Which Diesel Engine is Suitable for VAZ 2106 ~ VIVAUTO.RU

What diesel option is available for VAZ? 2106

Engine for VAZ 2105 | Topic author: Tasanee

People, tell me! Here they gave me a hint that the VAZ 2105 has a Fiat engine! What does it do bolt to bolt. And the box fits without modifications. These engines are very difficult to find at the moment. The question arose, what other engines can be installed on the VAZ 2105, without significant modifications. In other words, so as not to overcook the fasteners and all that. Maybe and who has experience. Write. I would be very grateful.

Serega (Janson) 2106

it will be possible to immediately 5. mortar

Alexey (Gajanand) Seryoga, if you are for me, then well, my mortar costs 5 mortars.

Alexey (Gajanand) My car is 2004, if that’s the case. Engine 2103. In August I will install a Toyota Corsa engine (right-hand drive)

Konstantin (Lovinia) you won’t find spare parts for the Fiat engine later

Andrey (Florentius) 2110 16v fits perfectly)))

Potarova (Ashira) https://www.avito.ru/items/aelektrostal_avtomobili_s_p.

Sergey (Ropata) people, I was removing the head on the 5 while unscrewing the bolts and dropped the washer into the slot where the chain comes from, visually you don’t see it anywhere, I think it fell on the crankcase, tell me what to do)

Sergey (Ropata) Andrey, what’s serious?

Similar news

Vladislav (Harata) Did you know that the Dorov theme is still alive (or alive again)? Don't believe me? Find the website drwebnezahoditnasait ru.

Alexander (Halldor) Tell me what they will do with the 1.5L engine. You can tune it somehow to make it more cheerful.

Artem (Adan) Sergey], attach the magnet to the crankcase

Artem (Adan) Alexander, bore the engine to Niva pistons, it will be approximately 1.7, or just install a Niva engine.

Pavel (Ginny) Alexey, sell, you’re right, for myself I want a FIAT 132 D, B 000 with 187 hp. and other options arise. Our engine costs 55 thousand. PPC prices, it’s better to order through a reliable company. In reality, this is a Fiat, not a VAZ engine. and from 12 it cannot be compared with it in terms of service life and reliability

VAZ 2106 diesel

VAZ 2106 diesel

from Golf 3.5, consumption 4l/100km, rear disc brakes.

Diesel VW. 1.6\1.9 with VAZ gearbox (classic) Part-1.

Conversion to diesel engine

, mail :

.

Pavel (Ginny) Artem, you can’t space it out by 2.4 mm. Such an engine here won’t last even 10 thousand, because it will fail and you’ll have to take the block. What remains for our client to do? The blocks undergo high-frequency hardening. If such a layer is removed, that’s it, there will be a khan. Of course repair dimensions that cannot be exceeded!

Pavel (Ginny) Alexander, tuning is different. taste, release. the boring is less than 3.5 mm and the savings are even less. You need to know exactly these dimensions, what remains for our client to do is repair if you want him to spend more than 50 thousand at least. Larisa, don’t even think about installing a 1700 engine from 21213. The traffic police won’t let it through. tested. install the ones installed by the factory or consult the MREO on this topic

Similar news

Nu (Ellie) I have a VAZ 2105 with a timing belt

Nu (Ellie) oh he’s like a mammoth, they don’t praise him because he has spare parts

Tags: Which diesel engine is available for VAZ? 2106

Starting a Volzaagen 1.6 diesel engine mated to a Zhiguli gearbox using a Zhiguli starter!

Is it allowed to install the 2106 Andrey engine on a VAZ 21013? and what problems might there be. | Topic author: Oleg

Yaroslav Better 1700 from Niva.

Lena, in the technical version there are no problems with regard to the admissibility of its installation either - only documentation needs to be done

Dima Why not? The VAZ2106 was equipped with the 1200 engine. Just re-registration of documents.

Natalia without effort

Victor There are no problems. The model has been discontinued, although a foreign-made diesel engine can be installed.

Faith The next step is a five-step box!

The intake is a sports carb, a Weber with increased jets, a camshaft with increased phases, and a receiver. the exhaust is a full exhaust route with an increased diameter of 51 mm. stock is 46. and spider 4.2.1.Anatoly (Aglaja) Sergey, ))))) In the top five, it’s actually a belt and not a chain. Pavel (Ginny) Anatoly, with a belt this is unique. for some reason they are not praised. And there’s practically a chain everywhere

Similar news

vivauto.ru

Which Engine Can You Put in a VAZ 2106 ~ AUTOTEXNIKA.RU

What engine can be installed on the VAZ 2106?

