Having decided to purchase a new car, many car enthusiasts are faced with the choice of whether to choose a conventional manual transmission, an automatic transmission, a CVT or a robot. Today on the automotive market you can find models that satisfy almost all of our requirements and you just need to decide what suits you best. In this article we will look at what modern automatic transmission options are offered by various manufacturers and hope that our information will allow you to make the best choice.

So, the most familiar version of a manual transmission is well known to almost all drivers. It has its pros and cons. The mechanics have diehard fans, but everything is moving forward and constantly improving. Today, an increasing number of drivers prefer cars with various types of automated transmissions. This can be explained by the simplicity and ease of operation, as well as a greater feeling of comfort from the trip. The tendency to switch from manual to automatic is especially noticeable among female drivers. In this category of drivers, a manual automatic transmission will be chosen by a very small number of drivers. But automatic machines are also different, although not everyone understands how to identify a classic automatic or CVT. This group often includes:

- classic automatic or torque converter;

- variable speed drive;

- robot.

Automatic transmission

This category most often includes torque converters, which are most widespread in the modern automotive market. The operating principle of such a system is based on the fact that the automatic transmission is filled with a special transmission fluid, which is in constant motion in a vicious circle. This is achieved by constant pressure, which creates an oil flow that produces torque.

Like any other gearbox mechanism, the automatic is constantly being improved. If in the first years of the appearance of such automatic transmissions, the devices had 4 stages, today the most common automatic transmissions are those with 6, 7, and sometimes 8 gears. Such transmissions have a number of advantages, but along with this they also have significant disadvantages.

Advantages of an automatic transmission

- The car is much easier to drive in urban environments.

- Having an automatic transmission will make it more difficult to stall on the road, but if this happens, it will be impossible to get out of the problem area with the help of “swinging”.

- The automatic makes it easier to start on slippery roads, eliminating the possibility of slipping.

- The possibility of engine overheating is excluded.

- The transition from one gear to another is very smooth and is almost not felt in the cabin.

- Electronics are able to adapt to individual driving style.

Minuses

- Quite a high price for car models with automatic transmission.

- Automatic transmissions require high costs during maintenance or repair.

- The automatic transmission requires strict control over the level of transmission fluid. You can only replace it with an original or an approved analogue, which is also not cheap.

- Higher fuel consumption compared to conventional mechanics.

- A car with such an automatic transmission cannot be towed over long distances.

- The overclocking process is often not very good.

Driving comfort

About the creeping mode AMT 2.0

. When the brake pedal is released, movement begins, but with a greater delay. The car begins to accelerate unevenly, with twitching. The speed of the creeping mode is also questionable. At first everything happens so slowly and belatedly, but then it accelerates faster than we would like for driving in a traffic jam, and we have to slow down.

About engine braking on AMT

. Many people pay attention to the fact that the AMT has engine braking, while the CVT does not. Perhaps in mountainous conditions this is a useful function, but in city traffic jams this only has drawbacks. With AMT, the car cannot drive, roll, or roll up smoothly compared to a CVT. Either acceleration or engine braking occurs. It feels like being on an electric car in an amusement park. In a traffic jam you constantly have to play with the gas and brake pedals, such a game is very tiring.

Variable speed drive

Against this background, it feels like a normal automatic transmission. It starts, rolls, rolls up. On any climb, you can be sure that the car will move. Maneuvering in the parking lot does not raise any questions.

Variable speed drive

This is a more modern automatic transmission model that operates on a slightly different principle.

Classic mechanics and a CVT can sometimes be quite difficult to distinguish even for very experienced drivers, and not everyone understands well how a CVT differs from an automatic transmission. Visually, these are often very similar shift levers, but the operating principle of both mechanisms is significantly different.

