The role of rims

Wheel rims deserve more attention, and not the generally accepted attitude, according to the principle: “they go and go.” Why? Because the condition of the car’s rims affects many aspects of the condition of the car’s systems, cost savings and traffic safety.

Being an integral element of the chassis and suspension of a car, faulty rims affect the following parameters:

- Serviceability of suspension elements. Radial or axial displacement of a damaged disk leads to failure of the steering mechanism, shock absorbers, and suspension elements.

- Savings and safety. A faulty wheel rim means tire failure, which means the cost of replacing it, increased fuel consumption and decreased safety while driving.

Restoration of car wheels - restoration and painting

As practice shows, wheels are precisely the part of the car that most often requires repair or replacement. Bad roads, potholes, bumps, and various kinds of obstacles lead to the destruction of wheel rims, as a result of which they require restoration.

Porsche wheels before and after restoration

Damage to wheel rims can be of different types. In case of severe deformation, cracks in the area of the hub or seats, or destruction of the structure due to overheating, no repair or correction will help.

In this case, you will just have to worry about buying new disks. If we are talking about minor deformation, chips, scratches or paint damage, then there is reason to believe that restoration can fix everything.

Straightening alloy car rims

If you find a disc on your car that is deformed, it can be restored using an operation such as straightening. Rolling of cast wheels on a roller stand is not carried out, as this can destroy the structure of the product. In this case, the pressing force of the rollers cannot be accurately calculated. Therefore, such restoration is not suitable for light alloy products.

The straightening of cast disks is carried out on a special machine, where the deformed area is corrected using various attachments on the hydraulic piston roller. In this case, the effort can be strictly dosed. The structure of the product remains intact - editing does not destroy it.

Some craftsmen use a hammer to straighten cast wheels for minor deformations. Light tapping straightens the shape, and the maximum possible restoration of the shape of the car wheel occurs, allowing it to be used. This method requires a lot of patience, as well as serious experience and relevant skills.

Argon welding of alloy car wheels

Restoring cast light-alloy wheels for cars using conventional welding is unacceptable. Due to heating, the structure of the disks is destroyed and they are no longer suitable for use. However, modern technologies offer a method such as argon welding. It is necessary in cases where repairs are carried out to eliminate microcracks, scratches or fusion of missing areas.

Argon welding is a combined method that includes elements of electric and gas welding. In this case, the work is carried out in an argon environment, which prevents surface oxidation while the repair lasts. And the structure in this case remains unharmed.

Argon welding of alloy wheels

Many experts argue that restoration of cast wheels using any type of welding is unacceptable. In this case, the product loses strength and cannot be considered reliable. Such repairs require only very mild operating conditions for the product.

Car wheel painting

The final part that completes any car wheel repair is painting them. Coloring can be done using two methods:

- powder;

- acrylic.

Powder painting is the highest quality, “native” method. It is used to apply paint to car wheels during the manufacturing process. However, this method is very difficult to carry out at home - it requires a special oven in order to fry the coating after it is applied. In addition, as we remember, the structure of light-alloy car wheels is destroyed if they are heated. Therefore, this method is clearly not suitable for restoration.

Powder coating of wheels

Acrylic paints provide a lower quality finish. And its service life is much shorter than that of powder paint. However, this method is quite applicable at home and is well suited for restoring car wheels.

Painting wheels with acrylic paint

Modern industry offers a large selection of acrylic enamels that are well suited for restoring the paintwork of a wheel. It should be remembered that it is important to organize the process correctly and diligently adhere to the technology. It includes the following operations:

- washing;

- drying;

- degreasing;

- grinding;

- puttying scratches and chips;

- re-grinding;

- padding;

- painting.

In order for the coloring to turn out to be of high quality and the paint to last for a long time, you need to conscientiously complete all points of the technological process. Otherwise, the enamel simply will not lie on the surface or will soon begin to fall off.

For restoration painting work, choose only high-quality materials: primers, putties and enamels. When grinding, change the abrasive tool with a gradual reduction in grain size. Be careful not to overdo it - rushing can ruin everything.

Conclusion

Restoration repair of alloy wheels of a car includes various works to return the product to characteristics that allow its further operation.

This may be an edit to correct shape defects. Argon welding is also possible for sealing microcracks and building up material in places where it is missing. The final stage is a complex of painting works.

Alloy wheels after restoration work and painting

When carrying out restoration work, you should remember the features of cast wheels - this will help to avoid their irreversible damage. Be careful and patient - there are no minor details here, every little thing can be important.