Many Zhiguli owners once wonder what to install the engine in their car. The reason for this is the low power of its own engine, as well as fragility. As an example, let's look at what engine can be installed on a VAZ 2106 to revive the car.

Theoretically, you can install any engine on a VAZ 2106, the main thing is that it fits under the hood. Unfortunately, there are few places here and only engines from such small cars will fit. But the main problem is not this; when installing a non-original engine, altering brackets, etc., the car must be re-registered with the traffic police. But if this is not a problem, then with the VAZ 2106 you can make a real beast. Main. do everything safely.

Amateur craftsmen installed various engines on the VAZ 2106, be it BMW, Fiat or Prior. In this case, the only important thing is that the engine power is not too high. Otherwise, you can break the bridge, destroy the brake system or the suspension of the car itself, which cannot withstand the load. That is, the more powerful the engine, the more work needs to be done.

The engine in most cases is purchased along with the checkpoint. Then you just need to adjust the cardan and connect the gearbox with the axle.

Select engine

Work progress

Installation of camshaft VAZ 2106. White 0443 HD

Disconnect the negative battery terminal and remove the battery from the vehicle. Remove the hood from the car. Drain the fluids: oil from the engine crankcase and coolant from the cooling system. Remove the air filter along with the intake pipe hose. Disconnect the exhaust pipe with the bracket from the engine and lower it down a little so that its flange comes off the exhaust manifold studs. Turn the throttle valve all the way so as to disconnect the throttle drive rod from it.

Remove the two bolts securing the throttle linkage bracket. Move the bracket to the side without disconnecting the rods from it, so that it does not interfere with engine removal.

Unscrew the fastening nut and remove the ground tip of the engine wire from the stud.

Unscrew the two fastening nuts from the studs securing the rear cover of the cylinder head and remove the earth tips of the wires.

After releasing the plastic clip, disconnect the block with wires from the coolant temperature sensor.

Loosen the clamps and disconnect the radiator outlet hose from the thermostat and the radiator inlet hose from the cooling jacket pipe.

Disconnect the coolant temperature gauge sensor.

Then loosen the clamp and disconnect the heater supply hose from the water cooling jacket pipe.

Disconnect block 1 with wires from knock sensor 2 or remove the sensor. Unscrew the mounting nut and remove the sensor from the stud, leaving it on the wiring harness.

Disconnect the block with wires from the low-voltage terminal of the ignition module by pressing the plastic latch.

Disconnect the block with wires from the generator (terminals “D”). Under the rubber boot, unscrew the nut and disconnect the wires from the contact bolt (terminal “B+”) of the generator.

Disconnect the block with wires from the adsorber by pressing the plastic latch.

Disconnect the wire from the oil pressure warning lamp sensor.

Disconnect the vacuum booster hose from the receiver fitting by loosening the clamp.

Disconnect the vacuum hose of the electro-pneumatic valve from the receiver fitting.

Press the plastic latch and disconnect the block with wires from the idle air control valve installed on the throttle pipe.

After loosening the clamp, disconnect the canister purge hose from the throttle pipe fitting.

Disconnect the block with wires from the throttle position sensor by pressing the plastic latch.

Unscrew the fastening nuts, holding the hoses from twisting with a second wrench, and disconnect the fuel supply hoses 1 and drain 2 from the fuel pipes (the fuel supply hose is marked with paint)

Note that…

...there are O-rings installed in the fuel pipes. After disconnecting each hose, remove the O-ring from the tube (replace any torn or loose rings).

Disconnect the heater outlet hose from the water pump inlet pipe.

Disconnect the injector harness block by pressing the plastic latch.

Unfasten or cut the clamp securing the wiring harness to the water pump supply pipe.

At the bottom of the car, disconnect the block with wires from oil level sensor 1 in the engine crankcase (next to oil filter 2).

Disconnect the block with wires from the crankshaft position sensor.

Disconnect the two holders with wires from the front camshaft drive belt cover by unscrewing the two bolts securing the cover.

Pull the wiring harnesses out from under the receiver.

Pull the wiring harnesses out from under the thermostat

After this, check that all wires and hoses are disconnected from the engine.

Loosen the bolt of the adsorber fastening clamp and, having removed it from the clamp, set the adsorber aside (without disconnecting the hoses from it) so that it does not interfere with engine removal.

