Automatic transmission lost reverse speed

In general, trouble came out of nowhere.

This morning I reversed the car out of the yard, went out to close the gate, sat down and that’s it - the reverse gear died. It turns on - and the switching delay on R is the same as before and the speed drops (though less than on D), but it doesn’t move - if you increase the speed to 3-4 thousand, it tries to back up a little out of the blue, but it doesn’t pull.

Forward all speeds work fine, I didn’t notice any changes. Yesterday I spent 3 hours in traffic jams, after which I drove another 30-40 km - everything was fine. And in the morning - such a surprise. Maybe I overstrained him in traffic jams, although this didn’t happen in the summer - I don’t understand.

Automatic transmission A140E, in six months I have driven 16 thousand, when buying the car I partially changed the ATF 2 times.

I immediately went to change the fluid in the machine. The ATF drained was very dark - I used to change it on my previous car after 20 thousand - I drained it while it was still red and transparent, but now it is almost black. We opened the pan - and there were a lot of shavings - not to say that it was a nightmare, but not a little. We washed the filter - it was certainly dirty, but not completely clogged - I will order a new one and change it again. I didn’t touch anything - no solenoids/valves - there were no conditions, and I don’t really know where to look yet. I filled in new oil - I drove out - the rear became “even smaller” - now accelerate - don’t accelerate, there is no traction back, and the drop in revolutions is very small compared to D.

In general, can anyone recommend anything?

Volkswagen Passat Turbo › Logbook › Automatic transmission repair (reverse gear lost)

Suddenly, out of the blue, reverse gear disappeared. She was there in the morning, but upon arrival at work she was gone. Although, if I accelerated at 3000+ rpm, it started to go crazy.

I didn’t think twice about it - I took the car to Kinergo for repairs. Don’t even ask about the manual transmission option - comfort is more important to me. And there is no need to argue either.

A languid two weeks of waiting... And you can pick it up. Just bring the money.

The fault is a manufacturing defect. Although, what a waste if the box worked for 15 years... A flaw, let’s say. And in cars 2002 or 2003+ it has already been fixed. More specifically: a locking bracket on the hydraulic plate that holds some kind of lid. It was just thin and rubbed the lid - the pressure was released. And in the new revision, instead of a thin bracket, a thick flat one was installed. Now not my photo with the same problem (bracket in the center):

And the new part looks like this (at the very top center):

Now a photo specifically of my stove:

For those who have no idea how the box works. Here it is at the link.

I have already driven 1000 km - everything is fine. And there is a guarantee. Not the greatest truth - half a year.

And finally my photo

hydroplates. You can clearly see how the lid is worn in two places! Of course, she was missing ATF and the transmission was slipping.

Why doesn't the automatic transmission engage reverse gear?

A transmission is a part of a vehicle that takes on heavy loads during a trip. That is why, during its design, much attention was paid to the reliability of the constituent elements. The first problems with this unit may arise after 80,000 km, for example, the reverse gear stops engaging. This manifestation at an earlier time period is possible if the car owner did not take care of the automotive system. In particular, maintenance was neglected and transmission fuel of inadequate quality was used.

Causes

What could be the reasons why the reverse gear in a VAZ car does not engage? In fact, there can be a lot of them, because the problem with switching gears, one way or another, lies in the transmission system and, in particular, in the gearbox itself.

Gear shift lever in a VAZ 2109 car

- Incomplete release of the clutch. As a rule, if the clutch is not disengaged correctly, all speeds may not engage well, but sometimes this problem affects only the reverse gear.

- The gearbox drive levers or rods are damaged. The fastening may also be loose. To eliminate such a malfunction, it is necessary to conduct a thorough inspection of the unit and transmission system. If necessary, it is recommended to replace all damaged system components.

- The lubricant in the gearbox has run out. In this case, the problem with switching gears will affect all gears without exception. Therefore, the likelihood of such a problem, unless only reverse gear is engaged, is very small. As you understand, you should check the level of consumables in the system and, if necessary, add oil to the gearbox.