And remember: not only your safety, but also the health of your passengers, as well as drivers of oncoming cars, depends on the reliability of your vehicle’s wheels.

[democracy]

[democracy]

Author: Lagoda Vladislav Fedorovich

Higher education: secondary specialized. Specialty: Auto mechanic. Good knowledge of the design of foreign-made passenger cars. Work skills: replacing the timing belt of the cylinder head, chassis wheel alignment and maintenance. Repair…

okuzove.ru

How to repair rims

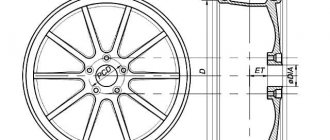

The condition of domestic roads makes us increasingly pay attention to such an event as repairing car rims. Repair of car wheels, depending on their type, can be divided into two types: repair and restoration. Moreover, the second type of repair relates more to the restoration of alloy wheels.

repair stamped and steel wheels ourselves, using a sledgehammer. But the external appearance of a repaired dent is very, very deceptive. A simple recommendation for repairing standard wheel rims, which are steel and stamped, is that if you get a dent on the rim, you should contact a tire shop. The equipment will allow you to roll the disc or roll it out.

With regard to alloy wheels, everything is a little more serious. Experts do not recommend repairing light alloy wheels using the rolling method. The structure of the metal is damaged and the cast disc loses its quality.

Repairing alloy wheels is a more serious matter due to the characteristics of the disk material. You should know that a real master will never undertake repairs to alloy wheels, as a rule, in two cases: if there is a crack at the base of the spokes or a crack near the mounting holes. He won’t take it, even if he is a “magician and wizard of argon welding.”

Repairing wheel rims with your own hands is a completely doable undertaking. But, under one condition: if the damage to the disk does not affect its parameters. As a rule, repairing and painting discs with your own hands is carried out in the case of small cracks on standard discs, which can be welded by conventional welding. This is the so-called disk restoration.

Restoration of alloy wheels can be done with your own hands if you are proficient in argon welding. If not, then the way out is service.

Painting alloy wheels

As a rule, after impacts on the road and wheel straightening, damage remains on the paintwork. In this case, painting alloy wheels will help. You can entrust this procedure to professionals at a car service center or do it yourself. Naturally, the latter will cost much less.

On a note

Alloy wheels can be painted in the color of the metal or in any other color, for example, in the color of the body. Before painting, preparation must be done. The alloys from which cast wheels are made most often have an aluminum base.

This non-ferrous metal has many useful properties, one of which is self-protection against corrosion. All parts made of aluminum or its alloys begin to be covered with a film of oxides from the moment of casting. This film has the highest tightness and protects the alloy from contact with oxygen.

It is also useful to read: Review of the main methods of straightening a car body

However, the oxide film has very low adhesion. The paint does not stick to it and will peel off after a while. To be precise, the paint falls off along with the top layers of oxides. One way or another, it is impossible to paint aluminum parts with high quality without special preparation.

Preparing alloy wheels for painting consists of:

- stripping to bare metal;

- applying a special primer (adhesive primer for non-ferrous metals);

- painting;

- application of protective varnish.

To clean the disc, use an angle grinder with a fine abrasive or wire attachment or a sandblaster. Sandblasting provides the highest quality of cleaning, since the surface of the disc is complex and the grinder head does not reach everywhere.

If painting is done with your own hands, and there is no sandblasting equipment available, then fine cleaning can be done with a drill. However, this will take much more time and effort. There are also chemical methods for removing old coatings, but in garage conditions their implementation is problematic.

On a note

Primer for non-ferrous metals performs an insulating function. The alloy wheel should be primed immediately after cleaning and degreasing. It should be remembered that the oxidation process of non-ferrous metals occurs very quickly, and an extremely undesirable film of oxides may appear within a few hours.

After applying the first layer of primer, after a short technological break, the second layer is applied. In this form, the disk can be left for any time. The soil will reliably protect the alloy from the appearance of patina.

Both special paints and body paints are suitable for painting the disc. You can paint it with metallic, xerallic and even liquid rubber. By the way, liquid rubber in cans, which is found on the shelves of car dealerships today, does not require lengthy preparation of the disc. It is enough to wipe its surface with solvent and wait until it evaporates completely.

The most famous brand of liquid rubber is Plasti Dip. This paint is applied straight from the can, and when dry it forms a film that can be easily removed. It is removed without a trace and does not harm the base at all.

The wheels can be painted with regular “repair” cans of automotive paint. But in this case, complete preparation is needed, the stages of which are described above.