How does a variable compression ratio engine work?

The idea of creating a gasoline engine, where the compression ratio in the cylinders would be a variable value, is not new. So, during acceleration, when the greatest engine output is required, you can sacrifice its efficiency for a few seconds by reducing the compression ratio - this will prevent detonation, spontaneous combustion of the fuel mixture, which can occur under high loads.

With uniform movement, on the contrary, it is desirable to increase the compression ratio in order to achieve more efficient combustion of the fuel mixture and reduce fuel consumption - in this case, the load on the engine is low and the risk of detonation is minimal.

Japanese designers were the first who managed to bring the idea to a production model.

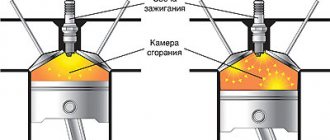

The difference in compression ratio depending on the TDC position of the piston. In the left picture the motor is in economy mode, in the right - in maximum efficiency mode. A: When a change in compression ratio is required, the electric motor turns and moves the actuator arm. B: The drive lever turns the control shaft. C: When the shaft rotates, it acts on the lever associated with the rocker arm, changing the angle of the latter. D: Depending on the position of the rocker arm, the TDC of the piston rises or falls, thereby changing the compression ratio.

The essence of the technology developed by Nissan is to, depending on the required engine output, continuously change the maximum height of the pistons (the so-called top dead center - TDC), which in turn leads to a decrease or increase in the compression ratio in the cylinders. The key part of this system is the special mounting of the connecting rods, which are connected to the crankshaft through a movable rocker arm block. The block, in turn, is connected to an eccentric control shaft and an electric motor, which, at the command of the electronics, sets this cunning mechanism in motion, changing the inclination of the rocker arms and the TDC position of the pistons in all four cylinders simultaneously.

Engine Infiniti VC-Turbo.

As a result, during acceleration the compression ratio decreases to 8:1, after which the engine switches to an economical operating mode with a compression ratio of 14:1. Its working volume varies from 1997 to 1970 cm3. The turbo-four develops a power of 268 hp. With. and a torque of 380 Nm - significantly more than the 2.5-liter V6 of its predecessor (its figures are 222 hp and 252 Nm), while consuming a third less gasoline. In addition, the VC-Turbo is 18 kg lighter, takes up less space under the hood and achieves maximum torque in the lower rev range.

By the way, the compression ratio adjustment system not only increases the efficiency of the engine, but also reduces the level of vibrations. Thanks to the rocker arms, the connecting rods occupy an almost vertical position during the working stroke of the pistons, while in conventional engines they move from side to side (which is why the connecting rods got their name). As a result, even without balance shafts, this 4-cylinder unit is as quiet and smooth as a V6. But the variable TDC position using a complex system of levers is not the only feature of the new engine. By changing the compression ratio, this unit is also capable of switching between two operating cycles: the classic Otto cycle, according to which the majority of gasoline engines operate, and the Atkinson cycle, found mainly in hybrids. In the latter case (with a high compression ratio), due to the larger piston stroke, the working mixture expands more, burning with greater efficiency, as a result, efficiency increases and gasoline consumption decreases.

In addition to two operating cycles, this engine also uses two injection systems: classic distributed MPI and direct GDI, which increases fuel combustion efficiency and avoids detonation at high compression ratios. Both systems operate alternately, and at high loads - simultaneously. A positive contribution to increasing engine efficiency is made by a special coating of the cylinder walls, which is applied by plasma spraying and then hardened and honed. The result is an ultra-smooth, mirror-like surface that reduces piston ring friction by 44%.

Another unique feature of the VC-Turbo engine is the Active Torque Road active vibration reduction system integrated into its upper mount, which is based on a reciprocating actuator. This system is controlled by an acceleration sensor that detects engine vibrations and in response generates dampening vibrations in antiphase. Infiniti first used active mounts in 1998 on a diesel engine, but that system turned out to be too cumbersome, so it was not widespread. The project lay shelved until 2009, when Japanese engineers began to improve it. It took another 8 years to solve the problem of excess weight and size of the vibration damper. But the result is impressive: thanks to ATR, the 4-cylinder unit of the new Infiniti QX50 is 9 dB quieter than the V6 of its predecessor!

Source

Found a typo? Select a fragment and press Ctrl+Enter.

Tags: Technologies Infiniti Nissan VC-Turbo top dead center TDC engine efficiency piston compression ratio fuel mixture Atkinson cycle cylinders

Previous article Tomahawk cruise missiles. About corn fuel and environmental friendliness

Next article “Russian” perovskite. Artificial lighting and record efficiency

Provided by SendPulse

Likes 0

- 0

- 0

- 0

- 0

Pre-ignition and detonation

The mixture entering the combustion chamber should not explode, but burn, evenly, and throughout the entire period of time while the piston moves down.

Under this condition, energy is consumed as efficiently as possible, and the parts of the piston group wear out evenly and do not overheat. The difficulty is that the combustion speed of the mixture is usually much faster than the speed of the piston.

In this regard, the main problem arises that stands in the way of those who set out to increase the compression ratio. As the pressure increases, the mixture spontaneously ignites.

This phenomenon is called pre-ignition. Moreover, combustion of the mixture occurs when the piston is just completing the compression phase. In this case, the energy of the burning fuel creates additional resistance and is wasted on performing a useless action.

The second problem: the release of excessive amounts of energy. In other words, an explosion. This phenomenon in engine theory is called detonation and has extremely negative consequences.