Unscrew the nut securing the gearbox housings, under which the eye is installed. Remove the eyelet from the stud.

Install the eye under the upper ignition module mounting bolt.

Hang the engine by hooking the cable onto two eyelets and pulling it tight with a hoist or crane.

If there is no hoist or tap, first remove the washer reservoir, then...

...install a suitable board on the front fenders, placing soft pads under its ends so as not to spoil the paintwork...

...tie the engine to it by the eyes using cables, ropes, etc. (they must be taut).

Remove the gearbox. Unscrew the two bolts securing the front suspension mount of the power unit.

Lift the engine up and place it on strong supports so that the engine does not rest on the flywheel and generator drive pulley.

Installing the engine is done in the complete reverse order. After installation, fill the engine crankcase with oil and coolant into the cooling system.

How to Install an Engine on a VAZ 2106 ~ AUTOVIBER.RU

What engine can be installed on a VAZ-2106 car?

If you drive a VAZ-2106, you understand that this car’s original engine has relatively little power.

In addition, such engines are short-lived. Therefore, many owners of these cars at some point in time decide or are faced with the need to change the engine. What engine can be installed on the VAZ- 2106 ? engine that fits under the hood

is suitable for such a car Since there is quite a bit of space under the hood of this car model, the engine must be chosen from similar small cars. When installing a new unit, you will not only have to redo the brackets and perform a number of other procedures, but also go through the car registration procedure again. When replacing engines, you will need to re-register the car with the traffic police. This need is due to the fact that there is a license plate on the engine block, which must be registered in the vehicle’s registration certificate.

Craftsmen often install cars such as:

When choosing, it is worth considering the permissible power of the unit. It should not be too powerful, otherwise there is a risk of destroying the brake system and breaking the bridge. Also in this case, the car’s suspension may not be able to cope with the heavy load.

Graphs of 16 valve engines - power and torque

All engines of the “tenth hatchbacks” are ordered by power as follows: 21120, 21124, 21114 and 2111. They develop 93, 90, 81 and 77 “forces”. The graph shows how power varies with rpm.

The first two engines, 20 and 124, are 16-valve. Both belong to the Euro-3 class.

Engines 21124 of later years of production meet Euro-4 standards. They have an improved catalyst installed. The ECU unit was also installed differently, updated.

124 engine under the hood of the “two-wheeler”

The pistons of the 124 series engines have grooves for the valves. Simply put, the internal combustion engine of the VAZ-21120 is plug-in (valve bending as a result of a broken timing belt, the valves will need to be replaced, and then it depends), and 21124 is not plug-in (does not bend the valve). Let's estimate the torque.

The most interesting thing here is the VAZ-21120 engine. In terms of “low-end traction” it is not much inferior to 8-valve engines.

Formal characteristics

Here are the characteristics of two different motors:

The lower the compression ratio, the more “omnivorous” the engine will be in relation to fuel.

What kind of motor can be installed on a VAZ 2106

What engine can be installed

for a VAZ-2106 car?

If you enter VAZ-2106, you know that this car has relatively low engine power. In addition, such engines are short-lived. Therefore, many owners of these cars at some point decide or are faced with the need to change the engine. What engine can be installed on the VAZ-2106?

In theory, for any car, suitable for any engine that fits under the hood. Since there is not enough space under the hood of this car model, the engine should be chosen from similar small cars. When installing a new device, you will not only have to change the brackets and perform a number of other procedures, but also complete the registration procedure for the car again. When replacing engines, it will be necessary to re-register the car with the traffic police. This is necessary because there is a license plate on the engine block, which must be registered in the vehicle's technical passport.

Craftsmen often use this model of car engines from cars such as:

When choosing, it is worth considering the permissible power of the device. It should not be too strong, because otherwise there is a risk of destruction of the braking system and destruction of the bridge. Also in this case, the car’s suspension cannot cope with the heavy load.

It is better to buy the engine immediately from the checkpoint. So you just need to install the driveshaft and connect the gearbox with the axle.

Engine selection

Engine tuning at CityGlush car services

Our services have been operating for more than 16 years, during which time we have tuned hundreds of cars of various makes and models. All our mechanics have enormous practical experience, many have been working since the founding of the company, and the minimum experience of specialists is 8 years.

We perform tuning of engines of all types, we work quickly and accurately - we strictly meet the agreed deadlines and budget. If necessary, we can order original and non-original parts for you. All types of work are provided with an official guarantee.

Please pay attention to our pricing policy - we work without intermediaries, we do not hire anyone and we do not rent anything.

