car and is about 150 thousand kilometers (on older cars this figure is lower - about 70 - 100 thousand / km). If the vehicle is used in low temperature conditions, the service life of the belt is reduced to 60-100 thousand/km. In any case, experts recommend diagnosing the condition of the timing belt at least every 15 thousand kilometers.

Quality of spare parts

Quality determines the correct ignition of the air-fuel mixture, which affects the efficiency of the power unit. Installing and using cheap products in the machine can cause low drive tension, which will result in the belt quickly bursting.

Incorrect belt replacement

Errors made when installing the timing belt lead to asynchronous opening and closing of the valves, resulting in reduced engine power. The cause is usually too loose or too high a tension on the shafts. If the replacement of the product was carried out with errors, it may break after 1-2 thousand kilometers.

Characteristic signs of incorrect replacement:

- the product slides to the side;

- cracks have appeared or become noticeable on its surface;

- An unusual sound is heard when the engine is running.

Broken tension rollers

Tensioner rollers are designed to tension the belt on the engine shafts, so that it does not jump off while the engine is running. If the tension is weak, the strap will begin to slip, which will cause an increase in temperature and rapid wear of the auxiliary units. If the tension is excessive, the product can quickly burst, and a characteristic symptom will be a sharp sound from under the hood.

Destruction of timing belt teeth

With serious wear, the rubber teeth located in mesh with the shaft gears break off. With such a problem, the engine may not start, although the belt itself appears to be intact. The operation of the power unit as a result of tooth destruction is disrupted, as this leads to a failure of the ignition system.

Pump wedge

If the pump is jammed, it may not respond to turning, which leads to strong tension and breaking of the belt while the vehicle is moving. This problem is more relevant for domestic vehicles.

Foreign elements

If foreign elements get into the distribution mechanism (this could be dirt, small stones, engine oil), the camshaft or crankshaft may jam. To avoid this problem, it is necessary to periodically check the protective cover and fastenings.

Video: causes of timing belt damage

In the video, user Igor Belov spoke in detail about why the timing belt breaks.

Broken timing belt/chain: main reasons

If we compare modern engines with their predecessors, today's engines have more power and shorter service life. Regarding the problem of valve bending, it is precisely to achieve greater efficiency from the engine that the distance from to is minimal. Even a slightly open valve bends as the piston rises to TDC. It turns out that various technical innovations in engine building did not in any way affect the well-known problem, which is inherent in the vast majority of engines, regardless of the type of motor and manufacturer. We are talking about bending of valves when the drive belt breaks or.

An important rule when operating a car is to monitor the condition of the timing belt and replace it in a timely manner. The belt should not have any delaminations, cracks or other defects. Also, various technical liquids are not allowed to come into contact with its surface. The appearance of squeaks, creaks and other extraneous sounds will require the owner to check the tension and condition, as well as the tension and other rollers.

To answer the question of when to change the timing belt, you need to study the operating instructions for a particular car. Often on new cars, the belt is changed after 60 thousand kilometers traveled or after 2-3 years (whichever comes first). A planned replacement with an original belt involves the next replacement every 50 thousand km. It is advisable to select non-original belts with caution and change them every 40 thousand km.

Now a few words about the chain drive. The timing chain requires less attention, since replacing the chain on average is necessary once every 150-200 thousand km. and more. In this case, it is necessary to monitor the chain tension, the condition of the tensioner and chain guide. Increased noise during engine operation, the appearance of a metallic clang and other signs will indicate the need to immediately check these elements.

So, let's return to the belt, which is less reliable compared to the chain. The timing belt most often breaks for the following reasons:

- belt wear as a result of long-term use or use of a low-quality product;

- jamming (water pump);

- jamming of the crankshaft, camshaft;

- tension roller malfunction, timing rollers jamming;

- destruction of the timing belt as a result of engine oil getting on its surface;

- mechanical damage after contact with sharp edges, camshaft gears;

What are the signs of a broken belt?

You can determine that the timing belt has broken by the following “symptoms”:

- Abrupt stopping of the engine and inability to start it. Attempts to start the power unit only worsen the situation, since the piston causes new damage to the failed valve.

- After a belt breaks, engine operation may be accompanied by a metallic knock and ease of rotation of the crankshaft by the starter. This is due to the lack of compression in the engine cylinders, as a result of which nothing holds the pistons.

