What is an economizer and why is it needed?

An economizer is a specially designed device for carburetor engines. Its main functions include regulating the intake of the combustible mixture.

The following types of forced idle economizers are used in cars of the domestic manufacturer VAZ:

- EPHV - sometimes also called a solenoid valve (EMV).

- EMR (power mode economizer).

EPHH allows excellent gas savings, especially when driving on uneven terrain. During long descents, it suspends the fuel supply through the idle system. This is how engine braking occurs.

This driving mode has a beneficial effect not only on the driver’s wallet, since fuel is consumed more slowly, but such driving is also much safer. After all, when driving on a descent, the car is more confident and safer compared to driving in neutral gear.

Fuel Shark gasoline economizer: where to buy

Before going on sale, the Full Shark economizer undergoes several basic quality checks, as well as performance tests. The company produces into mass production only high-quality products that are capable of performing their main functions. Each fuel economizer has certificates and documents confirming its suitability for use on vehicles of various models. Due to its popularity and demand, as evidenced by real reviews of Fuel Shark, the fuel saving device is freely available. You can buy Fuel Shark on the online store website by filling out a special order form. After providing all the necessary data, call center operators will contact you to arrange delivery. The Fuel Shark device, customer reviews of which are extremely positive, as confirmed by the Fuel Shark forum, is a sought-after and indispensable device for absolutely any car. As you know, fuel consumption constantly fluctuates due to changes in driving style, terrain and density of cars on the roads, so installing such a simple fuel economizer as Fuel Shark will allow you to avoid such problems and significantly save material costs on gasoline.

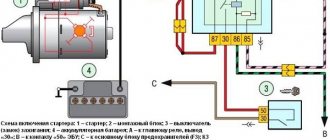

EPHH device

An economizer is installed on top of the VAZ 2107 carburetor. It is located not far from the air filter and consists of a housing, a shut-off needle that blocks the fuel outlet from the idle system, connected to the diaphragm needle, and an adjusting screw for the “amount” of the fuel mixture.

It is the jet that stops the flow of fuel into the combustion chamber. He does this if 2 important conditions are met - the crankshaft speed exceeds 1800-2000 rpm and the driver’s foot does not affect the accelerator. The EPHH is controlled without human intervention, since its operation is regulated by a small controller connected to the ECU (electronic control unit).

Design and adjustment of the OZONE VAZ 2107 carburetor

Old VAZ models, as a rule, were equipped with carburetors of the following brands: Solex, Weber and Ozone; their popularity over many years of operation has not decreased, but rather, on the contrary, increased.

However, like everything in this world, over time, carburetors fail and need repair, cleaning, and adjustment, which in turn puts a considerable burden on car owners, requiring them to have certain knowledge and free time.

In order to save time and money, I bring to your attention a detailed guide on how to clean the carburetor, service it, and also how to adjust the VAZ 2107 carburetor.

To begin with, I propose to talk about what a carburetor is and “what it is eaten with.”

The principle of operation of a carburetor from different manufacturers is essentially the same; its task is to create a fuel-air mixture, mixing it in certain proportions with fuel and air, after which it is supplied to the combustion chamber, where ignition occurs... Well I think the rest is clear!?

There are three types of carburetors: float - this is perhaps the most common among all, needle and bubbler - quite rare.

In today's article we will talk about the Ozone carburetor.

Before you begin, you need to understand something; the fact is that some carburetor modifications may differ significantly from those installed on a similar car model.

- DAAZ 2107-1107010 - installed on the VAZ 2105, as well as the VAZ 2107.

- DAAZ 2107-1107010-20 - installed, as a rule, on new VAZ 2106 VAZ 2103.

- DAAZ 2107-1107010-10 – installed on VAZ 2106 or VAZ 2103 engines without a vacuum corrector with an ignition distributor.

- Autonomous idle system.

- Float chamber.

- Idle shut-off valve.

- Econostat.

- Dosing system.

- Throttle valve.

- Crankcase gas exhaust compartment.

- Transition system for both cameras.

- Acceleration pump.

- Econostat system.

- Maintains constant fuel level.

- Idle support.

- Support for engine starting and warming up.

- Jets (air and fuel), diffuser, VTS atomizer, well and emulsion tube are located in the main metering chamber.