The variator has two disks or pulleys, with a belt or, in rare cases, a chain stretched between them. When moving, these pulleys move or move apart, thereby changing the gear ratio. The difference between a CVT and an automatic is the fact that it has no gears at all. This mechanism was developed with the following goal: to make the transition from one speed to another as smooth as possible, which results in the absence of a power gap. The driver and passengers of the car receive maximum comfort from traveling in a car with a CVT, which is ensured by an amazingly smooth ride. Operating such a gearbox is almost no different from operating a classic automatic transmission. The variator has its obvious advantages, but, unfortunately, this is not an ideal option at all and designers still have a lot of work to do to eliminate a number of shortcomings. The following points can be considered as the pros and cons of the variator:

Advantages of CVTs

- Completely smooth ride for a comfortable ride.

- Fast acceleration, which is ensured by the fact that the torque is always at its peak, due to its design.

- The weight of the mechanism is very light.

- Saving in fuel consumption.

Disadvantages of CVTs

- Not suitable for those who like aggressive driving with sudden starts and frequent slipping.

- This device must not be loaded onto trailers or towed.

- The CVT is a rather noisy device, which is very noticeable in the cabin.

- The service life of the variator is somewhat shorter than that of a conventional automatic transmission.

- It has a fairly high cost of repair and maintenance. Sometimes it can be extremely difficult to find a workshop that can carry out high-quality repairs of this mechanism.

- A CVT requires lower production costs, but the service life is also much shorter compared to a classic automatic.

Consumption

Fuel consumption 1.8l with AMT

:

Fuel consumption 1.6l with CVT

:

The average speed is almost equal, and the difference in gasoline consumption is 3.5 liters! With a full tank, Vesta with AMT can travel 387 km, and with a CVT 537 km. Over 20 thousand kilometers (about a year of operation) you will spend 118,680 and 85,560 rubles on gasoline, respectively. The CVT is more economical by 33,120 rubles per year

. The difference over three warranty years will be about 100 thousand rubles.

Robot

A robotic gearbox is an attempt by designers to combine “mechanics” and an automatic transmission. The principle of operation of this device is that it is almost no different from the principle of operation of mechanics, but the speeds are switched automatically by a special control unit on a servo drive. Here the driver will feel the usual pause at the moment of switching and a number of other obvious signs of “mechanics”. In addition, this gearbox provides the ability to switch to full manual control. Today such a box can be found on cars of any class, from budget to premium.

Manufacturers have developed two types of robotic automatic transmissions:

- with one clutch - single disc;

- with two clutches.

Fans of such cars note both the pros and cons of driving such cars.

The only advantages of the first option can be considered a fairly low cost and economical fuel consumption. At the same time, while driving, the gear shift is very noticeable, which is expressed by jerks. The driver has to constantly adjust and try to release the gas in time.

The second option is that robots with two clutches combine the positive aspects of mechanics and a classic automatic machine. They are designed on the principle of two gearboxes working together – with even and odd gears. Both boxes are constantly in working order and due to this, the transition from one speed to another is almost imperceptible. There is no power gap at the moment of switching, and the car can accelerate quite quickly. Such devices are much less afraid of increased loads.

The obvious disadvantages of such boxes include frequent problems with servomechanisms, which are difficult to repair and often require complete replacement, which is quite expensive. The automatic transmission itself works without problems for approximately 120 -170 thousand km. Then there will be expensive repairs or complete replacement.

Which is better: DSG 6 or 7

DSG type gearbox is a robotic transmission unit. For the first time, Skoda and Volkswagen began to use this type of box in their cars en masse. We must remember: DSG and automatic are not the same thing. In this case, the driver's participation in changing gears is not required. The abbreviation DSG stands for relatively simply:

- in English - Direct Shift Gearbox;

- in German – Direktschaltgetriebe.

Main advantages and features of DSG type boxes:

- there is practically no gap between different gears;

- ease of control - no need to operate three pedals (gas, clutch, brake);

- fuel is consumed more efficiently - 10% less than when driving a manual or conventional automatic transmission.

It is worth noting: some boxes allow gear shifting not only in automatic modes. But also manually. This option is not available on all models. It should be noted that the design principle of the DSG box is almost completely consistent with the usual mechanical one. The main difference from a conventional manual transmission is the presence of two clutches at the same time. When changing gears, one of the clutches disengages. The second, on the contrary, turns on.

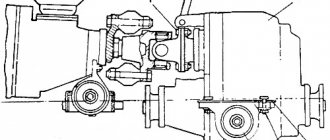

DSG device

It is in this way that the transmission torque is switched. Based on what was written above, it becomes clear that there are also two transmission shafts. In fact, the DSG is two boxes at once:

- for even gears;

- for odd gears.

The two boxes themselves work simultaneously. When you start moving, two gears are engaged simultaneously - first and second. But at the same time the clutch on the second one is disabled. At the moment of gear shifting, the clutch of the first gearbox is disengaged. The second clutch is turned on. All other gears are switched in a similar manner.

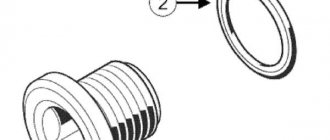

DSG clutch

Many owners wonder: why is a gearbox of this type called robotic - when the switching process is 100% automatic? The reason for this is the microprocessor system used to change gears. This is what distinguishes the box in question from a regular automatic machine. The gears are switched using conventional synchronizers. But the forks are driven by special hydraulic cylinders.

The clutch drive itself on the DSG is also turned on and off by hydraulic elements. A special unit – mechatronics – controls all processes occurring inside the transmission. The block includes the following main components:

- electronic;

- hydraulic;

- electrical.

The work of mechatronics consists of analyzing data from special sensors - they monitor the speed of rotation of the shafts at the input and output of the box, oil temperature and many other characteristics. The device in question is programmed. Specialist developers have written a special program for controlling electrohydraulics.

Appearance of mechatronics

Today, the automaker Skoda uses 2 different types of DSG preselective gearboxes - 6 and 7. Version 6 was released a little earlier, in 2003. But it continues to be used to this day. Version 7 - released in 2006. The first thing that distinguishes these gearboxes is the number of gears. It corresponds to the markings (6 and 7, respectively).

Another important difference between the DSG 6 (the model is marked as VW02E) is the “wet” clutch. All basket discs are constantly in a special oil bath. Moreover, such oil simultaneously solves two problems - cooling and lubrication. Which also has a positive effect on the clutch life. The box marked 6 is used on more powerful engines. She can easily “digest” a thrust of 325 Newtons. Allowed for use with 3.2 l 250 hp engines.

The DSG 7 box operates on a “dry” clutch; this model is marked as VW 0AM. Its cost is slightly less. A gearbox of this type is initially developed for low-power engines - with a torque of less than 250 hp. Moreover, this version of the box requires less oil and saves up to 10% of fuel. Often used for crossovers. It is difficult to determine which is better - wet or dry. Each box was designed to solve specific problems. Owner reviews of both types are positive.

What is better to choose

As you can already understand from the article, each type of transmission has its own pros and cons, and the choice must be made based on your personal capabilities and needs.

- If you prefer comfort and leisurely driving, then you should choose a car equipped with a CVT.

- For those who like reliability and frequent changes of car, a classic automatic is suitable. Cars of this type are the most popular in today's car market.

- An automatic robot with one disc can be a good solution for car enthusiasts who have limited financial resources but want to purchase a car with an automatic. Despite the low level of comfort, the motorist receives an inexpensive car with economical fuel consumption.

A robot with two disks should only be purchased new. When buying a used car, the owner must be prepared to soon replace or overhaul the robotic box, which means significant costs.

Robotic gearbox

A robotic gearbox is a device that receives and transmits torque to the drive wheels, first converting it. The entire process in such a device is controlled automatically.

Manual transmission

However, this does not make it an automatic transmission option. The only similarity is the clutch box present in the body. The robotic gearbox is similar to a manual gearbox, which is controlled by an automated system.