Thus, increasing the compression ratio can play a cruel joke on the engine owner. To avoid unpleasant consequences, it is worth familiarizing yourself with such a concept as octane number.

Definition of compression

To fully understand the meaning of this term, throw aside the automobile reference books. Remember one thing: compression is the greatest pressure inside the cylinder, which occurs only at the end of compression. It is measured in various units of measurement, but most often it is defined in atmospheres. Note that this process is constantly changing due to the degree of engine wear.

The required pressure in the cylinder is individual for each container and depends on its volume. To fully understand the difference between the two concepts above, you just need to look at the following table:

| Motor model | Volume (liters) | Pressure (atmospheres) |

| YaMZ 236 | 11,15 | 24 — 37 |

| EURO-4 | 11,76 | 33 — 39 |

| Lexus ES 300 (used) | 3 | 15 — 16 |

| VAZ 2101 | 1,6 | 10 — 13 |

| D240 | 4, 75 | 25 — 29 |

The nature of heat transfer during compression

Compression of a fresh charge in a diesel cylinder is a complex polytropic process, depending on many factors: parameters of the initial charge state, temperature level of the cylinder, engine design, piston ring density, etc. In the initial period of compression, as a rule, the charge temperature is lower than working cylinder wall temperature. Therefore, compression occurs with heat supplied from the cylinder walls to the charge. This section of the compression line in the PV diagram (see figure below) is steeper than the adiabatic, the compression polytrope index n is greater than the adiabatic index: n1 > k.

Rice. 1 Scheme of the compression process in diagrams: a) PV and b) TS

As the charge is compressed, its temperature rises, and heat transfer from the walls decreases. When the temperature of the charge becomes equal to the temperature of the walls (point m in the figure), the heat exchange stops; at this moment the compression polytrope index becomes instantly equal to the adiabatic index: n1 = k.

With further compression, the temperature of the charge will be higher than the temperature of the cylinder walls, as a result of which heat is removed from the charge to the walls. In this section, the compression line runs parallel to the adiabatic line, and the compression polytrope index is less than the adiabatic index: n1 < k.

According to experimental data, for marine diesel engines the n1 indicator varies from 1.5 at bottom dead center to 1.1 at top dead center. However, when calculating work processes using the Grinevetsky-Mazing method, it is assumed that the compression process is carried out throughout the entire stroke of the piston at a constant compression polytrope: n1 = const. In this case, the same compression work is provided as with a variable value of the n1 indicator in the real cycle.

Ways to change the compression ratio

With modern power units, this characteristic can be adjusted both up and down. If you need to increase the parameter, then the cylinders are bored and pistons with a larger diameter are installed. Anyone interested in understanding the differences in combustion engine compression and compression ratio will find this information helpful. After all, among car enthusiasts there are supporters of various types of tuning.

Another, no less effective way to change the compression ratio is to reduce the combustion chamber. In this case, a layer of metal is removed from the junction of the cylinder head with the engine block. This operation is carried out using a planing or milling machine.

If for some reason there is a need to lower the compression ratio, then, on the contrary, it is worth placing an alloy gasket between the cylinder block and the cylinder head. Another method is to remove a layer of metal from the piston bottom. However, it is more difficult to implement, since it will require certain efforts, skills and abilities. In addition, this procedure requires a lathe.

Calculation of compression ratio

For any internal combustion engine, it is important that this parameter has the maximum possible value. However, if you need to force the engine, you should know how this characteristic can be calculated. This is necessary in order to avoid detonation, which can cause the engine to simply fail.

The formula used for the calculation is as follows:

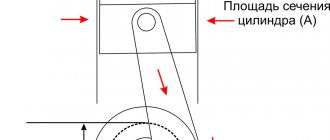

where CR is the compression ratio, V is the working volume of the cylinder, C is the volume of the combustion chamber.

The car enthusiast who wants to know the difference between compression and compression ratio will be interested in such calculations. Perhaps this will be useful to him in practice.

To determine this parameter for only one cylinder, the total engine displacement should be divided by the number of “glasses”. As a result, we obtain the value of V from the formula above.

But determining the C indicator is much more difficult, but still possible. To do this, experienced motorists and mechanics involved in engine repairs have the right tool in mind - a burette. It is graduated in cubic centimeters. The easiest way is to pour gasoline into the combustion chamber, and then measure its volume with a burette. All that remains is to enter the obtained data into the formula.

How does the impact occur?

So what does the compression ratio affect? Here it is worth considering the amount of work that the power unit produces. And the higher this parameter, the more energy will be released during the combustion of the air-fuel mixture. Accordingly, engine power increases.

For this reason, most manufacturers are trying to increase the power performance of the motor through one effective technique. They began to resort to it since the end of the last century. Instead of moving in the direction of increasing the volume of the cylinders and combustion chamber, specialists, and they certainly know the difference between compression and compression ratio, strive to increase precisely the latter indicator.

However, there are limitations. The working mixture cannot be compressed indefinitely - upon reaching a certain value, it detonates, that is, explodes. At the same time, this only applies to gasoline engines. Diesel power units have no risk of detonation. Actually, this explains their higher compression ratio.

And in order to avoid such a destructive effect, because detonation is detrimental to the engine, the octane number of gasoline increases. And this, in turn, increases the cost of fuel. In addition, those additives that serve this purpose lead to a deterioration in the environmental parameters of the engine.