- First of all, a detailed inspection should be carried out, then everything should be thoroughly washed and cleaned of dirt and other imperfections.

- Afterwards, you need to clean the mesh filter and wash the float chamber.

- Next you need to clean the air jets.

- And finally - adjustment of the float system (1), trigger mechanism (2) and idle speed (3).

- Check the position of the float and, if necessary, align the holder bracket. This is necessary for the correct, uniform lowering of the float into the chamber.

- Next is adjustment with the needle valve closed. Open the chamber cover, then move the float aside and lightly pull the bracket tab. The task is to achieve the required distance between the cover gasket and the float; it should be within 6-7 mm, in no case more or less. If the immersion is more than 1-2 mm, if it is more, then the needle can be considered faulty.

- The distance between the needle and the float when the needle valve is open should be 15 mm.

- This procedure can be carried out on a disassembled carburetor or directly on the engine.

- Adjusting the VAZ 2107 carburetor: starting system

- In order to adjust the starting system, you need to remove the air filter, then you need to start the engine and pull the choke towards you.

- Forcefully open the air damper by 1/3, then set the speed to 3200-3600 per minute.

- After this, release the air damper and set the rotation speed to 300 less than the initial one.

- How to adjust the idle speed of a VAZ 2107 carburetor

Let's look at the main part of the VAZ 2107 carburetor components

This knowledge is enough to clean and adjust the VAZ 2107 carburetor yourself. There is no need to know more, although it will not hurt for overall development.

The carburetor is adjusted after cleaning and assembly. Before you start disassembling and cleaning, I suggest you remember the main saying of any auto mechanic - “Don’t make a fuss while it’s quiet,” meaning that you shouldn’t get into a place where everything is in order or disassemble something that has nothing to do with the breakdown.

How to properly adjust the carburetor of a VAZ 2107

Attention! This work does not require dismantling the carburetor.

The strainer, which is located in front of the entrance to the float chamber, is checked at least once every 60,000 mileage.

How to check the strainer

This is done as follows. Use manual fuel pumping and fill the float chamber with fuel, after which you will be able to see the shut-off valve close. Then move the top filter cover and remove the valve. It must be thoroughly washed in solvent, then dried using compressed air.

When the engine behaves incorrectly during loads, there are dips or loss of power, or the car “reacts poorly to the pedal,” most likely you have a problem with the fuel supply. In addition, often the cause is a faulty strainer.

Important! It is strictly forbidden to wipe the bottom of the float chamber using a fluffy or any other rag, since after such cleaning, invisible fibers may remain on the bottom of the chamber, which will clog your jets during operation.

You might be interested in: Replacing the fuel filter for Lada Kalina. Fuel pump repair: replacing the mesh

The float chamber is cleaned using a rubber bulb and then dried with compressed air.

Checking the tightness of the shut-off needle is carried out using a bulb, since the pressure force that occurs during squeezing is equal to the pressure in the fuel pump.

When replacing the carburetor cover, you need to make sure that the floats are in the up position. You should feel strong pressure during installation, after which you need to listen carefully to the carburetor for air leaks.

If there is even the slightest leak, the needle and valve body must be replaced.

Adjusting the VAZ 2107 carburetor: float system

Read more: Starline autostart, how to set up autostart on a Starline alarm

To adjust idle speed, you need to warm up the engine to operating temperature, then use the quality screw to set the maximum speed, and use the quantity screw to set the value to 100 rpm. above normal. Start the engine using the quality screw and adjust the speed.

- At this point, the adjustment of the VAZ 2107 carburetor can be considered complete, now I hope you will not have any problems with how to adjust the carburetor with your own hands.

- In order to consolidate your knowledge, I recommend to your attention the following video on how to adjust the carburetor with your own hands.

08/16/2015 Hello everyone! This post will give recommendations on setting up the Ozone 2105 and 2107 carburetor for normal operation.

The overall success of carburetor tuning lies in the identified serviceability of the associated engine systems. These systems include spark plugs, ignition coil, distributor contacts or hall sensor and switch, phases and clearances in the gas distribution mechanism.

The carburetor itself must be technically in good working order. If there is a blockage in the carburetor channels or another factor affecting its proper operation, then it is not recommended to proceed with adjustments.

Our tuning example includes a completely washed and blown carburetor, but with incorrect settings of the jets, positions of the adjusting screws and float.