Video: how to determine if the timing belt has broken

The video from the Renault Repair channel describes in detail how to independently determine whether the timing belt is damaged or broken.

What are the consequences of a broken timing belt?

The most serious consequence of a broken timing belt is damage to the valves, as a result of which the car owner is faced with the need to overhaul the unit and restore the gas distribution mechanism. This can happen while the engine is running, when the pistons move continuously from top dead center to bottom dead center. The rupture occurs during the release of gases or fuel injection (at this time the piston moves down). In this case, the movement of the pistons in the cylinder continues and parts of the device collide with each other.

If the timing belt breaks, the extent of the consequences will depend on the characteristics of the engine and the conditions under which the breakdown occurred:

- Due to a broken belt, the camshaft stops rotating, causing the valves to stop in one position. At this moment, the crankshaft continues to move by inertia and the pistons go to the open valves, which immediately bends. On some power units, for example, on the VAZ 2111, 8 cl, the pistons are equipped with special recesses, thanks to which contact with the valves is excluded in the event of a break. But, modern engines are designed to provide the greatest power with a minimum volume, so the pistons do not have recesses.

- If the belt breaks at idle, only a few valves may be damaged. Moreover, the higher the rotation speed of the crankshaft, the higher the likelihood of failure of the guide bushings. This problem causes a major overhaul or replacement of the cylinder head.

- On a diesel engine, the consequences of a broken timing belt will be destruction of the valve, camshaft with bearing elements, cylinder head, connecting rods and pushers. This is due to the design of such motors, due to which the valves have virtually no free play when the piston is in the top dead center position.

- For cars equipped with a Japanese engine, when the timing belt breaks, damage to all valves, breakage of bushings, pistons and cylinder heads are typical. Such malfunctions are typical when the machine is moving at high speed.

How long can you drive on a broken belt?

After the timing belt breaks, you should not attempt to continue driving.

Video: the dangers of a broken timing belt

The video from the Car Program channel describes the consequences that a car owner will face if the timing belt breaks.

What will happen, what consequences await?

You know, sometimes you can get away with it, that is, without suffering any damage. Just install the new one, set up the car and that’s it – let’s move on! But sometimes you end up with very expensive repairs.

When the timing belt breaks, it is mainly the valves that suffer - if we “exaggerate the picture”, it turns out that the upper camshaft does not work due to a break, the valves are frozen in one position, but the crankshaft pushes the piston up - this is where the piston and valve meet , and the weak link suffers - very often the valve bends.

Less often, but again it happens - the camshaft pastel breaks, or the upper part of the piston breaks.

This is a very unfavorable situation, at a minimum you need to change the valves, which means disassembling the engine - buying a new gasket, lapping the valves correctly, etc. ON some foreign cars, repairs reach 30,000 rubles. But if the pastel and pistons are damaged, then it’s even more expensive.

“But wait,” you say, but what about “getting away with it”?

Yes, this also happens - many manufacturers make special recesses in the upper part of the piston. The bottom line is this: when a break occurs, the piston goes up - the valve is in place - but when the piston reaches the top point, it falls into the hole and no “jam” occurs. You just need to put on a new belt, set the marks and start the engine. ALL!

“Just wonderful,” you say. But why shouldn’t all manufacturers do this?

Again, it’s simple - if we exaggerate, the indentations do not have a particularly good effect on the compression of the fuel mixture, which means you will lose power, which all manufacturers are now fighting so hard for. That's why they install pistons with a straight top! Not very comfortable! BUT remember, manufacturers plan the service life of all parts, so if you are told to change the belt at 100,000 km, this means it will not break at 100,200 km, it will last for a long time, but why take such a risk? Change it as written - there will be no problems.

What to do after a belt breaks?

If the timing belt is broken, then:

- It is necessary to open the engine compartment and lift (or completely dismantle) the protective cover of the mechanism.

- It is important to carefully evaluate the appearance of the belt (the torn product will be visible). If it breaks at the very bottom, you will need to turn the crankshaft half a turn to find it.

- The vehicle must then be towed to a garage or service station. If the car is equipped with an automatic transmission, the assistance of a tow truck will be required, since towing is not allowed on such vehicles.

How to replace the timing belt yourself?

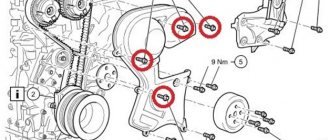

16-valve engines are equipped with two camshafts with a separate gear for each. Before making a replacement, the user should look in the service manual to see where the timing marks are located and what type they look like.

Algorithm for replacement:

- The engine compartment of the car is opened, the negative terminal is disconnected from the battery (the ignition must first be turned off).

- The wheel is removed from the belt side. To do this, you need to jack up the car and unscrew the bolts with a wheel wrench.

- Then the engine cover and the protection of the power unit are dismantled (the bolts or screws are unscrewed). You will also need to remove the generator drive belt. Depending on the design features of the engine, it may be necessary to dismantle the expansion tank with power steering oil or adsorber. In some cars you need to remove the air conditioner bracket, air intake, intercooler with terminals.

- Using a hexagon, it is necessary to unscrew the bolts securing the protective cover of the strap and gears.

- If the car is equipped with a crankshaft position sensor, it is necessary to disconnect the block with cables from the device.

- Then the timing belt tensioner pulley bolt is unscrewed and the bearing itself is removed. If the system is equipped with a guide or support roller, this must also be removed.

- The worn timing belt is being dismantled.

- The position of the mark on one or two camshaft gears is checked (depending on the 8- or 16-valve engine). It is always important to check that these marks match the marks on the timing drive. If they do not match, you need to combine them with each other yourself. To do this, turn the camshaft with a key.

- If you need to check the alignment of the marks on the gears with the mark on the oil pump body, you must remove the toothed pulley with a special washer. If the screw does not come out, rest the handle of the L-shaped key against the rod, connect the battery and crank the starter once. After this, the battery must be disconnected.

- The next step is to install the support roller, if it is provided for by the engine design.

- The new belt is first placed over the crankshaft sprocket and then wound onto the support roller, camshaft sprocket and pump gear. When performing this task, you should monitor the location of the marks on the camshaft gears. If the risks have gone astray and no longer match, they must be set again.

- Next, install the tension roller and tighten it (you need to screw it without tightening it until it stops).

- Check the evenness of the belt lining. Then it is tightened using a special wrench (the roller must be turned counterclockwise). Next, holding the latter with a tool, you need to fix its position by tightening the mounting screw (all the way).

- The product tension is diagnosed - you need to turn the belt lengthwise using your fingers. It should rotate no more than 90 degrees.

- At the final stage, it is necessary to return all removed parts and spare parts to their places.

- The engine is started and its operation is assessed (by ear). If the product is installed correctly, there should be no abnormal sounds.

When installing the timing belt yourself, it is important to pay attention to:

- the presence of a hum and whistle of the roller, which indicate the belt is overtightened;

- detonation - weakening of its tension;

- black smoke from the exhaust pipe - incorrect markings on the shafts.

Preventive measures

The main preventative measure for timing belt breakage is its timely replacement.

Additional preventive measures include:

- Use of high-quality original spare parts.

- Periodic monitoring of the tension level of the product, the condition of the pump and rollers. It is important that the tension is uniform in all areas, without sagging.

- External assessment of the belt condition. If the first signs of damage and cracks appear on the product, the user needs to replace the timing belt as soon as possible.

How to extend the life of your timing belt

The main preventive measure to prevent unexpected timing belt breakage is its timely replacement with a new one. Experts recommend doing it after every sixty thousand kilometers. Try to use original new components.

The entire mechanism of the gas distribution system must be regularly checked for serviceability. This is especially true for the roller system and pump. The tension of a new belt in good condition is uniform. It shouldn't sag.

To prevent the new timing belt from breaking, the following points should be monitored:

- The degree of oil pressure indicated by the warning lamp.

- Serviceability of seals. If they leak oil, the belt will quickly become unusable. If you notice oil stains on the surface of the asphalt or engine, you should eliminate the causes of these leaks.

- Do not use the push start method. This provokes a quick break of the new timing belt.

By following these measures, you will reduce the likelihood of a new drive suddenly breaking. But this does not provide a 100% guarantee of preventing a break. Therefore, it is best to carry with you all the necessary tools and new components for replacement.

Care must be taken to periodically inspect the new drive and replace it when it is faulty. This will prevent breakage and maintain the integrity of the engine.

We recommend

Signs and symptoms

There are six main signs that the timing belt has jumped.

- The car engine is unstable.

- The engine constantly stalls.

- Noticeable loss of engine power and thrust.

- The engine starts with problems or does not start at all.

- The power plant is stuck.

- The sound of the engine becomes louder - a metallic knock appears.

Most often, it happens that the product jumps one tooth, and because of this, the engine continues to operate, but increases fuel consumption, and there are also interruptions in operation and starting.

If you suspect that several teeth have jumped, you should not restart the engine. In the worst case, this can cause the valves to bend.

Does a broken accessory drive belt lead to serious consequences?

If a belt breaks on a car, which transmits torque to several units at once, this can lead to the following consequences:

- Deterioration of steering control due to lack of operation of the power steering pump. The steering wheel becomes “oak”.

- Battery problems. The alternator will stop charging the battery and the car may stall within a short period of time.

- Air conditioner failure. This can hardly be called serious consequences, but this breakdown can cause a number of inconveniences.

In any case, this action can lead to a number of malfunctions in adjacent components of the car. Therefore, it is not recommended to drive for a long time with a broken belt on attachments.

Causes

The timing belt is an important element of the car, so it needs to be serviced promptly. The reasons that lead to its jump are as follows:

Contact of oil or cooling liquid on the belt surface

As soon as traces of technical fluid appear on the product, the belt should be changed immediately. Otherwise, this can lead to slipping through the teeth, sliding off the pulley, and even breaking.

It is a serious mistake when drivers simply clean the dirty surface and continue to use this product.

Practice shows that if liquid gets on the belt, it is completely absorbed into the rubber. It loses its properties and begins to stretch.

Late replacement

Most timing belt manufacturers recommend changing their products approximately every 60 thousand kilometers. However, this figure may vary up or down, depending on the quality of the product.

Improper use

It happens that a product may jump due to errors during its operation. A common example is a weakened roller or tensioner. When the belt tension weakens, there is a possibility of slipping from the pulley grooves. In the opposite situation, if when installing the belt, it is overtightened, this will lead to its breakage.

Slippage can also occur when one of the pulleys has strong play. Therefore, it is very important to monitor the tension level of all parts of the mechanism.

The labels are set incorrectly

Sometimes the jump is not visible outwardly, but the engine does not start well and immediately stalls. This can happen if the marks were knocked down or incorrectly set initially. A shift of even one tooth can cause problems with the motor. If the engine is diesel, it will not start even if there is an error of one tooth.

Is it possible to drive if the accessory belt breaks?

Some motorists argue that driving with a torn belt on auxiliary units is acceptable. But in practice, such actions are not entirely beneficial for your car.

If we are talking about one belt that transmits torque to all additional units, then we can say that further movement is impossible. The car needs to be towed.

In the case where the machine has several belts for different parts of the attachment, the subsequent path will depend on the specific breakdown. It is not recommended to drive with a torn belt on the generator or power steering. A break in the air conditioner is not so critical. With this breakdown you can continue moving.

Consequences

The consequences of the timing belt jumping several teeth can be different - from replacing the timing belt itself to repairing the car’s gas distribution mechanism.

The amount of damage depends on whether the engine has recesses for valves in the pistons or not.

A jump can occur while the valves are being lowered to inject fuel or release gases. The pistons are still moving and can hit the valves hard. This will lead to bending of the latter. This situation is similar to a broken timing belt. You can read more about which engines this happens on in this article.

To avoid this situation, it is recommended to do a timely inspection and, if necessary, change the consumable.

Repair cost

The average price for replacing a belt and roller in car services ranges from one to three thousand rubles. The price range is due to the fact that replacing parts on foreign cars costs approximately 2–3 times more than on domestic cars.

If it turns out that you also need to change the engine water cooling pump and the crankshaft oil seal, then the price will increase by another 1 - 1.5 thousand rubles.

Although there is a huge selection of products on the market at different price levels, you should only choose brands recommended by the manufacturer or their high-quality analogues. Using cheap parts can lead to serious damage and expensive repairs.

For example, if the valves are bent as a result of a belt slipping, then almost the entire cylinder head will have to be replaced. Even if the repair is carried out by yourself, the cost of replacing valves, pump, belt, filling oil and antifreeze, and other parts will be at least 10,000 rubles.

The gas distribution mechanism/timing mechanism provides control of gas flows in the cylinders of the internal combustion engine, and also switches phases during the gas distribution process. One of the main parts in this mechanism is the belt/blade. It connects the internal combustion engine shafts (camshaft, crankshaft) in a certain sequence and is needed so that when the pistons move (up/down), only the required valves open/close. This creates the pressure inside the cylinders required to ignite the working mixture. The timing belt is an extremely important element in the structure of the power unit. Next we will talk about what causes a broken timing belt. The consequences of a break and their elimination often cost the car owner a pretty penny.