- Bad gear oil. The transmission fluid has already lost its properties and cannot fully ensure lubrication of all gearbox components. In this case, the problem will also affect all gears without exception, although in practice there have been cases when problems occurred with engaging the reverse gear. In this case, an oil change will be required.

- Poorly adjusted rocker: the gearbox rocker cardan needs to be adjusted. Due to poor adjustment of the rocker, the reverse gear sometimes not only does not engage, but also falls out. This problem is one of the most common among VAZ 2109 cars, so we will consider fixing it first.

Almost every owner of a domestic car has at least once encountered problems with partial gearbox failure. If reverse gear on your VAZ-2109 has stopped engaging, then the cause may be one of the malfunctions:

- The clutch is not completely disengaged. With this problem, problems occur when all gears are engaged, but sometimes only the reverse one fails.

- The gearbox levers are damaged or broken or their mountings are loose. Problems can only be resolved by diagnosing the box, as well as replacing damaged parts. In this case, moving the lever may be accompanied by a crunching sound.

- If only reverse gear does not work, then with a low degree of probability it is time to claim that the transmission fluid has simply run out. Usually, with this problem, all gears do not engage. If, however, you notice that the gear oil level in the box is extremely low, then simply top it up.

- In practice, there were cases when the rear “speed” could not be engaged due to the poor quality of the fluid in the gearbox. In this case, it must be replaced.

- The most common problem with engaging certain gears is an unadjusted gearbox universal joint. You can notice it by this sign: at first, the backward movement was activated unclearly, and then another mode was activated instead. Later the box stopped working normally altogether.

Characteristics of malfunctions in the absence of reverse gear

Speed switching is carried out using a selector with alphabetic/numeric designations. Thanks to this, it is possible to select the desired mode.

It should be noted that these symbols are duplicated on the dashboard.

Why did reverse gear disappear on the automatic transmission? The inability to engage reverse gear occurs for the following reasons:

- the friction layer of the brake band has worn out;

- damage to the piston rod;

- cuff wear;

- deformation of the forward clutch discs.

As a rule, the transmission cannot shift to 3rd gear due to the fact that the oil sealing rings have worn out. When the release bearing is deformed, extraneous noise will be noted during operation. The automatic transmission needs diagnostics.

If only 1st gear is activated forward, while the car is able to drive in reverse, it is worth checking the control valve and the integrity of the gear on the gear selector shaft. This problem can be solved by cleaning the valve and replacing the deformed gear.

You should pay attention to the condition of the rocker bushing and how securely the lever is fixed. In this case, you need to remove the lever cover and the rocker, after which you should start replacing the plastic bushing with a similar spare part.

The automatic transmission mechanism is quite complex, which is why its repair and restoration work is best left to professionals. They will carry out a full diagnostic, the results of which will determine why the automatic transmission does not work in a specific or all gears.

Troubleshooting

Many transmission malfunctions that cause the reverse gear to disappear or fall out can be eliminated without removing the unit from the car.

If the cause is a loosening of the bolt securing the clamp on the rod, then to correct the defect it is necessary:

- Place the car on a lift.

- Completely loosen the clamp nut.

- Place the gearshift lever in the fully engaged reverse gear position.

- Fully engage reverse gear at the gearbox using the shift rod on the crankcase.

- Tighten the clamp mounting bolt.

Backstage adjustment

If tightening the clamp does not help get rid of the problem, then you need to check the condition of the shift drive parts. One of the reasons why the reverse gear does not engage may be a poorly adjusted rocker.

To make adjustments to the mechanism, you may need the following tools:

- two wrenches with a size of 13 mm, preferably a socket design;

- any wrench or 10 mm socket;

- small hammer;

- slotted screwdriver.

Since the cause of malfunction of the link can be wear of parts, spare parts may be needed:

- universal joint of the rocker;

- Sometimes the shift rod seal may need to be replaced.

Two people are required to adjust the rocker or replace parts of its drive. One person must change gears from the passenger compartment, and the second must adjust the travel of the shift rods.

The order of work is as follows:

- Provide access to the bottom of the car by placing it on a pit or a lift.

- Using a 13 mm wrench, loosen the clamp installed on the gear shift rod.

- Remove the rod from the box rod.

- Using a screwdriver, carefully remove the boot.