Adjusting the float Remove the top carburetor cover and place it in a horizontal position with the float up. Measure the gap between the float and the carburetor gasket. The gap should be 4.5 mm. Place the carburetor cover in a horizontal position with the float down.

Adjustment of the float stroke is carried out by its two stops by bending them.

Setting the initial position of the throttle valve 1 Screw in the throttle stop screw until the screw begins to touch the throttle stop lever. After touching the screw, turn the screw 90 degrees clockwise. When tested against light, a thin ring of light should be visible.

Setting the initial position of the throttle valve 2. Screw in the throttle stop screw until the screw begins to touch the throttle stop lever.

After touching the screw, turn the screw 0.5 - 1 degree clockwise so that the screw supports the damper lever, but does not open it. The groove for the screwdriver on the screw must be aligned with the mark on the screw seat.

When checking for light, the light ring should not be visible.

Adjusting the fuel quantity screw

Adjusting the additional air supply screw

Adjusting the EPHH valve The EPHH valve must be screwed into the mounting hole until the EPHH nozzle touches the limiter. This moment can be determined by lubricating the rubber ring with oil and observing the contact of the ring with the mounting hole. The valve must not be overtightened. An overtightened valve may become faulty.

Setting the idle speed using the IKS-1 device (instructions for the device) Start the engine, set the mirror in a position convenient for observation, and use the quantity screw to set the minimum stable engine crankshaft speed. Using a mirror, observe the flame in the cylinder, the color of which depends on the composition of the working mixture.

— Slowly turn out the mixture screw until the flame turns bright orange, indicating an overly rich mixture. — Slowly turn the mixture screw in until the orange color disappears and the flame appears bright blue, indicating a normal mixture for best engine performance.

Purpose of the economizer for carburetor power modes

EMR is necessary to saturate the combustible mixture through the carburetor. In this case, the throttle opens and the engine starts running at full speed. In this situation, the engine power increases significantly, plus there is an additional opportunity to increase speed.

Some users install an EMR economizer on the VAZ 2107 carburetor precisely to increase power. But they must be able to do this competently, since while driving the load on the engine increases, which, of course, can lead to engine failure.

Video - Installation of the EPHH system

An increase in fuel consumption can be due to many factors, including improper operation of the EMR. If the valve spring is weakened or broken, the economizer valve will be constantly open, re-enriching the air-fuel mixture. When the gas pedal is fully pressed, this increases engine power, but in other modes, on the contrary, it leads to a drop in power.

Because of this, the driver is forced to press harder on the gas, which further increases fuel consumption. If the EMR diaphragm has lost its seal or the cap is not tightened properly, gasoline will enter the intake manifold below the throttle valve and also leak out. The latter is especially dangerous because it can cause fuel to ignite.

The operating procedure of the economizer of power modes of the Solex carburetor

When the car engine is running, chamber throttle 1 remains closed at idle. Therefore, an area of low air pressure appears under the damper. The economizer inlet is open, so the vacuum region extends to the diaphragm inside the economizer. The spring is gradually pulled back in the direction of the housing cover of the EPHH VAZ 2107. At this stage, the ball valve is closed.

After the driver presses the gas pedal, the pressure on the back side of the diaphragm drops, causing the valve to open. Then the fuel from the float chamber enters the emulsion well passing through the nozzle. At this moment, the fuel substance is well enriched with oxygen, so the car is given significant acceleration.

All 2020 Solex economizers come into operation only when the gas pedal is fully depressed.

What do they promise?

Those who have not yet had the opportunity to familiarize themselves with all the bonuses that come with purchasing a Fuel Shark economizer can study the list and immediately think about the reality of these promises. Comments (sometimes humorous and overly emotional) from those who have already formed an opinion about the purchased device are given in parentheses.

So, the economizer:

- Increases the mileage of the car (it just adjusts the speedometer);

- Saves 15-30% of gasoline (refills the fuel used in the tank);

- Does not require maintenance (since there is nothing to maintain);

- Saves money (how? You have to buy it!)

Moreover, we cited only the most harmless reviews. Some will simply not be allowed through by censorship, while others too quickly shift to the identity of the inventor.