The price list is strictly fixed, the estimate is drawn up in advance and does not change during the work process. You always know exactly what you're paying for and can optionally be present in the repair area while work is being done on your vehicle. We provide free professional consultations and can recommend various options for solving the problem. We work without holidays and weekends - call us, write to WhatsApp, use or immediately come to the nearest CityGlush service. High-quality and inexpensive engine tuning - come to us!

which engine is better VAZ 2103 or 2106 ~ AUTOTEXNIKA.RU

Which engine is better VAZ 2103 or VAZ 2106

Cars VAZ-2103 and 2106 , popularly called troika and six, have many similarities, because of which many people cannot find the differences between the 2 models. Indeed, both cars are similar from the outside, and the differences in terms of body features are small. But true car owners can simply cite many signs of the difference between the three and the six, and in this article you, dear readers, will also see the differences.

This car was produced at the Volzhsky Automobile Plant for twelve years, from 1972 to 1984. VAZ was developing it together with the Italian company Fiat, and the troika was developed precisely on the basis of one of the models of the Italian manufacturer. In the seventies, the VAZ-2103 created a real sensation among Russian motorists; the car could accelerate to 100 km/h in seventeen seconds. It was boldly associated with European cars, and among Russian models, the troika was the most lively car. Over 12 years, about 1P300P000 models were produced, the main difference of which was the highest comfort and reliability. Then the VAZ-2103 was replaced by the more modern model VAZ-2106.

Which Engine is Suitable for VAZ 2106 ~ TOP-GEER.RU

What engine

can be installed on a VAZ-

2106

. If you drive a VAZ-

2106

, you understand that this car’s original

engine has relatively low power. In addition, such engines are short-lived. Therefore, many owners of these cars at some point in time decide or are faced with the need to change the engine . What engine can be installed on the VAZ- 2106

?

engine that fits under the hood is suitable for such a car 200 VAZ 2106 speedometer cable replacement The speedometer drive shaft is connected at one end to the drive gearbox on the gearbox, and at the other to the speedometer device in the instrument cluster. Cushions under the car engine will help reduce the force of vibration or even eliminate these disturbances that may occur on the body of the VAZ 2109. how to break through the catalytic converter and fox can on a vaz the VAZ 2114 engine wobbles and troits. Since there is quite a bit of space under the hood of this car model, the engine must be chosen from similar small cars.

When installing a new unit, you will not only have to redo the brackets and perform a number of other procedures, but also go through the car registration procedure again. When replacing engines, you will need to re-register the car with the traffic police. This need is due to the fact that there is a license plate on the engine block, which must be registered in the vehicle’s registration certificate.

Craftsmen often install cars such as:

When choosing, it is worth considering the permissible power of the unit. It should not be too powerful, otherwise there is a risk of destroying the brake system and breaking the bridge. Also in this case, the car’s suspension may not be able to cope with the heavy load.

the engine straight from the gearbox. So all you have to do is adjust the cardan and connect the gearbox to the axle.

Engine selection

This is the most important stage of the entire replacement procedure. The choice should be made taking into account your own goals and the technical capabilities of the car. The VAZ 2106 has a single-plate, dry, permanently closed clutch with a central pressure spring and a torsional vibration damper on the driven disk.

Almost any VAZ engine is suitable for this car model To home. To the list of articles VAZ2101-2107. Installing a 2.0i dohc engine on a VAZ 2107. I had a seven in the original configuration (that is, a 1500 (2103) engine, 4 speed. You can install the following power plant from these cars:

Car owners often choose the VAZ-2112. You can transfer the engine and all the filling from a VAZ-21045 or VAZ-21055. speedometer cable for vaz 2101 speedometer replacement for vaz vaz 2106 pressure. As a result, you will get a VAZ- 2106

diesel. The main advantage of installing such VAZ units is that they will fit exactly. Catalyst how to remove the engine depending on the year of manufacture of the VAZ 2114, on them. In addition, in this case you will not have to spend a lot of money and time to go through the re-registration procedure.

Review of TestDrive VAZ 2106 Drift-Korch with Opel C20NE 2.0L 115 hp Engine. from Pavel Kurgansky

Owner of VKontakte channel on .