- Using a 10 mm wrench, unscrew the fixing bolt on the cardan shaft.

- Knock off the cardan shaft with light blows of a hammer. It is important not to damage the shaft.

- Remove the universal joint seal boot.

- If there is an oil leak, the sealing gland on the box rod must be replaced.

- Install a new boot (or leave the old one if it is intact) and install the universal joint on the shaft.

- Align the hole on the cardan with the notch on the shaft.

- Tighten the 10 mm clamp and install the boot completely in place.

- Install the rod on the cardan rod and adjust the gearshift lever travel.

- The second person should sit in the driver's seat, set the gear shift lever to neutral, move it slightly to the right and hold it in that position.

- After this, you need to tighten the 13 mm clamp nut.

Typically, after such a repair, the reverse gear starts to engage without problems. In addition, the operation of the entire gear selection mechanism on the VAZ-2109 becomes clearer.

The video from the author MegaMeyhem shows the process of replacing the backstage.

Changing the gearbox oil

If the oil seal on the rod is damaged, oil leaks out of the gearbox housing, and dirt can get into the box itself. These factors may be the reason why reverse gear stops engaging. In addition, the oil in the box loses its properties during operation, so it must be replaced preventively at least once every 35–40 thousand kilometers.

Before replacing, you need to check the condition of the oil in the box. To do this, you need to remove the oil dipstick installed in the gearbox housing and visually assess the quality of the oil. The presence of metal and dirt particles in the oil on the dipstick is unacceptable. The oil itself should be quite liquid and not stick to your hands in a thick layer.

Dipstick with oil level marks

To replace, you will need the following materials and tools:

- New oil. When purchasing oil, you need to consider the type of gearbox. For fairly rare four-speed gearboxes, three liters of oil are required, for newer five-speed ones - 3.3 liters. The oil itself must have a tolerance of 80W-85, the manufacturer does not matter.

- A container for draining old oil with a volume of at least 4 liters.

- A funnel with a hose for pouring new oil or a syringe.

- Wrenches 12 and 17 mm of any type.

- Rags and cleaning solvent.

The actual work order is as follows:

- Place the car with the heated gearbox on the pit.

- Remove the rubber plug from the gearbox ventilation valve installed on the top of the crankcase.

- Clean the valve and plug from dust and dirt. It is convenient to clean parts with thin wire and a rag.

- Reinstall clean parts.

- Wipe off dirt from the bottom of the box. Unscrew the plug on the bottom of the box housing.

- Place a container under the drain hole and drain the oil. It will completely merge in at least 20-25 minutes.

- After this, screw the drain plug back into place and carefully tighten it with a wrench. First, the plug and hole must be thoroughly wiped with a rag.

- Pour fresh oil through the oil level dipstick hole in the box.

- During filling, it is necessary to check the oil level, which normally should be between o and “MAX” on the dipstick rod.

- If there is an overflow, the oil can be pumped out with a large medical syringe with a tube on the spout.

- Within a few days after the change, it is advisable to check the level and appearance of the oil. You also need to make sure that there are no leaks through the plug and box seals.

Rubber crankcase ventilation cap Drain hole on the crankcase Dipstick in the upper part of the crankcase An oil funnel installed in the dipstick hole

On early versions of front-wheel drive VAZ gearboxes there is no hole for the dipstick. To fill the oil in the crankcase of such boxes there is a control hole closed with a threaded plug. Filling is carried out using an oil syringe. The oil level is considered normal when it reaches the lower edge of the inspection hole.

The arrow indicates the inspection hole on the side of the gearbox housing. Filling oil with a transmission syringe.

One of the common reasons why the reverse gear of a VAZ 2109 does not engage is the breakdown of spring 2 installed in a separate mechanism.

Gear selection mechanism

To access it, it is necessary to remove and repair the mechanism itself, located inside the box.

A short list of necessary actions:

- Disconnect the car.

- Remove the air filter completely.

- Remove the left wheel and loosen the CV joint hub nut.

- Drain the oil from the gearbox crankcase.

- Remove the two bolts securing the left ball joint to the steering knuckle.

- Unlock and remove the steering tip.

- Remove the fist from the CV joint splines.

- Completely remove the left drive.

- Remove the starter and negative wire from the gearbox housing.

- Remove the gear shift rods from the gearbox and clutch.

- Unscrew the speedometer drive cable.

- Place a support under the box housing and remove the box support fastening

- Remove the gearbox from the vehicle and disassemble it.

When disassembling the gearbox, it is necessary to check the condition of the gear locks, since wear is the main reason why the reverse gear spontaneously jumps out of gear. You can get to the lock without removing and disassembling the box; it is located on the side of the crankcase and is closed with a screw plug. Disassembling the gearbox and inspecting the gear selection mechanism will also help solve the problem in which the reverse gear on the VAZ-2109 does not turn off.

Malfunction of the brake band and friction discs

If the problem is related to the belt, the forward gears are activated without problems, but when the rear gears are engaged, the car does not move. The correct solution in this case is to replace the tape.

The automatic transmission does not go backward, only forward at 1st and 2nd speed in most cases due to wear of the friction discs. In rare cases, flashing the machine's firmware helps. Failed parts must be replaced.

If there are strong impacts when shifting gears in an automatic transmission, the reason for this may lie in the failure of the clutch and brake discs. Also, if the clutch breaks down, when moving, the vehicle jerks and begins to slip. Installation of a new accessory part is required.

Torque converter and piston failure

The torque converter needs to be checked if the car does not move, there is no reverse speed, and a jolt is felt if it switches from “Parking” to “Neutral” mode. Also, you need to check the oil level in the box and the filter element.

If the piston is mechanically deformed, its debris gets into the transmission fuel and can damage the inside of the box. The result of this is difficulty in engaging reverse gear. The piston must be replaced with a similar component.

Lack of gear oil

One of the signs of a faulty transmission is the presence of dark-colored oil. If the automatic transmission does not move back when hot, it is worth checking the oil with the engine running and warm.

If there is a lack of this fluid, extraneous noise will be noted from the box. The frequency of its replacement on an automatic machine is 40,000 / 60,000 km.

Thus, the automatic transmission requires constant care; the gear oil should be changed in a timely manner. Diagnostics of the box is necessary if the automatic transmission does not engage reverse gear. The problem is often associated with a lack of oil or a broken torque converter. The control unit can fail as a result of a voltage surge in the vehicle's on-board network or exposure to moisture on the board.

Five main problems with automatic transmission reverse gear

1. There are all shifts for forward movement, but when engaging reverse gear there is no movement. There may be several reasons: the friction layer on the brake band is worn out, the cuffs are broken, or the brake band piston rod is broken. The problem is eliminated by replacing the faulty element.

2. The reverse gear on the automatic transmission has disappeared , the car does not move backward, but only forward at speeds 1 and 2. The main reason: the friction discs of the freewheel clutch are worn out, this can be eliminated by replacing the discs.

3. Slipping when the oil is warm, no problems when the oil is cold. Reason: wear of the same friction discs. Or prerequisites for wear, manifested in an increased proportion of friction dust in the oil. Replacement and cleaning will help us.

4. There is no movement in any direction, and when switching from “P” mode to “N” mode, there is no characteristic push. The main reason is a malfunction of the torque converter, lack of oil in the box, or dirty filter. The solutions are obvious - replacement, topping up, cleaning.

5. The reverse gear of the automatic transmission does not engage , forward movement is only at 1st speed. Reason: the splines of the drive drum of the sun gear are cut off. The box should be disassembled and the drum replaced.

Do not rush to disassemble the automatic transmission!

There can be any number of reasons for automatic transmission malfunctions. But before you start expensive repairs at a car service center or in your own garage, open a manual specialized for your car. Or rather, a section with diagnostic methods. And only after roughly deciding what problem you have, you can take any action to eliminate it. Otherwise, you can break a generally serviceable box or overpay extra money to a car service center.

Design and principle of operation of reverse gear

First, let's look at the principle of operation of reverse gear on an automatic transmission. Manufacturers have introduced a special lock into modern automatic transmissions. This is done by the brake band. Thanks to it, the driver does not feel sharp jolts from the machine when switching from the “Forward” mode to “Reverse” or moving backward.

Attention! Before you start moving the car back, press the brake pedal, wait until the car comes to a complete stop and only then move the selector lever to “R” mode and press the gas pedal. Moving the lever to the “Reverse” position when moving forward will damage the automatic transmission.

So what happens in the automatic transmission when the driver moves the selector lever to “R” mode.

- The driver stops the car and moves the selector lever to “Reverse”.

- The signal goes to the ECU.

- From the electronic control unit it is transmitted to the corresponding solenoid valves. They open up.

- The oil enters the torque converter, accelerates and, under pressure, presses on certain clutch packs that communicate with the gears.

- The brake band clamps the remaining friction discs.

- Reverse motion is set.

- The car is moving backwards.

If some part is faulty, then the transfer may not take place or the automatic transmission will switch to reverse gear thoughtfully.

How does an automatic transmission work in a car?

An automatic transmission uses a hydraulic system to select the desired gear. All such manipulations in automatic transmissions involve the use of fluid as a component that transmits forces. The “intelligent” work, recognizing when it is necessary to switch to another stage, is carried out by the control unit and the control unit.

The driver in a car with an automatic transmission uses a selector mounted in the interior to engage reverse gear, park or drive mode. This lever acts kinematically on certain elements of the box. The automatic unit consists of the following modules:

- torque converter;

- gearbox with planetary gears;

- hydraulic control unit.

The clutch is not present in a classic form in such cars. Its functions are performed by a torque converter. Thanks to this element, torque is transmitted from the power plant to the transmission. The design of the GTF differs significantly from the clutch in a manual transmission, since due to its features it is capable of increasing the transmitted force due to the presence of fluid.

The planetary gearbox receives torque from the torque converter. Next, the force is distributed to the drive axle. The node is also capable of varying the value, increasing or decreasing the coefficient, based on the current driving conditions of the vehicle.

Signs of automatic transmission malfunction in the valve body

- The box only works well in cold/hot conditions. Solenoid contamination.

- The car cannot move, the reverse works. It's a valve problem.

- Transmissions are not activated. The solenoid is broken.

- Only reverse and first gear work. The valve is stuck.

- Slipping as you move uphill. Solenoid or valve body channels.

- Shocks and jerks during transmission operation. Such breakdowns can cause contamination of the valve body and broken wiring.

- The car stalls when changing to the next gear if you don't accelerate. The valve stuck, breakdowns occurred in the mechanical part of the automatic transmission.

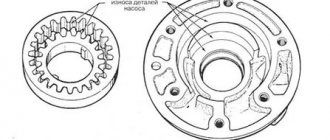

"Iron". Planetary gear, hubs and calipers.

As the box and sealing elements wear, vibrations increase. Multiply this by oil starvation and you get completely non-ideal conditions for contacting metal parts. They begin to wear out, crumble, and burst. Failures in the “iron” part of the machine are typical for older machines; they rarely occur on new ones.

Why won't the automatic transmission turn on?

Engineers have not yet created mechanisms that can work forever and uninterruptedly, so over time the components break down. Problems, for example, when the reverse gear on an automatic transmission is lost, occur due to intensive wear of individual parts or for other reasons.

In order to correctly diagnose possible problems with the box, it is necessary to understand the reasons why failures occur. The lack of first gear is noticeable on the car when the car starts hard from the second stage. In such a situation, the culprit is the solenoid, which did not open due to failure. In some cases, it is important to check the integrity of the wiring coming to it from the electronic control unit.

The car can move off from first gear calmly, but then there is no transition to the 3rd gear. At the same time, it is not noticeable that the reverse speed disappears or there are problems with it. It is necessary to look for the source of trouble in the valve, which sticks when starting this transmission. We recommend disassembling it and thoroughly cleaning the channels.

For the fourth stage that is not working, other factors may appear. The driver is recommended to first check whether the “Overdrive” mode is turned on, as evidenced by the indicator on the panel marked “O/D OFF”. Cleaning the potentially clogged valve responsible for switching to this mode will also help.