Economizer malfunctions

Here are the main symptoms that may indicate that the economizer is not working correctly:

- Fuel consumption has increased;

- Unstable operation at idle;

- The power of the internal combustion engine (ICE) has decreased;

- A warm engine does not start the first time;

- Drops of the fuel mixture appeared in the economizer.

After tuning a VAZ 2107 car, many motorists notice an increase in fuel consumption. You need to understand that after installing the EMR, gasoline consumption may increase, and this is quite normal. And especially when the service life of the internal combustion engine exceeds 5-6 years.

The engine may be unstable at idle due to a malfunction in the control unit. Therefore, voltage is applied to the solenoid, and it is retracted accordingly, affecting the operation of the internal combustion engine. A clogged nozzle or idle channel may be to blame for incorrect engine operation, so it cannot fully pass the mixture.

Electropneumatic valve

The idle air valve (or economizer) is designed to stabilize engine operation at low speeds. Idle stability is ensured by the electro-pneumatic valve included in the economizer.

The electro-pneumatic valve itself operates through a control unit. Depending on the number of engine revolutions, the unit sends a signal to open or close the valve. The valve, in turn, increases or decreases the fuel pressure in the system, which ensures idle stability. In addition, this operating scheme can significantly reduce fuel consumption.

The electro-pneumatic valve is designed to stabilize engine operation at low speeds

To check the electric pneumatic valve, you will need a simple hose that matches the diameter of the fitting of the valve itself. To quickly remove the hoses, it is recommended to use screwdrivers. To check the valve you must:

- Make sure the engine is cool.

- Open the hood of the car.

- Clean the surface of the electro-pneumatic valve from dust and dirt.

- Remove all supply lines from the valve.

- Connect the hose to the fitting in the center of the valve.

- Using a pump, create a vacuum of air in the hose (this can be done without a pump, sucking air from the hose with your mouth, but be careful).

- Turn on the ignition and make sure that the valve operates with characteristic clicks when opening and closing. In operating condition, the valve should not allow air to pass through. If it is faulty, then even with the ignition off, air will immediately begin to flow through it.

Diagnostics and repair of EPHH

Diagnosing a faulty economizer is not that difficult; you just need to understand how it works and the principle of operation of the economizer. In the future, you will be able to eliminate the main difficulties yourself.

You can replace the EPHH or clean the jet without dismantling the carburetor. The procedure is carried out as follows:

- Carefully remove the air filter.

- Disconnect the power wire from the economizer, after which it should be unscrewed from the housing.

- Remove the jet and thoroughly wash it in kerosene.

- Briefly connect the economizer to the battery. If the drive is more than 5 mm, this indicates normal operation of the device. Otherwise, it will have to be replaced with a new one.

Important!

All repair and diagnostic work must be carried out with a dry carburetor, that is, the fuel must be drained from it.

To independently diagnose a malfunction of the EMR injection VAZ 2107, we suggest you watch the video:

Setting up the DAAZ 2107 carburetor

https://www.youtube.com/watch?v=CCo52WIF2O4

How to check the main carburetor systems, remove it from the intake manifold and drain the fuel, read the article (Carburetor). Also carefully read the article (safety precautions for car repair and maintenance), this will help you avoid fuel fires.

You can replace the EPHH or clean its jet without removing the carburetor. Remove the air filter, disconnect the wire from the economizer and unscrew it from the carburetor body. Remove the jet from the plastic drive and wash it. Using two wires, connect the EPHH to the battery; if the drive retracts more than 5 mm, the economizer is working.

Carry out any work related to the EMR only on a removed carburetor, draining the fuel from it. Place the bottom of the carburetor on a clean table and remove the 3 screws securing the cover and diaphragm. Remove the cap and diaphragm, being careful not to lose the spring. Remove the vacuum ignition timing regulator hose and place it on the valve. Try to suck air through this hose. If the valve is working properly, then air will not pass through. If air passes through, the valve must be replaced.

The DAAZ plant, the main supplier of carburetors for VAZ cars, does not produce spare valves, so it will either have to be removed from another carburetor, or products from other manufacturers will have to be used. To remove the valve, you will need a flat head screwdriver and a blow torch. Using a blowtorch, heat the bottom of the carburetor to a temperature of 100–120 degrees and use duckbills to pull the valve out of the seat.

Do not overheat the carburetor. When the carburetor has cooled, be sure to clean all EMR passages. Before installing a new valve, heat the carburetor to 80–90 degrees. Then insert the new valve and, using light blows, through a mandrel whose internal diameter is slightly larger than the cut valve tube, press it into place.