Video: replacing the timing belt on a VAZ

The video from the Nik Nikolsson channel describes the process of replacing the timing belt using the example of a VAZ 2108 with a carburetor.

The gas distribution mechanism/timing mechanism provides control of gas flows in the cylinders of the internal combustion engine, and also switches phases during the gas distribution process. One of the main parts in this mechanism is the belt/blade. It connects the internal combustion engine shafts (camshaft, crankshaft) in a certain sequence and is needed so that when the pistons move (up/down), only the required valves open/close. This creates the pressure inside the cylinders required to ignite the working mixture. The timing belt is an extremely important element in the structure of the power unit. Next we will talk about what causes a broken timing belt. The consequences of a break and their elimination often cost the car owner a pretty penny.

Timing belt modifications

Since the invention of the car, developers have offered different types of timing belts. At different times, mechanism belts were made from different materials and in different variations:

- leather product;

- metal chain;

- a metalized modification with a rubber base, which is used today on cars of all types and from various manufacturers.

Timing belt

The indisputable advantages of modern timing belts include:

- Ease of use.

- Reliability of the design.

- Acceptable price.

A metal chain is highly expensive and complex in design, and therefore this type of belt is practically not used in budget cars. Leather samples have a short service life and, despite their minimal cost, are not popular among modern motorists.

Symptoms of a broken timing belt

It's no secret that even the most reliable mechanisms break down when they run out of working resources . And the timing belt, which is of great importance and ensures stable operation of the engine, is no exception! Not only professionals, but also ordinary car enthusiasts know that the consequences of a broken timing belt can be very negative, for example, for the vehicle engine.

And in order to identify the problem in a timely manner, you need to know the signs of a broken timing belt. Typically, a broken timing belt is accompanied by a bang, and the power unit stalls, but other elements of the system continue to operate normally. A new engine start in this situation is often accompanied by a “metal” knock and “ease” of rotation of the starter element, due to an incorrect compression process in the cylinders.

When symptoms of a timing belt rupture appear, you need to stop the car, lift the hood and look at its condition.

Although often motorists do not always have the opportunity to stop and check the road surface for integrity, and this often leads to extremely negative results.

How to understand that a new timing belt has broken

Typically, if the timing belt breaks, the engine will stop immediately under other normal conditions. When further attempts are made to start the engine, this cannot be done, or in difficult cases a metal knock is heard. The break of a new timing belt is accompanied by a bang, but if the radio is running in the car at the same time, you may well miss this sound.

If you suspect that the new timing belt has broken, stop immediately and inspect the vehicle by opening the hood. This breakdown is immediately noticeable. You should not try to restart the engine before inspection if you think that a break has occurred. After all, when starting an engine with a broken drive, the valves may bend, and the breakdown will only worsen.

We recommend

Why does the timing belt break?

As stated earlier, the main function of the timing belt is to ensure the operation of the camshaft , which in turn synchronizes the operation of the piston and valve systems of the vehicle. When the belt breaks, this process becomes desynchronized.

Broken timing belt

The reasons for a broken timing belt are different, let’s look at some of them.

Existing limit

Modern timing belts have excellent performance characteristics , including service life. For example, in foreign-made cars it can work flawlessly for up to 150 thousand kilometers. But everything has a limit! Over such a long period of time, it simply “wears out” - its thickness decreases, the ability to maintain the required tension decreases, and other performance characteristics are lost. And that's why the belt breaks.

Wear remains the most common cause of belt damage, so experts recommend periodically checking the belt for wear and, if necessary, replacing it. Note that in Russian Ladas the belt can travel much less than approximately 30-50 thousand km, but sometimes the belt breaks after driving only 15,000. Therefore, complaints are often heard from the owners of Priora, Kalina and other models of this plant.

Advice. If you purchased a Russian car, and even one with mileage (albeit not much), then it would be better to immediately change the belt to avoid problems!

Broken tension rollers

From the names of the parts it is clear that the rollers are intended to provide tension to the timing belt. This prevents it from slipping and jumping off the teeth. In general, a roller is a bearing with a special layer at the top.

Why do valves bend when the timing belt or chain breaks?

Despite the improvements, the general traditional principle of operation of the timing belt and engine valve mechanism remains unchanged. As you know, raising the piston to TDC (top dead center) means that at the specified moment the valves are closed. This is necessary to create pressure and seal the combustion chamber.

If the timing belt breaks, then the valves simply do not have time to close, which means they collide with the rising piston. When the timing belt breaks, the camshafts immediately stop. This immediate stop occurs for two reasons:

- since the drive force from the belt or chain disappears;

- the camshaft cams themselves are retarded by return springs;

As for the crankshaft, this element continues to rotate by inertia. The inertial rotation of the shaft does not depend on what gear and at what speed the car was moving, at what speed the engine was running, etc. still turns the crankshaft. In other words, if the timing belt breaks, then the timing mechanism immediately stops and the valves remain open, while the crankshaft continues to rotate and the moving pistons hit the valves that are open at this time.

The result of a broken belt is that the piston meets the valves, after which the valves immediately bend. Often the valve stem is bent, although sometimes various deformations of the valve disc are also possible. Less common is damage to the piston itself, which is also a consequence of a broken belt and bent valves.

Engineers and car manufacturers are well aware of this problem. To prevent the consequences of a broken timing belt/chain, some old internal combustion engines had special grooves for the valves on the piston. These grooves actually provided the necessary free space, which allowed the open valves not to collide with the upward moving piston. In such motors, after the valve drive broke, the valves did not bend.

Modern engines also have characteristic recesses on the piston. It is worth noting that these grooves avoid the risk of damage to the valve while the engine is running. If the timing belt breaks on such engines, the indicated grooves do not prevent the valves from bending, that is, the valves still bend even if there are special grooves on the piston.

Results of timing belt breakage and probable costs

More about the likely consequences

Novice motorists usually ask the question: “What will happen if the timing belt breaks?” The results of fabric rupture, as well as its causes, vary.

How significant they will be depends mainly on the design characteristics - the “simpler” the motor is designed, the lower the likelihood of serious damage!

Typically, a timing belt rupture entails:

- Engine overhaul.

- Repair/complete replacement of the gas distribution mechanism.

- Replacement of valves due to their bending due to incorrect operation of the timing belt. This happens when the valves are lowered, releasing gas/injecting fuel mixture. At this moment, the crankshaft, rotating inertia, hits the piston. It's the pistons that do the heavy lifting. Although, this problem mainly occurs in cars in which the dimensions of the combustion chamber are deliberately reduced, or there is no recess on the surface of the pistons. To determine the level of damage, it is advisable to take the car to a service center, since it may be necessary to dismantle the head and diagnose the motor using special equipment. Ideally, it is necessary to replace the complete valve set, even if the engine was idling when it broke and not all valves were damaged.

- Collapse of participants in the piston system. Usually Japanese cars suffer from this, and this happens due to a significant impact on the heads from the valves. When the blade ruptures at high speeds/high revolutions and the valves “fly”, the bushing bursts and the pistons are punctured by debris. Then there will be an extremely expensive repair with a head change.

The most severe consequences of a break in the gas distribution mechanism are observed in diesel power units. Due to their design features, there are “obstacles” to the movement of the valves, and therefore in the event of a rupture, when the valve is at a dead center, the following can simultaneously happen:

- camshaft failure;

- cylinder head failure;

- deformation of connecting rods;

- the valves will be bent.

Costs for eliminating the results of timing belt rupture

The price of the valve, excluding associated expenses, is approximately 1000 rubles (give or take). It’s quite easy to calculate the cost if you need to change all 16 valves of a modern engine. The cost of such a replacement will be very significant.

In addition, you will need to purchase some “little things”, for example:

- Belt or complete timing gear kit, including all bearings;

- a gasket for each of the manifolds (intake/exhaust);

- cylinder head gaskets and valve plugs;

- fasteners;

- It is possible that you will need to purchase a pump (water pump) when wear is suspected.

In addition, if you plan to carry out the necessary work yourself, you will need the appropriate keys, screwdriver, pins, and sometimes a special tool.

Replacing the timing belt

Procedure for replacing the timing belt

To remove the old timing belt, you must perform the following steps:

- Remove the timing case, which is secured with several bolts.

- Unscrew the fasteners on the crankcase protection.

- Remove the belt from the compressor by dismantling it, remove the belt and return the compressor to its proper place.

- Remove the belt from the generator.

- To de-energize the contacts, you must remove the terminal from the battery.

- Unscrew the fasteners on the engine and remove the generator, terminal and water pump pulley, remembering to first remove the corresponding bolts.

- It is possible that it will be necessary to dismantle the base of the power unit.

- Remove the protection cover from the timing belt.

After completing all these steps, you can make a replacement. To do this, you need to remove the cover from the toothed pulley and remove the torn timing belt. Then you need to install a new blade, not forgetting to tighten the tensioner. If wear is detected on the rollers, they also need to be changed. Then perform the steps described above in reverse order to return the structure to its original state.

Please note! For a specific car model, there are characteristic nuances in removing and installing the timing belt, although in general they are very similar.

Prevention of timing belt rupture

You will certainly protect yourself from serious consequences due to a ruptured timing belt if you periodically replace it, driving approximately 60 thousand km with it. In this case, it is advisable to take original components and not wait until the fabric breaks on its own.

In addition, it is worth regularly monitoring the level of web tension, as well as the condition of the water pump and rollers. The tension should be uniform and there should be no sagging in its individual sections.

In addition, you should carefully monitor:

- behind the emergency light, which shows the oil pressure level;

- the condition of the valve seals (if they are worn out and oil leaks onto the canvas, it will fail in a short time, and oil specks on the asphalt under the car or on the engine become a clear sign of leaks).

Try to avoid starting the engine from a “pushrod”, since such jerks provoke a rupture of the timing belt more quickly.

But even following these recommendations, the car owner cannot have complete confidence that the canvas will not suddenly tear. And therefore, it is useful to always have the necessary tools and a spare timing belt, so that if it breaks, you can quickly replace it.

We briefly told you what to do if the timing belt breaks, but most importantly, how to prevent this from happening.

Breakage of a new timing belt: common causes

- Incorrect operation.

A break in the new timing belt may result from improper operation of the entire assembly. For example, when driving, the tensioners, rollers or pump may jam, which will lead to a break in the new timing belt.

Despite the external quality of this part, when a high crankshaft rotation speed is reached, a sharp change in operating conditions can damage it.

To prevent the new timing belt from breaking, you need to carefully monitor its tension. Excessive tightening can also cause part failure. However, by loosening the drive too much, you can get a similar result due to the belt jumping off the pulley grooves.

This situation can also arise if there is existing pulley play. That is why, in order to prevent engine damage, it is necessary not only to change the timing belt in a timely manner, but also to monitor its tension and the proper operation of each element of the mechanism in order to prevent breakage.

Oil getting on the surface.

If you notice traces of oil or antifreeze on the new belt, this means that it needs to be replaced.

If you do not install a new belt, the entire gas distribution mechanism will not work efficiently. The drive will slip, be removed from the pulley, and eventually break.

Don't think that just by wiping off an oil stain you can continue driving without taking any action. It is not possible to completely remove traces of oil from a new drive. After technical fluid gets on it, it is absorbed, depriving the drive of the qualities necessary for proper operation. Only replacing it with a new drive will help here.

Low quality product.

If you saved money by buying a timing belt, then you need to be prepared for the fact that troubles may arise during its operation. This is a case where the stingy pays twice, because a broken new timing belt can lead to high engine repair costs. We recommend purchasing an original drive from a seller whose quality you are confident in.

Car service workers know well how an attempt to save a couple of hundred rubles can result in repairs costing tens of times more. There is nothing surprising here, since a low-quality new timing drive can break without traveling even a couple of tens of thousands of kilometers. Constantly expecting a catch from such an important detail, you worry, which leads to driving mistakes and uncertainty in your own car.

External damage.

If the drive has served you for a long time or it was of poor quality to begin with, it may develop external damage, such as cracks, grooves, loose threads, and the like. These shortcomings cannot be eliminated. If such damage is present, a new drive must be installed as soon as possible.

Ignoring wear can lead to the fact that under load the defect will intensify and a breakage will occur. It is better to anticipate and prevent this situation than to blame yourself later and pay for expensive repairs and a new drive.

Harsh climate and active driving.

In many regions of Russia, the climate is such that the car is regularly exposed to too high or low temperatures. Therefore, car repair and maintenance must be approached with special care. Sudden changes in temperature can affect the wear of the new timing belt, which increases the likelihood of it breaking. In such conditions, it is better to use only original components for repairs and change the drive at the first signs of wear, without waiting for the expiration of the service life declared by the manufacturer.