Important! If the working fluid in the hydraulic system is weakly heated, the automation may not allow the transition to the 4th speed operating mode.

A special sensor is responsible for temperature control. When it fails, switching failures occur.

Obvious rearrangement between stages with jerks is a sign of wear on the friction discs. Due to failures with such important elements, a major overhaul will be required for the box.

When an automatic transmission does not engage reverse gear, it is necessary to blame the brake band or related parts, which include the piston, its cuff or the rod on which it is held. If there is no reverse gear on the automatic transmission, then the culprits may also be clutches blocking shifting. Failed parts will have to be replaced.

If a situation arises in which the rear does not work, but gears 1 and 2 start, then the automatic transmission has worn out the drive clutch discs. They need to be changed.

It is impossible to turn on the rear stage, as well as the front stage - the torque converter has “flyed”. There will be insufficient oil volume and the filters will be dirty.

The driver turns on the selector to drive back, but the car does not move. It is possible to move exclusively at 1st speed. This is a sure sign of cut drive drum splines.

Basic gearbox faults

Leaking seals, rings and bushings.

An absolutely normal situation after 200,000. Automatic transmission malfunctions arise due to simple wear and tear and obsolescence of parts. The sealing elements become tanned, crack, lose elasticity and begin to leak oil. This little nuisance signals to the car owner that the torque converter clutch has worn down to the adhesive layer and now does not perform its function. It begins to slow down more, slip and overheat terribly, transferring the temperature generated by the friction force directly into the lubricant. Dirty oil clogs the pump, destroys its seal and bushing, which leads to oil starvation and failure. In addition, oil with the remains of the clutch contaminates the valve body. Its channels become clogged and destroyed by abrasive treatment, it begins to work incorrectly and produce abnormal pressure into the box. Wear of the torque converter is preceded by an increase in fuel consumption, loss of vehicle dynamics, leaks on the box and extraneous sounds when the transmission is operating.

Oil on the body is a sign of leaking seals

Previously, sealing elements were made of cast iron, and they survived almost all gearbox mechanisms. Now they are made of rubber and Teflon. Dirty oil can eventually make holes in them, from which oil begins to ooze. The pump tries to correct the situation and pushes more and more transmission fluid there. Therefore, all sealing elements are changed at every opportunity and are produced in sets.

Lack of oil.

Due to insufficient oil quantity or pressure, the gearbox mechanisms no longer receive sufficient lubrication. The clutches and steel discs begin to slip. Loss of dynamics is a clear sign of the necessary repair of the box and it is very stupid to ignore it. Major repairs and diagnostics during this period will cost less, and after that the automatic transmission will live for a long time.

If the clutches have completely burned out, then the oil has most likely become almost black and definitely acquired a distinct burning smell. All clutches in the automatic transmission, even unworn ones, were saturated with burnt oil. Actually, it’s too late to repair, just restore or order.

Hydroblock.

Previously, hydraulic blocks were practically eternal. They were made of cast iron, there was no fine tuning, calculations and channels calculated down to fractions of a millimeter. A modern valve body is made of soft aluminum with a mass of thin channels, which are very easily clogged with oil debris and are bored out by it, like a file. Now they need to be cleaned periodically; this procedure is usually performed during major repairs. Their service life is one of the shortest among automatic transmission parts, and breakdowns have become commonplace.

Particles of debris either clog spools with solenoids, which leads to their sticking, or bore their channels, which leads to abnormal operation of delicate electronics. The result is always the same - if at least one valve in one of the clutches malfunctions, there is either excess pressure or a lack of pressure, the clutches begin to slip and die, then dragging along the entire gearbox, which now runs on burnt oil.

Solenoid plungers, clogged with oil, stick, and this leads to their switching every once in a while, jerking and jolting are observed.

But this was not enough for the engineers. They began to produce wiring for the electrical part of the automatic transmission in the form of cables as thick as a human hair, and transferred the electronic control unit from the car interior to the hydraulic plate itself. So that it overheats better, obviously.

With the help of such a cunning solution, the automatic transmission electronics have also become a very unreliable place. A small disconnected wire can give very frightening symptoms of a breakdown in the form of jerks and kicks in the gearbox switching.