- the car loses dynamics when accelerating;

- when you press the accelerator pedal, the engine starts to work with dips;

- there are jerks when moving at the same speed;

- the car begins to sway for no apparent reason;

- Black exhaust comes out of the muffler.

Carburetor ignition poses a great danger to the driver of a VAZ 2107.

The following malfunctions are typical for carburetors of all VAZ models:

- wear of rubber and paronite gaskets;

- end of valve life;

- flange deformation;

- cracks in membranes;

- valve needle sticking or worn out.

The carburetor consists of:

- top cover;

- housings;

- lower part.

Inside each of these parts there are smaller parts, which form the continuity of fuel supply and combustion.

The metal cast carburetor body contains many small parts

The top cover is located at the top of the carburetor and protects the engine from dirt and dust from the street. The main elements of the device are located in the body (the middle part of the carburetor) - two internal combustion chambers and diffusers. Finally, at the bottom, often called the base of the carburetor, is the throttle body and float chamber.

The VAZ 2107 carburetor consists of many small elements

The average owner of a VAZ 2107 does not need to remember the exact design of the carburetor. It is enough just to know the purpose and location of its main elements:

- Float chamber. Designed to accumulate gasoline in the amount necessary for engine operation.

- Float. Located in the float chamber to regulate the amount of incoming fuel.

- Needle valve mechanism. Designed to start or stop supplying fuel to the chamber as needed.

- Throttle and air dampers. Regulate the composition of the fuel-air mixture.

- Channels and jets. Designed to supply and adjust the composition of the fuel-air mixture entering the internal combustion chamber.

- Spray. Creates a fuel-air mixture of the required concentration.

- Diffusers. Designed to pump air into the carburetor.

- Acceleration pump. Optimizes the operation of all carburetor systems.

In addition, the carburetor has a number of additional functions:

- maintains a certain level of fuel;

- makes it easier to start and warm up the engine in the cold season;

- ensures engine idle operation.

The main function of a carburetor is to create and supply a certain amount of fuel-air mixture to the engine.

For self-repair, you will need a repair kit - a factory-prepared set of materials and parts necessary for the work. There are two types of standard repair kit:

- Full. Includes absolutely all possible elements that may be required to replace failed parts. It is usually purchased during major repairs or other serious faults.

- Incomplete. Allows you to carry out only one repair operation (for example, replacing jets).

The standard repair kit includes all types of gaskets, valve repair parts and adjusting screws

When repairing a VAZ 2107 carburetor, you will need a standard set of tools and a carburetor cleaner, which can be purchased at any auto store.

When repairing and servicing the carburetor, a special cleaner will be required.

Carburetors become dirty quickly. In a relatively short time, jets, channels and other small elements can become clogged with dust and impurities in the fuel. The moving parts of the device wear out quickly during aggressive driving. This primarily concerns sealing gaskets.

Typically, the carburetor repair process consists of disassembling, washing all parts, replacing worn and damaged elements, and reassembling.

Before starting repair work, you should pay attention to the following points.

- Work should be carried out on a cold engine to avoid the possibility of burns.

- You need to make sure that there is little fuel left in the system. Otherwise, most of the gasoline must be drained.

- Repairs must be carried out outside in dry weather or in a well-ventilated area (gasoline fumes can cause nausea and dizziness).

- You should prepare a clean place in advance for disassembling the carburetor and a container for washing it.

Before repairing the carburetor, you need to ventilate the room, clear the work area of debris and prepare the necessary set of tools.

Depending on the symptoms of the malfunction, you should pay attention to individual parts and components of the carburetor:

- If the engine idles unsteadily or stalls, then the economizer valve needle is most likely worn out.

- If during disassembly water is found in the cavity, then the carburetor has lost its seal. It is recommended to check all hoses and connections.

- The appearance of a flame under the hood indicates a fuel leak. A thorough inspection of all carburetor elements and a search for gaps or holes will be required.

- If, when independently adjusting the quality and quantity screws, the engine does not react in any way to the turns of the screws, you should remove them and check whether the threads are broken.

- If the carburetor starts to “shoot”, you need to check all wires and terminals for short circuits.