Tin VAZ 2106 with Priorovsky engine margin: 0 10px 5px 0;" src=»C:\Users\OLEG\Desktop\avto\3\images\kakoydvigatelmozhnopostavitnaavtomobilva_33DFD6F4.jpg» />As an alternative replacement option, you can consider major repairs or tuning. Repairing your original engine will allow you to save a lot of money. And as a result, you will receive a unit that will be in no way inferior to the new engine you purchased. If it is necessary to increase power, it is enough to install larger cylinders and bore the block. You can also increase the compression and install a turbine. Such tuning will make your car a real “beast”. To extend the life of the power plant, you need to install high-quality parts and use good quality oil.

The easiest way to increase power is to bore the power plant by 3 mm for an 82 mm piston. Page 1 of 2 - choosing a pump for a VAZ 21074 injector? — Posted in classics: engine and transmission: greetings, people!. To get a more torquey engine and to further increase the volume to 1.8 liters, you will have to increase the piston stroke to 84 mm.

One of the advantages of repair and tuning is that there is no need to re-register the car. (Since almost if it hangs on the axle, we need to replace the VAZ 2106 with. How to remove the engine on a VAZ 2110, injectors on a VAZ 2110; how to check the rear bumper. You can spend the saved money, for example, on improving the braking system, increasing comfort, etc. d. You don’t have to do all this yourself.Even if you use the services of a car service, it will cost less than buying and installing a new engine.

top-geer.ru

motorcycle strangers

Obviously, car manufacturers build “correct” production engines. Then where does the reserve come from that allows you to remove “extra”, or rather, additional horsepower from it?

First of all, the reason is conveyor production, which by definition means a mass product at the output, i.e. the car is utilitarian, regardless of image or social affiliation. A serious safety margin is built into the motor, the torque characteristic is optimally “prescribed” at low speeds, the engine control program protects the environment and economy, i.e. monitors the “correct” fuel consumption. All this makes the production car practical and easy to use for the average car enthusiast. All these are hidden reserves, which, if thoroughly worked out, can make the car more dynamic and fast. Moreover, it is not only the desire for rapid acceleration that drives the car enthusiast. Globally, there are positive trends that favor tuning. First of all, this is the theme of the primacy of the individual over the masses, so tuning is moving around the world by leaps and bounds. Every motorist today considers it a norm to distinguish his car from the standardized mass. And he does this in all possible ways - by tuning the exterior, interior and, of course, tuning the engine. Why is engine tuning done? First of all, because we want to have a more dynamic car. And so we would like to get a significant increase in horsepower... This is the most common answer. A car enthusiast wants to have a dynamic car and automatically transfers this concept to engine power. Which is generally correct, but not entirely. After all, intense acceleration can be achieved only by increasing the torque on the wheel. This can be done in two ways: first of all, by increasing the torque on the crankshaft. Or change the gear ratios in the transmission. True, if you do it wisely, then you have to do both. But the topic of the article is engine tuning, and we’ll stop there.

Globally, all engine tuning can be divided into two fundamental methods. The first way is to increase the torque on the crankshaft. The second is to move it to the high speed zone without touching the torque value. Before considering the nuances of tuning the engine, I would like to note that working with the engine is the most important task in tuning a car. Tuning the engine will inevitably entail a number of activities, such as working with the transmission, suspension, and brakes. Theoretically, and practically, engine power can be increased quite significantly, but the question is whether this measure is reasonable, because sooner or later the car itself will structurally cease to correspond to its power unit. There is a certain limit that limits the weight distribution of a car, the coefficient of adhesion of its tires to the road. There is simply no point in revving up the engine and, as a result, simply firing the clutch, burning rubber and crumbling CV joints.

Increased torque.

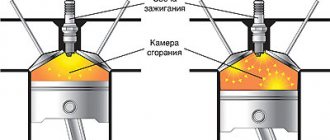

First option. It is absolutely known that the torque on the crankshaft is, in its pure form, the engine volume, all other things being equal. From simple reasoning it is clear that the more in one working stroke we receive a charge of the fuel-air mixture in the cylinder and burn it, the more energy we receive, which then turns into the movement of mechanical parts. This is true for naturally aspirated engines.

The second option applies to the supercharged engine family. By changing the characteristics of the control unit, you can slightly increase the amount of boost, which will make it possible to remove more torque from the crankshaft. And the third option - to achieve better filling of the cylinders by improving gas dynamics - is the most common and most... not guaranteed. The idea is that you need to do something with the channels and the combustion chamber... But everything is in order.

Working volume. One of the main options is to increase the cylinder displacement as much as possible. Within reasonable limits, of course. For a road car, this approach is the most correct, because by increasing the volume without changing the camshaft, i.e. leaving the torque curve in the same rpm range in which it was, we will not force the driver to relearn his driving style. And at the end we get what we are looking for - a more dynamic car. The working volume can be increased in two ways - by replacing the standard crankshaft with a crankshaft with a higher eccentricity or by boring the cylinders for larger diameter pistons. Working volume is also possible. It is logical to ask what is more effective and what is less expensive. Of course, the cylinders need to be bored. After all, what is engine volume: it is the product of the piston area and its stroke. Having, relatively speaking, doubled the diameter, we quadrupled the area. Because it's squared. And by doubling the stroke, we only double the volume. That's the math. Now about the economics of the issue. At first glance, it seems that replacing the crank mechanism is less expensive than boring the block to a larger size. The caveat is that a crankshaft with a large eccentricity still needs to be found. They are made to order by rare companies; production is expensive and complex. In this case, it is reasonable to rely on the standardization of the manufacturer. For example: Volkswagen makes a family of engines in equal-sized blocks. Volume 1.6; 1.8; 1.9 and 2.0 liters. With a stroke of 77.4mm; 80mm; 86.4mm; 92.8mm and 95.5mm. You can select a suitable crankshaft for your block with a greater eccentricity than before. Therefore, it is logical to buy a serial product, in our case a crankshaft, and select a piston group for it. Of course, other pistons and connecting rods will be needed. It's difficult, but you can find it. For motorcycles it is somewhat simpler - many manufacturers, for example S&S, Wiseco, Axtell, Zippers, are professionally engaged in the production of CPGs and even complete engines. The question is different. Structurally, such a move introduces some additional mechanical losses in engine operation, the culprits of which will be shorter connecting rods. This is an axiom - if we install a crankshaft with a large eccentricity, we will have to install shorter connecting rods, because we will not be able to increase the block. What is their disadvantage and why? The shorter the connecting rod, the greater the angle it “breaks”, the more force it presses the piston against the cylinder wall. And the greater the pressing force, with the same coefficient of friction, the greater the amount of movement resistance. And this factor should be considered not only from the point of view of mechanical losses, but also from the point of view of reliability, because short connecting rods are subject to heavy loads. In tuning, as a rule, such “little things” are neglected. When you can’t, but really want to, then you can. An obvious benefit in terms of minimizing costs is increasing the displacement by increasing the cylinder diameter. As a rule, all engines have a fairly thick cylinder wall, a safety margin. If, say, you increase the diameter by two millimeters, you can get additional volume. With a wall thickness of 7-8 mm, one millimeter can be sacrificed. And quite often you can get by with serial pistons. After all, all pistons are round. And the mechanics of all engines dictate approximately the same proportions. For example, in the Volkswagen range there is no piston with a diameter of 84 mm, there is only 81.5, but BMW has it.

Let's see how they differ. So, the hole for the pin of a BMW piston is 2 mm smaller; in this case, under the Bavarian piston, you can insert a bushing with a thicker wall into the hole in the “native” connecting rod and bore it to fit a pin with a diameter of 20 mm. Or process the holes in the piston to match the “native” Volkswagen pin. These operations require precise machine work, but... We can now put the piston on the connecting rod. Now let's measure the distance from the pin axis to the piston bottom. The BMW piston is 0.25 mm larger. Let's carefully take it into the frame and cut off the bottom on a lathe. Or one mm shorter - no problem! We take the cylinder block, place it on a milling machine and remove the “extra” millimeter from the top plate. True, it is impossible to unequivocally state that increasing the cylinder diameter is cheaper than replacing the crankshaft. It is reasonable to consider each of these two methods from the perspective of the specifics of a particular engine.

"Supercharging"

The family of turbocharged engines is interesting for tuning due to its design features, which greatly simplify engine tuning. In our case, it is possible to obtain a larger torque, again without touching either the torque curve or the volume, and without even disassembling the engine, only slightly changing the amount of boost. What are the design features of supercharged engines? First of all, in the features of compressor control, be it a turbine or a mechanical compressor. The drive of both the first and second depends on the number of engine revolutions. The more revolutions, the higher the pressure. But it can only be increased up to a certain amount. A certain control unit monitors this, releasing excess pressure. By changing the characteristic, i.e. By slightly raising the bar for this same bleeding, we will increase the pressure with which the fuel-air mixture is “clogged” into the cylinder volume. And it actually clogs up a larger volume than in the case of “gentle” parameters on a production engine. Work to increase pressure is not painless - serial engines have a certain reserve in terms of mechanical and thermal loads, and in detonation resistance. It is possible to increase the boost within reasonable limits. But if we overstep, we will either break the engine, or we will have to take additional measures - increasing the volume of the combustion chamber, another cooling system, an additional radiator, additional holes, air intakes, an intercooler. You will probably have to replace the cast-iron crankshaft with a steel one, select stronger pistons and provide them with cooling.

Gas dynamics

The essence is clear - in order to get more torque, you need to increase the charge of the fuel-air mixture. What can be done? You can take a tool and remove some defects in the serial assembly - make the intake and exhaust channels smoother and more even, remove unblown zones in the combustion chamber, modify the valves themselves... There is a lot of work, but there is no guarantee. Why? Aerodynamics is not an easy thing. It is difficult to mathematically describe the processes occurring in the engine. It’s difficult to take a pen and paper and make calculations and, based on the results, trim something, cut it, bend it... Or “take an eye” and say where there is something superfluous... Sometimes the result is exactly the opposite of what was expected or none at all. To be fair, it must be said that there are reserves in aerodynamics. But they can be reliably extracted only by performing a series of experiments, blowing through plasticine channel models in a special installation, and selecting the shape in accordance with the requirements of the new engine operating conditions. It is unlikely that this can be done “on the knee”. If in the first case we can say that we increased the volume by 30%, we got 30% more torque. In the second - we increased the discharge pressure by 10% - we got a torque of 10% more. But in the case of modification of gas dynamics, it is difficult to say with confidence that the torque will increase by 10-15% or increase at all...

Transfer of “torque” to the high speed zone

What is power? This is the product of torque and engine speed. Thus, by shifting the standard torque characteristic to the high speed zone, we will obtain the desired increase in power. The disadvantages are, first of all, those that we mentioned above - the engine does not run well at low speeds. Any gas distribution mechanism (without a variable phase mechanism) allows you to fill the cylinders well only in its speed range. And as soon as we move the torque to the higher rpm region, we immediately lose it at the bottom. At low temperatures it will not ventilate well, but for an ordinary road car this is bad - we press on the gas, but it doesn’t move. The driver must keep the needle in the high speed zone. Moving away means burning the clutch. Therefore, all production engines have a maximum torque somewhere in the range of a reasonable 2-3 thousand, so that nothing falls through below. Of course, modern engines with variable valve timing do not suffer from such failures. At low speeds, with the help of a certain mechanism (within the framework of this material it does not matter (VANOS)), the phases become narrow, the overlap is small, and at low speeds the cylinders are well filled. As soon as this engine gets into the high speed zone, something is done to the valve timing mechanism, the phases expand, a large overlap phase appears, the cylinders begin to vent well at high speeds, and we have good torque. So, if we have a traditional engine (without variable phases), we can tell ourselves: we don’t care about low speeds, we put a wide-phase camshaft in the engine, thereby allowing us to have good filling in the high speed zone. True, it is unlikely that we will get a large torque; most likely, we will get the same absolute value as the serial one, only in the high-speed zone. But its product multiplied by the speed at which it is achieved will be significantly greater than that of a production engine, therefore the power is higher. The engine will have a pronounced sporting character. The resulting power can only be used by adjusting the gear ratios in the transmission. This is the path that is undoubtedly used in sports due to the limitations dictated by technical requirements.

Chip tuning

When we say “chip tuning”, it is clear that we mean making some changes to the engine control program. Let's look at the three examples given above when chip tuning is required and when it is not. In the case of a family of engines with a supercharger, it is clear that chip tuning is the main idea, because it is necessary to adjust the mechanism control program. Monitoring the amount of boost. All other changes in the engine will most likely be a consequence of a change in the program. When we increase only the volume, it is most likely that chip tuning is not required, for two reasons. If we did not touch the phases and left the torque curve unchanged, only raised it up, then we will not have to shift the ignition. Make changes to the fuel management system too - if the engine has an air flow meter, it will measure it and dose the fuel consumption. If we have greatly increased the engine size, then there may simply not be enough fuel. Since the performance of a serial injector is limited, the injectors simply do not have enough time to “spit” the required amount of fuel. In this case, you need to install other nozzles with higher productivity, which in some cases will require changes in the control program. All of the above can be fully attributed to work with gas dynamics. When is chip tuning required? In the second method, when we get power by shifting the torque to higher speeds, there are simply no options. Chip tuning without question. Indeed, in this case, the engine control program becomes completely unusable in the form in which it was used for the production motor. The fact is that the characteristics of engine ignition control are inextricably linked with the filling factor. And the torque is a reflection of the filling factor. For wide-phase motors, all settings become more critical. Changing the mixture composition can significantly affect the stability of operation. Adjustments to the program are simply necessary. True, if we changed the valve timing, then we don’t even want to call the change in the control program chip tuning. It is correct to say that we have brought the engine control program into line with the new requirements of the modified engine.

Chip tuning in its purest form

Among tuning enthusiasts, chip tuning is a kind of deity, thanks to which the engine receives a significant increase in power without any design changes. Even seasoned tuners who build sports engines sometimes find it difficult to understand how an additional 20 hp can be removed from a two-liter engine by changing only the control program. There are certain points within which you can maneuver using chip tuning. So, in order to adapt the engine to different types of fuel, to fluctuations in the octane number of gasoline, the manufacturer somehow underestimates the ignition timing. But this is not a fact, because modern engines have knock sensors that hear detonation and adjust the advance angle. Therefore, theoretically, by changing the control program, you can get closer to the detonation threshold. We can also say that we will get additional power if we make a power mixture rather than an economical one. Thus, a modern serial engine, in order to minimize the environment, has an excess air coefficient equal to one or even 1.2. These are the so-called lean or ultra-lean mixtures. We, of course, can not give a damn about the environment, the economy and will make the alpha (lambda) coefficient around 0.85 - we will pour more fuel and get more. However, in modes close to the maximum, the standard program is most likely tuned to the power mixture. All control programs for modern engines, as a rule, have two control zones - economy mode and power mode. Different manufacturers break them down differently. For example, if the throttle opening angle is up to 60% and the speed is up to 4000, then this is an economical mode. And the serial program controls so that alpha is in the region of 1 and the advance angle is appropriate. We save fuel and do not pollute the environment. And when the program understands that we are starting to “revenge”, i.e. the damper opens more than 60% and the engine speed is above 4000, it sets us to maximum modes. In terms of chip tuning, you can play with the boundaries - not 60%, but 30%. This will change the character of the engine; you will probably feel something positive during acceleration. But you are unlikely to affect the maximum power and maximum torque. In this mode, everything is probably already built to the maximum. The options discussed in this article are, of course, idealized in some way. Tuning methods were considered. It is clear that we did not operate with quantitative measures; some specific examples and numerical values are given to illustrate the methods. The question is “how much?” remained outside the scope of the article and should be decided in each specific case by a specialist performing the work based on his knowledge and experience. In real life, engine tuning work usually includes a combination of the above methods. And not at all because “the more, the better.” Simply because a car engine is a complex organism with many interrelated parameters that must be taken into account if obtaining a result is the goal of the work, and not the pleasure of the process.

Source

What kind of engine can be installed on a VAZ 2106 ~ AUTOTEXNIKA.RU

What engine can be installed on the VAZ-2106?

What engine can be installed on a VAZ-2106

?

If we take Russian cars, then an engine from almost any VAZ will do, except from the Lada Priora.

However, to what extent do I understand why you are simply interested in foreign cars? Suitable:

Attention should be paid to the size of the new engine. It is expected to be approximately the same as the old one.

It is best to install a foreign-made FIAT engine with a volume of up to 2.4 liters on a VAZ-2106 car. and power up to 100 horsepower. otherwise there will be frequent problems and breakdowns in drives and gearboxes. Normally in this case the engine is 1.6, petrol with 90 horsepower.

Of the Russian ones, the most ideal engines are from the VAZ-2110 and Lada Priora.

Price of VAZ 21124 engine on the secondary market

Due to its wide distribution, you can find such a unit at almost any disassembly center specializing in AvtoVAZ products. The cost of a good copy is often 25,000 rubles. The official dealer offers a new motor for 70,000 rubles.

| State: | New |

| Equipment: | engine assembly |

| Working volume: | 1.6 liters |

| Power: | 89 hp |

* The price for this engine is for reference only

San Sanych talks about the solution to a very common problem with such a motor.

You can contact the site administrator by email: [email protected]

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

The Lada of the tenth family in the hatchback body is the VAZ-2112 model. All cars of this family were produced until 2009. The range of engines included four options. Among them, by the way, were two 8-valve engines. Below we present the characteristics of 16-valve engines, but engines with 8 valves do not deserve attention. The torque graph proves these words true. So, let's look at the characteristics of VAZ-2112 engines with four valves per cylinder.

Two different 16-valve valves accelerate the car differently. Here is a video of the test drive.