After flushing and repairing the carburetor, you can feel that the engine is running cleaner and more powerful.

Any repair begins with removing the carburetor mechanism from the car. Dismantling the device is carried out strictly according to the following scheme:

- Disconnect power from the battery.

- Remove the air filter housing (it prevents access to the carburetor).

- Disconnect all fuel and air supply hoses from the carburetor.

- Unscrew the bolts securing the carburetor to the body. If the bolts do not come out, you can apply WD-40 water repellent to them.

- Place the removed carburetor on a flat surface and clean it of dirt and gasoline stains.

Read more: What kind of car does Masha Rasputina have - what does the pop star drive?

The automotive industry is thriving - new types like electric vehicles and hybrids are being invented, production of models is being established, etc.

But this does not negate the fact that, figuratively speaking, outdated technologies remain on the roads, and therefore in the hands of motorists.

They may not be bad at all, but you won’t have any problems with them anyway. At least because of its venerable age for a complex mechanism.

Carburetor OZONE

This article will focus on this device. Along with other standard carburetors like Solex or Weber, OZONE was often installed on domestic cars. The operating principle of all three is the same, and much depends on its type, and not on the name of the plant.

The latter can be one of three - float, bubbler or needle.

The second is used extremely rarely, and in most countries it has simply been discontinued, but the latter still works in some places, but not in such quantities. The object in question belongs to the first type, which is still quite popular.

Consider the OZONE carburetor. 2107 - it is on this VAZ model that it can be found most often. But you need to know about some modifications that are also put into production.

First of all, this is DAAZ 2107-1107010, which is used most often. That is, this is the same standard OZONE carburetor that you will have to work with. In recent years of production of these models, they began to use such a modification as DAAZ 2107-1107010-20.

There is also a model that is not so popular, but it is worth mentioning. This is DAAZ 2107-1107010-10 - everything is, in principle, the same, but the ignition distributor here is designed without the use of a vacuum corrector.

The layout of the components is quite simple - for idle there is an autonomous system and a separate shut-off valve. There is a float chamber, which is mandatory for an OZONE carburetor of this type.

A throttle valve and metering system, as well as transition systems for chambers and a gas exhaust compartment are available. Actually, that's all you need to know about the design.

If more specific problems arise, you need to go to specialists.

- devices of the 2107-1107010-20 series were equipped with the latest versions of engines on the VAZ-2103 and VAZ-2106, which are equipped with vacuum correctors;

- modification of products 2107-1107010 was installed on power units 2103 (2106) of VAZ-2107 and VAZ-2105 cars;

- carburetors of the 2107-1107010-10 series were used on engines 2106 and 2103, which are equipped with an ignition distributor without vacuum correctors.

Replacing the economizer

Before starting work, you should collect all the necessary tools, then the replacement process will go much faster. You can make the replacement yourself, just follow these instructions:

- The engine must cool down for an hour before you can proceed with replacement.

- Using a 10 mm wrench, unscrew all the bolts that secure the air filter cover.

- Next, take a size 8 wrench and use it to unscrew the main fixing bolts. You now have access to the economizer sensor and carburetor.

- Now disconnect the connector that powers the micro valve.

- Using a screwdriver, unscrew the 2 bolts securing the EPH sensor.

- Remove the hose from the fitting, then move it to the side (it is advisable to fix it so that it does not interfere in the future).

- There is a spring installed under the panel located behind the sensor. It must be removed carefully, otherwise it may jump out and get lost. After installing the economizer, the sensor and spring should be replaced, as they begin to work worse over time.

- Then the entire system is installed; video tutorials from experienced car enthusiasts will help you with this.

Replacing the idle speed sensor

The idle speed sensor of the VAZ 2107 can only be removed together with the throttle body. To avoid burns when performing work, you must ensure that the engine is cool. To dismantle the sensor, perform the following operations:

After removing the sensor, you need to check the O-ring located at the mounting location of the idle speed sensor. If it is cracked or inelastic, it must be replaced.

Checking the idle speed sensor consists of monitoring the resistance between the terminals of its windings. Between AB and CD it should be approximately 53 Ohms, between AC and BD it tends to infinity. If the resistance is different, the idle speed sensor must be replaced with a new one.

Before installing a new sensor, you need to check the amount of protrusion of its needle. It should protrude no more than 23 mm. You can check this like this: